Distek VIP 4400 Installation manual

Operation Manual: VIP 4400 Vessel Washer

Operation

Manual

VIP 4400

Vessel

Washer

Operation Manual: VIP 4400 Vessel Washer

VIP 4400 Vessel Washer

Operation Manual

Document #: 3844-0002

Distek, Inc.

121 North Center Dr. • North Brunswick, NJ 08902

Phone 732.422.7585 • Fax 732.422.7310

http://www.distekinc.com

Operation Manual: VIP 4400 Vessel Washer

Notice

This document contains proprietary information. All rights are

reserved. No part of this document may be photocopied,

reproduced or translated without the prior written consent of

DISTEK Incorporated.

DISTEK, INC.

121 North Center Drive

North Brunswick, NJ 08902-4905

Tel. (732) 422-7585

Fax. (732) 422-7310

Website: http://www.distekinc.com

Document Revision History

Rev Date Notes

A 5/20/05 Initial Release

Operation Manual: VIP 4400 Vessel Washer

Contents

About this Manual ............................................................................... i

Purpose........................................................................................ ii

Audience ...................................................................................... ii

Contents ...................................................................................... ii

Prerequisites ................................................................................ iii

Documentation.............................................................................. iii

Conventions ................................................................................. iii

1Introduction .............................................................................1-1

Overview.................................................................................... 1-2

Specification ............................................................................... 1-2

Physical Site Considerations ............................................................. 1-3

Environmental Considerations........................................................... 1-3

Ambient Laboratory Temperatures ..................................................1-3

Ambient Laboratory Humidity ........................................................ 1-4

Air Quality Considerations............................................................. 1-4

Operation Warnings and Notes .......................................................... 1-5

General Instrument Overview ........................................................... 1-7

2Installation...............................................................................2-1

Unpacking................................................................................... 2-2

System Setup ............................................................................... 2-2

Installation Checkout ..................................................................... 2-2

3Operation ................................................................................ 3-1

Main Control Keypad ...................................................................... 3-2

Remote Nozzle Keypad ................................................................... 3-3

Filling the Rinse Tank ..................................................................... 3-4

Using the Vessel Washer.................................................................. 3-5

Using the Manual Wash Feature ......................................................... 3-5

Using the Manual Drain Feature......................................................... 3-6

Operation Manual: VIP 4400 Vessel Washer

Setting and Activating the Heater (Optional)......................................... 3-6

Using the Shaft Rinse (Optional) ........................................................ 3-7

Using the Visual Tank Level Indicators................................................. 3-8

Treating the Waste Tank Media ......................................................... 3-8

Emptying the Waste Tank .............................................................. 3-10

Priming the Waste Tank Drain Pump (If Necessary) ............................... 3-11

Emptying the Rinse Tank ............................................................... 3-11

Cleaning or Replacing the Filter and Filter Bottle ................................. 3-12

Using an Antifoaming Agent ........................................................... 3-13

4Maintenance .............................................................................4-1

General Information ...................................................................... 4-2

Cleaning the Tanks ........................................................................ 4-2

Opening the Top Cover ................................................................... 4-3

Tubing Replacement ...................................................................... 4-3

Cleaning the Water Inlet Valve Filter .................................................. 4-4

Temperature Calibration ................................................................. 4-5

5Troubleshooting......................................................................... 5-1

Troubleshooting ........................................................................... 5-2

Error Codes ................................................................................. 5-3

Service ...................................................................................... 5-4

Appendix A : Spare Parts and Accessories ...........................................A-1

Appendix B : Pre-Installation Considerations: Electrical Power Supply.........B-1

Appendix C : CE Declaration of Conformity .........................................C-1

About This Manual

Operation Manual: VIP 4400 Vessel Washer i

About this Manual

About This Manual includes information about what is contained in this manual and

the conventions used.

Purpose........................................................................................ ii

Audience ...................................................................................... ii

Contents ...................................................................................... ii

Prerequisites ................................................................................ iii

Documentation.............................................................................. iii

Conventions ................................................................................. iii

About This Manual

Operation Manual: VIP 4400 Vessel Washer ii

Purpose

This manual covers the installation, routine operation, maintenance and repair of

your Vessel Washer. It has information regarding the controls, indicators and

functions of the instrument. Please read Chapters 1, 2 and 3 before you operate

the instrument.

Audience

This manual is written for any person responsible for maintaining, operating or

troubleshooting the Distek Vessel Washer.

Contents

Chapter 1 - Introduction Provides a general overview of the

instrument.

Chapter 2 - Installation Describes how to unpack and properly

install and qualify the unit.

Chapter 3 - Operation Describes the operation of the unit.

Chapter 4 - Maintenance Explains the steps necessary to

maintain the unit.

Chapter 5 - Troubleshooting Provides a troubleshooting chart and

description of error messages to assist

the user if a problem should arise.

Appendix A : Spare Parts and

Accessories

Provides a table of recommended and

optional spare parts.

Appendix B : Pre-Installation

Considerations: Electrical Power

Supply

Recommendation information

pertaining to electrical power supply.

Appendix C : CE Declaration of

Conformity

CE Declaration of Conformity

certificate.

About This Manual

Operation Manual: VIP 4400 Vessel Washer iii

Prerequisites

This manual assumes that you have an understanding of the principles of

dissolution testing.

Documentation

This manual contains important information regarding the safe operation and

maintenance of your Distek Vessel Washer.

Conventions

The following table contains Warnings, Cautions and Notes that are used

throughout the document for your protection. Please read this section before

using the instrument.

“WARNING” statements are used in this manual to prevent

injury to personnel.

Electrical hazard warning. Use caution as high voltage may

exist.

“CAUTION” statements are used to prevent damage to

equipment.

“NOTES”contain helpful information.

REQUIRED

ACTION

“REQUIRED ACTION” is used where necessary to distinguish

the action needed from Warnings, Cautions and Notes.

Chapter 1: Introduction

Operation Manual: VIP 4400 Vessel Washer 1-1

1Introduction

The Distek Vessel Washer is a very useful accessory in the dissolution lab, allowing

the chemist to minimize the time in between dissolution tests. This chapter will

provide an overview of the unit and system specifications.

Overview.................................................................................... 1-2

Specification ............................................................................... 1-2

Physical Site Considerations ............................................................. 1-3

Environmental Considerations........................................................... 1-3

Ambient Laboratory Temperatures ..................................................1-3

Ambient Laboratory Humidity ........................................................ 1-4

Air Quality Considerations............................................................. 1-4

Operation Warnings and Notes .......................................................... 1-5

General Instrument Overview ........................................................... 1-7

Chapter 1: Introduction

Operation Manual: VIP 4400 Vessel Washer 1-2

Overview

The Distek VIP 4400 Vessel Washer is a portable instrument designed to clean

dissolution vessels without having to remove the vessels from the dissolution

instrument. The unit is capable of cleaning up to 28 vessels without needing to be

emptied. To allow for more efficient cleaning, the unit can be configured with an

optional heater which allows rinse media to be heated to a temperature of up to

60ºC.

This manual contains important information regarding the safe operation,

maintenance and repair of your VIP 4400 Vessel Washer.

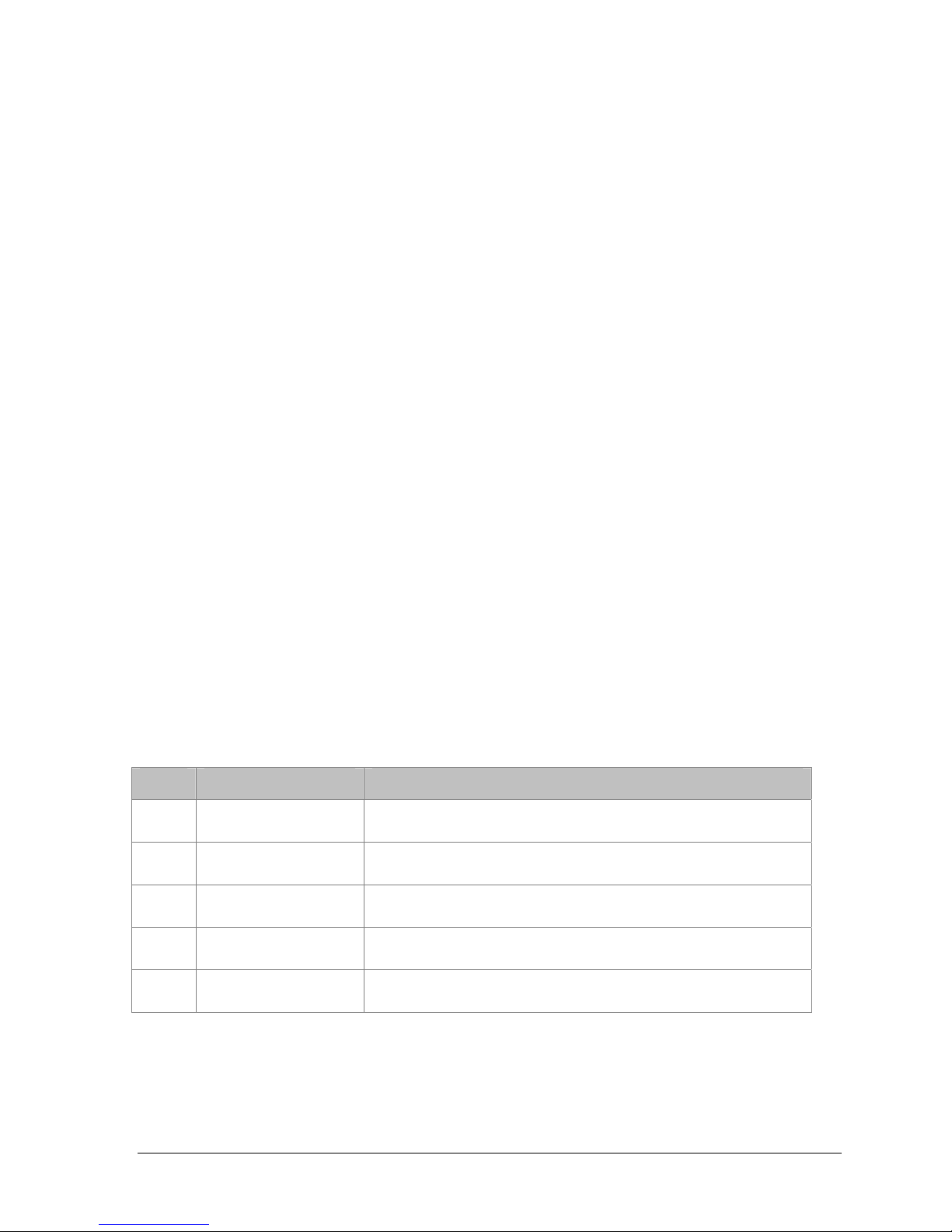

Specification

Table 1: System Requirement and Description

System Specifications

Dissolution Vessel Inner Diameter 3.970” ± 0.125”

(97.66mm – 104.01mm)

Dissolution Vessel Height

(Vessel Bottom to Flange Top)

6.485” ± 0.250”

(158.37mm – 171.07mm)

Unit Dimensions 26”W x 26”D x 39”H

(66cm x 66cm x 99cm)

Weight (Empty) 150 lbs. (68 kg)

Sound Level Approximately 65 dB A

Interface Ports RS-232 & USB 2.0

Construction Materials Cast Aluminum, Stainless Steel, Acid

Resistant Heating Element, Engineered

Plastics

Wash Cycles Light, Medium & Heavy

Wash Cycle Per Vessel Approximately 30 – 45 Seconds

(Depending on Light/Medium/Heavy Cycle)

Rinse Tank

Tank Volume 38 Liters (10 Gallons)

Level Indicators - Electronic Level Sensors for Full/Empty

- Sight Gauge Indicator

Fill Port Quick Disconnect Fitting on Top Cover

with Automatic Shutoff

Waste Tank

Tank Volume 76 Liters (20 Gallons)

Level Indicators - Electronic Level Sensors for Full/Empty

- Sight Gauge Indicator

Empty Time Approximately 8 Minutes

Chapter 1: Introduction

Operation Manual: VIP 4400 Vessel Washer 1-3

Rinse Tank Heating (Optional)

Temperature Control Electric Immersion Heater

Temperature Control Range 25ºC - 60ºC

Temperature Accuracy ±2ºC

Heating Time Approximately 55 Minutes to Heat 38

Liters from 25ºC to 45ºC

Display and Resolution Continuous LED Display of Rinse Tank

Temperature, 1 Centigrade Resolution

Power Requirements

Electrical Power 115V ± 15V 50/60Hz 5A (10A with heater)

or

230V ± 15V 50/60Hz 3.5A (7A with heater)

(Operating voltage pre-set at factory)

Physical Site Considerations

The dimensional requirements specified below are adequate to allow for the unit

to be freely moved throughout the laboratory:

1. The minimum aisle width needed is 28” (0.71m).

2. There must be no obstruction (cabinet, shelf, or outlet) that intrudes into the

aisle for the minimum footprint of the unit up to a height of 45” (1.14m).

3. The floor must be capable of sustaining the weight of the unit and all of its

accessory parts without significant bending.

4. Because of the limitation in travel of the instruments wheels, the floor should

be clear of any obstructions. Obstructions, such as floor mats could make

rolling the unit difficult and can result in injury to the user or damage to the

instrument.

Environmental Considerations

Ambient Laboratory Temperatures

Distek recommends that the laboratory temperature

control system fans be kept on at all times.

Maximum Conditions:

1. The VIP 4400 is designed to be installed and operated in laboratories where

the maximum operating temperature does not exceed 30°C.

2. The maximum allowable ambient operation temperature is 30°C.

Chapter 1: Introduction

Operation Manual: VIP 4400 Vessel Washer 1-4

Minimum Conditions:

To assure controlled operation within specified tolerances, the VIP 4400 is

designed to be operated in laboratories where minimum operating

temperatures do not drop below 15°C.

Variability or Short Term Fluctuations:

To assure controlled operation within specified tolerances, the system used

to control the temperature of the laboratory where the VIP 4400 is installed

must be able to maintain the ambient air temperature within ±2.5°C of set

point (worst case).

Ambient Laboratory Humidity

Maximum:

Water vapor and/or hydrogen chloride vapor, from dissolution media, can

cause serious effects when condensed on electrical components and

contacts. The lab’s environmental controls should maintain the humidity

level below the dew point, to minimize the risk of condensation.

Minimum:

It is important that the humidity level be kept at or above 30% relative

humidity, to minimize the risk of damage to control circuits caused by static

discharge.

Air Quality Considerations

Distek vessel washer systems are designed to be operated in a lab environment

that has no visible dust problem, and with organic solvent vapor levels as low as

possible. Operation is not recommended in dusty lab environments, or in labs with

significant chlorinated or reactive solvent vapor levels. These dust or vapor levels

may have serious effects on system components.

Chapter 1: Introduction

Operation Manual: VIP 4400 Vessel Washer 1-5

Operation Warnings and Notes

For your safety, the information in this manual

must be followed to minimize the risk of fire or

explosion, electrical shock, or to prevent

property damage, personal injury or loss of

life.

Use this equipment only for its intended

purpose as described in this Operation Manual.

Never attempt to operate this instrument if it

is damaged, malfunctioning, partially

disassembled, or has missing or broken parts,

including a damaged cord or plug.

Improper servicing or adjustment practice can

cause equipment failure or serious physical injury.

This equipment must be adjusted and serviced by

qualified electrical maintenance personnel who

are familiar with the construction and operation of

the equipment and the hazards involved. Take

diligent care during adjustment. All exposed

points on the control circuit boards are

electrically hot with respect to earth ground.

Dangerous voltages exist on the circuit boards

when powered. Disconnect AC power from the

units while troubleshooting. Be alert. High

voltage can cause serious or fatal injury.

All units equipped with heaters have

thermostatic protection. In the event of a

malfunction, the heater will automatically cut

off. The thermostat will automatically resets

after cooling down.

Take proper precautions when handling

dissolution media. Liquid in vessel may be

HOT. Wear splash protection to avoid

exposure to scalding, acidic, caustic, or

pharmaceutical hazards. Bacteria have been

shown to thrive in certain media, especially at

test temperatures.

The VIP 4400 is capable of handling all of the

commonly used dissolution media such as 0.1 N

HCL, phosphate buffers and sodium lauryl

sulphate.

Chapter 1: Introduction

Operation Manual: VIP 4400 Vessel Washer 1-6

In the event of a hazardous material spill on

the external surface of the instrument, the

unit can be cleaned with a disposable cloth or

paper wipe, then rinsed and dried with water.

The same approached can be used for internal

spill but the power must be disconnected first!

Prior to performing any cleaning or

decontamination method, the user should

verify the method with Distek.

Improper remote PC control of the VIP 4400

system may lead to unexpected pump and/or

heater operation.

The VIP 4400 is supplied with proper

components and settings for the specified

operating voltage (see label for information).

Do not attempt to convert unit to another

mains supply without contacting Distek's

factory first!

External cables (excluding power cable) are

limited to less than 3 meters length in order to

maintain electromagnetic compliance.

Some forms of electromagnetic interference may

cause unexpected operation. If this occurs, the

unit will return to normal operation once the

interference is removed.

Chapter 1: Introduction

Operation Manual: VIP 4400 Vessel Washer 1-7

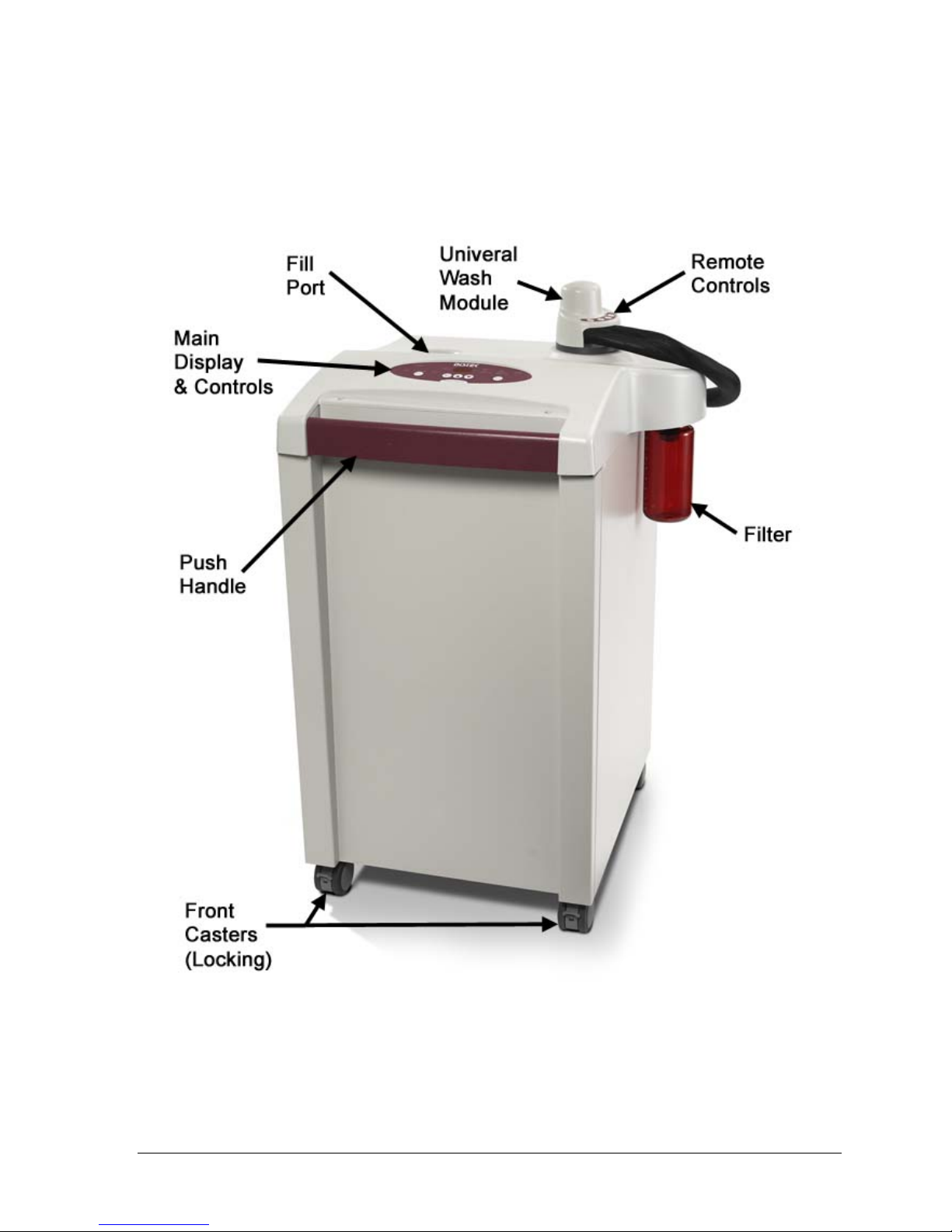

General Instrument Overview

Figure 1: Instrument Overview

Chapter 2: Installation

Operation Manual: VIP 4400 Vessel Washer 2-1

2Installation

This chapter will describe the steps necessary to properly unpack and install

the instrument.

Unpacking................................................................................... 2-2

System Setup ............................................................................... 2-2

Installation Checkout ..................................................................... 2-2

Chapter 2: Installation

Operation Manual: VIP 4400 Vessel Washer 2-2

Unpacking

The VIP 4400 is shipped on a pallet. The unit and cardboard box are strapped

to the pallet. The following steps describe how to unpack the instrument:

1. Cut the straps holding the box to the pallet.

2. Lift the box straight off the unit.

3. Cut the strap holding the unit to the pallet.

4. Unlock the two rear casters.

5. Lift unit off the pallet.

System Setup

After the instrument has been removed from its shipping box, follow these

remaining steps:

1. Open the top cover by removing the two front screws.

2. Insert the overflow vessel into the top of the waste tank. The waste

tank is the larger tank located in the back of the unit. There is a black

gasket on the right hand side. Insert the overflow vessel into the hole in

the gasket.

3. Remove the wash handle, shaft rinse (if applicable) from inside the

instrument and close the top cover.

4. Insert the wash handle into the holder located on the top cover.

5. Insert the shaft rinse handle into the clip located on the right hand side

panel.

6. Re-insert the 2 screws for the top cover.

Installation Checkout

Your instrument has been tested thoroughly prior to shipment. To detect any

problems caused by shipping and handling, Distek recommends a careful check

of all crucial operating functions after completing the installation of the VIP

4400.

This check should include, at a minimum:

•Filling up the rinse tank

•Testing the heater, if applicable

•Performing a light, medium & heavy wash

•Emptying the waste tank

Chapter 3: Operation

Operation Manual: VIP 4400 Vessel Washer 3-1

3Operation

The chapter will describe the function of the cleaning head and main keypad on

the instrument. It will also provide step-by-step instructions to perform many of

the common tasks.

Main Control Keypad ...................................................................... 3-2

Remote Nozzle Keypad ................................................................... 3-3

Filling the Rinse Tank ..................................................................... 3-4

Using the Vessel Washer.................................................................. 3-5

Using the Manual Wash Feature ......................................................... 3-5

Using the Manual Drain Feature......................................................... 3-6

Setting and Activating the Heater (Optional)......................................... 3-6

Using the Shaft Rinse (Optional) ........................................................ 3-7

Using the Visual Tank Level Indicators................................................. 3-8

Treating the Waste Tank Media ......................................................... 3-8

Emptying the Waste Tank .............................................................. 3-10

Priming the Waste Tank Drain Pump (If Necessary) ............................... 3-11

Emptying the Rinse Tank ............................................................... 3-11

Cleaning or Replacing the Filter and Filter Bottle ................................. 3-12

Using an Antifoaming Agent ........................................................... 3-13

Chapter 3: Operation

Operation Manual: VIP 4400 Vessel Washer 3-2

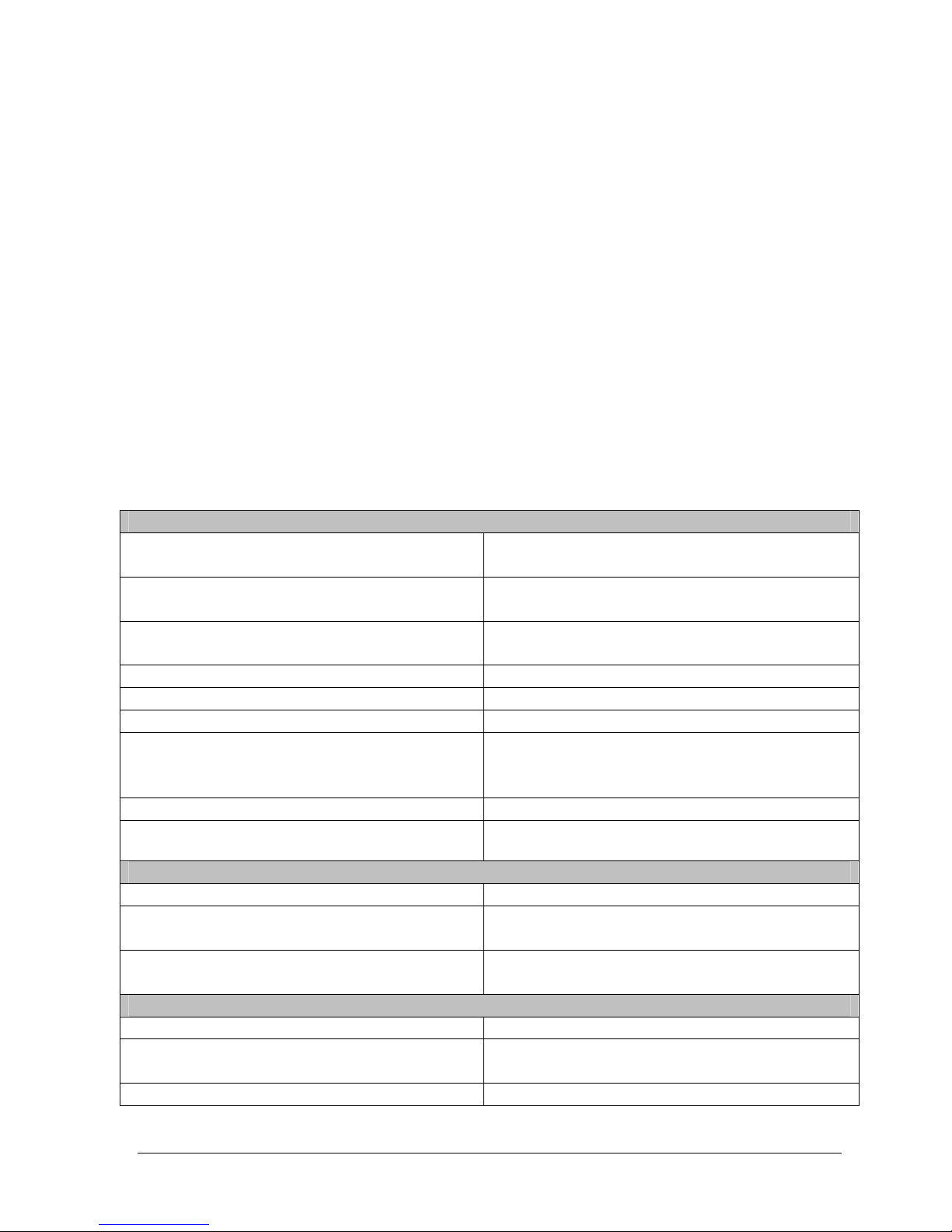

Main Control Keypad

The wash cycle, heater control (optional), tank sensors and error messages are

displayed and controlled via the main keypad (see Figure 2).

The following LEDs and buttons are displayed on the main keypad:

Table 2

Button/LED Function

Power When power is supplied to the unit this LED will be

illuminated.

Wash Cycle & SELECT Button Three wash cycles are available: LIGHT, MEDIUM &

HEAVY. Pressing the SELECT button toggles

between the three settings. See Using the Vessel

Washer on page 3-5 for more information.

Heater LED and Display When the heater LED is illuminated, the heater is

activated. The two digit display shows the

temperature of the media in the rinse tank in ºC.

ON/OFF/SET and Up/Down

Arrows

Pressing the ON/OFF/SET button will toggle the

heater from activated or off (the heater LED will

toggle). Holding the ON/OFF/SET will cause the

display to flash the set temperature. Using the Up

or Down Arrow keys will change the set

temperature. Holding the ON/OFF/SET will return

the unit to normal operation, displaying the current

tank temperature.

Waste Tank LEDs When the waste tank is full the FULL LED will be

illuminated and when the tank is empty, the EMPTY

LED will be illuminated. When the tank is full, the

unit will audibly beep.

Rinse Tank LEDs When the rinse tank is full the FULL LED will be

illuminated and when the tank is empty, the EMPTY

LED will be illuminated. When the tank is empty,

attempting to run the unit will result in an audible

beep.

Error LED If the system encounters an error, this LED will

illuminate and a two digit code will be displayed in

the display window. See Error Codes on page 5-3

for more information.

ABORT Button Pressing this button will abort the current action

and return to unit to an idle state.

Chapter 3: Operation

Operation Manual: VIP 4400 Vessel Washer 3-3

Figure 2: Main Keypad

Remote Nozzle Keypad

The remote nozzle contains a keypad that allows the user to run all the normal

actions when the nozzle is securely placed in the vessel. The following list

describes the functions of each button (see Figure 3).

Table 3: Remote Keypad Functions

Button Function

Manual Drain This button will drain all the media from the vessel for an

unspecified period of time. To stop this action the ABORT

button must be pressed.

Manual Wash This button will both drain and wash the vessel for an

unspecified time. The wash will continue to run until the

ABORT button is pressed. This action is useful when needing

to clean the vessel for an extended period of time.

Auto Wash This action will use one of the 3 wash cycles (Light, Medium

or Heavy) that has been set on the main keypad.

Abort This will abort whatever action is currently running.

Other manuals for VIP 4400

1

Table of contents

Other Distek Washer manuals