T195SV Vapor Recovery Vent

Instruction & Maintenance Manual

Product Description

Civacon’s T195SV sequential vapor recovery vent design increases flow while

loading and unloading. This vent is designed to work on a 20” Manhole

cover with or without mounting bolt holes. The o-ring will seal on the outside

diameter of a bolt pattern. The T195SV conforms to API 1004 and EN13083

regulations.Civacon’s T195SV is a direct replacement for the 1985SV and all

competitors’ vapor recovery vents. Compatible with diesel, biodiesel, gasoline,

ethanol and methanol

WARRANTY

All parts and products are thoroughly inspected and tested from the time raw

material is received at our plant, until the product is completed. We guarantee

that all products are free from defects in materials and workmanship for a

period of one year from the date of shipment. Any product that may prove

defective within said one year period will, at our discretion, be promptly

repaired, replaced or credit given for future orders. This warranty shall not apply

to any products which has been altered in any way, which has been repaired by

any party other than an authorized service representative, or when such a failure

is due to misuse or condition of use. We shall have no liability for labor costs,

freight costs or any other costs or charges in excess of the amount of invoice

for the products.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED AND SPECIFICALLY THE WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE.

WARNING!!

CIVACON products should be used in compliance with the applicable federal,

state and local laws and regulations. Product selection should be based on

physical specifications and limitations, compatibility with the environment,

and the material being handled.

CIVACON MAKES NO WARRANTIES OF

FITNESS FOR A PARTICULAR PURPOSE.

TECHNICAL ASSISTANCE

If at any time during the installation a question arises that is not covered in this

manual or with any other applicable documents feel free to call the Customer

Service Department or visit our website at www.civacon.com.

In the U.S., call 1-888-526-5657

In all other countries, call your local agent.

Manual

This manual contains the inspection, maintenance schedule and instructions for

repairing and replacing parts for the T195SV vapor recovery vent. The following

schedule, based on the environmental conditions in the northern United

States, is only a recommendation: Inspection and maintenance intervals must

be adjusted according to use and operating conditions.vents. Compatible with

diesel, biodiesel, gasoline, ethanol and methanol

NOTE: All information subject to engineering and/or other changes. All trade names are copyrighted. Patents Pending. ©2018 Civacon. ©2018 Delaware Capital Formation, Inc.

All Rights Reserved. DOVER and the DOVER logo are registered trademarks of Delaware Capital Formation, Inc., a wholly-owned subsidiary of Dover Corporation.

www.civacon.com 9393 Princeton-Glendale Road Hamilton, Ohio, USA 45011

Phone: (800) 422-2525 Fax: (800) 421-3297

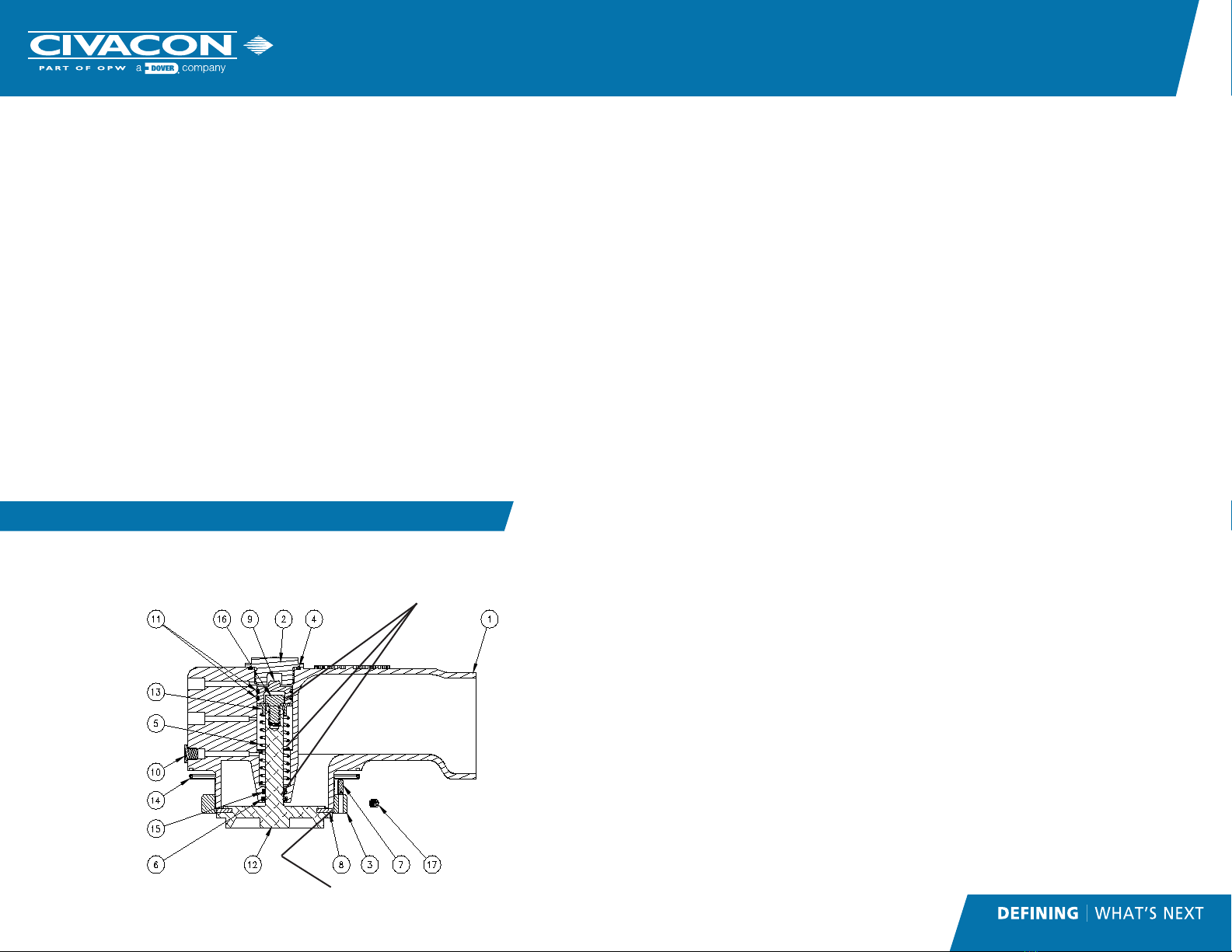

Actuating Port

Sequential

Out Port

Exhaust

Port

01-10-002PA Apr 2018