DINDAN 20ACU/004 User manual

ÀÒÉÒä·Â

English

Enclosure cooling unit

Model

20ACU/004

User's guide

ÀÒÉÒä·Â

English

1

Content Page

1. Over view 3-5

2. Specifications 6-7

3. Notification 8

4. Technical information 9-10

5. Installation 11-18

6. Maintenance 19

7. Fault Indication 20

8. Assembly and part number 21

Introduction

Cooling unit for control cabinet is used for diminishing internal heat by

providing cool air to the control cabinet that can protect sensitive equipment It is

specially designed to resist surrounding temperature as high as 40-50 oC and can

function well in any factories including those with intensive dust, particles and oil mist

or with high acidity.

2

3

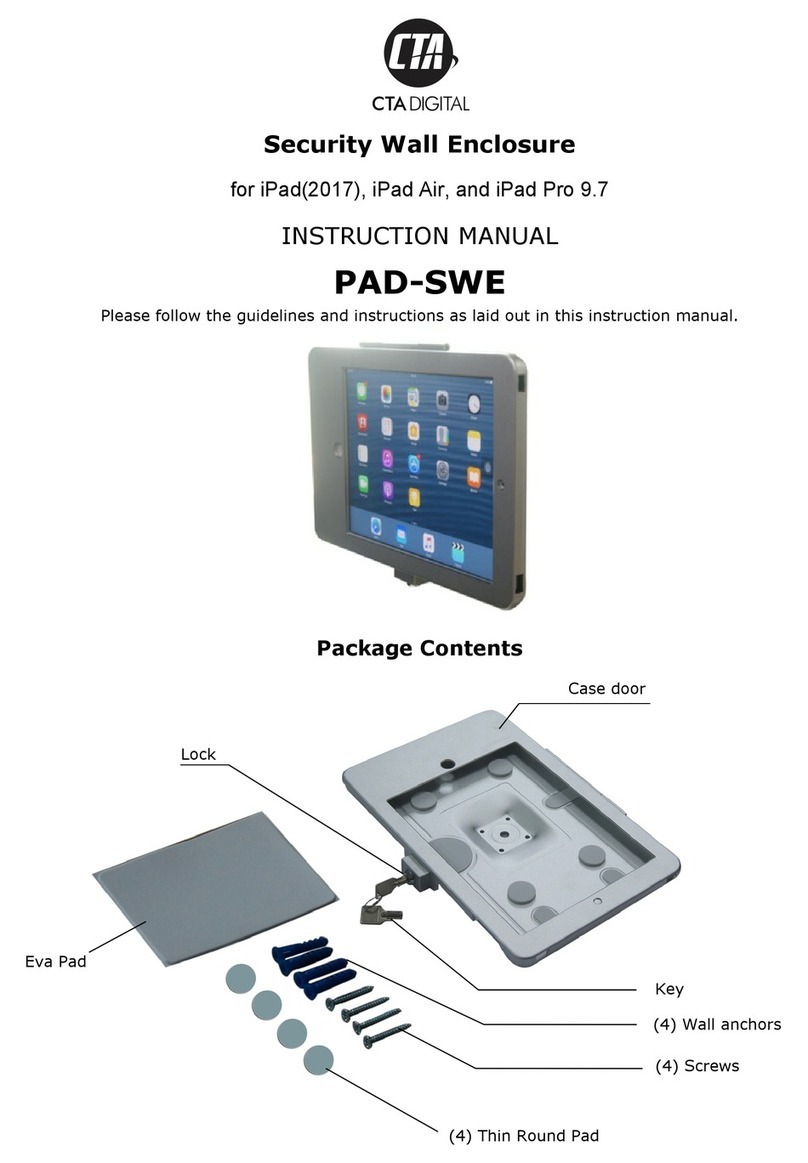

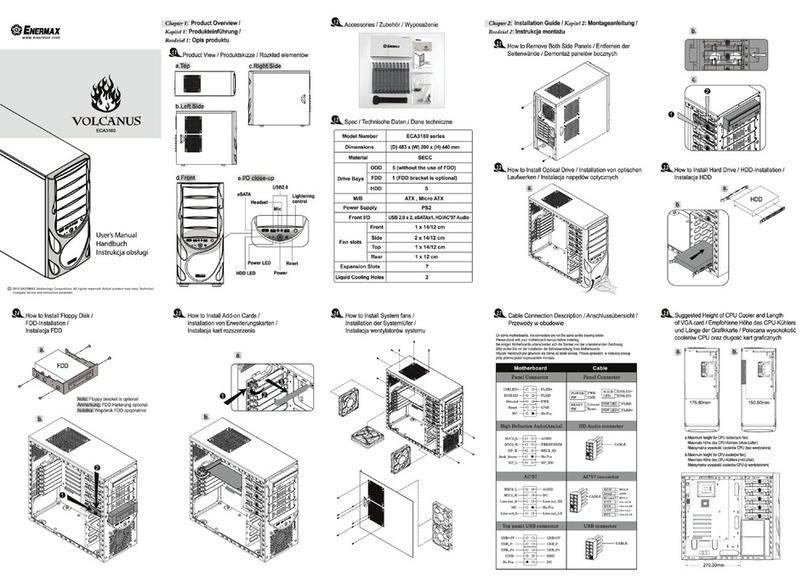

1. Over view

20ACU/004

4

Main controller

(Hiprosent control)

Compressor

Condensor coil

Condensor fan 1

Drain pan

Temperature display

Evaporator coil

Evaporator fan

Filter

Condensor fan 2

5

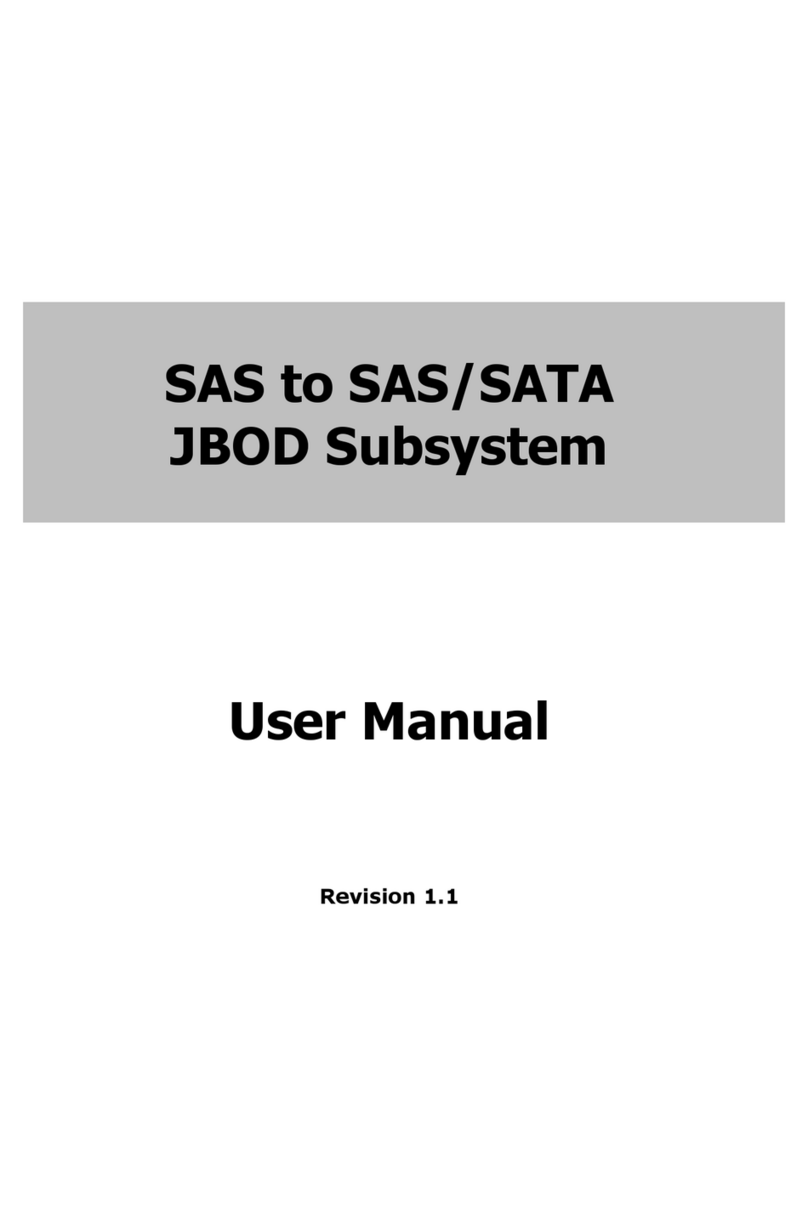

HIPROSENT CONTROL (EGS035)

Control and Monitor

A1 = LED status

A2 = LED Over/Under Voltage Status

A3 = LED compressor's status

S1 = Temperature setting switch (Up)

S2 = Temperature setting switch (Down)

Cable and signal

B1 = Temperature sensor (inside cabinet)

B2 = Over heat sensor

B3 = Ice sensor

B4 = Ambient temperature sensor

220VAC

M1 = Compressor

M2 = Condenser Fan

M3 = Evaporator Fan

OP1 = Output Alarm

M1

1Ph

OP1

Display

S1

A2

A3 S2

A1

B1

B2

B3

B4

12BC7856910NO

COMM

NC

CON16

CON20

Temperature

220V 50/60Hz

Main connection

from 10A BREAKER

supply by Customer

M3

1Ph

C1

M2

1Ph

2. Specifications

6

Characteristics (under normal operating condition at ambient temp. +35oC)

Model 20ACU/004

Capacity

Watt

600

Installation type panel

Input single-phase (V.) 220V+20% / -15%

frequency (Hz.) 50/60

current (A.) 1.9

Compressor hermetic type rotary

refrigerant type 134a

System operate direct expand yes

Hi-prosent ctrl1 thermostat yes

condensor thermal detector yes

anti-freeze detector yes

compressor overheat detector none

water detector none

Protection over drain protect system yes

Display thermometer (red 7 segment 19 mm.) yes

system status (2 colour LED) yes

Electrical equip. safety device 7A. slow-blow fuse

Evaporator coil face area x rows 42.5 sq.inch x 2

servo fan (r.p.m.) 2850

number of fan x cfm (0.18 inH2O) 1 x 135

Condenser coil face area x rows 78.75 sq.inch x 3

servo fan (r.p.m.) 2850

number of fan x cfm (0.2 inH2O) 2 x 158

Physical data approx.weight (kgs.) 31.5

dimension (mm.) W:384 D:177 H:619

condensate drain OD. 3/8 inch

internal casing electro-galvanize

Air filter width x lenth (mm.) 110 x 536

*under normal operating condition at ambient temp. +45oC

7

Cutting area

384 mm.(Unit width)

Cutting Area 586 mm.

654mm.(heigh)

4-Marking holes for cutting

14-3.2 Drill

22

120

100

100

100

100

100

150 210

16

19.7

Installation Plate & Templet for cutting Area

View From Outside of Cabinet

120

120

96

185

Cutting Area185 mm.

192

57 46.3

12

Ambient Air In

Cold Air Out

Warm Air

Out

Drain Tube OD. 9.5mm

384177

Return Air In

2

Socket plug

Air Filter Pocket

619

133

40

Overdr ain hole

3. Notification

Before, drilling, and cut. should use clean dry cloth, or the inventory doesn’t

lead the electricity, covers the equipment for protects iron dust touches the

electrical equipment while installing. (In case of machine still operate.)

Cooling unit should be installed in the good circuration area

Check vertical and horizontal level of which their error shall be allowable

within +/- 2 oin order to facililate efficient drainage

Should always install gasket between Installation plate and Cooling Unit

before hang the cooling unit on the installation plate

Installing of drain tube (Page 17)

In order to minimize water condensation, cabinet doors should be tightly closed

during operation

Circulation fan should be installed in cabinet if various equipment is densely

installed inside

In order to obtain highest performance and durablility, repair and alteration of

cooling unit should be under care of distributor

Should not adjust temperature difference more than 10oC betwee

enviromental temperature and cooling space, to prevent moisture build up on

some part in the cooling area when you open the cabinet panel

If it is necessary to set temperature lower than 25oC, it is recommended to

use precision cooling unit or contact your Professional Maker.

The equipments that are locate in the cooling air stream have to be

obstructed by the insulator to prevent water condensation

8

9

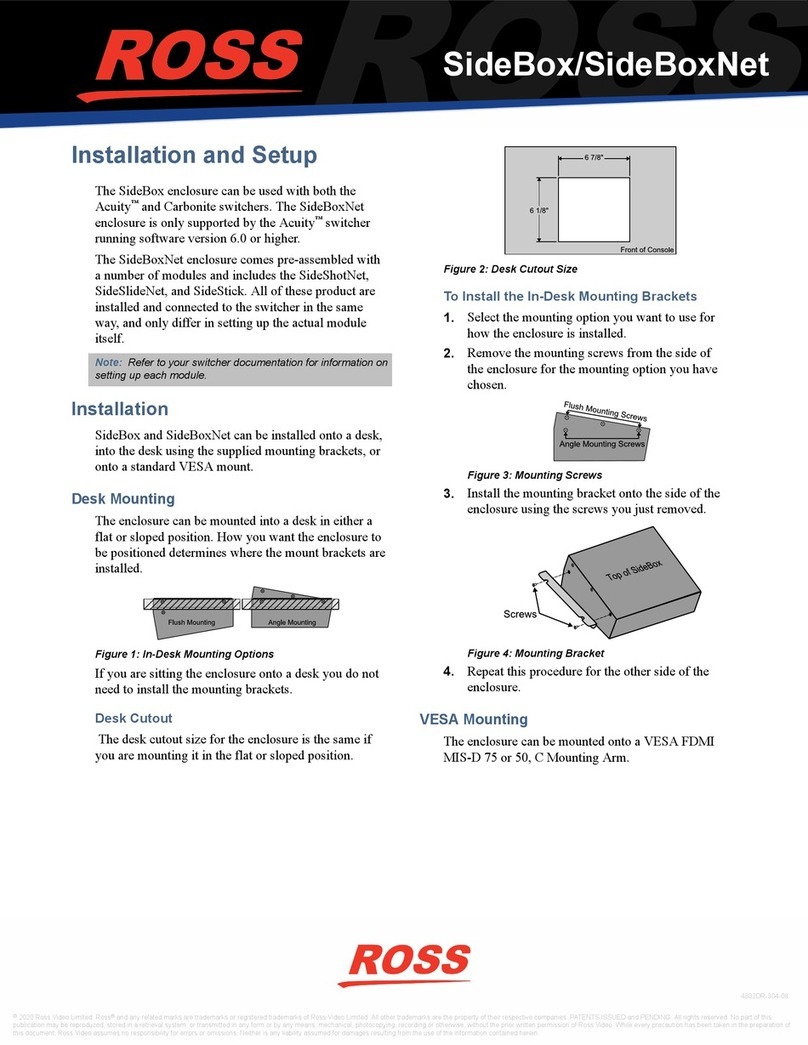

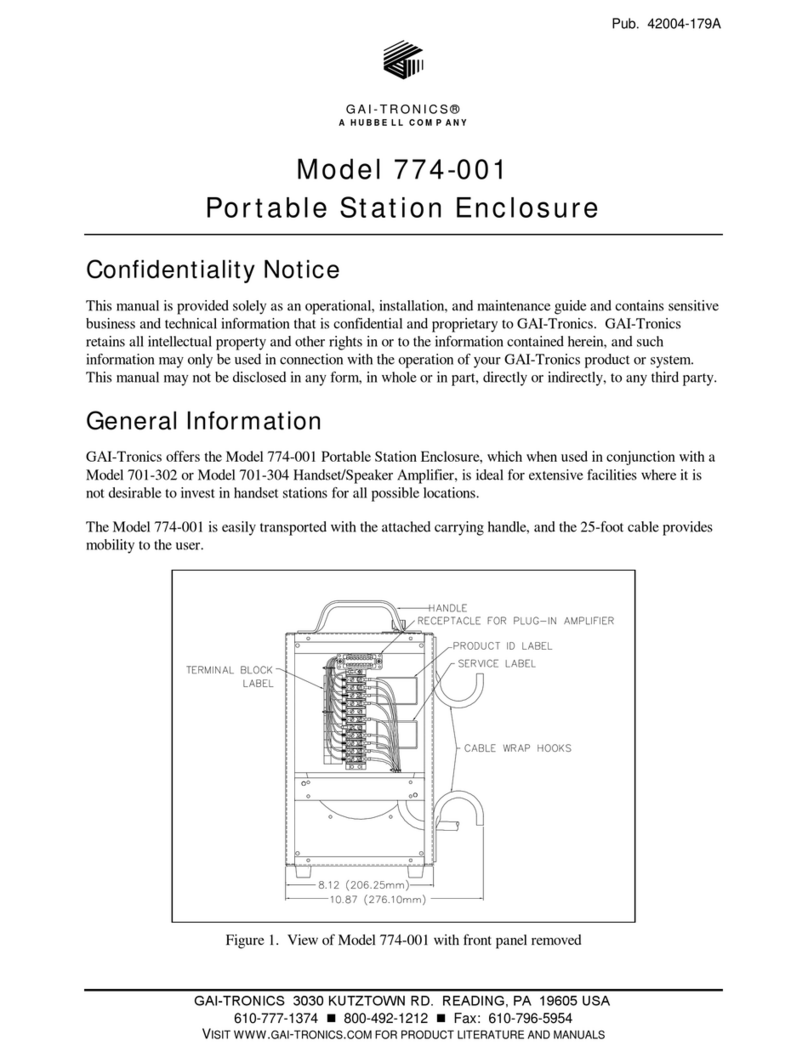

CORRECT INCORRECT

General Condition

Storage: Cooling unit should be stored at temp not exceeding 70 oC

Transportation: This type of cooling unit can't be laid down horizontally.

Installation: It shall be installed in vertical direction only

(please see figure below)

Disposal of damaged Cooling Unit

As its refrigeration system contain Refrigerant and lubricating oil for

compressor, in order to protect environment, these substances should be

disposed of properly or other under direction given by distributor.

4. Technical information

Protective equipment

Refrigeration system has been tested with high pressure device at 350 PSI.

This series of cooling unit also contains electronic circuit and sensors are

installed at significant points to monitor any defect of refrigeration cycle in order

to reduce burden of the user and to prolong use life of cooling unit at more

costeffective practice.

Note

- LED light will display green colour (continuously) to indicate condition.

- Under any abnormal condition, please see pages 20.

10

Correct installation Incorrect installation

Refrigeration Cycle

Drainage

Drainage of condensed water from cooling system shall be done by inserting

drain tube under drainpan (see page 17) and trying not to left it twisted. Make

sure, the other end of drain tube is not lower than water level in the container,

in order to avoid water reflux

Condenser

Evaporator

Compressor

Cap.tube

Filter

dryer

External

Internal

Drain tube

Drain tube Drain tube

11

5. Installation

Accessories for 20ACU/004

Items Quantity

Cooling unit 1

User's guide & Warranty card 1

Socket plug guard 1

Socket plug 1

Special holder 2

Foam gasket 1

Air filter 1

Installing plate 1

3/8'' Drain Tube ( 200 cm. ) 1

3 x 1 Sq.mm VCT power cord. 200 cm. 1

Self tapping screw 1/8'' x 3/8'' (for Installation plate) 20

Self tapping screw 1/8'' x 1/2'' 4

(for Installation Socket plug guard)

M6 x 20 mm. bolt 2

Plain washer (for M6 x 20 mm. bolt) 2

1/2” Cable clamp 2

6” Cable tie 3

12

Installation procedure

1. Align installation plate in the position to be installed.

2. Layout 14 positions for drilling and cutout along the dot line with Jigsaw

Cutting line / เส้นแสดงการตัด

2

1

3

4

5

6

7

13

14

12

11

10

9

8

3. Cover eqipments inside cabinet with clean and dry cloth,and cover with paper

boxes at position will be drilled and cutted in order to prevent metal scrapt

falling in cabinet.

4. Drill and cut the holes and area as be pointed out from installation plate.

13

Paper box

5. Chamfer the cutted edge and paint rust proff colour.

6. Put the socket plug in the position and screw it

be careful the socket plug cover must be opened downward only

14

7. Socket plug Installation

7.1 Put the cable in the socket plug and screw.

7.2 Install the socket plug guard.

8. Installation plate attachment

8.1 Install the Installation plate with 14 self tapping screws

8.2 Connect main power line with 220VAC which be connected to 10 Amp.

breaker (Main power is 1 Sq.mm.)

Beware Breaker shouldn't be shared its load with any other components.

15

ฝาครอบแหล่งจ่ายไฟ

Socket plug guard

9. Attach the foam gasket to the installation plate and fasten the special holders

on it and then hang the cooling unit on this holders, fasten another 2 screws

M6 x 20 mm. at the bottom of the cooling unit.

10. Uncover the frontal case of cooling unit then plug-in the plug.

16

M6 x 20 mm. bolt (2 unit)

Special holders

Foam gasket

Installation plate and it foam

11. Install the draining tube by the illustrature below

Beware:

Avoid dipping draing tube below than water level

which be clogged its drainage

12. Turn on breaker for operation

17

Tire with 6” CABLE TIE

Fixed with 1/2” CABLE CLAMP

Fixed with 1/2” CABLE CLAMP

3/8” Draining tube

Tank

Illustrate of drainage wiring

Water level

Air diverter installation(In the necessary case)

1. Divert air down

Turn the air diverter to blow air down as shown below the drill and fix it.

2. Divert air to left and right

Turn air diverter to left or turn air diverter to right

Drill and fix the diverter as shown below

Note: Air diverter is the additional, not appropriate with common installation

equipment.

18

Illustrate diverting the air to left Illustrate diverting the air to right

19

6. Maintenance

Maintenance of DINDAN cooling unit can be simply done by giving care to the air

filter and condensor coil not to be clogged up. The cleaning interval for the air filter

depends on how dirty it is of the area where it is installed.

In case of abnormal function, it can be noticed from LED light which is to change

in corresponding with abnormal condition of cooling unit. For more details please

see page 20.

Table of contents