PW1/PW2 KIT (09/12) Page 2

Pre-Installation

Upon receipt of the pump wire kit, carefully check the model number against the bill of lading.

Next, check the pump wire kit model number against the compressor unit application requirement

to assure proper match of the pump wire kit to the specific application.

Pump wire kits are required for the following two types of applications. Check the application

requirements and reference Figure 1 below to ensure that you have the appropriate pump wire kit

for your specific application.

A pump wire kit is required for the following:

1) SC, SD, SCW Compressor Units in radiant panel hydronic heating applications. The specific

pump wire kit required is determined in Figure 1 from the compressor unit model and power supply.

2) SW Compressor Units utilized in an application requiring both radiant panel hydronic heating

(with an HWM) and priority domestic potable water heating (with a DWM) from a single compressor

unit. The specific pump wire kit required is determined in Figure 1 from the compressor unit model

and power supply.

*SW Series available in R-407C only.

Figure 1. Pump Wire Kit Model Specification

PW1-1872 Installation

WARNING

BEFORE REMOVING ANY ACCESS PANELS AND INITIATING ANY PHASE OF

THIS INSTALLATION MAKE SURE THAT POWER IS TURNED “OFF” TO ALL

EARTHLINKED® AND FIELD SUPPLIED SYSTEM COMPONENTS. FAILURE TO DO

SO COULD RESULT IN PROPERTY DAMAGE, SERIOUS INJURY OR DEATH.

WARNING

WEAR ADEQUATE PROTECTIVE CLOTHING AND PRACTICE ALL APPLICABLE

SAFETY PRECAUTIONS WHILE INSTALLING THIS EQUIPMENT. FAILURE TO DO

SO MAY RESULT IN EQUIPMENT AND/OR PROPERTY DAMAGE, PERSONAL

INJURY OR DEATH.

1. After turning “OFF” power to all EarthLinked® and field supplied system components at the

appropriate breakers, remove the front and top panels of the compressor unit cabinet.

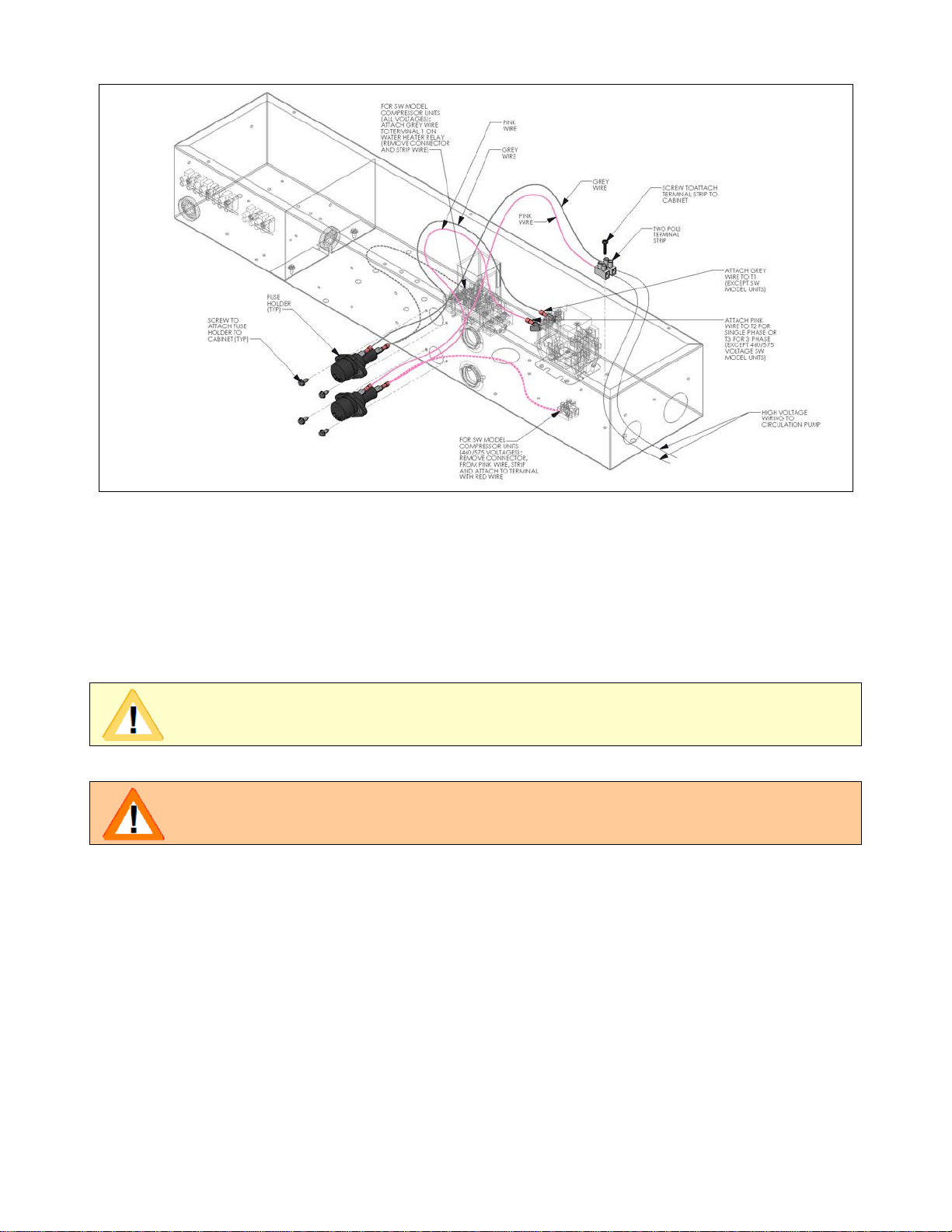

2. Reference Figure 2 for PW1 assembly to electrical box. Remove available hole covers from the

front of the electrical box.