horizontal) and not more than two bends. No reduction in flue pipe below the exhaust diameter

should be used. The pipe connecting the furnace to the chimney should be at least 24 gauge.

Thicker gauges are available and will resist corrosion longer

and need fewer replacements. Slope the flue pipe back

towards the heater, 1/4” per foot of horizontal run. That way

if any condensation forms in the pipe it will be carried back

into the heater. The connector pipe should be installed so

that the upper pipe section fits inside the lower section. This

way any condensation building up inside the pipe will stay

inside the pipe as it flows down the inside surface.

Horizontal pipe runs should have the pipe seams turned up

Particular attention should be paid

to the point where the flue passes

through a wall or ceiling. This pen-

etration should always be made

with a thimble, insulated pipe, and

then proper accessories following

manufacturers instructions.

Chimney connectors must not

pass through the ceiling,

concealed spaces, or enter the chimney in the attic, unless

proper clearance or insulated pipe is used following manufac-

turers instructions. REMEMBER that all single wall chimney

connector sections

should be connected

with at least 3 sheet

metal screws per joint.

A fire in the stack may

cause vibration and poorly fastened piping may come apart causing an extreme fire and smoke

hazard. Do not extend single wall chimney connector past the inside edge of the flue liner. f you

have a manufactured stainless steel chimney, attach single wall chimney connector to single wall

chimney connector adapter. Where the pipe connects to a masonry chimney, the flue to the chimney

should be larger than the single wall chimney connector so you can insert the pipe out to the inside

edge of the chimney, but not past. Then seal as tight as possible and cover with a trim collar.

3

Chimney Requirements

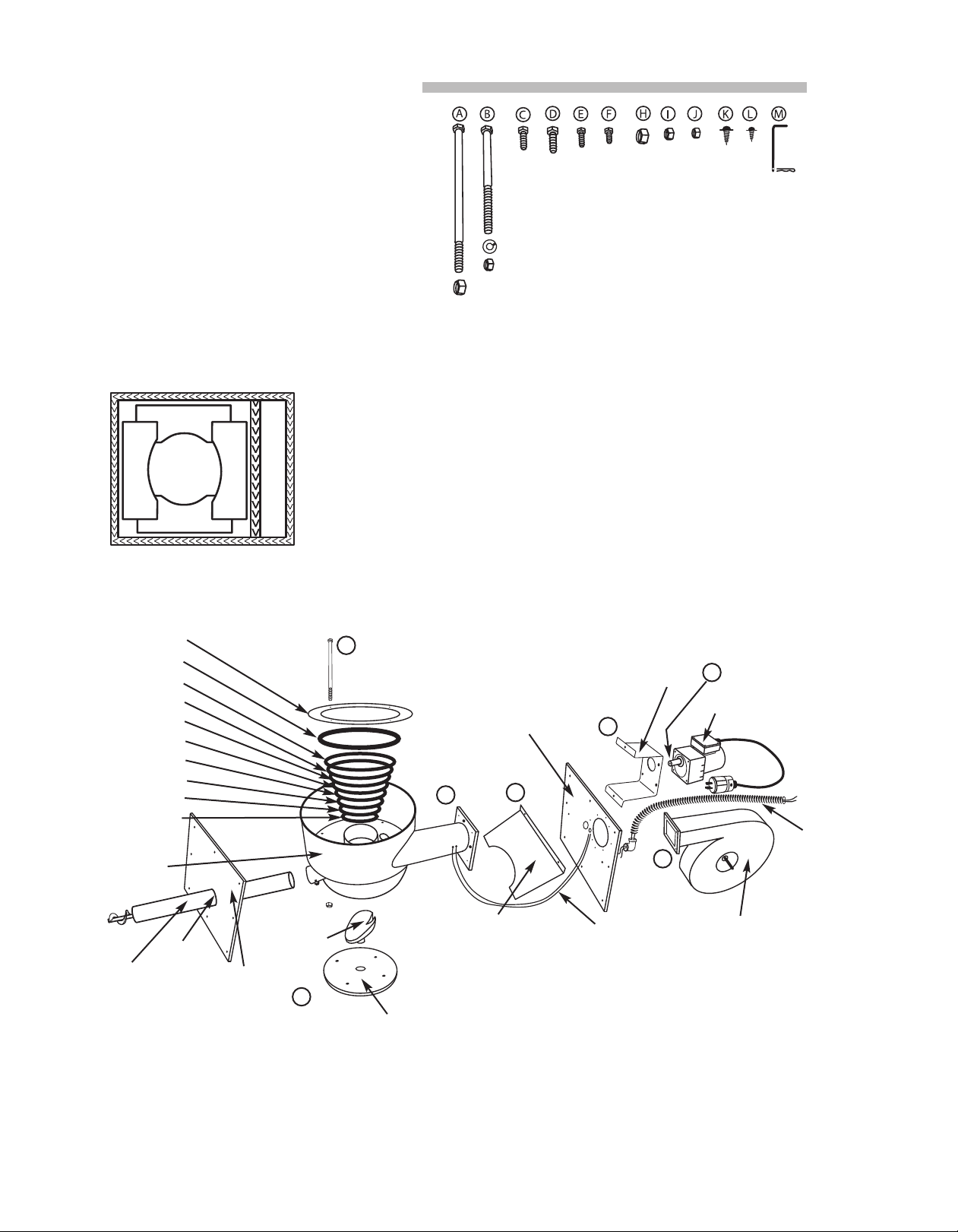

Use an 8” Class “A” approved chimney. Refer to manufacture’s instructions.

The minimum height of a chimney system for the D.S. Furnace

is 20 feet. The chimney must exceed the roof of a house at a

minimum of 3 feet at any point of exit. n a pitched roof installation

the chimney must be 2 feet higher than anything within a 10 foot

radius of the chimney. t is important to have a chimney draft of

-0.06 water column. t is required to abide by the manufacturer’s

instructions on Class A chimneys as well as local building codes.

t is not recommended to build a chimney on an addition that is

lower than the main part of your house. Do Not extend the single

wall chimney connector past the inside of a masonry chimney

liner. Never connect this unit to a chimney serving

another appliance.

Should you have a problem with inadequate draft

you should see page 15.

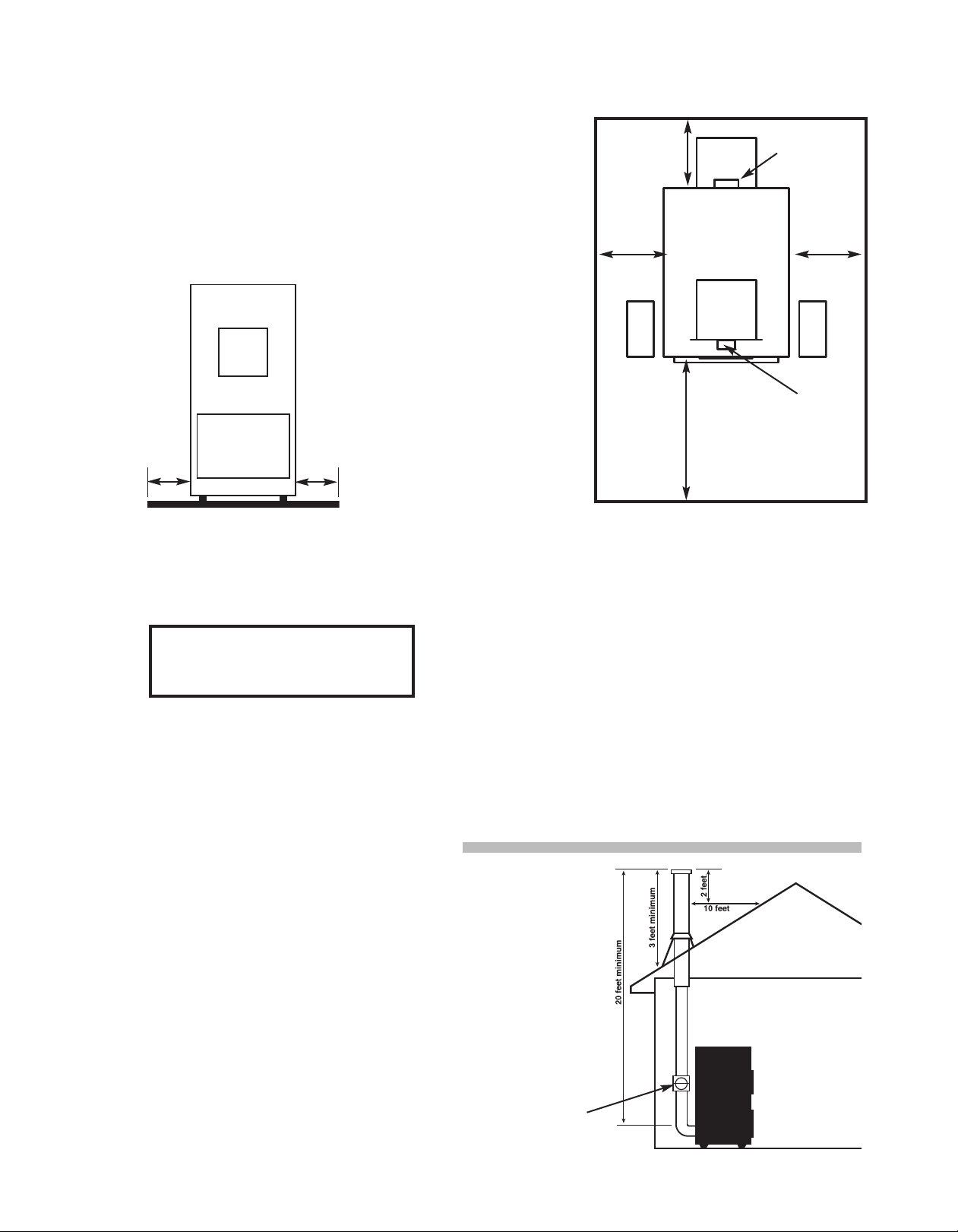

Minimum Clearance to Combustibles

Control side to comb stibles 21”

A ger side to comb stibles 12”

Back to comb stibles w/single wall stove pipe 30”

Back to comb stibles w/do ble wall stove pipe 18”

Top to comb stibles 18”

Front to comb stibles 36”

Single wall stove pipe to comb stibles 18”

Do ble wall stove pipe to comb stibles 6”

Top of plen m to ceiling 2”

Barometric

Draft

Control

CAUTION:

Keep furnishings and other combustible

materials away from the boiler.

Floor Protection

8” on back & 2 sides, 16” on front

Fig.1

A - Optional Control Box

Location

B - Limit Switch

C - Hot Air Outlet

D - 8” Exhaust

E - Cold Air eturn Box

8” 8”

Top View

Front

of Furnace

30”

12”

see

below*

12”

see

below*

36”

A

A

B

C

D

E