01/042017 Düker GmbH, www.dueker.de 7

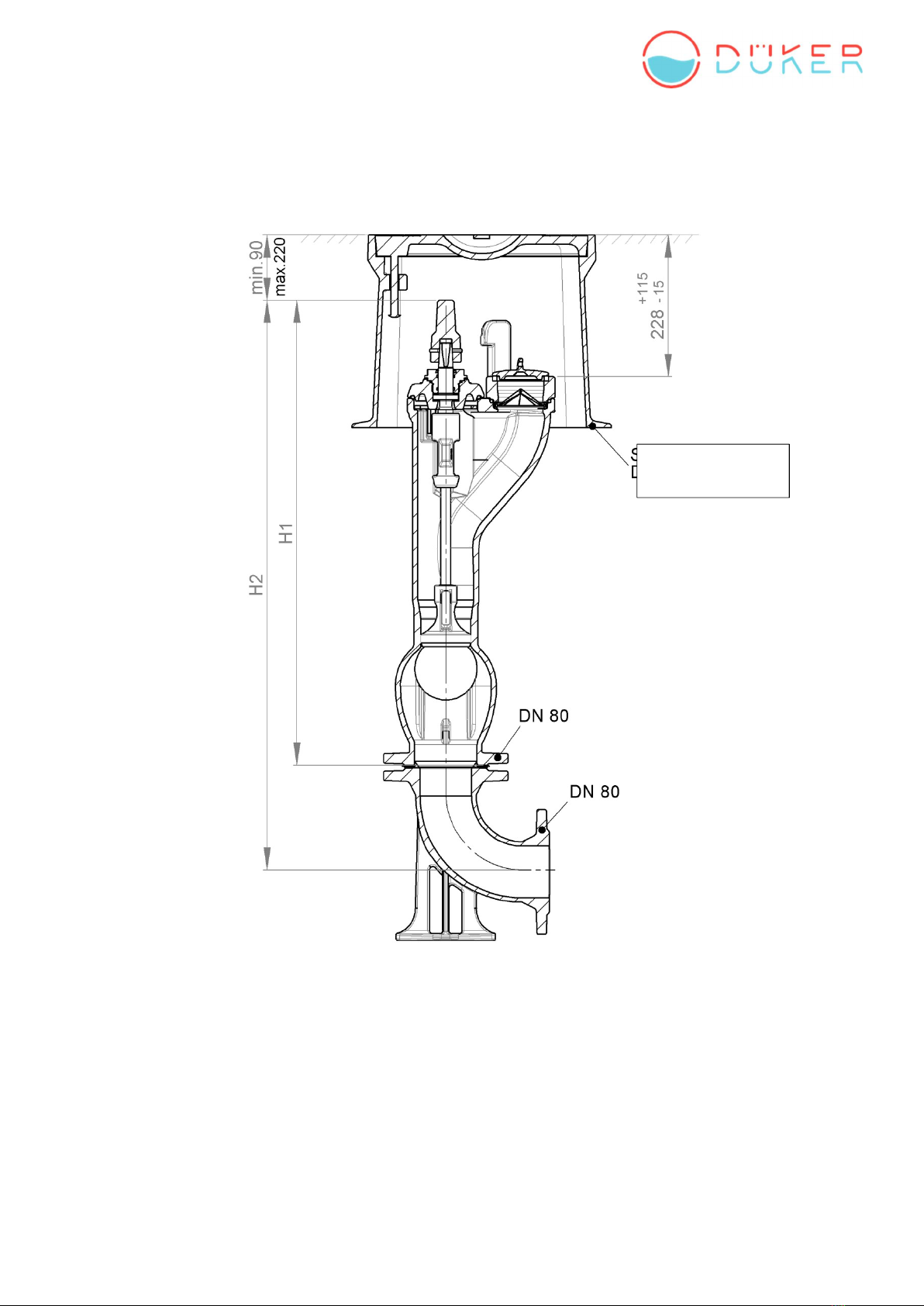

5.4. Performances

Robust, one-piece obturator, completely covered with high grade Polyurethane elastomer.

Obturator designed in flow-optimized shape.

Automatic draining and protection against pressurised water safely guaranteed by inside enamelling

Stem bearing maintenance-free by use of 2 O-Rings.

Stem thread produced by rolling process, therefore highest protection against wear and tear.

Protection during replacement of the obturator linkage by integral linkage locking device.

5.5. Operation

The hydrant will be closed by turning the stem in clockwise direction, actuation anti-clockwise opens the

hydrant. To open the hydrant fully, approx. 9 turns are necessary. Due to the fact that the obturator acts

radially, absolutely tight sealing can be achieved with low effort.

When open or closing the hydrant, always turn the stem to the perceptible contact of the

mechanical end stops. The maximum operation torque MOT up to 105 Nm is valid for both

directions of rotation. If the max. torques are reached without satisfying closing or opening,

the application of higher torques will not achieve a better tightness of the obturator and can

lead to a destruction of the coating of the end stops or the stem drive.

=> Throttling or intermediate positions of the obturator during water flow are not allowed!

To avoid to high pressure in the upper column, the hydrant should not be closed as long the valves of the

standpipe are closed.

Automatical draining:

The outlet of the automatical draining is opened, when the hydrant is closed. The complete draining of the

hydrant will be carried out within a drainage time of 2 – 3 minutes, depending on the column length (soil

cover) and the water absorbing capacity of the surrounding soil. (EN 1074-6: max. 10 minutes)

Protection against pressurised water:

When opening the hydrant (approx. 2 turns), at first the drainage outlet will be closed against the

pressurised water, due to the design of the obturator.

Further opening (approx. 1 turn) will open the water flow.