Dolmar PS-34 Operating instructions

Other Dolmar Chainsaw manuals

Dolmar

Dolmar AS-3625 User manual

Dolmar

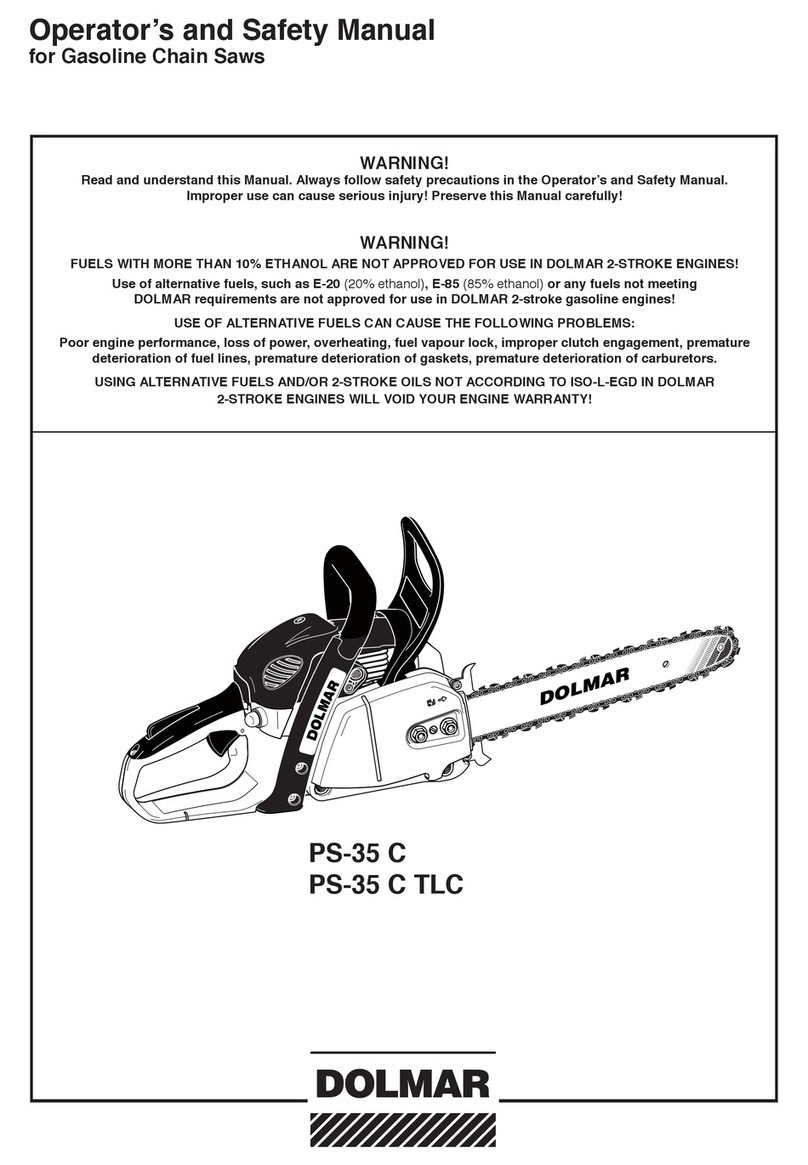

Dolmar PS-35 C Instruction Manual

Dolmar

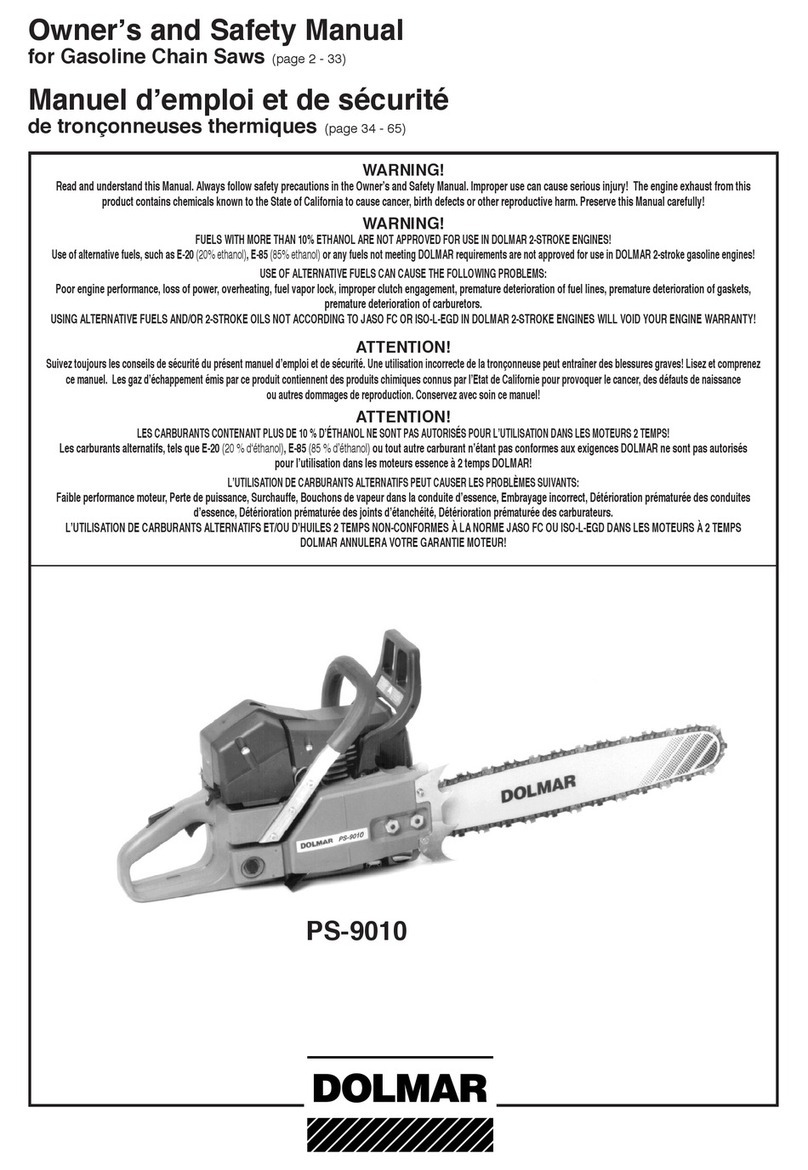

Dolmar PS-9010 User manual

Dolmar

Dolmar AS-3726 User manual

Dolmar

Dolmar AS-3726 User manual

Dolmar

Dolmar AS4030 User manual

Dolmar

Dolmar DCS34 Instruction Manual

Dolmar

Dolmar 109 HappyStart User manual

Dolmar

Dolmar ES-154 User manual

Dolmar

Dolmar ES-183 A Guide

Dolmar

Dolmar PS-32 User guide

Dolmar

Dolmar PS-6100 Operating instructions

Dolmar

Dolmar PS-32 Instruction Manual

Dolmar

Dolmar ES-153 A User manual

Dolmar

Dolmar PS-351 Operator's and safety manua Instruction Manual

Dolmar

Dolmar AS-1813 User manual

Dolmar

Dolmar PS-350 Guide

Dolmar

Dolmar PS-220 TH User guide

Dolmar

Dolmar PS-220 PS-221 User manual

Dolmar

Dolmar PS-7310 H Instruction Manual