DRI-EAZ PRODUCTS, INC.

15180 Josh Wilson Road, Burlington WA 98233 •Tel: (360) 757-7776 Svc Fax (360) 757-6784 www.dri-eaz.com

PN 07-00397 Microswitch Kit Instructions - 2/28/02 1

DrizAir 1200/2400 Pump Troubleshooting Guide

All service procedures below are to be executed with the power off, i.e., unplugged.

Tools Required: (1) 5/16” Nutdriver or wrench (1) Phillips Screwdriver

(1) Flathead Screwdriver (1) Q-Tip Cotton Swab

(1) Needlenose Pliers (1) 6" x 8" piece of Cardboard

Preparation:

1. Read all pump and testing instructions carefully before

checking and servicing pump on dehumidifiers.

2. Make sure you have all the parts and tools required to

perform inspection, repair and upgrade as listed in these

instructions.

3. Make sure the dehumidifier is disconnected from the

power source before starting any of the following proce-

dures.

Removing Dehumidifer Cover and Accessing Pump

4. DrizAir 1200: Remove the six 3/8” bolts holding on the

front cover in the following order. While unit is standing

up, remove the two near the wheel axle. Place unit on its

back, remove the two located on top, in front of cover.

Last, remove the two located on bottom of unit near the

front feet. All bolts can be identified because they are all

3/8”. Remove front cover.

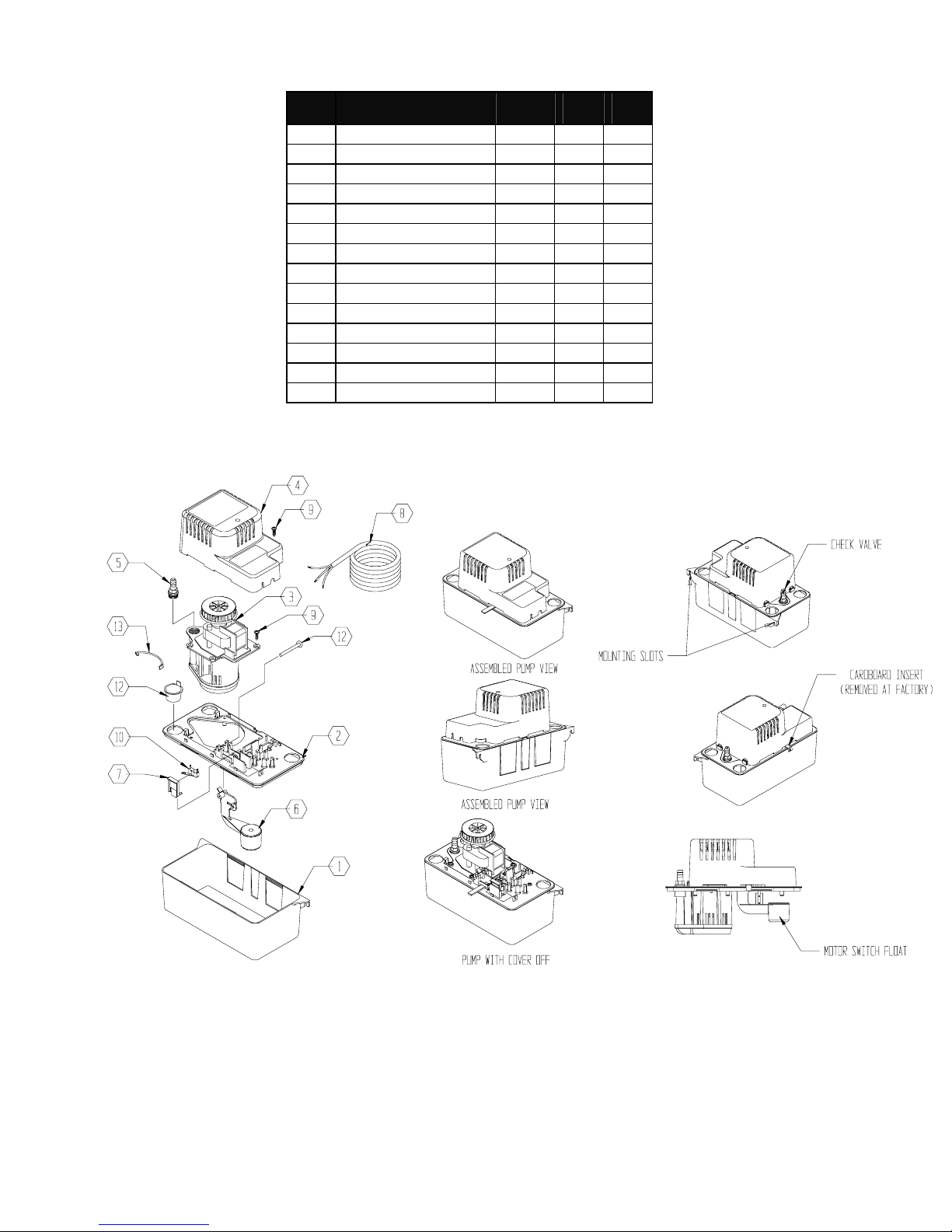

DrizAir 2400: Lay unit on its back and unscrew the four

7/16” bolts on the grey bucket. Remove bucket and turn

upside down. Then set the pump on it, using it as a table.

5. DrizAir 1200, Carefully snip the zip tie holding the coiled

power cord, and remove the two 5/16” mounting bolts lo-

cated to the rear of the pump with nut driver.

DrizAir 2400, Carefully snip the zip tie holding the power

cord in place inside unit.you may not need to snip the zip

tie if there is already plenty of slack in the power cord to

set pump on grey bucket. The objective is to remove the

pump just far enough to access the two Phillips screws

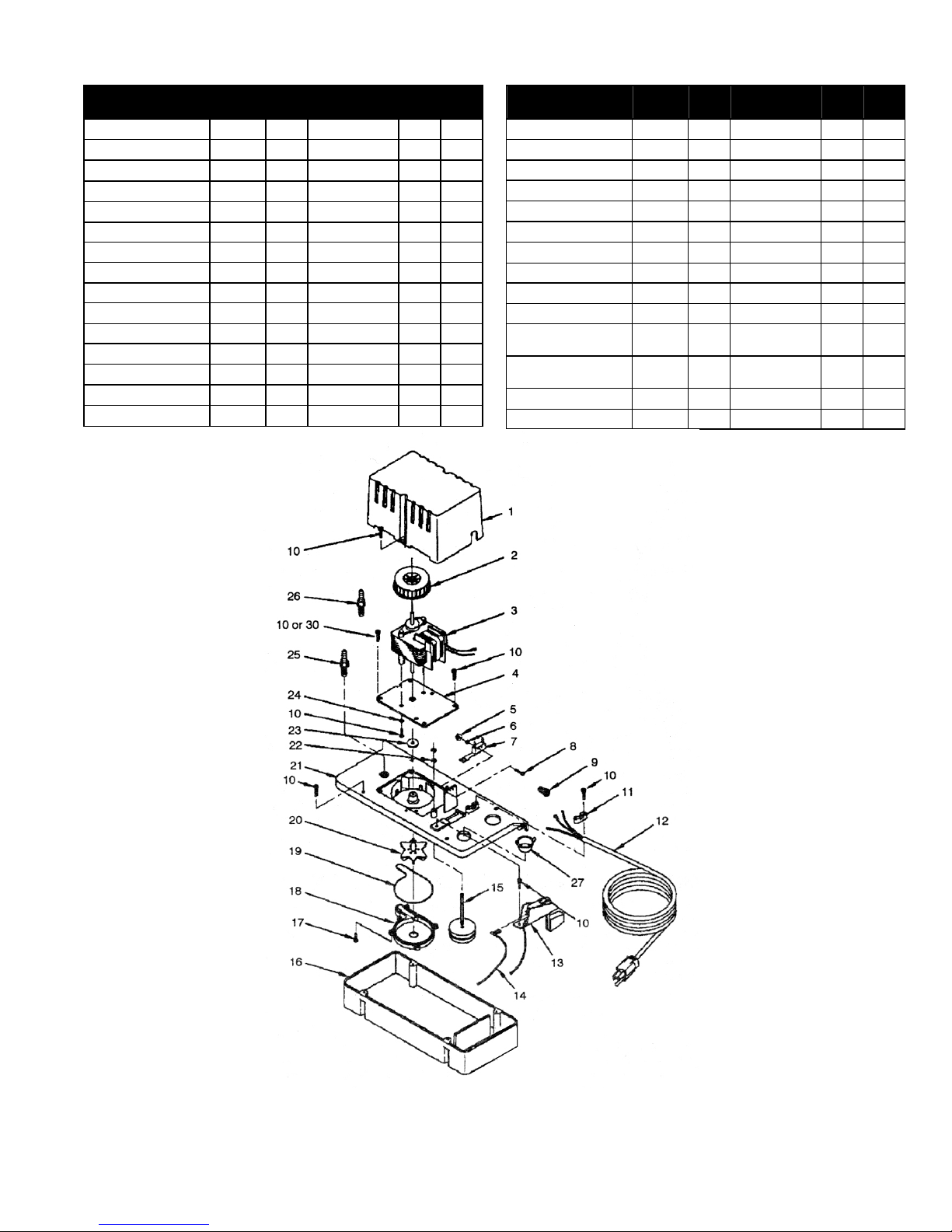

[#10], one on each side of pump cover [#1].

Inspecting External Pump Components

6. With pump exposed, inspect ½” clear drain tube entering

pump on right side to insure it’s properly seated into

pump. If too short or kinked it may need to be replaced.

7. Pull tube out and verify bottom of tube has a 35-degree

notch cut into it. This prevents a seal from occurring be-

tween the hose and bottom of resourvoir tank. If seal oc-

curs, water will back up in the drip tray and overflow.

8. Using screwdriver, remove pump-out tube from black

check valve [#25] located on left side of pump. Be careful

not to break fixture.

9. Unscrew check valve.

10. Look into the bottom of the check-valve assembly. Using

needle nose pliers carefully remove bottom of check valve

assembly by inserting one side of pliers approximately

1/8” into hole, grasp and pull carefully. A small bearing

should fall out so be careful not to lose it. Now you can

inspect for debris in assembly and clean accordingly.

Clean and reinstall.

Removing Pump

11. Remove pump from base by sliding to the left. While

slightly lifting the silver pump shield up, pull pump up and

out to left. Place piece of cardboard on top of refrigeration

coils and rest pump gently on top of it, using it as a table.

12.Remove two pump cover screws [#10], and set pump cover

[#1] aside.

Inspecting Internal Pump Components

13. With cover removed, visually inspect microswitch [#7]

for looseness. If loose, gently tighten screws [#8]. Note:

Over tightening will cause switch to bind up inside and

fail. If switch is snug and no parts missing, continue.

14. Check operation of microswitch by lifting float stem

[#15] upward, listening for the switch activation “click”

sound. Then, let float stem fall on its own, listening for

the “click” going downward. Switch may need adjusting

or replacement if “click” doesn’t occur in both directions.

Adjustment: The microswitch needs to be level to its

mounting peg. If switch is tilted too far back it will not

activate microswitch lever. Note: Do not bend mi-

croswitch lever to compensate for unevenness. Loosen

screws, adjust until level and gently re-tighten.

Replacement: If switch lever hangs up in either up or

down direction, replace microswitch.

Note: Be careful not to over tighten mounting screws and

nuts in either an adjustment or replacement switch situa-

tion. Also, be sure to include two locking washers [#6]

per screw, one underneath head of screw [#8] and one

prior to installing hex nut [#5].

15. Inspect to insure two “C”clips [#22] on float stem are in

place, one above and one below microswitch lever.

16. Check to insure float moves freely up and down and is not

restricted. If restricted, clean float stem [#15] and access

port. A Q-Tip works well for this procedure.

17. Check to see if impeller [#20] is spinning freely by spin-

ning the black plastic wheel located on top of motor.

18. Remove the remaining four Phillips screws [#10] from the

top of the pump assembly and separate it from the blue

reservoir tank [#16]. (Any missing microswitch screws or

nuts may be found here.)

19. Inspect bottom of reservoir tank for debris and dirt build

up. Clean accordingly.

20. Visually inspect impeller cover [#18] and gasket for

cracks, warps or exposed gasket material.

21. Remove four impeller cover screws [#17] and check for

debris in housing.

22. Assemble in reverse order. Run unit through several

pump outs to insure repairs.