8

4

INSTALL AND OPERATION

4.1 Installation

The compressor must be mounted on a firm, level base Where is with well-ventilated

and rain-proof , non-hazardous locations

The environment temperature is required to be lower than 40 degree C.

4.2 Check before running

Oil level check

Check the oil level which must be keep between max. and min. line.

Note: if the oil level is too high, air valves will carbonize, if it is too low , will

result in insufficient lubrication and cylinder sticking

-- Check connect fitting and valve to make sure no leakage

-- Check rotary direction of motor, the right direction should be a cooling wind to the

cylinder

--install intake air filter on pump block

4.3 Running

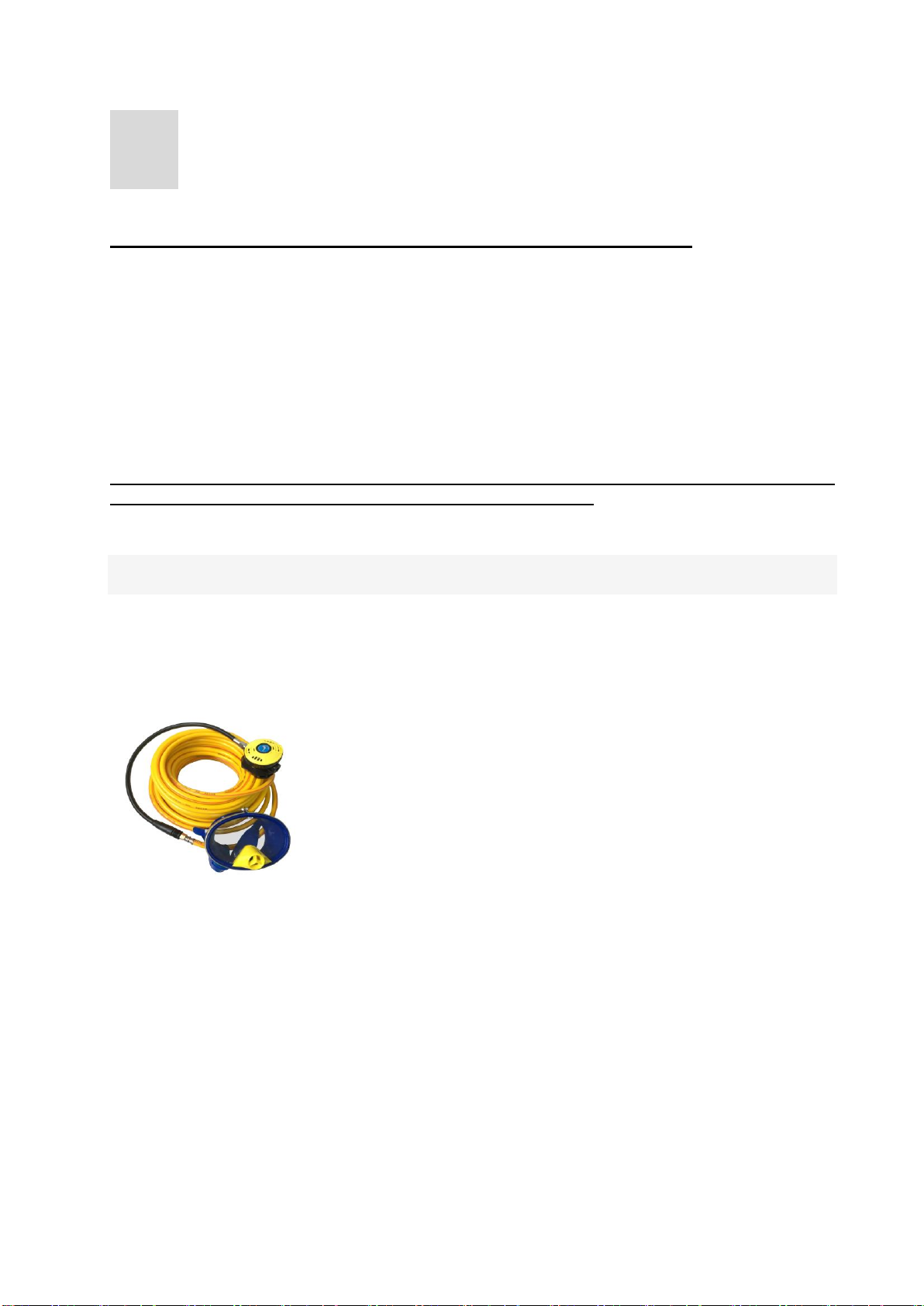

1. Connect air hose to discharge outlet port with fast plug in coupling

2. Open discharge check valve

3. Close drain valve under air tank

4. Start engine to run compressor

5. Compressor will download automatically when reach rated pressure

( presetting unload pressure is 0.8Mpa/ 8bar/ 110psi),

and load again when pressure drop down to minimum pressure

( presetting load pressure is 0.5Mpa/ 5bar/ 75psi)

6. Turn around regulator to make discharge pressure go through air hose to suitable for

mask breathe.

7. Shut off engine to stop compressor when finish work