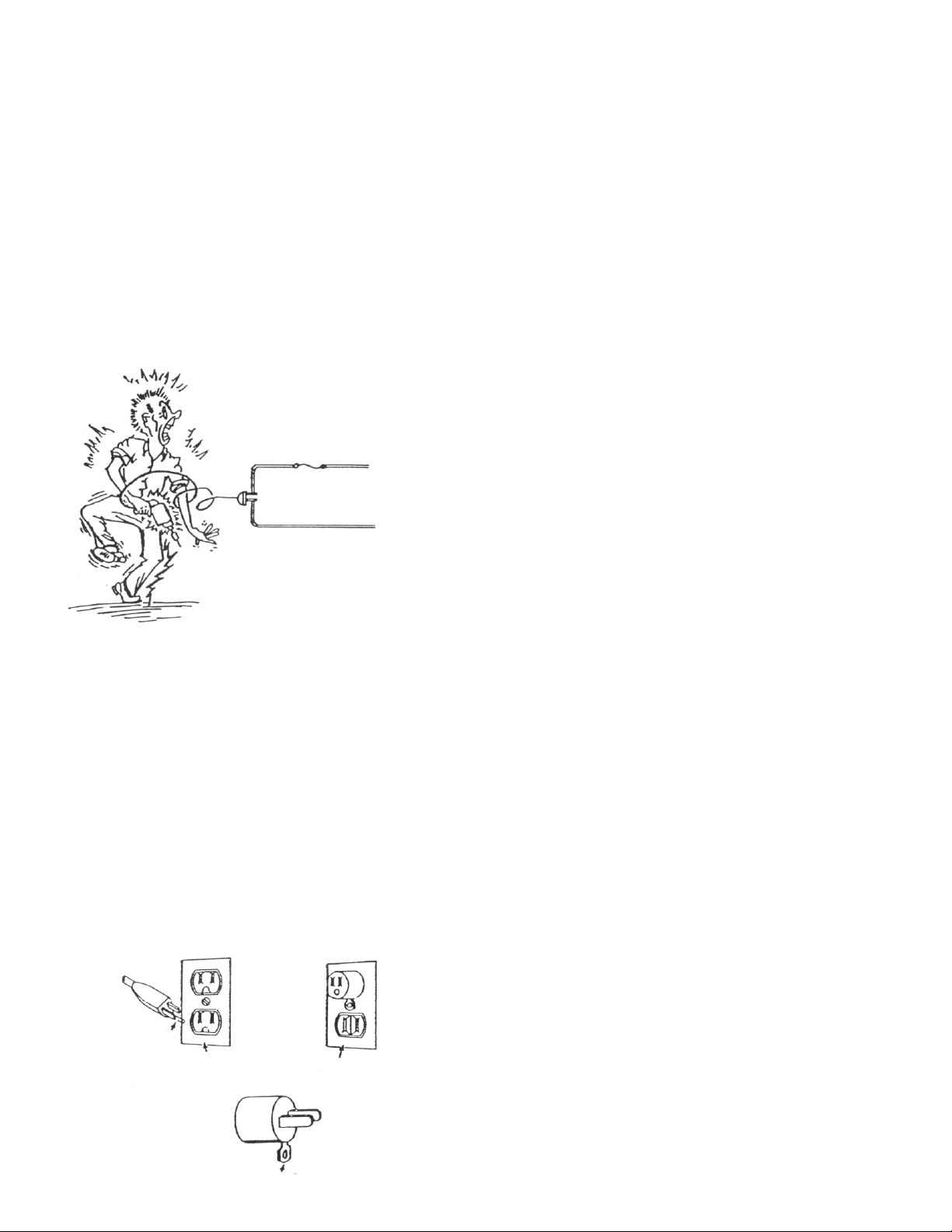

THE NEED FOR GROUNDING

In the event of a malfunction or breakdown, grounding provides

a path of least resistance for the electric current to reduce the

risk of electric shock. This tool is equipped with an electric cord

having an equipment grounding conductor and a grounding

plug. The plug must be plugged into a matching outlet that is

properly installed and grounded in accordance with all local

codes and ordinances.

s Note: Do not modify the plug provided - if it will not fit the

outlet, have the proper outlet installed by a qualified

electrician.

Improper connection of the equipment-grounding conductor

can result in a risk of electric shock. The conductor with

insulation having an outer surface that is green, with or without

yellow stripes, is the equipment - grounding conductor. If repair

or replacement of the electric cord or plug is necessary, do not

connect the equipment-grounding conductor to a live terminal.

Check with a qualified electrician or serviceman if the grounding

instructions are not completely understood, or if in doubt as to

whether the tool is properly grounded.

Repair or replace damaged or worn cord immediately.

Periodically check the ground circuit of the cord for continuity.

The use of a ground-fault protected receptacles is

recommended.

s WARNING: THIS TOOL SHOULD ONLY BE USED WHERE

POINT OF OPERATION GUARDING DEVICES HAVE BEEN

PROPERLY INSTALLED SO THAT IT IS IMPOSSIBLE FOR

THE OPERATOR’S HANDS OR FINGERS TO REMAIN

WITHIN THE POINT OF OPERATION DURING THE ACTUAL

MACHINE CYCLE.

s WARNING: Read all instructions. When using electric

tools, basic safety precautions should always be used to

reduce the risk of fire, electric shock, and personal injury,

including the following:

1. ALWAYS USE SAFETY GLASSES

(ANSI Z87.1 with side shields or an equivalent).

Polycarbonate lenses have been found to provide better

impact resistance than glass lenses

2. WEAR PROPER APPAREL

No loose clothing, gloves, neckties, rings, bracelets, or

other jewelry to get caught in moving parts. Non slip

footwear is recommended. Wear protective hair covering

to contain long hair.

3. DO NOT USE IN DANGEROUS ENVIRONMENT

Do not use power tools in damp or wet locations, or expose

them to rain. Keep work area well lighted. Do not use tool in

presence of flammable liquids or gases.

4. KEEP WORK AREA CLEAN

Cluttered areas and benches invite accidents.

5. DO NOT OVER-REACH

Keep proper footing and balance at all times.

6. REDUCE THE RISK OF UNINTENTIONAL

STARTING

Make sure switch is in off position before plugging.

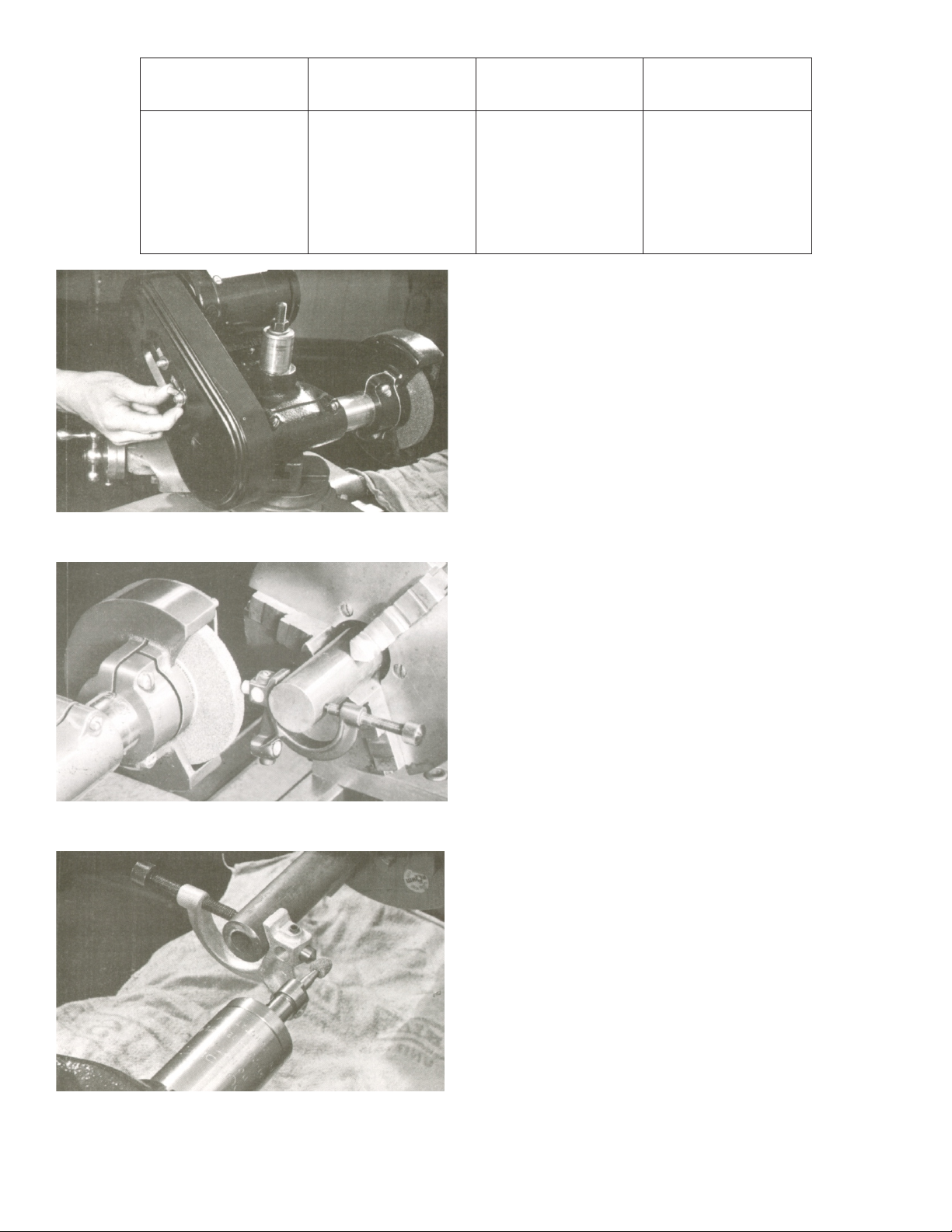

7. CHECK DAMAGED PARTS

Check for alignment of moving parts, breakage of parts,

mounting, and any other conditions that affect its

operation. A part that is damaged should be properly

repaired or replaced by an authorized service center

unless otherwise indicated elsewhere in this instructional

manual. DO NOT USE TOOL IF SWITCH DOES NOT

TURN IT ON AND OFF. HAVE DEFECTIVE SWITCHES

REPLACED BY AUTHORIZED SERVICE CENTER.

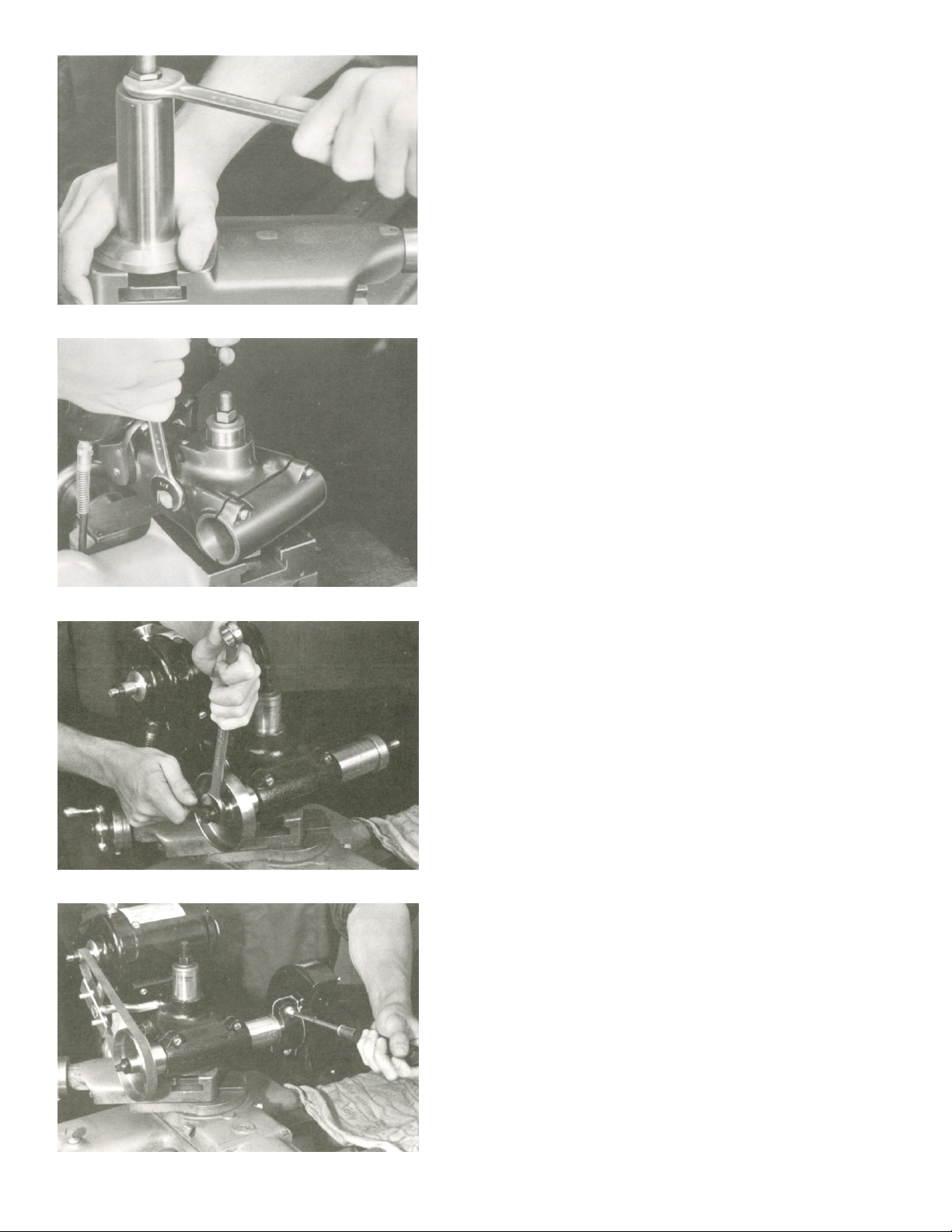

8. DISCONNECT TOOLS

When not in use, before servicing and when changing

accessories, such as grinding wheels, etc.

9. REMOVE KEYS AND WRENCHES

Form habit of checking to see that keys and adjusting

wrenches are removed from tool before turning it on.

10. MAINTAIN TOOLS WITH CARE

Keep tools sharp and clean for best and safest

performance. Follow instructions for lubricating and

changing accessories. Inspect tool cords daily and if

damaged, have repaired by authorized service facility.

Inspect extension cords before use and replace if

damaged. Keep handles dry, clean, and free of oil and

grease.

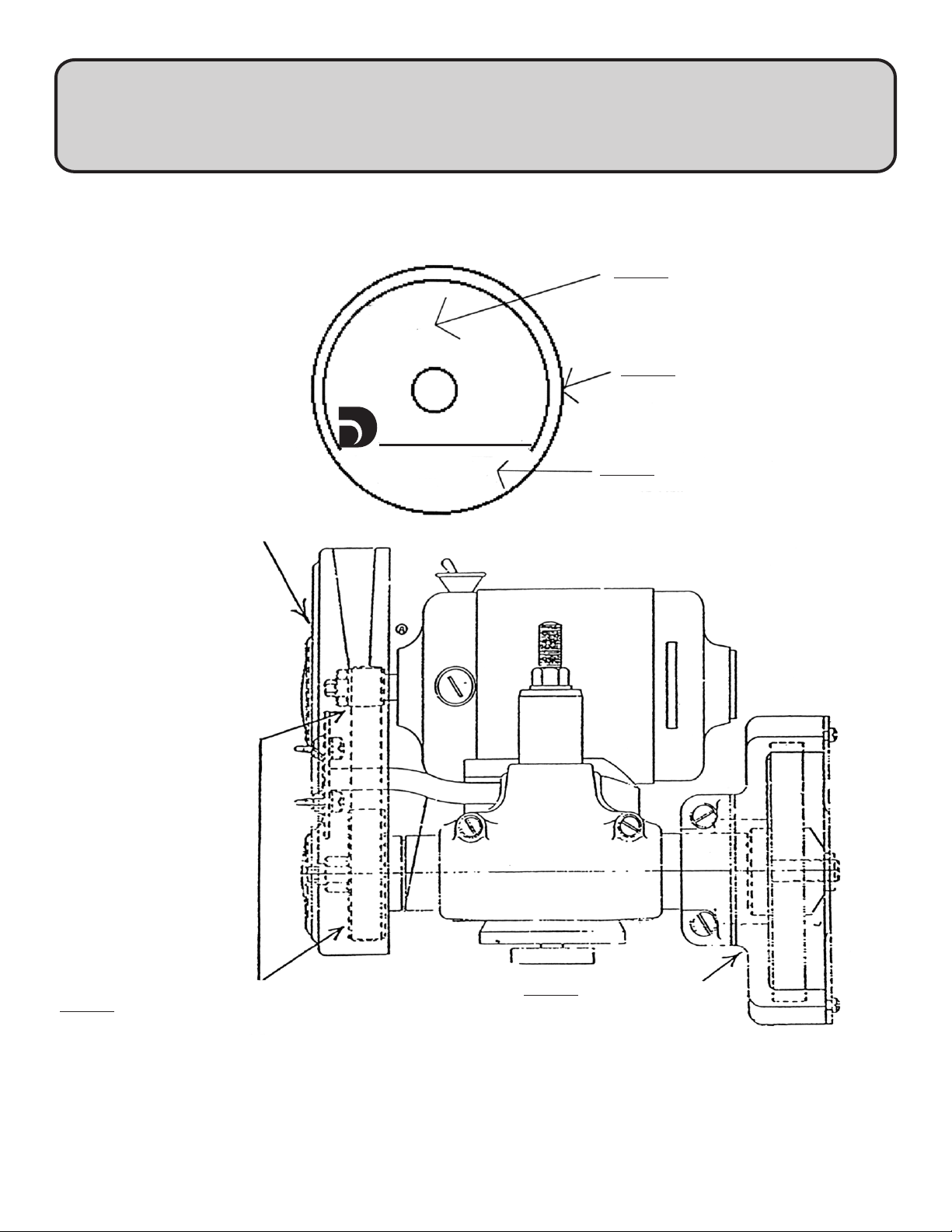

s SAFETY INSTRUCTIONS

FUSE INTACT

HOT LINE

THIS SYSTEM IS DANGEROUS!

Don’t act as a conductor—Make

sure the tool is grounded through

the cord.

GROUNDING

BLADE COVER OF

GROUNDED

OUTLET BOX

GROUNDING MEANS

COVER OF

GROUNDED

OUTLET BOX

3