Ecoer MGH96 User manual

�-

t

.

•· , I

Ecoer

96% AFUE Gas Furnace MGH96 Model

Condensing Gas Furnace

Installation, Operation, and Maintenance Manual

•

lntertek

3124627

�1 CERTIFIED®

2

| Ecoer 96% AFUE Gas Furnace Installation, Operation & Maintenance

07-2020| Ecoer Inc..

Data subject to change

Installation, Operation & Maintenance Manual Ecoer 96% AFUE Gas Furnace | 3

Ecoer Inc. | 07-2021 Data subject to change

Table of Contents

1 Key to Symbols and Safety Instructions 4

1.2 Safety 4

2 Dimensions 7

3 Introduction 8

4 Codes and Standards 9

4.1 Safety 9

4.2 General Installation 9

4.3 Combustion and Ventilation Air 10

4.4 Duct Systems 10

4.5 Acoustical Lining and Fibrous Glass Duct 10

4.6 Gas Piping and Gas Pipe Pressure Testing 10

4.7 Electrical Connections 10

4.8 Electrical Power Supply 10

4.9 Venting 10

5 Electrostatic Discharge (ESD) Precautions Procedure 10

6 Location 11

6.1 General 11

7 Installation 13

7.1 Upflow Installation 13

7.2 Horizontal Installation 14

7.3 Condensate Line and Over Flow Pressure Switch 17

7.4 Filter Arrangement 22

7.5 Air Ducts 23

8 Combustion Air and Vent System 26

8.1 Combustion Air and Vent Safety 26

8.2 Combustion Air/Vent Pipe Sizing 26

8.3 Comnustion Air And Vent Piping Assembly 28

8.4 Combustion Air / Venting 29

8.5 Vent System 30

8.6 Combustion & Ventilation Air Requirements 31

8.7 Vent and Supply (Outside) Air Safety Check Procedure 34

9 Gas Supply and Piping 35

9.1 General 35

9.2 High Altitude Derate 36

9.3 Propane Gas (LP) Conversion 37

9.4 Gas Piping Connections 37

9.5 Gas Piping Checks 38

10 Electrical Connections 39

10.1 115V Wiring 39

10.2 Electrical Connection to J-box 40

10.3 Power Cord Installation in Furnace J-box 40

10.4 BX Cable Installation in Furnace J-box 40

10.5 24-V Wiring 40

10.6 Accessories (Field Supplied) 40

10.7 Grounding 40

11 Start-Up, Adjustment, and Safety Check 43

11.1 General 43

11.2 Start-Up Procedures 43

11.3 Furnace Start-Up 43

11.4 Sequence of Operation 44

44

11.5 Gas Manifold Pressure Measurement and Adjustment 45

11.6 Gas Input Rate Measurement (Natural Gas Only) 46

11.7 Temperature Rise Adjustment 46

11.8 Circulator Blower Speed Adjustment 47

12 Operational Checks 48

13 Safety Circuit Description 48

13.1 General 48

13.2 Integrated Control Module 48

13.3 Chamber Limit Switch - Fixed 48

13.4 Fan Mounted Limit Switch 48

13.5 Rollout Switch - Resettable 48

13.6 Overflow Protection Pressure Switch (Overflow Switch) 48

13.7 Pressure Switches 48

13.8 Flame Sensor 48

14 Troubleshooting 49

14.1 Electrostatic Discharge (ESD) Precautions 49

14.2 Resetting From Lockout 49

14.3 Troubleshooting Chart 49

15 Service and Maintenance Procedures 52

15.1 Annual Inspection 52

15.2 Filters 52

15.3 Induced Draft And Circulating Blower Motors 52

15.4 Flame Sensor (Qualified Service Technicians Only) 52

15.5 Ignitor (Qualified Service Technicians Only) 53

15.6 Burners 53

15.7 Inspecting the Heat Exchanger (Qualified Service Technicians Only) 53

15.8 Condensate Drain 53

15.9 Repair and Replacement Parts 53

16 Before Leaving Installation 53

17 Wiring Diagram 55

4 |

E

coer 96%

A

F

UE

Gas Furnace

Installation, Operation & Maintenance

07-2021 | Ecoer Inc.

Data subject to change

1 Key to Symbols and Safety Instructions

1.1 Key to Symbols

Warnings

Warnings in this document are identified by a

warning triangle printed against a grey background.

Keywords at the start of a warning indicate the type and seriousness

of the ensuing risk if measures to prevent the risk are not taken.

The following keywords are defined and can be used in this document:

DANGER indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION indicates a hazardous situation which, if not avoided, could

result in minor to moderate injury.

NOTICE is used to address practices not related to personal injury.

Important information

This symbol indicates important information where

there is no risk to people or property.

1.2 Safety

Please read all instruction in the manual and retain all manuals for future reference.

INSTALLER: Use the information in this booklet to install the appliance

and affix this booklet adjacent to the appliance after installation.

USER: Keep this booklet of information for future reference. Refer to the

User's Information Manual for more information.

SERVICER: Use the information in this booklet to service the appliance

and affix the booklet adjacent to the appliance after servicing.

WARNING: FIRE OR EXPLOSION HAZARD

Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

—Do not try to light any appliance.

—Do not touch any electrical switch; do not use any

phone in your building.

—Leave the building immediately.

—Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

—If you cannot reach your gas supplier, call the fire

department.

Installation and service must be performed by a qualified

installer, service agency, or the gas supplier.

WARNING: FIRE OR EXPLOSION HAZARD

Do not use this furnace if any part has been under water. A

flood-damaged furnace is extremely dangerous. Attempts

to use the furnace can result in fire or explosion. A qualified

service agency should be contacted to inspect the furnace

and to replace all gas controls, control system parts,

and electrical parts that have been wet, or the furnace if

deemed necessary.

WARNING: FIRE OR EXPLOSION HAZARD

The furnace is designed and approved for use with Natural

Gas and (LP) Propane Gas ONLY.

DO NOT BURN ANY LIQUID FUEL OR SOLID FUEL IN THIS

FURNACE.

Burning any unapproved fuel will result in damage to

the furnace's heat exchanger, which could result in Fire,

Personal Injury, and/or Property Damage.

Installation, Operation & Maintenance Manual Ecoer 96% AFUE Gas Furnace | 5

Ecoer Inc. | 07-2021 Data subject to change

WARNING: FOLLOW ALL SAFETY CODES

Wear safety glasses, protective clothing, and work gloves.

Have a fire extinguisher available. Read these instructions

thoroughly and follow all warnings or cautions included in

literature and attached to the unit. Consult local building

codes as well asthe current editions of the National Fuel

Gas Code (NFGC) NFPA 54/ANSI Z223.1 and the National

Electrical Code (NEC) NFPA 70.

WARNING: FIRE, EXPLOSION, ELECTRICAL SHOCK, AND

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in dangerous

operation, serious injury, death,or property damage.

Improper installation,adjustment,alteration,maintenance,

or use could cause carbon monoxide poisoning,explosion,

fire,electrical shock,or other conditions which may cause

personal injury or property damage. Consult a qualified

service agency,local gas supplier, or your distributor for

information or assistance.

CAUTION: CUT HAZARD

Failure to follow this caution may result in personal injury.

Sheet metal parts may have sharp edges or burrs. Use care

and wear appropriate protective clothing, safety glasses

and gloves when handling parts and servicing furnaces.

CAUTION: INSTALLATION REQUIREMENTS

Use only with type of gas approved for this furnace. Refer to

the furnace rating plate.

Install this furnace only in a location and position as

specified in Section 6 "Location" of these instructions.

Provide adequate combustion and ventilation air to the

furnace space as specified in Section 8.4 "Combustion Air

/ Venting".

Combustion products must be discharged outdoors.

Connect this furnace to an approved vent system only, as

specified in Section 8.5 "Vent System" of this manual.

When a furnace is installed so that supply ducts carry

air circulated by the furnace to areas outside the space

containing the furnace, the return air shall also be handled

by duct(s) sealed to the furnace cabinet and terminating

outside the space containing the furnace. See Section 7.5

"Air Ducts".

A gas-fired furnace for installation in a residential garage

must be installed as specified in the warning box in Section

6 "Location".

The furnace may be used for construction heat provided

that the furnace installation and operation complies with the

first CAUTION in Section 6 "Location" of these instructions.

WARNING: FIRE HAZARD

Always install furnace to operate within the furnace's

intended temperature-rise range with a duct system which

has an external static pressure within the allowable range,

as specified in Section 11 "Start-Up, Adjustments, and

Safety Check" or the furnace rating plate.

WARNING: FIRE HAZARD

The furnaces must be kept free and clear of insulating

materials. Inspect surrounding area to ensure insulation

material is at a safe distance when installing furnaces or

adding insulation materials. Insulation materials may be

combustible.

See Section 3, Fig. 3 for required clearances to combustible

construction.

Maintain a 1 in. clearance from combustible materials to

supply air ductwork for a distance of 36 in. horizontally

from the furnace. See NFPA 90B or local code for further

requirements.

These furnaces SHALL NOT be installed directly on

carpeting, tile, or any other combustible material other than

wood flooring. This furnace SHALL NOT be installed in the

downflow orientation.

NOTICE: FURNACE RELIABILITY HAZARD

Improper installation or misapplication of furnace may

require excessive servicing or cause premature component

failure. Application of this furnace should be indoors with

special attention given to vent sizing and material, gas

input rate, air temperature rise, unit leveling, and unit

sizing.

WARNING: FIRE, EXPLOSION

Check entire gas assembly for leaks after lighting this

appliance.

Never test for gas leaks with an open flame. Use a

commercially available soap solution made specifically

for the detection of leaks to check all connections, as

specified in Section 9 "Gas Supply and Piping" section.

NOTICE:

The condensate from this unit is acidic, ensure that all

local and national codes are adhered to when draining

condensate. If proper procedures are not followed, this

may lead to property damage.

6 | Ecoer 96% AFUE Gas Furnace Installation, Operation & Maintenance

07-2021 | Ecoer Inc.

Data subject to change

CAUTION:

Before heating season begins, examine the furnace to

ensure that:

1. All flue gas carrying areas external to the furnace

(i.e. chimney, vent connector) are clear and free of

obstructions.

2. The vent connector is in place, slopes upward and is

physically sound without holes or exccessive corrosion.

3. The return-air duct connection(s) is physically sound,

is sealed to the furnace cabinet, and terminates outside

the space containing the furnace.

4. The physical support of the furnace is sound without

sagging, cracks, gaps, etc around the base so as to

provide a seal between the support and the base.

5. There are no obvious signs of deterioration of the

furnace.

6. The burner flames are positioned correctly by

comparing with pictorial sketches of the main burner

flame (see Section 12, Fig 42).

Instructions for lighting/shutdown operation:

FOR YOUR SAFETY

“WHAT TO DO IF YOU SMELL GAS”

If you do not follow these instructions exactly, a fire or explosion

may result causing property damage, personal injury or loss of life.

Use only your hand to push the gas control switch.

Never use tools. If the switch will not move by hand,

don’t try to repair it; call a qualified service technician.

Force or attempted repair may result in a fire or

explosion.

Do not use this appliance if any part has been under

water. Immediately call a qualified service technician

to inspect the appliance and to replace any part of the

control system and any gas control which has been

under water.

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use

any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the

fire department.

This appliance does not have a pilot, it is equipped

with an ignition device which automatically lights the

burner. Do not try to light the burner by hand.

BEFORE OPERATING smell all around the

appliance area for gas. Be sure to smell next to the

floor because some gas is heavier than air and will

settle to the floor.

WARNING

A.

C.

D.

B.

1. STOP! Read the safety information above on this

label.

2. Set the thermostat to lowest setting.

3. Turn off all electric power to the appliance.

4. This appliance is equipped with an ignition device

which automatically lights the burner. Do not try to

light the burner by hand.

1. Set the thermostat to lowest setting.

2. Turn off all electric power to the appliance if

service is to be performed.

3. Remove access panels.

4. Push gas control switch to “OFF”.

5. Replace access panels.

5. Remove access panels.

6. Push gas control switch to “OFF”.

7. Wait five (5) minutes to clear out any gas. Then

smell for gas, including near the floor. If you smell

gas, STOP! Follow “B” in the safety information

above on this label. If you don’t smell gas, go to

the next step.

8. Push gas control switch to “ON”.

9. Replace access panels.

10. Turn on all electric power to the appliance.

11. Set thermostat to desired setting

12. If the appliance will not operate, follow the

instructions “To Turn Off Gas To Appliance” and

call your service technician or gas supplier.

FOR YOUR SAFETY READ BEFORE OPERATING

OPERATING INSTRUCTIONS

TO TURN OFF GAS TO APPLIANCE

SWITCH SHOWN IN

THE “OFF” POSITION

202082290022

WARNING: FIRE, EXPLOSION

See instructions for lighting/shutdown operation (as

shown at the bottom of this page, as well as on a sticker

directly on the inside of the furnace panel). Should the gas

supply fail to shut off or if overheating occurs, shut off the

gas valve to the furnace before shutting off the electrical

supply.

WARNING: CARBON MONOXIDE POISONING HAZARD

Furnace operation requires air for combustion and

ventilation. Do not block or obstruct air openings on

furnace or spacing around furnace required for supplying

sufficient combustion air and ventilation.

WARNING:

This product can expose you to chemicals including Lead

and Lead components, which are known to the State

of California to cause cancer and birth defects or other

reproductive harm. For more information go to www.

P65Warnings.ca.gov.

Installation, Operation & Maintenance Manual Ecoer 96% AFUE Gas Furnace | 7

Ecoer Inc. | 07-2021 Data subject to change

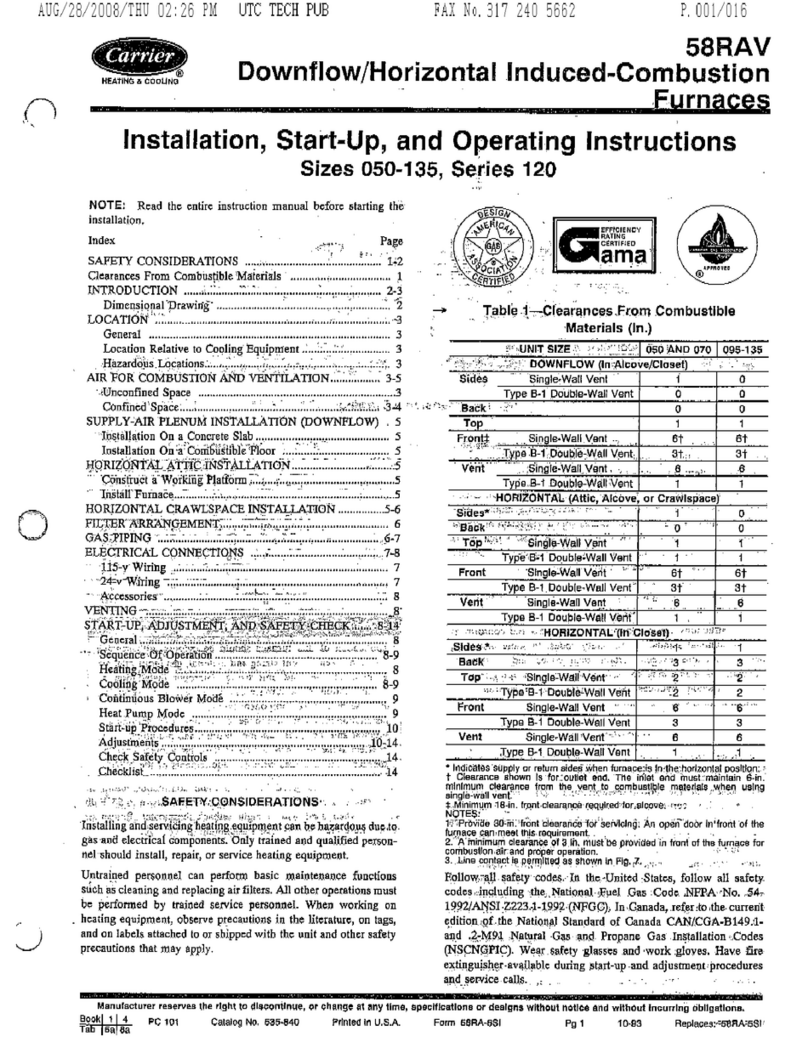

2 Dimensions

Figure 1

(Right)

(Front)(Left)

)devomerlenaphtiwmottoB()poT(

LEFT SIDE RETURN AIR

22-13/16”(580mm)

14”(355mm)

Combustion Air Inlet

Gas Pipe Entry

Electrical Entry

Condensate Drain

Thermostat Wiring

33-3/4”(857mm)

28-3/4”(730mm)

19-1/2”(495mm)

RIGHT SIDE RETURN AIR

Combustion Air Inlet

Gas Pipe Entry

Electrical Entry

Condensate Drain

Thermostat Wiring

24”(610mm)

26-1/2”(672mm) 25-3/4”(655mm)

Combustion Air Inlet Vent Outlet

Dimensions

Furnace Model "A" Cabinet Width

In. (mm)"

"D" Supply- Air Width

In. (mm)"

"E" Return- Air Width

In. (mm)"

Shipping Weight

lbs (kgs)

MGH96M060B3A 17.5 (445) 16 (406) 15-27/32 (402) 162.5 (73.7)

MGH96M080B3A 17.5 (445) 16 (406) 15-27/32 (402) 168.5 (76.4)

MGH96M080C4A 21 (533) 19.5 (495) 19-13/32 (493) 184.6 (83.7)

MGH96M100C5A 21 (533) 19.5 (495) 19-13/32 (493) 194.6 (88.3)

MGH96M100D5A 24.5 (622) 23 (584) 22-27/32 (580) 205.1 (93.0)

MGH96M120D5A 24.5 (622) 23 (584) 22-27/32 (580) 209.5 (95.0)

Table 1 Dimensions & Weight

8 |Ecoer 96% AFUE Gas Furnace Installation, Operation & Maintenance

07-2021 | Ecoer Inc..

Data subject to change

3 Introduction

This 3-way Multipoise Category IV Fan-assisted furnace is AHRI and ETL design-

certified. A Category IV Fan-assisted furnace is an appliance equipped with an

integral mechanical means to either draw or force products of combustion through

the combustion chamber and/or heat exchangers. This furnace is factory-shipped

for use with natural gas.

This furnace is not approved for installation in mobile homes, recreational

vehicles, or outdoors. This furnace is designed for minimum continuous return-air

temperature of 60°F (16°C) (DBT) or intermittent operation down to 55°F (13°C)

(DBT) such as when used with a night setback thermostat. Return-air temperature

must not exceed 85°F (29°C) (DBT). Failure to follow these return-air temperature

limits may affect reliability of heat exchangers, motors, and controls. (See Section

4.1, Fig. ).

For accessory installation details, refer to the applicable instruction literature.

A Natural Gas to LP conversion kit, supplied by the manufacturer with every furnace

unit, shall be used to convert to propane gas (LP).

This furnace is for indoor installation in a building constructed on-site.

This furnace may be installed on combustible flooring in alcove or closet at

minimum clearance as indicated by Figure 3.

This furnace requires a special venting system. Refer to Section 8, "Vent System"

of this manual for installation instructions related to venting. In the US this furnace

is for use with schedule-40 PVC, PVC-DWV, CPVC, or ABS-DWV pipe, and must not

be vented in common with other gas-fired appliances. For installations in Canada,

refer to Section 8.4, "Combustion Air/Venting" of this manual. Construction

through which vent/air intake pipes may be installed is maximum 24 inches (610

mm), minimum 3/4 inches (19 mm) thickness (including roofing materials).

Remove all shipping brackets and materials before operating the furnace.

WARNING: FIRE, EXPLOSION, ASPHYXIATION HAZARD

Improper adjustment, alteration, service, maintenance, or

installation can cause serious injury or death.

Read and follow instructions and precautions in User's

Information Manual provided with this furnace. Installation

and service must be performed by a qualified service agency

or the gas supplier.

This product is not to be sold or installed in the State of California in

the South Coast Air Quality Management District or San Joaquin Valley

Air Basin territory.

CAUTION:

INSTALLATION

1. This furnace must be installed in accordance with

the manufacturer's instructions and local codes. In

the absence of local codes, follow the National Fuel

Gas Code ANSI Z223.1/ NFPA54.

2. This furnace must be installed so there are

provisions for combustion and ventilation air. See

manufacturer's installation information provided

with this appliance.

OPERATION

This furnace is equipped with manual reset limit switch(es)

in burner compartment to protect against overheat

conditions that can result from inadequate combustion air

supply or blocked vent conditions.

1. Do not bypass limit switches.

2. If a limit opens, call a quallified service technician

to correct the condition and reset the limit switch.

This furnace is approved for UPFLOW and HORIZONTAL installations.

WARNING: FIRE HAZARD

Do not install the furnace on its front or back. See Figure 2.

Figure 2

Front Back

Installation, Operation & Maintenance Manual Ecoer 96% AFUE Gas Furnace | 9

Ecoer Inc. 7-2021 Data subject to change

Figure 3

Clearance arrows do not change with furnace orientation

1’’

TOP/PLENUM

0’’ BACK

0’’ SIDE

SIDE

MOTTOB

0’’

0’’

3’’

FRONT

Ø

SIDES* FRONT BACK TOP

(PLENUM)

0"3"0"1"

Minimum clearance from combustible construction

When the unit is installed in the horizontal orientation, there must be 7"

clearance in order to install the externally mounted drain trap.

If installed in an alcove or closet

24 inches is required for service and maintenance.

Horizontal installation in attic or crawl space

Indicates supply or return sides when furnace is in the horizontal position. Line

contact only permissible between lines formed by intersections of the side and

back of the furnace cabinet and building joists, studs or frame.

Horizontal applications require a solid, supportive structure for installation

(refer to Section 7.2 “Horizontal Installation”).

For upflow and horizontal applications, the furnace must be pitched a minimum of

1/2" (12.7 mm) to a maximum of 3/4" (19 mm) forward for proper drainage.

See Section 7, "Installation" of this manual for more information.

Figure 4

1/2”~3/4”

1/2”~3/4”

4 Codes and Standards

Follow all national and local codes and standards in addition to these instructions.

The installation must comply with regulations of the serving gas supplier, local

building, heating, plumbing, and other codes. In absence of local codes, the

installation must comply with the national codes listed below and all authorities

having jurisdiction. Follow all codes and standards for the following:

4.1 Safety

US: National Fuel Gas Code (NFGC) NFPA 54-Latest/ANSI Z223.1-

latest edition and the Installation Standards, Warm Air Heating and Air

Conditioning Systems ANSI/NFPA 90B

CANADA: National Standard of Canada Natural Gas and Propane

Installation Codes (CAN/CSA-B149.1-05)

Figure 5

Max 85°F/29°C

Min 60°F/16°C

OUTLET

AIR

FRONT

Return Air Temperature

4.2 General Installation

US: Current edition of the NFGC and the NFPA 90B. For copies, contact

the National Fire Protection Association Inc., 1 Batterymarch Park,

Quincy, MA 02169; (www.NFPA.org) or for only the NFGC, contact the

American Gas Association, 400 North Capital Street, NW, Suite 450,

Washington, DC 20001 (www.AGA.org)

CANADA: NSCNGPIC.For a copy,contact Standard Sales, CSA

International,178 Rexdale Boulevard, Etobicoke (Toronto),

Ontario,M9W 1R3 Canada

10 |Ecoer 96% AFUE Gas Furnace Installation, Operation & Maintenance

07-2021 | Ecoer Inc.

Data subject to change

4.3 Combustion and Ventilation Air

US: Section 9.3 of the NFGC, NFPA 54/ANSI Z223.1-latest edition Air

for Combustion and Ventilation

CANADA:Part 8 of CAN/CSA-B149.1-05,Venting Systems and Air

Supply for Appliances.

4.4 Duct Systems

US and CANADA: Air Conditioning Contractors Association (ACCA)

Manual D, Sheet Metal and Air Conditioning Contractors National

Association (SMACNA), or American Society of Heating, Refrigeration,

and Air Conditioning Engineers (ASHRAE) 2001 Fundamentals

Handbook Chapter 34 or 2000 HVAC Systems and Equipment

Handbook Chapters 9 and 16

4.5 Acoustical Lining and Fibrous Glass Duct

US and CANADA: Current edition of SMACNA and NFPA 90B as tested

by UL Standard 181 for Class I Rigid Air Ducts

4.6 Gas Piping and Gas Pipe Pressure Testing

US: NFPA 54/ANSI Z223.1-latest edition Chapters 5,6, 7, and 8 and

National Plumbing Codes

CANADA: CAN/CSA-B149.1-05 Parts 4,5 and 6 and Appendices

A,B,E,and H.

4.7 Electrical Connections

US: National Electrical Code (NEC) ANSI/NFPA 70-latest edition

CANADA: Canadian Electrical Codes CSA C22.1.

4.8 Electrical Power Supply

Voltage: ANSI C84.1- latest edition (104-127 volt)

4.9 Venting

US: NFGC NFPA 54/ANSI Z223.1-latest edition; Chapters 12 and 13

CANADA: CAN/CSA-B149.1-05 Part 8 and Appendix C.

5 Electrostatic Discharge (ESD) Precautions Procedure

NOTICE: FURNACE RELIABILITY HAZARD

Improper installation or service of furnace may cause

premature furnace component failure.

Electrostatic discharge can affect electronic components.

Follow the electrostatic discharge precautions procedure

listed below during furnace installation and servicing to

protect the furnace electronic control. Precautions will

prevent electrostatic discharges from personnel and

hand tools which are held during the procedure. These

precautions will help to avoid exposing the control board to

electrostatic discharge by putting the furnace, the control

board, and the person at the same electrostatic potential.

1. Disconnect all power to the furnace. Multiple disconnects maybe required.

DO NOT TOUCH THE CONTROL OR ANY WIRE CONNECTED TO THE

CONTROL PRIOR TO DISCHARGING YOUR BODY'S ELECTROSTATIC

CHARGE TO GROUND.

2. To discharge your body's electrostatic charge to ground, firmly touch the

clean, unpainted, metal surface of the furnace chassis which is close to

the control board.Tools held in a person's hand during grounding will be

satisfactorily discharged.

3. After touching the chassis, you may proceed to service the control board or

connecting wires as long as you do nothing to recharge your body with static

electricity (for example; DO NOT move or shuffle your feet, do not touch

ungrounded objects, etc.).

4. If you touch ungrounded objects (and recharge your body with static

electricity), firmly touch a clean, unpainted metal surface of the furnace

again before touching control board or wires.

Use this procedure for installed and uninstalled (ungrounded) furnaces. In the case

of control board replacement, before removing the replacement control board from

its packaging, discharge your body's electrostatic charge to ground to protect the

control from damage. If the control is to be installed in a furnace, follow steps 1

through 4 before bringing the control board or yourself in contact with the furnace.

Put all used and new control boards into containers before touching ungrounded

objects.

An ESD service kit (field supplied) may also be used to prevent ESD damage.

Installation, Operation & Maintenance Manual Ecoer 96% AFUE Gas Furnace | 11

Ecoer Inc. | 07-2021 Data subject to change

6 Location

6.1 General

This multipoise furnace is shipped in packaged configuration. Some

assembly and modifications are required when used in any of the

three applications . This furnace must:

Be installed so the electrical components are protected from water.

Not be installed directly on any combustible material other than wood

flooring. Refer to Section 3 Fig 3. for required clearances.

Horizontal installation in attics and crawl spaces have additional

requirements. Refer to Section 7.

Be located close to the chimney or vent and attached to an air

distribution system. Refer to Section 7.5 "Air Ducts".

Be provided ample space for servicing and cleaning. Always comply

with minimum fire protection clearances shown on the furnace

clearance to combustible label. Refer to Section 3, Fig 3.

The following types of furnace installations may require OUTDOOR AIR for

combustion due to chemical exposures:

Commercial buildings

Buildings with indoor pools

Laundry rooms

Hobby or craft rooms, and

Chemical storage areas

WARNING: CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in personal injury

or death, and unit component damage.

Corrosive or contaminated air may cause failure of parts

containing flue gas, which could leak into the living space.

Air for combustion must not be contaminated by halogen

compounds, which include fluoride, chloride, bromide, and

iodide. These elements can corrode heat exchangers and

shorten furnace life. Air contaminants are found in aerosol

sprays, detergents, bleaches, cleaning solvents, salts, air

fresheners, and other household products. Do not install

furnace in a corrosive or contaminated atmosphere. Make

sure all combustion and circulating air requirements are

met, in addition to all local codes and ordinances.

If air is exposed to the following substances, it should not be used for combustion

air, and outdoor air may be required for combustion:

Permanent wave solutions

Chlorinated waxes and cleaners

Chlorine based swimming pool chemicals

Water softening chemicals

De-icing salts or chemicals

Carbon tetrachloride

Halogen type refrigerants

Cleaning solvents (such as perchloroethylene)

Printing inks, paint removers, varnishes, etc.

Hydrochloric acid

Cements and glues

Antistatic fabric softeners for clothes dryers

Masonry acid washing materials

All fuel-burning equipment must be supplied with air for fuel combustion. Sufficient

air must be provided to avoid negative pressure in the equipment room or space. A

positive seal must be made between the furnace cabinet and the return-air duct to

prevent pulling air from the burner area and from draft safeguard opening. Also see

Section 7.5 "Air Ducts".

Figure 6

18-IN.

MINIMUM TO BURNERS

Installation in a garage

12 |Ecoer 96% AFUE Gas Furnace Installation, Operation & Maintenance

07-2021 | Ecoer Inc.

Data subject to change

WARNING: FIRE, INJURY OR DEATH HAZARD

When the furnace is installed in a residential garage, the

burners and ignition sources must be located at least 18

inches above the floor. The furnace must be located or

protected to avoid damage by vehicles. When the furnace is

installed in a public garage, airplane hangar, or other building

having a hazardous atmosphere, the furnace must be

installed in accordance with the NFGC. (See Fig. 6).

CAUTION: INJURY AND/OR PROPERTY DAMAGE HAZARD

Improper use or installation of this furnace may cause

premature furnace component failure. This gas furnace may

be used for heating buildings under construction provided

that:

—The furnace is permanently installed with all electrical

wiring, piping, venting and ducting installed according

to these installation instructions. A return air duct

is provided, sealed to the furnace cabinet, and

terminated outside the space containing the furnace.

This prevents a negative pressure condition as

created by the circulating air blower, causing a flame

rollout and/or drawing combustion products into the

structure.

—The furnace is controlled by a thermostat. It may not

be "hot wired" to provide heat continuously to the

structure without thermostatic control.

—Clean outside air is provided for combustion. This is

to minimize the corrosive effects of adhesives, sealers

and other construction materials. It also prevents the

entrainment of drywall dust into combustion air, which

can cause fouling and plugging of furnace components.

—The temperature of the return air to the furnace is

maintained between 60°F (16°C) and 85°F (29°C),

with no evening setback or shutdown.

—The use of the furnace while the structure is under

construction is deemed to be intermittent operation

per our installation instructions.

—The air temperature rise is within the rated rise range

on the furnace rating plate, and the gas input rate has

been set to the nameplate value.

—The filters used to clean the circulating air during

the construction process must be either changed or

thoroughly cleaned prior to occupancy.

—The furnace, ductwork and filters are cleaned as

necessary to remove drywall dust and construction

debris from all HVAC system components after

construction is completed.

—Verify proper furnace operating conditions including

ignition, gas input rate, air temperature rise, and

Installation, Operation & Maintenance Manual Ecoer 96% AFUE Gas Furnace | 13

Ecoer Inc. | 07-2021 Data subject to change

7 Installation

This furnace can be installed in upflow or horizontal orientations.

(see Section 7.3, Fig 13-18).

7.1 Upflow Installation

Bottom return air inlet

These furnaces are shipped with the bottom closure panel installed in bottom

return-air opening. Remove and discard this panel when bottom return air is used.

To remove bottom closure panel, perform the following:

1. Tilt or raise furnace and remove the screw holding bottom filler panel. (See

Fig. 7.)

2. Remove bottom closure panel.

Figure 7

BOTTOM CLOSURE PANEL

BOTTOM FILLER

PANEL SCREW

SCREW

Removing bottom closure panel

Figure 8

Upflow Installation

Tilt the unit slightly (minimum 1/2 (12.7 mm) to maximum of 3/4 (19 mm))

from back to front to aid in the draining of the heat exchanger.

1/2”~3/4”

WEIVEDISWEIVTNORF

Upflow Application-Setting Equipment

Side return air inlet

These furnaces are shipped with bottom closure panel installed in bottom return-air

opening. This panel MUST be in place if only side return air is used.

Depending on the installation requirements, side return-air openings can

be used in UPFLOW and most HORIZONTAL configurations.

These furnaces come standard with knockout holes to aid in right/left

return configurations. To do this, knockout the holes and cut the sheet

metal and insulation accordingly.

14 Ecoer 96% AFUE Gas Furnace Installation, Operation & Maintenance

07-2021 | Ecoer Inc.

Data subject to change

7.2 Horizontal Installation

WARNING: FIRE, EXPLOSION, AND CARBON MONOXIDE

POISONING HAZARD

Failure to follow this warning could result in personal

injury, death, and/or property damage. Do not install

the furnace on its back or hang furnace with control

compartment facing downward. Safety control operation

will be adversely affected. Never connect return-air ducts

to the back of the furnace.

The furnace can be installed horizontally in an attic or crawl space on bottom or

either the left-hand (LH) or right-hand (RH) side (See Figure 9). The furnace can be

hung from floor joists, rafters or trusses or installed on a non-combustible platform,

blocks, bricks or pad.

7.2.1 Furnace Suspension

If suspending the furnace from rafters or joists, use 3/8" threaded rod and

2”x2”x1/8” angle iron as shown in Figure 10. The length of rod will depend on the

application and the clearances necessary. (See Fig. 10 and 11)

Figure 9

Horizontal Left-Hand Side Installation

Horizontal Right-Hand Side Installation

1/2”~3/4”

1/2”~3/4”

FRONT VIEW

FRONT VIEW

SIDE VIEW

SIDE VIEW

Tilt the unit slightly (minimum 1/2" (12.7 mm) to maximum of 3/4" (19 mm))

from back to front to aid in the draining of the heat exchanger.

Horizontal Application-Setting Equipment

Installation, Operation & Maintenance Manual Ecoer 96% AFUE Gas Furnace |15

Ecoer Inc. | 07-2021 Data subject to change

7.2.2 Horizontal Applications

Horizontal applications, in particular, may dictate many of the installation’s

specifics such as airflow direction, ductwork connections, flue and combustion

air pipe connections, etc. The basic application of this furnace as a horizontal

furnace differs only slightly from an upright installation. When installing a furnace

horizontally, additional consideration must be given to the following:

Drain Trap and Lines

In horizontal applications the condensate drain trap is secured to the furnace side

panel, suspending it below the furnace.

A minimum clearance of 7 inches below the furnace must be provided

for the drain trap.

Additionally, the appropriate downward piping slope must be maintained from the

drain trap to the drain location. Refer to Section “Condensate Drain Line & Drain

Trap”.

NOTICE:

If the drain trap and drain line will be exposed to

temperatures near or below freezing, adequate measures

must be taken to prevent condensate from freezing. In this

scenario, it is recommended to add foam insulation around

the drain line, and heat tracing may also be necessary

based on the application.

Leveling

Leveling ensures proper condensate drainage from the heat exchanger and induced

draft blower. For proper flue pipe drainage, the furnace must be level lengthwise

from end to end. The furnace should also have a slight tilt with the access doors

downhill ((minimum 1/2(12.7 mm) to maximum of 3/4(19 mm)) from the back

panel. The slight tilt allows the heat exchanger condensate, generated in the

recuperator coil, to flow forward to the recuperator coil front cover.

Refer to Figure 9.

Alternate Electrical And Gas Line Connections

This furnace has provisions allowing for electrical and gas line connections through

either side panel. In horizontal applications the connections can be made either

through the “top” or “bottom” of the furnace.

Drain Pan

A drain pan must be provided if the furnace is installed above a conditioned area.

The drain pan must cover the entire area under the furnace (and air conditioning

coil if applicable).

Furnace Suspension

If the furnace is installed in a crawl space it must be suspended from the floor joist

or supported by a concrete pad. Never install the furnace on the ground or allow it

to be exposed to water. See Furnace Suspension for further details (See Fig. 10).

16 |Ecoer

9

6% AFUE Gas Furnace Installation, Operation & Maintenance

07-2021 | Ecoer Inc.

Data subject to change

Figure 10

PROVIDE 8" MINMUM CLEARANCE BETWEEN

CENTER ROD AND FURNACE CABINET

TO ALLOW FOR CIRCULATOR BLOWER REMOVAL

3/8" DIAMETER

THREADED ROD

(6 PLACES)

SUPPORT NUTS

2"X2"X1/8" ANGLE IRON

(3 PLACES)

POSITION AS CLOSE AS POSSIBLE

TO BLOWER DECK TO ALLOW FOR

CIRCULATOR BLOWER REMOVAL

ASSURE FURNACE IS LEVEL FROM

END TO END AND HAS A SLIGHT

FORWARD TILT WITH THE FRONT

OF THE FURNACE 3/4"

BELOW THE BACK OF THE FURNACE

TILT OUTWARD TO ALLOW FOR

DOOR AND CIRCULATOR BLOWER

REMOVAL

HOLD DOWN NUTS

Horizontal Installation

Figure 11

FURNACE MUST BE LEVEL

FROM END TO END. FURNACE MUST BE SLIGHTLY TILTED

FORWARD WITH THE DOORS 1/2”~3/4”

BELOW THE BACK PANEL.

7” MINIMUM DRAIN

TRAP CLEARANCE

DRAIN PAN

GAS LINE WITH DRIP

LEG (3” MINIMUM)

DRAIN LINE WITH 1/4” PER

FOOT DOWNWARD SLOPE

36” MINIMUM SERVICE

CLEARANCE REQUIRED

FURNACE MUST BE SUPPORTED

AT BOTH ENDS AND MIDDLE

Horizontal Installation

Installation, Operation & Maintenance Manual Ecoer 96% AFUE Gas Furnace |17

Ecoer Inc. | 07-2021 Data subject to change

7.3 Condensate Line and Over Flow Pressure Switch

NOTICE

For horizontal left hand installation (air discharge to the

left), condensate overflow pressure switch hoses need to

be rerouted (see Figure 17).

To achieve higher energy efficiency than non-condensing furnaces, condensing

furnaces will generate a significant amount of condensate water from combustion

to recover latent heat in the flue. Condensate generated from the flue must be

collected and discharged to the drain line. For some venting directions and

furnace installations, rerouting of the condensate and/or overflow pressure switch

hoses may be required. Follow the instructions below and Figures 13-17 for each

installation.

Follow the information listed below when installing the drain system. Refer to the

following sections for specific details concerning furnace drain trap installation and

drain hose hook ups.

The drain trap supplied with the furnace must be used.

The drain line between furnace and drain location must be constructed

of 3/4” PVC or CPVC.

Ensure that the condensate hose connections between the pressure

switches/inducer drain port and the condensate trap are sloped

downward toward the drain to allow for proper drainage.

The drain line between furnace and drain location must maintain a 1/4"

per foot downward slope toward the drain.

Do not trap the drain line in any other location than at the drain trap

supplied with the furnace.

Do not route the drain line outside where it may freeze.

7.3.1 Standard Right-Hand or Left-Hand Side Drain Hose Connections

Figure 12

DRAIN TRAP

MOUNTING

BRACKET

Ф16 mm HOSE

Ф14 mm HOSE

Optional Ф14 mm ELBOW

Optional Ф16 mm ELBOW

DRAIN TRAP Ф21 mm

HOSE

CLAMPS

Ф18 mm

HOSE

CLAMPS

INCOMING

GAS PIPE

RUBBER GASKET

Included Accessories for Condensate Drain Trap Installation

* Only used when exhaust pipe is vented out of the side of the furnace's cabinet

(regardless of installation orientation).

If the drain line is routed through an area which may see

temperatures near or below freezing, precautions must be taken

to prevent condensate from freezing within the drain line. In this

scenario, it is recommended to add foam insulation around the

drain line, and heat tracing may also be necessary based on the

application.

If an air conditioning coil is installed with the furnace, a common drain

may be used. An open tee must be installed in the drain line, near the

cooling coil, to relieve positive air pressure from the coil’s plenum.

This is necessary to prohibit any interference with the function of the

furnace’s drain trap.

NOTICE

The condensate from this unit is acidic, adhere to all local

and national codes when draining condensate. If proper

procedures are not followed, this may lead to property

damage.

NOTICE

Condensate trap at furnace must be PRIMED for proper

draining may not occur. The condensate trap can ONLY

be primed by pouring water into the inducer drain side of

condensate trap.

18 |Ecoer 96% AFUE Gas Furnace Installation, Operation & Maintenance

07-2021 Ecoer Inc.

Data subject to change

7.3.2 For Upflow Installation

Top venting (see Fig. 14)

1. Connect vent pipe and air intake pipe (if applicable) to the couplers on the

furnace top panel.

2. Use filed supplied straight 2'' diameter pipe. If 3'' pipes are used, use a field

supplied transition.

3. Depending on which side the condensate trap is mounted, remove 2 caps

on the side where trap is mounted. Mount trap with manufacturer provided

screws.

4. Remove cap from the inducer drain port (see Fig. 13).

Figure 13

5. Connect Φ16 mm hose between condensate collector box and drain trap

and connect Φ14 mm hose between inducer drain port and drain trap. (see

Fig. 14).

6. Cut the excess hoses as needed.

7. Secure and tighten all hoses using manufacturer provided hose clamps.

Figure 14

DRAIN TRAP

14 mm HOSE

HOSE CLAMP

HOSE

CLAMP

EXHAUST COUPLER

AIR INLET

COUPLER

16 mm HOSE

HIGH/LOW

FIRE

PRESSURE

SWITCH

METAL

HOSE CLAMPS

CONDENSATE

COLLECTOR BOX

Upflow Installation, Top Venting

Installation, Operation & Maintenance Manual Ecoer 96% AFUE Gas Furnace | 19

Ecoer Inc. | 07-2021 Data subject to change

7.3.3 For Horizontal Installations

For installations with right air discharge and venting outlet through furnace

top panel (see Figure 15).

1. Remove cap from left side panel of furnace and cut the insulation

accordingly.

2. Remove 3 screws securing air inlet coupler on top panel and remove

coupler.

3. Mount air inlet coupler to the left side of the furnace cabinet using the same

screws saved from last step. Connect air inlet pipe to air inlet coupler.

4. Seal the top panel air intake hole using the caps removed from side panel.

5. Use field supplied elbow and metal hose clamps to make flue vertical.

Elbows should be as close to the furnace as possible. Connect the vent

outlet pipe. Use filed supplied straight 2'' diameter pipe. If 3'' diameter

pipes are used, use a field supplied transition.

6. Use provided or field supplied (if applicable) mounting bracket to mount

drain trap to the proper location on right side panel .

7. Screws for mounting bracket should not interfere with any components

inside the furnace.

8. Cut and remove 1/4" from the end of the inducer drain port. Reference

Figure 13.

9. Connect (using hose clamps) 16 mm hose between condensate collector

box and drain trap.

10. Connect (using hose clamps) 14 mm hose between the drain port and drain

trap.

11. Cut the excess hose as needed.

12. Secure and tighten all hoses

Figure 15

Φ16 mm HOSE

Φ14 mm HOSE

HOSE CLAMP

VENT OUTLET

AIR INLET

DRAIN

TRAP

HIGH/LOW FIRE

PRESSURE SWITCH

Φ14/16 mm

ELBOW (optional)

AIR INLET

COUPLER

FIELD

SUPPLIED

ELBOW

CONDENSATE

COLLECTOR

BOX

FRONT

INDUCER

DRAIN

PORT

DRAIN TRAP

MOUNTING

BRACKET

JUNCTION

BOX

BOTTOM INDUCER

DRAIN PORT

Horizontal Right-Hand Side Installation

20 |Ecoer 96% AFUE Gas Furnace Installation, Operation & Maintenance

07-2021 Ecoer Inc.

Data subject to change

For installations with left air discharge and venting outlet through furnace

top panel (see Figures 16 and 17).

NOTICE:

In this installation, hoses connecting between ports of

overflow protection pressure switch (overflow switch)

and pressure tabs on the condensate collector box MUST

be switched. The overflow switch has two ports, which is

different from two other regular pressure switches that

have only one port. Make sure that black port (positive)

is connected to the lower position tap on condensate

collector box and gray port (negative) to higher tap of

condensate box. Connecting incorrectly will result in

failure to protect condensate overflow.

NOTICE:

Two pressure switches (one port type switches) should

be relocated to other side of furnace side panel to ensure

pressure switches are above water tap of condensate

collector box.

1. Remove cap from left side panel of furnace and cut the insulation

accordingly.

2. Remove 3 screws securing air inlet coupler on top panel and remove

coupler.

3. Mount coupler to the right side using the same screws saved from last step.

Connect air inlet pipe to air inlet coupler.

4. Seal the top panel air intake hole using the caps removed from side panel.

5. Use field supplied elbow and metal hose clamp to make flue vertical. Elbows

should be as close to the furnace as possible. Connect the vent outlet pipe.

6. Use provided or field supplied (if applicable) mounting bracket to mount

condensate trap on the proper location of the left side panel.

Figure 16

VENT OUTLET

AIR INLET

HOSE

CLAMP

HOSE CLAMP

Φ16 mm HOSE

DRAIN TRAP DRAIN TRAP MOUNTING BRACKET

14mm HOSE

HIGH/LOW FIRE

PRESSURE

SWITCHES

Φ14/16 mm ELBOW (optional)

JUNCTION

BOX

FIELD

SUPPLIED

ELBOW

CONDENSATE COLLECTOR

BOX

AIR

INLET

COUPLER

Horizontal Left Side Installation, Vent Through Top Panel

7. Screws for mounting bracket should not interfere with any components

inside the furnace.

8. Connect 16 mm hose between condensate collector box and drain trap. Cut

the excess hose to correct length prior to connection.

9. Connect 14 mm hose between the side inducer drain port (remove black

rubber plug to connect hose) and drain trap. Refer to Figure 16.

10. Plug both holes on inducer elbow using provided plugs.

11. Cut the excess hoses as needed.

12. Secure and tighten all hoses.

13. Relocate junction box to the other side of cabinet if necessary.

14. Relocate the High/Low Fire Pressure Switches (2) to the opposite side of

the cabinet (as shown in Figure 16 and 17). Screws for mounting these

switches should not interfere with any components inside the furnace.

Figure 17

Upright

Overflow

Pressure Switch

High/Low Fire

Pressure Switch

Ensure condensate

hose is connected to

side inducer drain port

on inducer as shown.

Pressure Switch Position

This manual suits for next models

6

Table of contents

Popular Furnace manuals by other brands

Lennox

Lennox Elite O25 Brochure & specs

Carrier

Carrier 050-135 Series 120 manual

Johnson Controls

Johnson Controls LP9C C User's information manual

Ingersoll-Rand

Ingersoll-Rand A951X040BU3SAA Installer's guide

Carrier

Carrier 58MCA Users information manual for the operation and maintenance

SummerAire

SummerAire SBB Installation and owner's operating instructions

VERDER

VERDER CARBOLITE GERO E Series manual

ICP

ICP FLO115DABR-A Installation Instructions and Use & Care Guide

Newmac

Newmac WAO E Installation, operating and service manual

vita

vita vacumat 4000 premium t operating manual

Amana

Amana GMS8 Service instructions

Lennox

Lennox GSR21Q Series User's information manual