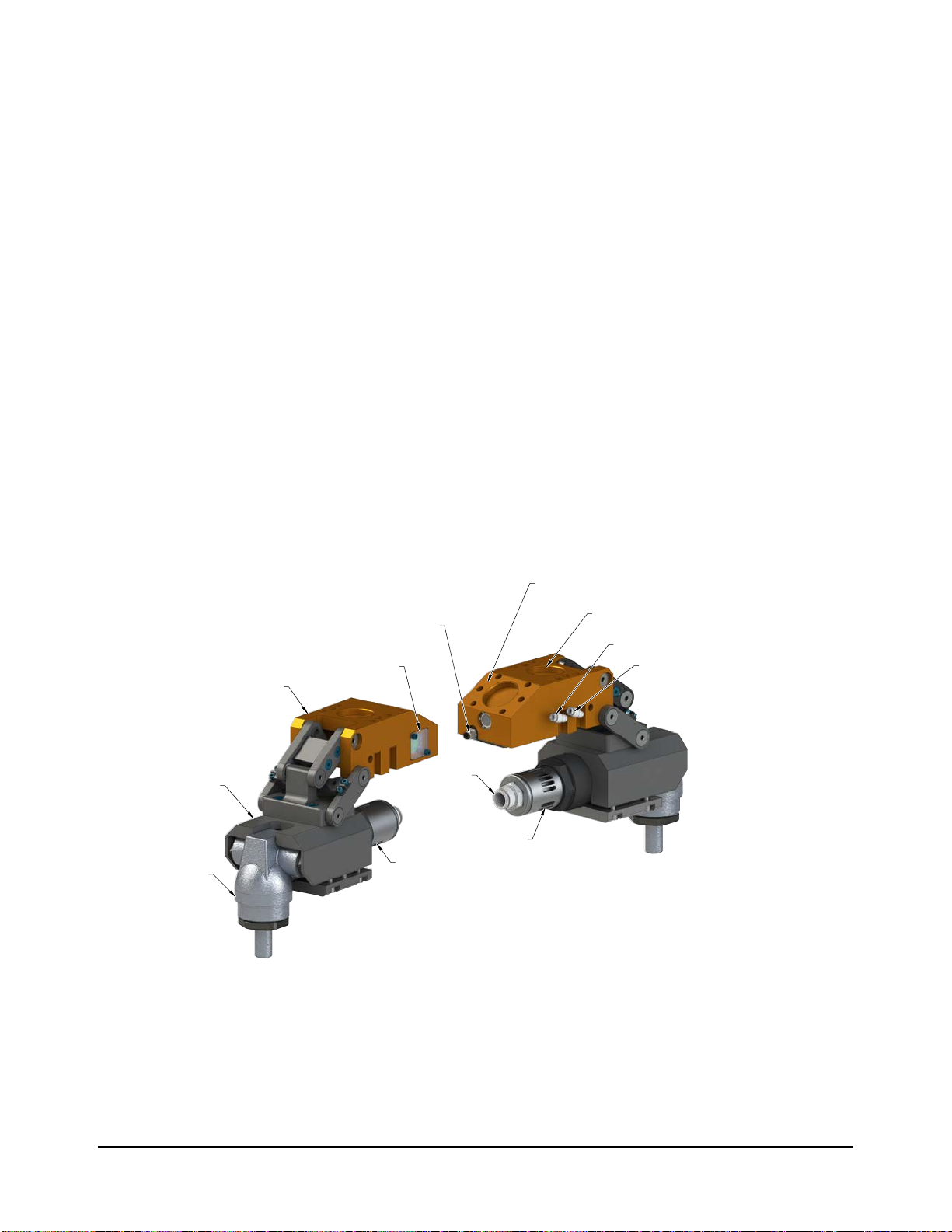

Manual, Pneumatic Angle Grinder (CGV)

Document #9610-50-1056-02

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1 919‑772‑0115 • Fax: +1 919‑772‑8259 • www.ati‑ia.com

3

Table of Contents

Glossary........................................................................................................................................... 5

1. Safety......................................................................................................................................... 6

1.1 ExplanationofNotications.........................................................................................................6

1.2 General Safety Guidelines............................................................................................................6

1.3 Safety Precautions........................................................................................................................6

2. Product Overview..................................................................................................................... 7

2.1 Technical Description ...................................................................................................................8

2.1.1 Environmental Considerations ...........................................................................................8

2.1.1.1 Operation............................................................................................................8

2.1.1.2 Storage...............................................................................................................8

2.2 Compliance Unit Performance.....................................................................................................9

3. Guidelines for Transporting, Unpacking, and Storing the CGV......................................... 10

3.1 Protection During Transportation..............................................................................................10

3.2 Inspect the Product Condition When Delivered.......................................................................10

3.3 Unpacking and Handling............................................................................................................10

3.4 Storage and Preventive Maintenance During Storage.............................................................10

4. Installation ...............................................................................................................................11

4.1 General Guidelines: .................................................................................................................... 11

4.2 Robot Mounting Options............................................................................................................ 11

4.3 Installation Procedure.................................................................................................................13

4.4 Optional Installation of Accessories .........................................................................................14

4.4.1 Exhaust Assembly (ATI P/N 9005‑50‑6273).....................................................................14

4.4.2 Position Sensing...............................................................................................................15

4.4.3 90° Mounting Bracket (ATI P/N 9005‑50‑6274)................................................................16

4.5 Pneumatic Connections .............................................................................................................18

4.6 M8 Sensor Connection ...............................................................................................................19

4.7 Sensor Assembly Cable (P/N 9105-C-ZC27-ZC28) ...................................................................20

4.8 Set-up of the RS485 Communication Interface........................................................................20

5. Operation ................................................................................................................................ 23

5.1 Tool Working Environment.........................................................................................................23

5.2 Safety Precautions......................................................................................................................23

5.3 Normal Operation........................................................................................................................24

5.3.1 Air Quality.........................................................................................................................24

5.3.2 Lubrication........................................................................................................................24

5.3.3 Media Selection................................................................................................................24

5.3.4 CGV Approach Path Should Be Slow and at anAngle.....................................................24