ECOALLIANCE ECO-135LEB User manual

This manual suits for next models

7

Table of contents

Other ECOALLIANCE Water Heater manuals

Popular Water Heater manuals by other brands

Hubbell

Hubbell GX200 Installation & operation manual

Whirlpool

Whirlpool Residential Electric Water Heater Installation Instructions and Use & Care Guide

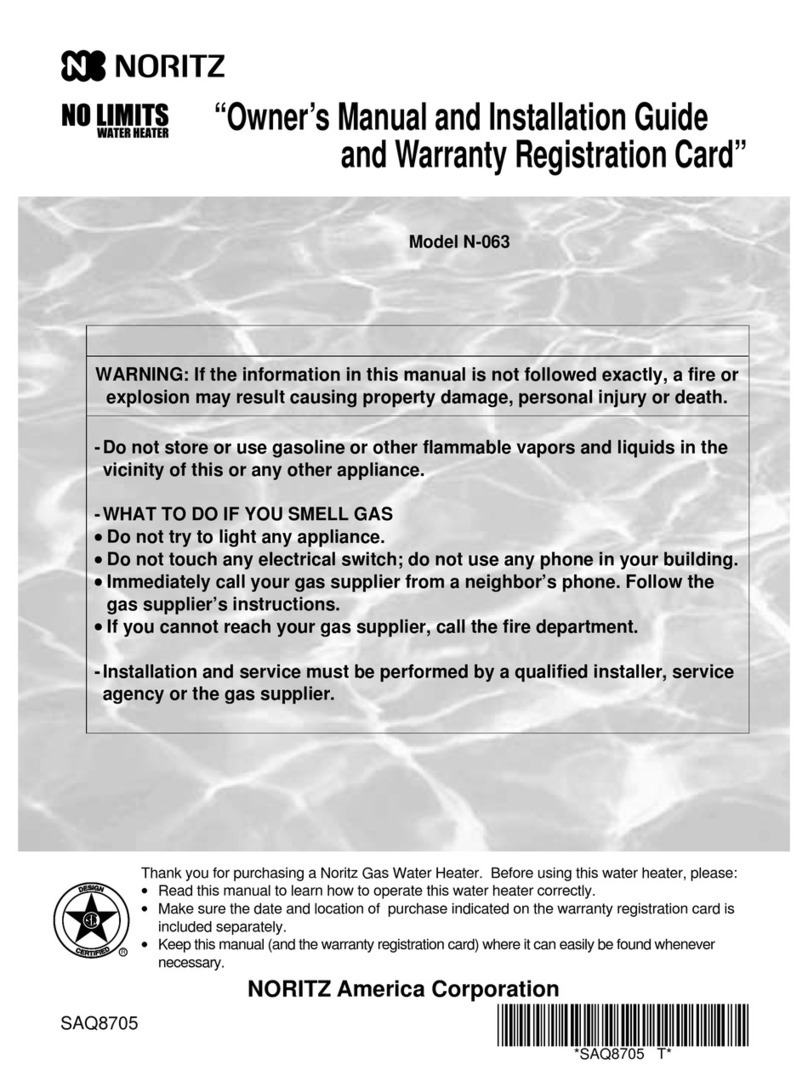

Noritz

Noritz N-063 Owner's manual and installation guide

Rinnai

Rinnai EHP32-HPST265 installation manual

RBI

RBI FUTERA III Series HeatNet Installation & operation manual

Elwa

Elwa HOTRUN-X Series Operating and installation instructions

STIEBEL ELTRON

STIEBEL ELTRON HSBB 180 Plus Operation and installation

Kenmore

Kenmore POWER MISER 153.331712HA owner's manual

Strebel

Strebel S-WG 100 Installation, operating and maintenance manual

Kenmore

Kenmore 153.552400 Use and care guide

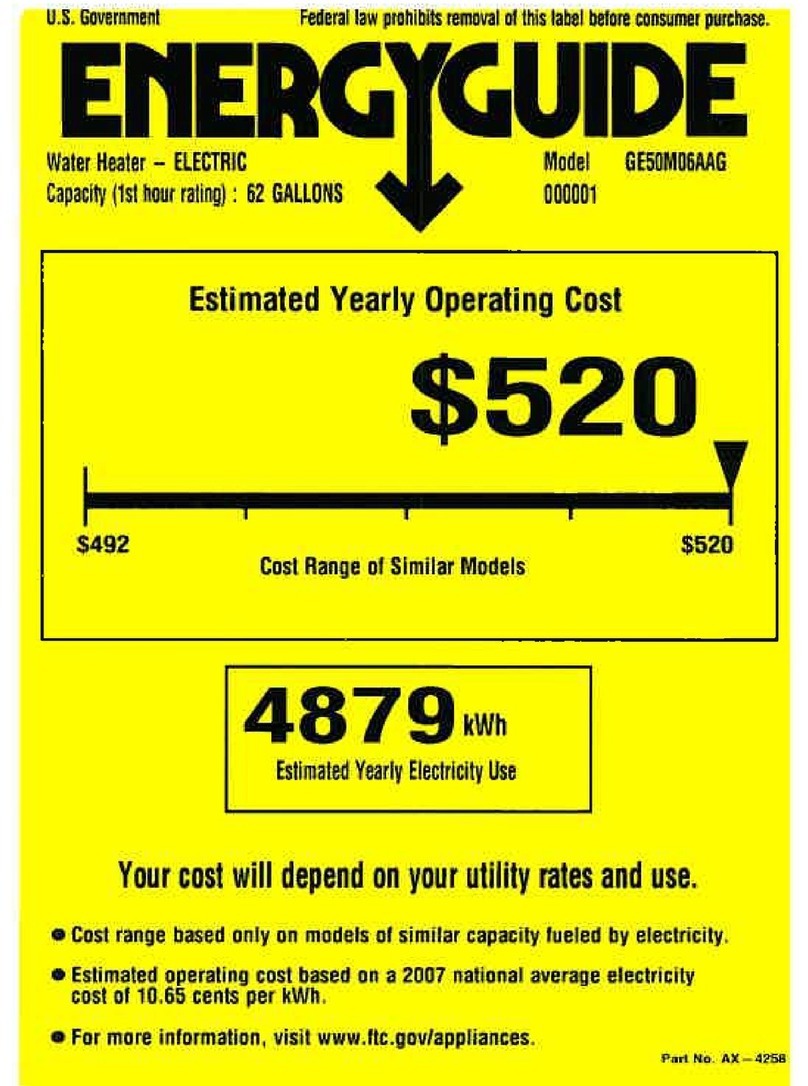

GE

GE 50M06AAG Energy guide

Camec

Camec IWH-1.5 Installation and operating instructions

Dux

Dux DN15DS Installation and owner's guide

Timberk

Timberk SWH RES 150V instruction manual

Gorenje

Gorenje FTG80SM Instructions for use

Kospel

Kospel POC.D 5/2 Installation and operating instructions

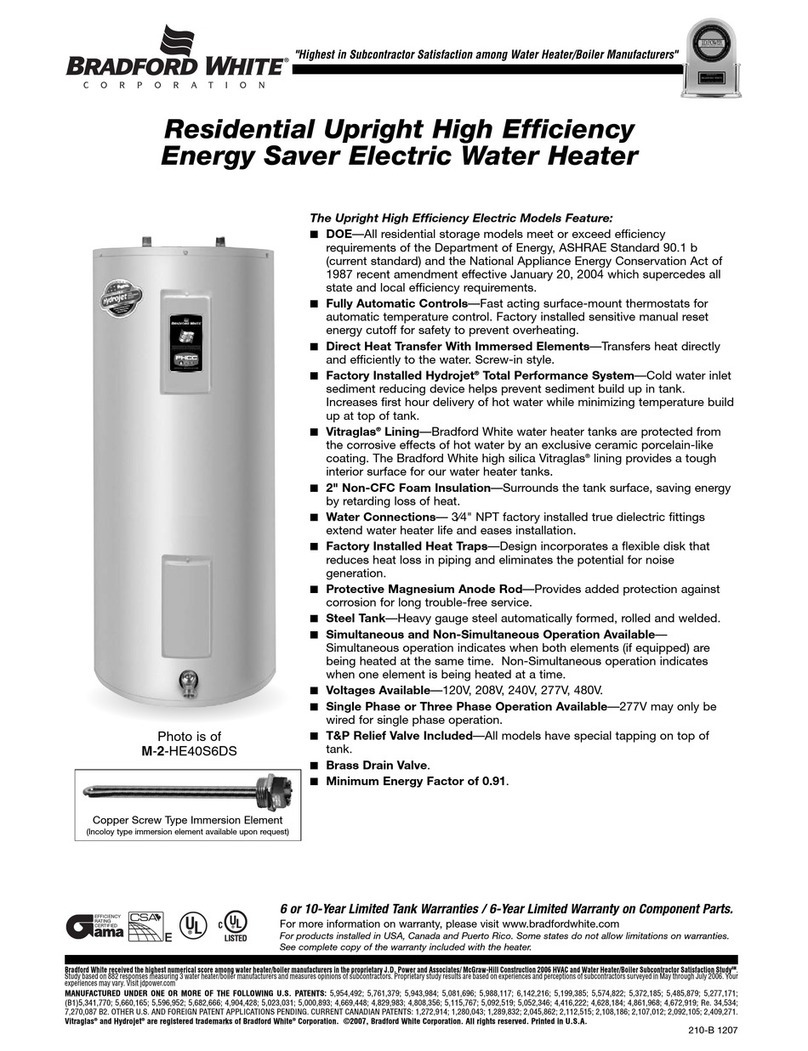

Bradford White

Bradford White M-2-HE40S6DS Specifications

Siemens

Siemens DG10016R2 Assembly and operating instructions