4

Technical Support

1-800-248-0892

Trim

Flange

Trim

Flange

VI. TrimmingtheUpperA-Arm

NOTE: It will be necessary to trim the flange off of

theupperA-arm inordertomakeclearanceforthe

flexmember (Figure8).

1. Removethecontrolarmmountinghardwareandreplacewithbolts

(D), flatwashers (E), and nylock nuts (C) being sure to insert them

withtheboltheadsfacingtheinsideofthecontrolmountinorderto

provideadequateclearancefortheairstrut(Figure8).

2. The inside flange on the upper control arm can be trimmed by

usingadie grinderwith acut-offwheelorgrinding bit.Be sureall

sharp edges are removed, and paint the exposed area when

complete(Figure8).

3. Thetop barfortheuppercontrolarmwill alsoneedtobetrimmed.

Grind1/8”off of a3” area (Figure8).

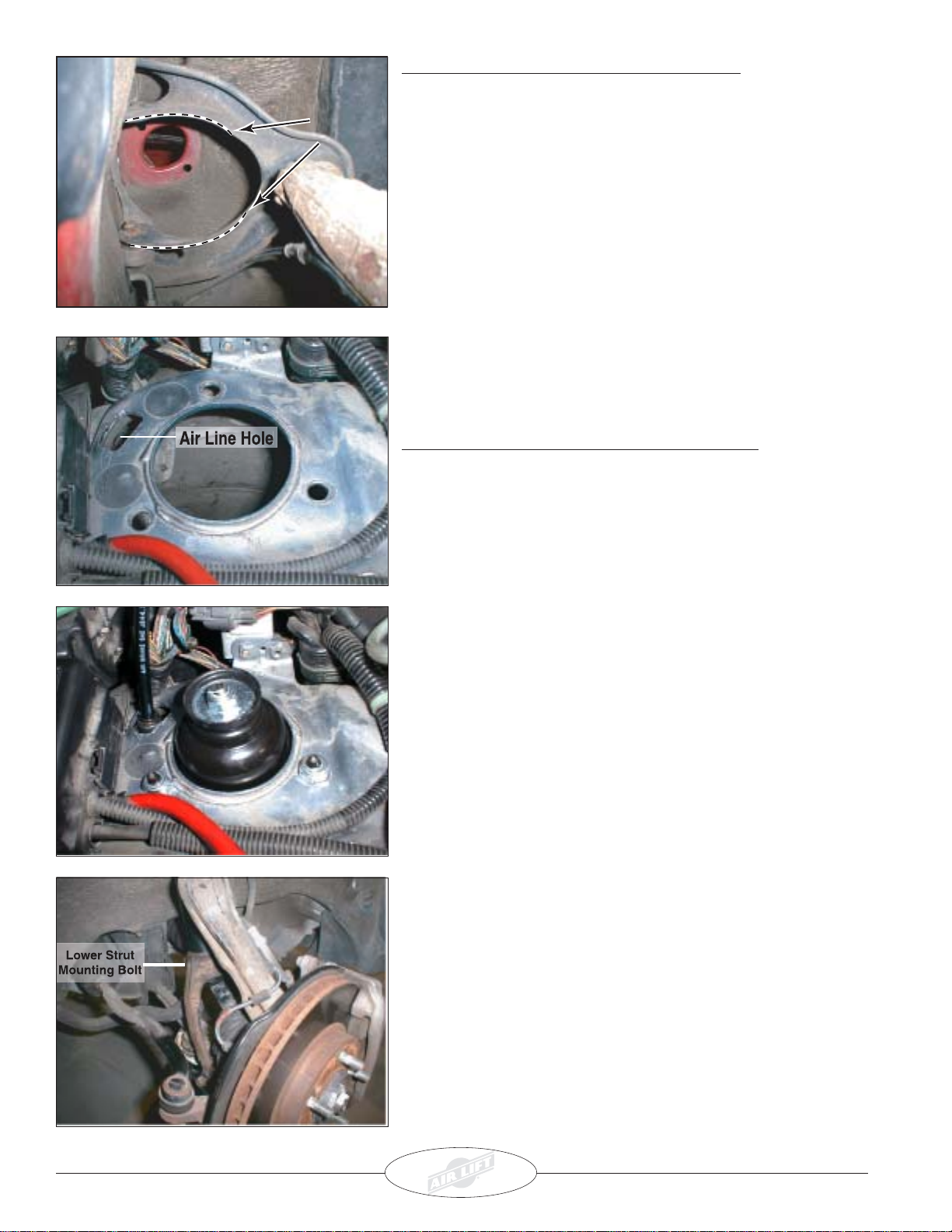

IV.Installing the StrutAssembly

1. Using the template at the end of the manual, line up the three

holesin thetemplate withthe threeholes inthe upperstrut tower.

2. Make a mark in the engine compartment where the fourth hole

will need to be drilled.

3. Remove the template and drill a hole in the upper strut tower

large enough to accomodate the air fitting from the top of the

strut(Figure9).

NOTE: Be surethat youhaveadequate clearancebeforedrilling.

NOTE: The same template will be used for both sides of the

vehicle.

NOTE: A silicone seal or rubber grommett is recommended to

protect the air line where it passes through the strut tower.

4. Place the upper strut mount back into the compartment.

NOTE: Rotate thestrutassembly sothatthe air fittingisthrough

the center previously drilled hole.

5. Fastenthestrut usingthethree previouslyremovednuts(Figure 10).

6. Tighten the nut at the top of the upper strut mount at this time.

7. Slide the lower end of the strut into the strut fork.

8. Replacethe previouslyremovedlowerstrutmountingbolt(Figure

11). Leave loose at this time.

9. Tighten the the lower strut mounting bolt.

10.Securelytighten thethreenylocknutsintheenginecompartment.

11. Install the air line at this time (Figure 10).

Figure 11

Figure 10

Figure 9

Figure 8