General

GL-3

7.Before the check and assembly of a disassembled part, clean it first.

8.During the reassembling, oil seal, gasket, O-washer, lock washer and

split pin should use the new one.

9.Replace the outer and inner rings of tapered roller bearing in whole set.

10.Arrange the disassembling procedures according to the part assembling

order.

11.Mark on the disassembled brake pipe about the connecting relationship.

12.Use suitable lubricating oil, brake fluid,cooling liquid and seal glue

according to standard.

13.Use general and special tools to ensure maintenance safely and effi-

ciently.

14.Deal properly with drained lubricating oil and solvent used to wash

parts.

How to Use Manual

1.Look up contents as quickly as possible. The contents of every section

are completely listed on the first page of each chapter.

2.The subject of each chapter is on the top of every page, showing the

name of each system of assembly.

3.The page code of each chapter is of two or three letters, to show the

name and page code of a certain chapter(ex, "BR-5").

4.A larger diagram is used to show the separated construction of an assem-

bly, its contents: tightening torque, lubricating points, and the other

information for maintenance. These are dor the reference of mainte-

nance, and you have to see the SPARE PARTS CATALOG for parts

booking.

5.The smaller diagram mainly indicate: every main checking procedures,

all the tools needed, work skills latent procedures which are not listed in

the larger diagram above. To some more complicated assembly system,

in dictate them with diagrams one by one.

6.The measuring units in this book are mainly international standard ones.

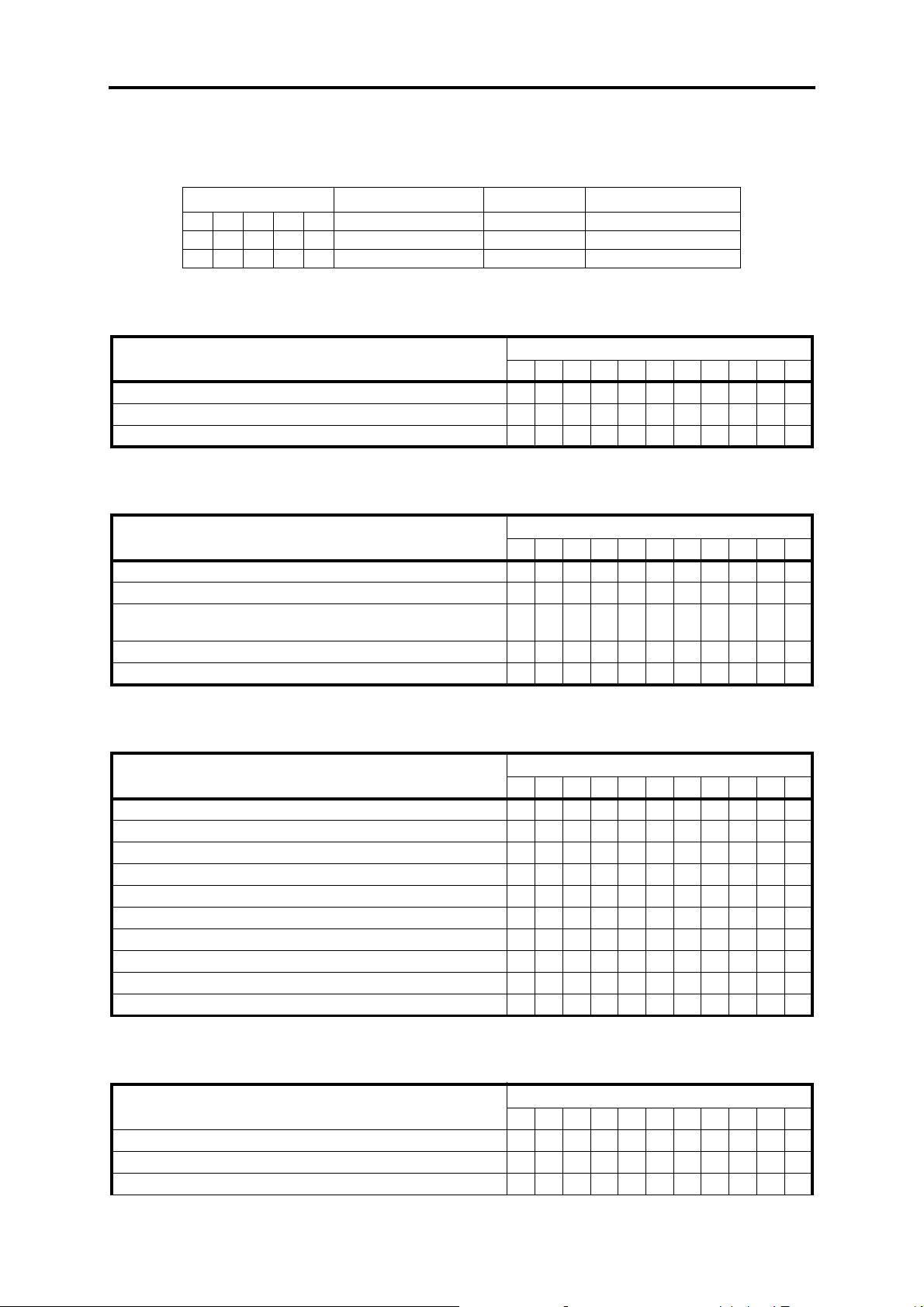

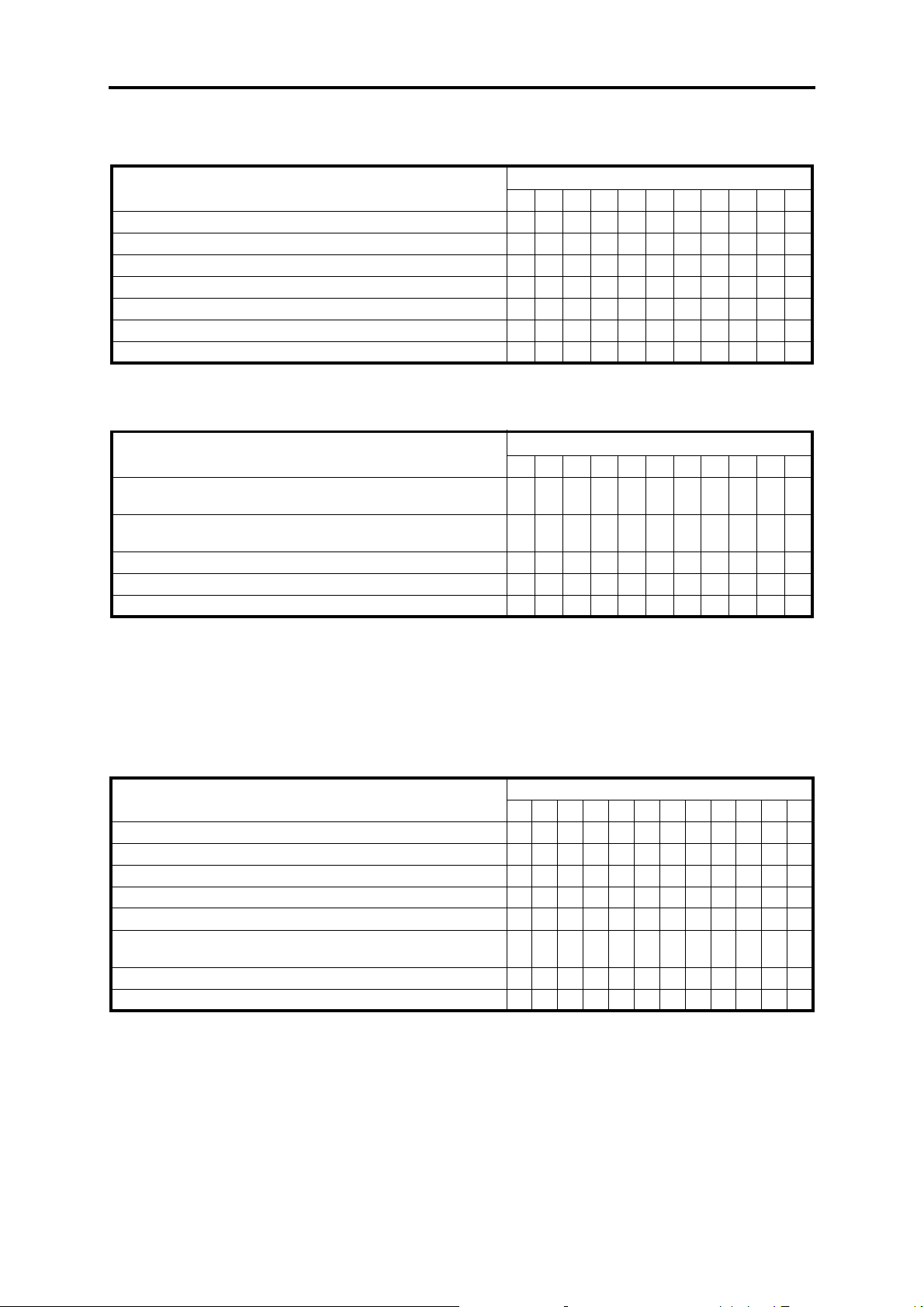

7.The data and axplanation of maintenance are in the last pages of every

chapter to be the reference.

8.In the procedure marked "Warning","Notes","Caution" strictly observe

these procedure norms, to avoid body hurt and damage to some parts.

Warning: indicates if you do not follow this instruction, it will

cause body hurts.

Note: indicates if you do not follow this instruction, it will cause

some parts damaged.

Except some instructions of warning and notice, again some help-

ful information are provided.