Pump Features:

PRIMING IS DONE AUTOMATICALLY

After initial priming TS Series Pumps are designed to re-prime

automatically in a completely open system, without the need of a discharge or suction check

valve. This can be achieved with the pump casing only partially filled with liquid and with a

completely dry suction line. The TS’s ability to handle air overcomes priming and vapour

handling problems common in conventional centrifugal pumps.

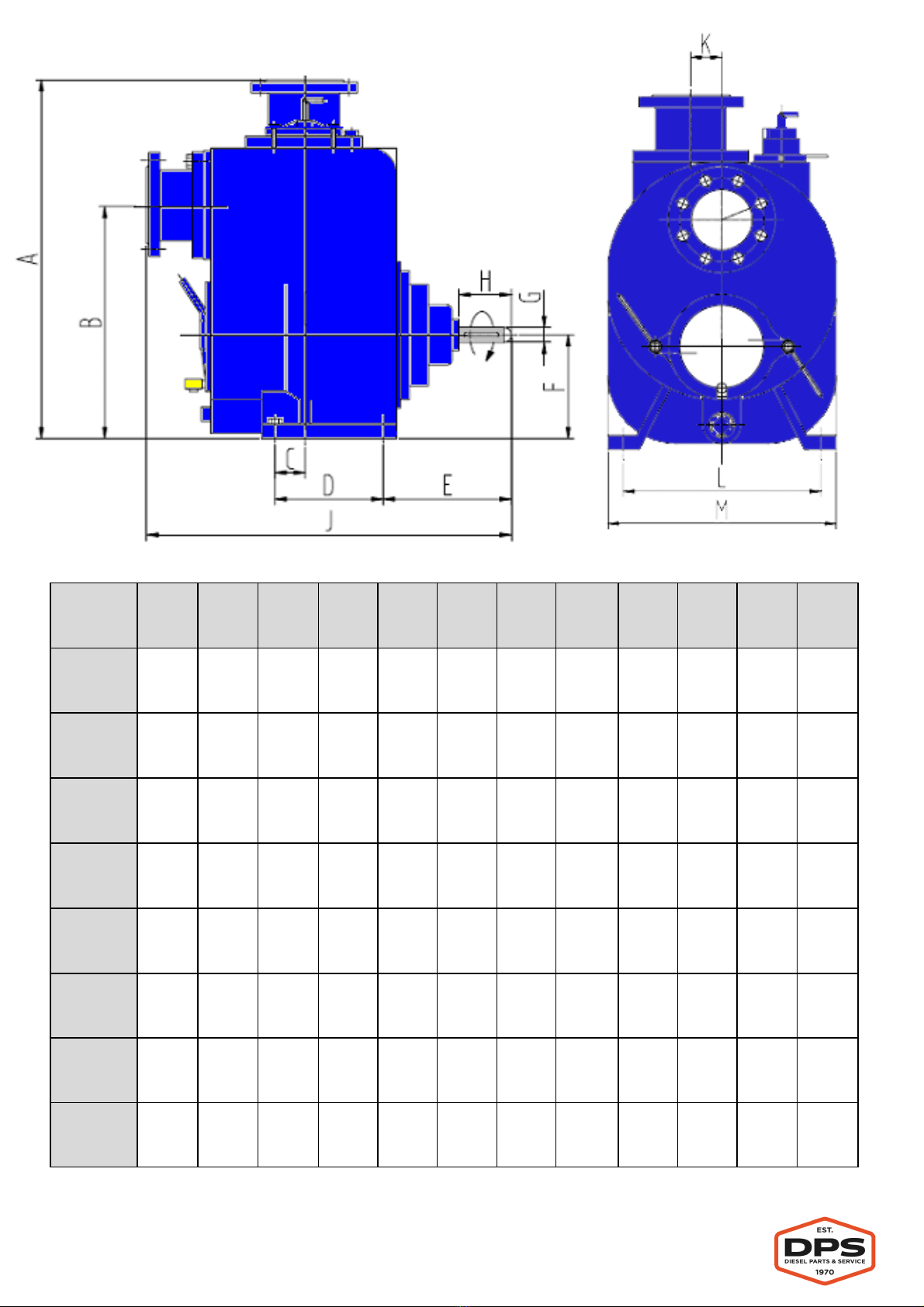

EXTERNAL SHIMLESS ADJUSTMENT

The external shimless cover plate allows for easy adjustment of clearance between the

impeller and the wear plate. This eliminates the need to re-align belts and couplings etc. The

collar and adjusting screw allow for incremental adjustments of the wear plate clearance.

Once the adjustments have been made, the collar locks into place maintaining the clearance

settings even if the cover plate is removed.

SOLIDS HANDLING IMPELLER

Two-vane, semi-open, solids handling impeller handles up to 3” dia solids, depending on the

pump model. Pump out vanes on the impeller shroud reduce the build-up of foreign material

behind the impeller and reduce pressure on the seal.

REMOVABLE COVERPLATE

The removable cover plate provides quick and easy access to the pump interior without

disconnecting the piping. Clogs and blocking material fibre can be removed and the pump

returned to service within minutes. The impeller, seal, wearplate and flap valve can also be

accessed through the cover plate opening.

ABRASIVE HANDLING MECHANICAL SEAL

Double floating, self-aligning, oil lubricated mechanical cartridge seal with stationary and

rotating face of silicone carbide

REMOVABLE ROTATING ASSEMBLY

Back pull out removal of the rotating assembly allows for easy inspection of the pump shaft or

bearings without disturbing the pump casing or pipe work. Simply remove the bolts for the

back of the pump and the rotating assembly slides out

www.dieselparts.com.au

DPS TS Series Trash & Sewage pumps are designed for economical and trouble-free operation

in handling solids-laden liquids. Pumps feature a large volute design which allows them to re-

prime automatically in a completely open system without the need of suction or discharge

check valves. This is workable with the pump only partially filled with liquid and a completely

dry suction line. Pumps will be able to handle up to 3” (75mm) spherical solids, depending on

the pump model. In case that the pump shaft or bearings need service or repair, the entire

rotating assembly can be back pulled out without disturbing the pump casing or pipe work.

Rotating assembly is sealed with an o-ring, allowing for external adjustments of the impeller to

wear-plate clearance.