17

Warranty Policy

Warranty Conditions

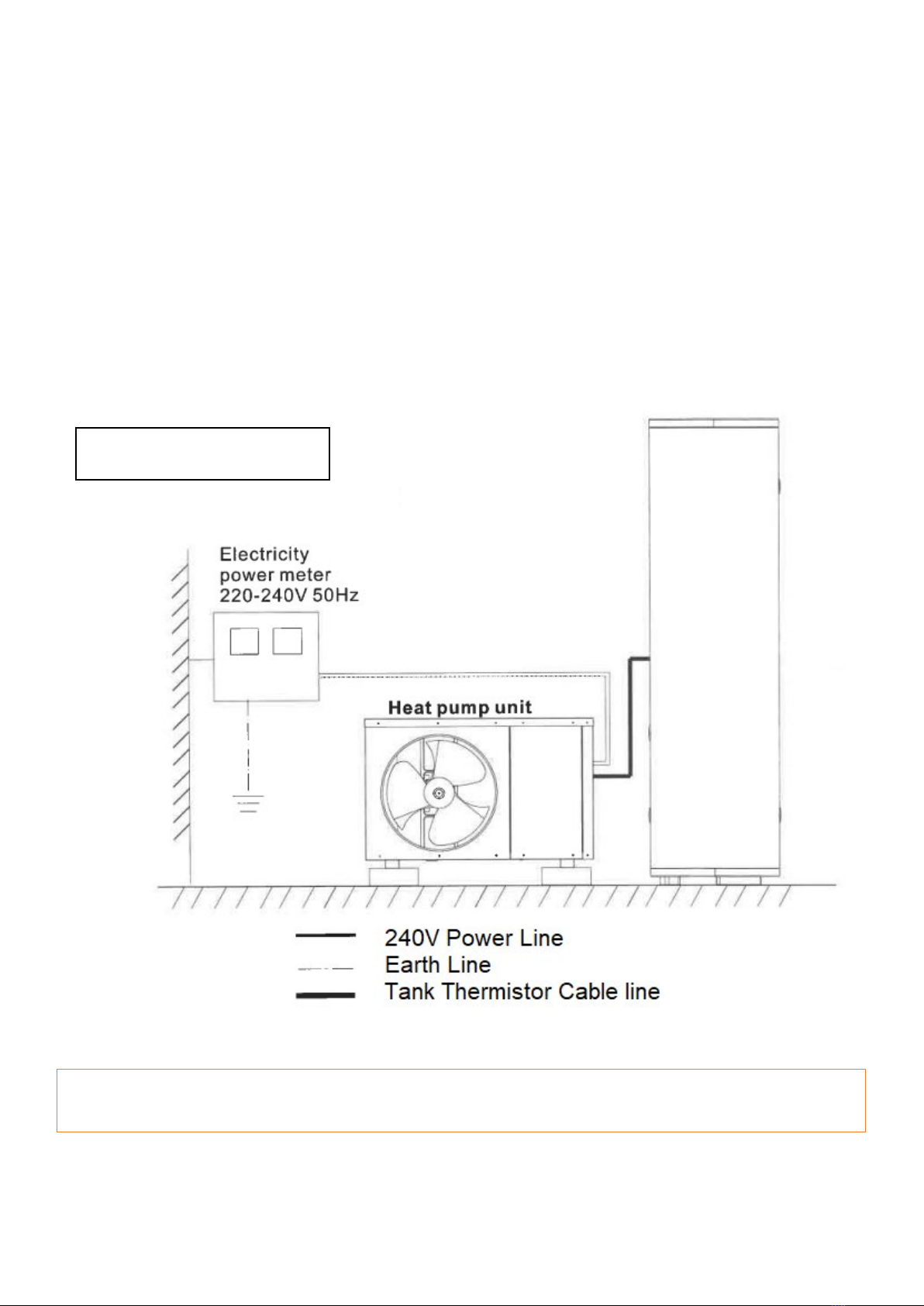

1. The Eco Alliance Pty Ltd DynaHeat™heat pump water heater system must be installed in accordance with the installation

instructions supplied with the DynaHeat™heat pump water heater system and in accordance with all relevant

statutory/local requirements of the state/province/municipality in which the water heater is installed.

2. Where a failed component or DynaHeat™heat pump water heater system is replaced under warranty, the balance of the

original warranty period will remain effective. The replaced part or DynaHeat™heat pump water heater system does not

carry a new warranty.

3. Where the DynaHeat™heat pump water heater system is installed in a position that does not allow safe, ready access, the

cost of accessing the site safely, including the cost of additional materials handling and/or safety equipment, shall be the

owner's responsibility.

4. The warranty only applies to the DynaHeat™heat pump water heater system and original or genuine (company)

component replacement parts and therefore does not cover any plumbing or electrical parts supplied by the installer and

not an integral part of the DynaHeat™heat pump water heater system. Such parts would include pressure regulating valve,

isolation valves, check valves, electrical switches, pumps or fuses.

5. The Heat pump Water Heater System must be sized to supply the hot water demand in accordance with the guidelines in

the Eco Alliance Pty Ltd DynaHeat™heat pump water heater system literature.

6. This warranty is for parts only. Any and all labour costs associated with diagnosis, removal of the faulty part and

installation of replacement parts will be solely the owner's responsibility.

Warranty Exclusions

1. Repair and replacement work will be carried out as set out in the Eco Alliance Pty Ltd DynaHeat™heat pump water heater

system warranty. However the following exclusions may void the warranty and may incur additional service charges and/or

cost of parts:

2. Accidental damage to DynaHeat™heat pump water heater system or any component, including: Acts of God, failure due to

misuse, incorrect installation, attempts to repair the water heater other than by a Eco Alliance Pty Ltd accredited service

agent or the Eco Alliance Pty Ltd service department.

3. Where it is found there is nothing wrong with the DynaHeat™heat pump water heater system; where the complaint is

related to excessive discharge from the temperature and/or the pressure relief valve due to high water pressure; where

there is no flow of hot water due to faulty plumbing; where water leaked are related to plumbing and not the DynaHeat™

heat pump water heater system or its components; where there is a failure of electricity or water supplies; where the

supply of electricity or water does not comply with relevant codes or acts.

4. Where the DynaHeat™heat pump water heater system or its component has failed directly or indirectly as a result of

excessive water pressure.

5. Overflow vent drain has not been installed or blocked or corroded.

6. Where the DynaHeat™heat pump water heater system has rusted as a result of a corrosive atmosphere.

7. Where the unit fails to operate or fails as a result of ice formation in the piping to or from the DynaHeat™heat pump water

heater system.

8. Where the DynaHeat™heat pump water heater system is located in a position that does not comply with the DynaHeat™

heat pump water heater system installation instructions or relevant statutory requirements, causing the need for major

dismantling or removal of cupboards, doors or walls or use of special equipment to bring the DynaHeat™heat pump water

heater system to floor or ground level or to a serviceable position.

9. Repair and/or replacement of the DynaHeat™heat pump water heater system due to scale formation above 200ppm

(water hardness) in the waterways or the effects of either corrosive water or water with a high chloride or low pH level

when the water heater has been connected to a scaling or corrosive water supply or a water supply with a high chloride or

low pH level as outlined in the Owner's Guide and Installation Manual.

10. Warranty service is provided to the original owner of the equipment only. Subject to any statutory provisions to the

contrary, this warranty excludes any and all claims for damage to furniture, carpets, walls, foundations or any other

consequential loss either directly or indirectly due to leakage from the DynaHeat™heat pump water heater system, or due

to leakage from fittings and/or pipe work of metal, plastic or other materials caused by water temperature, poor

workmanship or other modes of failure.