Rinsing

Check if the suction filter is in the provided position.

Insert the overflow pipe into the drain.

Place the surface filter into the machine

(first remove the protective film).

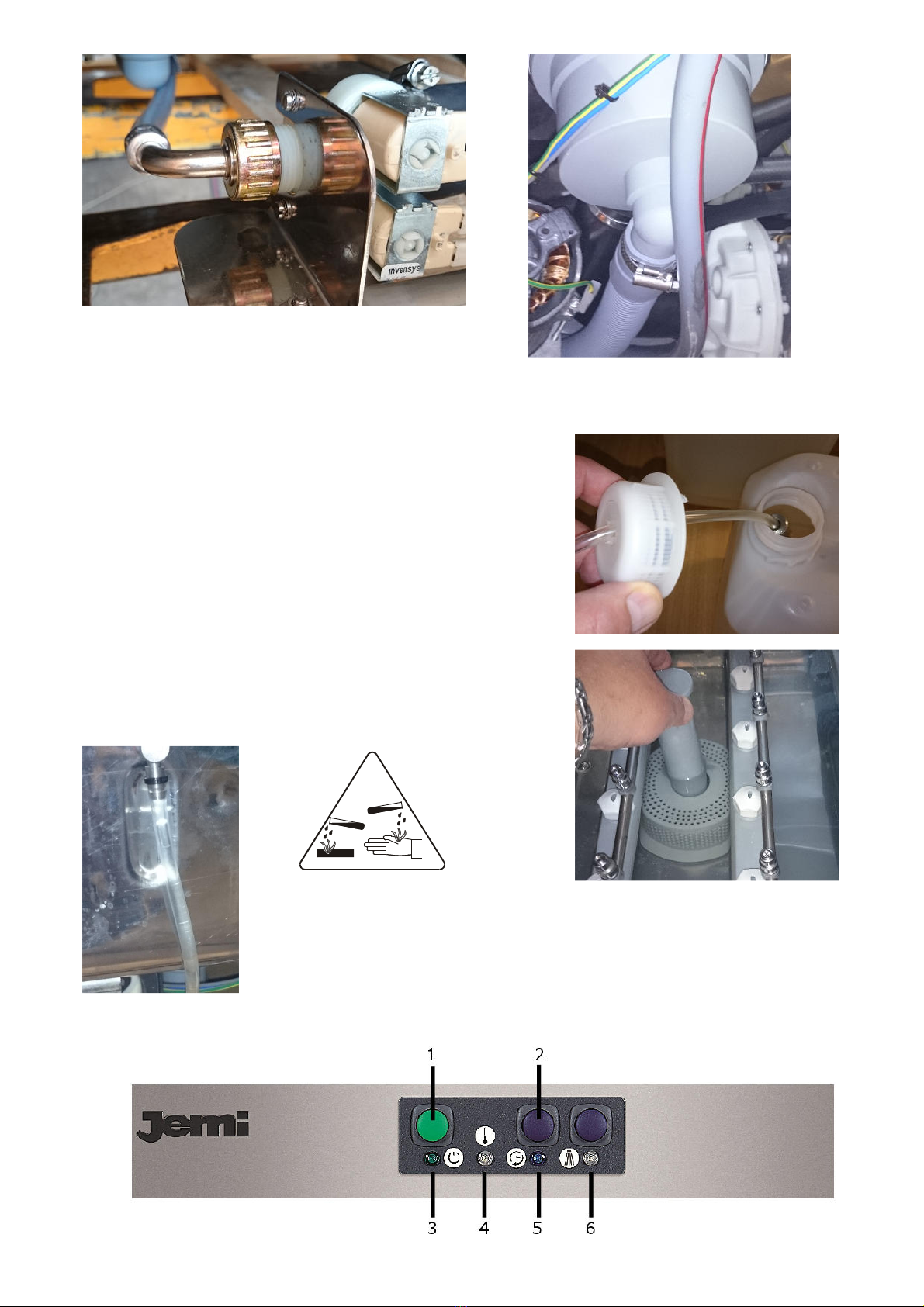

Close the door and press the mains switch (1)

The green indicator light (3) is illuminated.

The automatic filling of the tank is performed via the inlet valve, the pressure

increase pump and via the rinsing system. As soon as the machine attained the

water level, the machine will automatically close the water inlet by means of a

pressure control device. The pressure control device is set serially with an electro

valve which is responsible for filling the machine. At the last position, the tank is

being heated up.

The machine is ready for the rinsing process as soon as the correct temperature is

attained in the tank (about 57ºC).

The temperature display (4) is illuminated.

The time required to fill and heat the tank amounts to about 12 to 14 minutes.

Rinsing agent ( leaning agent)

For the automatic dosing of the liquid beer bottle cleaning agent the machine is

equipped with a cleaning agent dosing device.

Opening the door and inserting the basket or carrier for crates

Press the start button (2) for the rinsing process. The indicator lamp of the rinsing

process (5) is illuminated, the different stages of the rinsing process follow one

another: Rinsing, Dosing of the leaning hemicals, Re-rising.

hen the rinsing process is completed (6 min. 30 sec.), the control lamp (5) is

switched off and the machine can be used for another rinsing process, as soon as the

control lamp (4) is illuminated again.

Depending on the soiling of the bottles or crates, the machine can reuse the same

soapy water. If the soapy water is soiled too much, it is necessary to replace the

soapy water.

By pressing the continuous rinsing button (6) it is possible to perform a

basic cleaning of the soiled bottles.

By repeatedly pressing the button, the rinsing program will be switched off.

The machine must not be left unattended during operation.

Page 4