CONTENTS

P05

P06

P07

Outline

Chapter 1 1 4-Stroke Engines

2 Role of the ignition System

3 Ignition System Configuration

P08

P08

4 Types of Ignition System

5 Comprehensive Test

P35

P38

P39

Basics of

Ignition

Chapter 3 1 High Voltage Generation

2 High Voltage Control

3 Ignition Timing

P39

P40

4 Ignition Order

5 Comprehensive Test

P09

P13

P15

P25

Spark plugs

Chapter 2

The PLUGS CONFIGURATIONS •••••••••••••••••••••••••••P41

IGNITION TECH Q&A

FAKE PLUG

LINEUP •••••••••••••••••••••••••P61

Q&A

Q&A

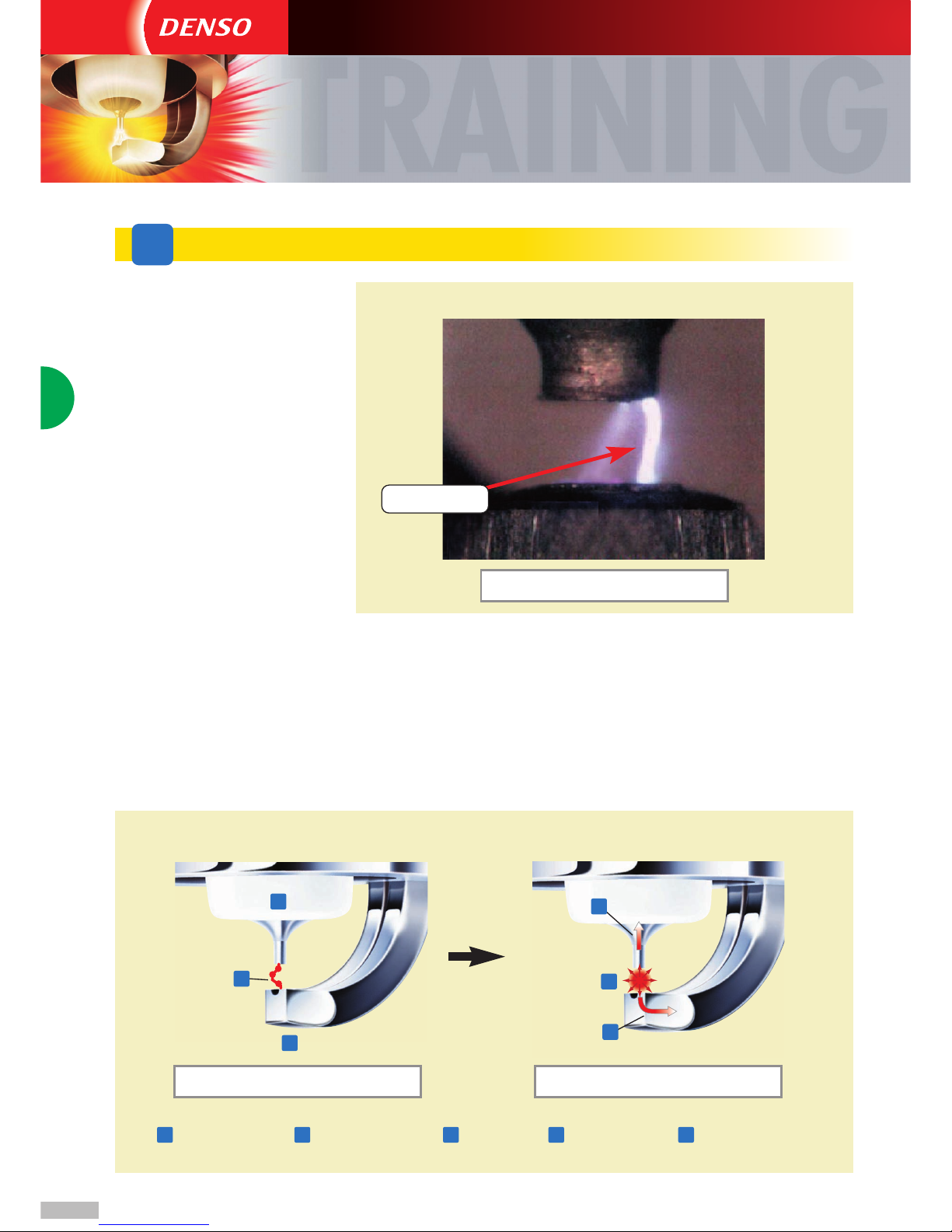

1 Spark and ignition

2 Structure

3 Types

4 Heat Range

P27

P29

P31

P34

5 Service Life

6 How to read Sperk Plugs

7 Troubleshooting

8 Comprehensive Test

Q1. What type of spark plug is the ? P43

Q2. Why was the center electrode of the reduced to only 0.4 mm? P44

Q3. How is the iridium tip of the welded to the electrode? P45

Q4. What advantages does the U-groove in the ground electrode have? P46

Q5. What advantages does the tapered cut in the ground electrode have? P47

Q6. What are the differences between and iridium spark plugs

offered as genuine parts by car manufacturers? P48

Q7. What type of material is used to produce the electrode employed for ? P49

Q8. Why can iridium now be used in electrodes? P50

Q9. In what other fields is iridium commonly used for? P50

Q10. Is the tip in the made of pure iridium? P51

Q11. Tell me about the firing performance of the . P52

Q12. Tell me about the required voltage in the . P53

Q13. What happens at idling when an is used? P54

Q14. What happens to fuel consumption when is used? P55

Q15. Does engine performance improve when is used? P56

Q16. Can spark plugs of other brand-names be substituted with ? P57

Q17. What type of cars can current be fitted with ? P58

Q18. Does the engine need to be specially set when fitting ? P58

Q19. How do I select the correct heat-range when fitting to my vehicle? P59

Q20. How would compare against high-performance spark plugs

offered by other spark plug manufacturers? P59

Q21. Is there anything I need to be aware of when fitting ? P60

Q22. Can the gap be adjusted?

Can I use any spark plug cleaners with the ? P60

Q1. What type of spark plug is the ? P66

Q2. What makes the ignitability of so good? P67

Q3. How does the superior ignitability of influence combustion? P68

Q4. How is the iridium tip of the welded to the electrode? P69

Q5. What is the difference between and ? P70

Q6. What patented technologies are used with ? P70

Q7.

What type of material is used to produce the electrode employed for

? P71

Q8. Why can iridium now be used in electrodes? P72

Q9. In what other fields is iridium commonly used for? P72

Q10. Is the tip in the made of pure iridium? P73

Q11. Tell me about the ignitability of the . P74

Q12. Tell me about the required voltage in the . P75

Q13. What happens at emission when an is used? P76

Q14. What happens to fuel consumption when is used? P77

Q15. Does engine performance improve when is used? P78

Q16. How does the compare to the 0.6mm iridium plugs,

platinum plugs and normal spark plugs? P79

Q17. Can spark plugs of other brand-names be substituted with ? P80

Q18. Does the engine need to be specially set when fitting ? P81

Q19. How do I select the correct heat-range when fitting to my vehicle? P81

Q20. How does the compare to iridium plugs from other makers? P82

Q21.

Can be used to replace plugs with 2, 3 or 4 ground electrodes?

P83

Q22. Is there anything I need to be aware of when fitting ? P84

Q23. Can the gap be adjusted?

Can I use any spark plug cleaners with the ? P85

Q24. What plugs are in the lineup? P86

SPECIFICATIONS ••••••••••••••••P63

•••••••••••••••••••••••••••••••••P93

••••••••••••••••••••••••••••••••••••••••••P97

SPECIFICATIONS •••••••••••P87

••••••••••••••••••••••••••••••••P88

••••••••••••••••••••••••••••P89

SPECIFICATIONS •••••••••••P91

CROSS REFERENCE ••••••••P92

DENSO Spark Plugs Package Lineup •••••••••••••••••••••P65

04