Possible Troubleshooting / Decalcification

Malfunction Possible cause / Remedy

It is not possible to switch on the

machine

The power supply to the machine is

interrupted, cause within the machine,

ontact the after-sales service

The machine is not being filled with

water

The check valve provided by the

customer is closed, the air trap is soiled –

therefore, the level switch does not work,

the inlet valve is soiled or defective

ontact the after-sales service

The machine fills up with water and

heats up, but it is not possible to start

the rinsing program

The door contact switch is not in

contact defective, the fine wire fuse is

blown

ontact the after-sales service

The machine is being filled continuously

with water

The overflow pipe is not inserted correctly

The bottles are not clean The rinsing temperature is too low, the

machine does not convey the cleaning

agent. The rinsing agent container is

empty, the jet nozzles are plugged

The bottles have a grey, smeary film Insufficient quantity of fresh water per

rinsing process – Check the water

pressure

The exterior of the machine should only be wiped with a damp cloth.

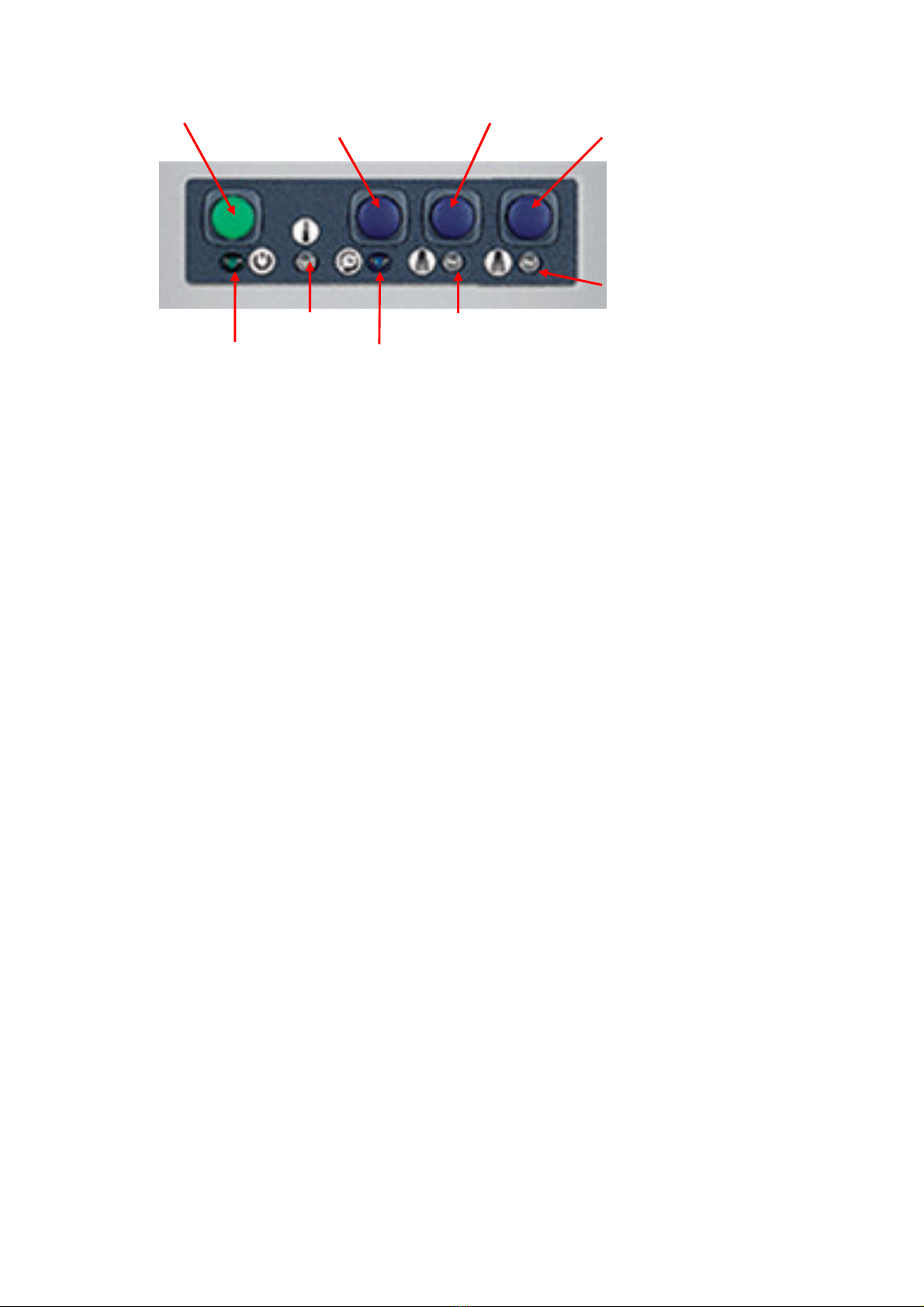

Please observe that life switches and control lights are in the area of the operating

panel.

Decalcifying the interior of the machine:

The supply system of the machine is only supplied with cold water Therefore, it is not

necessary to decalcify this area. Decalcify the machine as follows:

Clean the interior of the machine (refer to the instructions on the pages 5 and 6).

Remove the surface filter and the overflow pipe. Spray the interior, the overflow pipe,

the suction filter and the surface filter with a decalcifier (diluted or according the to

the instructions). Put the overflow pipe and the suction filter on the surface

filter.Warten Wait during the exposure time of the decalcifier. Switch on the machine

and wait for about 20 sec. Switch off the machine. Then reinsert the suction filter

and the overflow pipe according to the instructions. It is also possible to hose out the

interior after the decalcifying with a water hose Attention: Only spray into the

interior of the machine.

Attention: In particular, decalcify the heating elements in the inside of the tank in

regular intervals. Otherwise, the heating capacity would be reduced or they might get

damaged.

Page 7