HCM-410CP-IM (12/15) Page 7

Installation –Refrigerant Connections

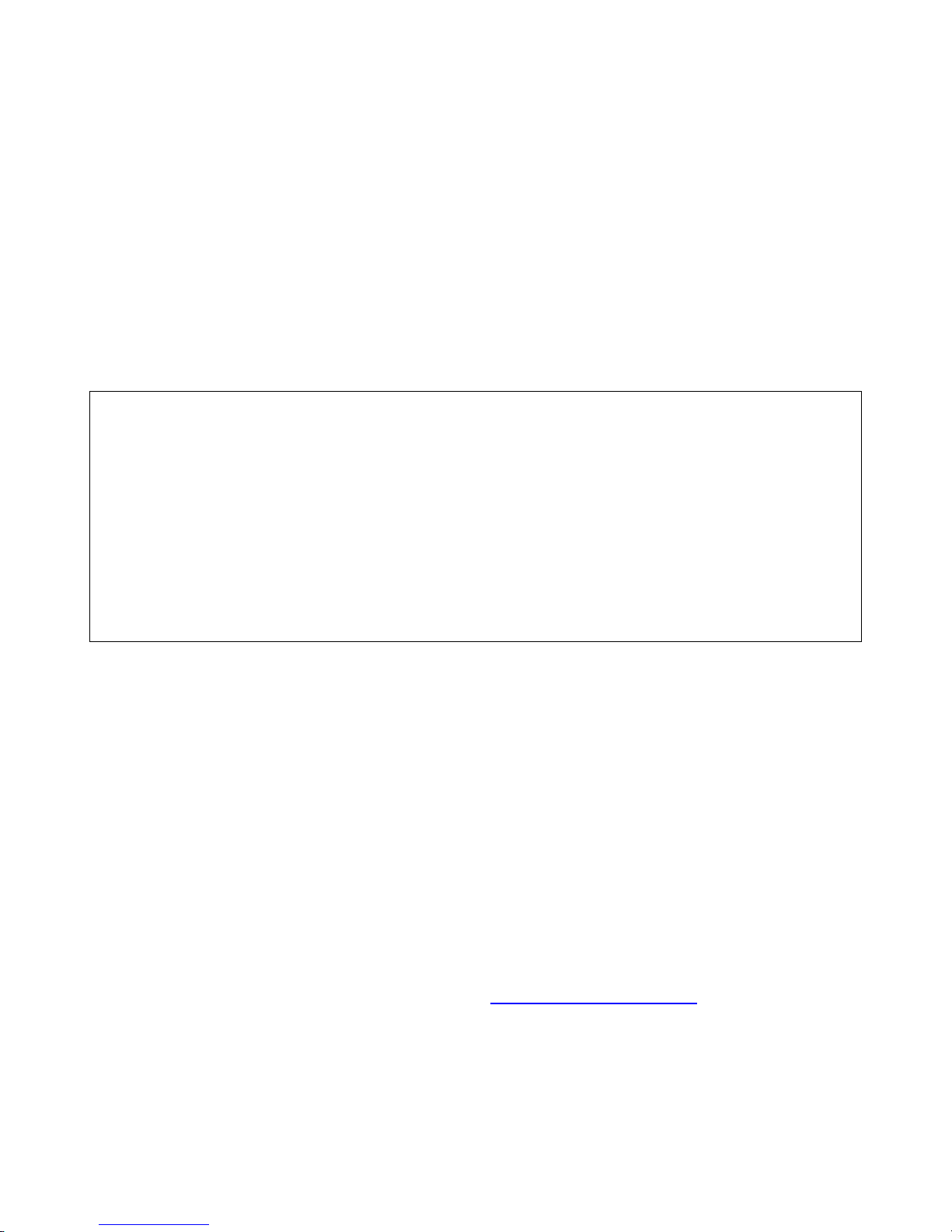

The Hybrid Cooling Module has two refrigerant connections on the service side of the unit as shown

in Figure 1. The connections are the same size as each other. Each connection is identified with a

label saying “Compressor” or “Earth loops”. Check Figure 1 and the table on page 3 to determine

coupling sizes to match the line set vapor tube size.

The refrigerant connections have caps brazed on at the factory. They should be un-brazed at the

time that tubing is to be connected to the Hybrid Cooling Module.

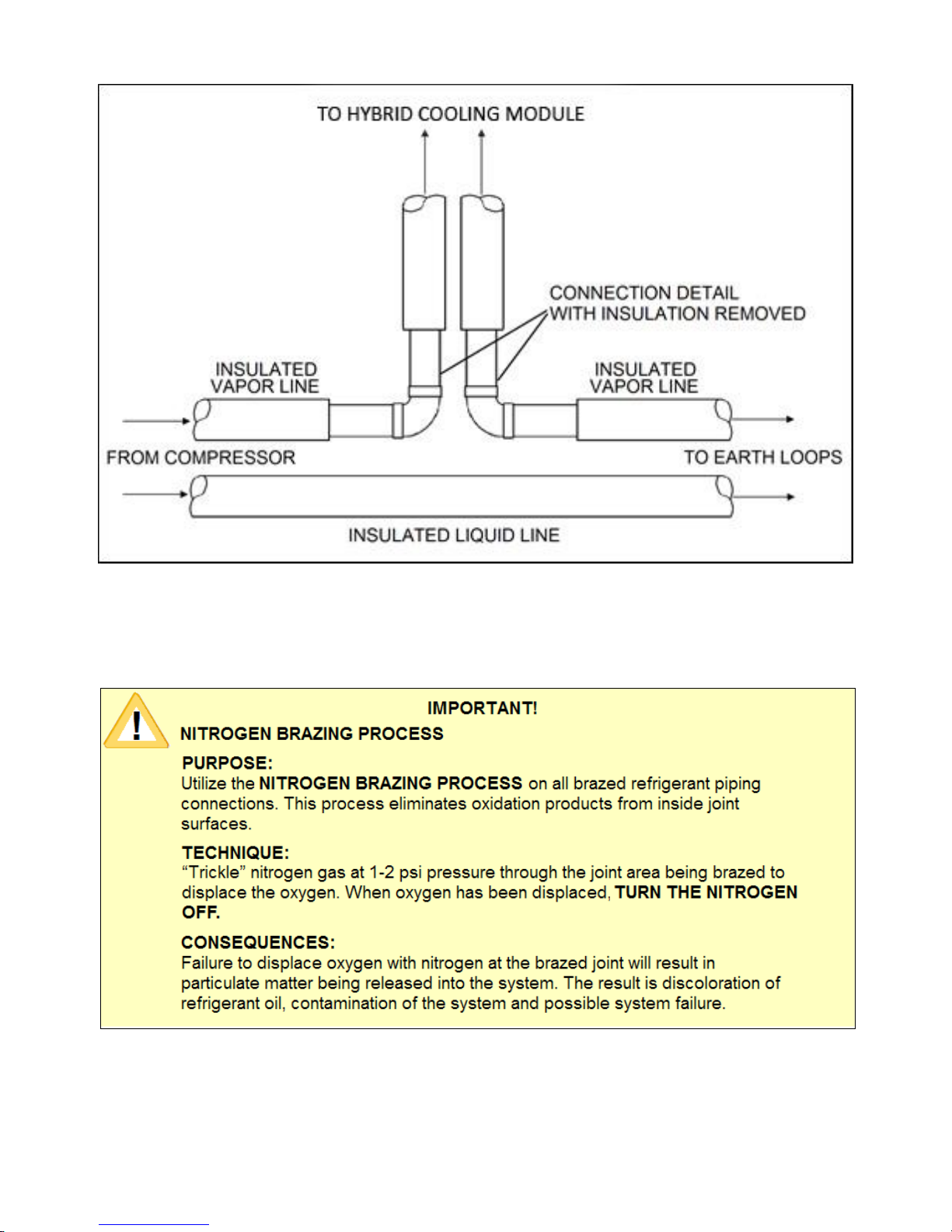

After locating the Hybrid Cooling Module as noted earlier, a trench 3 to 4 Feet deep is to be

excavated running from the Hybrid Cooling Module to the earth loop line set. If the lines to and from

the Hybrid Cooling Module are to be run parallel to and within 10 Feet of the building foundation or

basement wall, both lines are to be insulated with ½” wall thickness Armaflex®or InsulTube®tubing

insulation, cased within a PVC pipe. The PVC pipe must be a minimum of 3 Feet from the building

foundation or wall. This is illustrated for a typical application in Figure 3.

Figure 3. Hybrid Cooling Module Refrigerant Piping

A top view of typical Hybrid Cooling Module and line set vapor line connections are illustrated in

Figure 4. For new installations of an EarthLinked system with an HCM, an alternate method to the

one shown in Figure 4 is to run a single piece vapor line from the compressor unit to the HCM and

another single piece vapor line from the HCM to the vapor manifold of the earth loop system.

The Hybrid Cooling Module has a factory charge of dry nitrogen at

approximately 35 psig. Relieve the nitrogen from the system by means of the

Schrader valve located on the compressor unit connection shown in Figure 1.