Ecoer R-410A User manual

1/62

ESI (Ultra) Service Manual www.ecoer.com

03.2021Manufacturer reserves the right to change specifications or designs without notice.

ESI (Ultra) R-410A

Unitary Service Manual

Contents

1. General Information----------------------------

2. ESI (Ultra) Unitary System---------------------

2.1 Refrigerant Circuit----------------------------

2.2 Function and Control------------------------

2.3 Field Setting-----------------------------------

3. Troubleshooting----------------------------------

3.1 Problems without Codes --------------------

3.2 Error Codes list ----------------------------- -

4. Parts List--------------------------------------------

5. Appendix-------------------------------------------

5.1 Sensor Characteristics------------------------

5.2 Wiring Diagram-------------------------------

2

3

3

7

17

27

27

29

56

58

58

62

All phases of this installation must comply with National, State and Local Codes.

IMPORTANT

These instructions do not cover all variations in systems or provide for every possible contingency to

be met in connection with installing and servicing. Should further information be desired or should

particular problems arise which are not covered sufficiently for the purchaser’s purposes, the matter

should be referred to local distributor.

2/62

ESI (Ultra) Service Manual www.ecoer.com

03.2021Manufacturer reserves the right to change specifications or designs without notice.

1 General Information

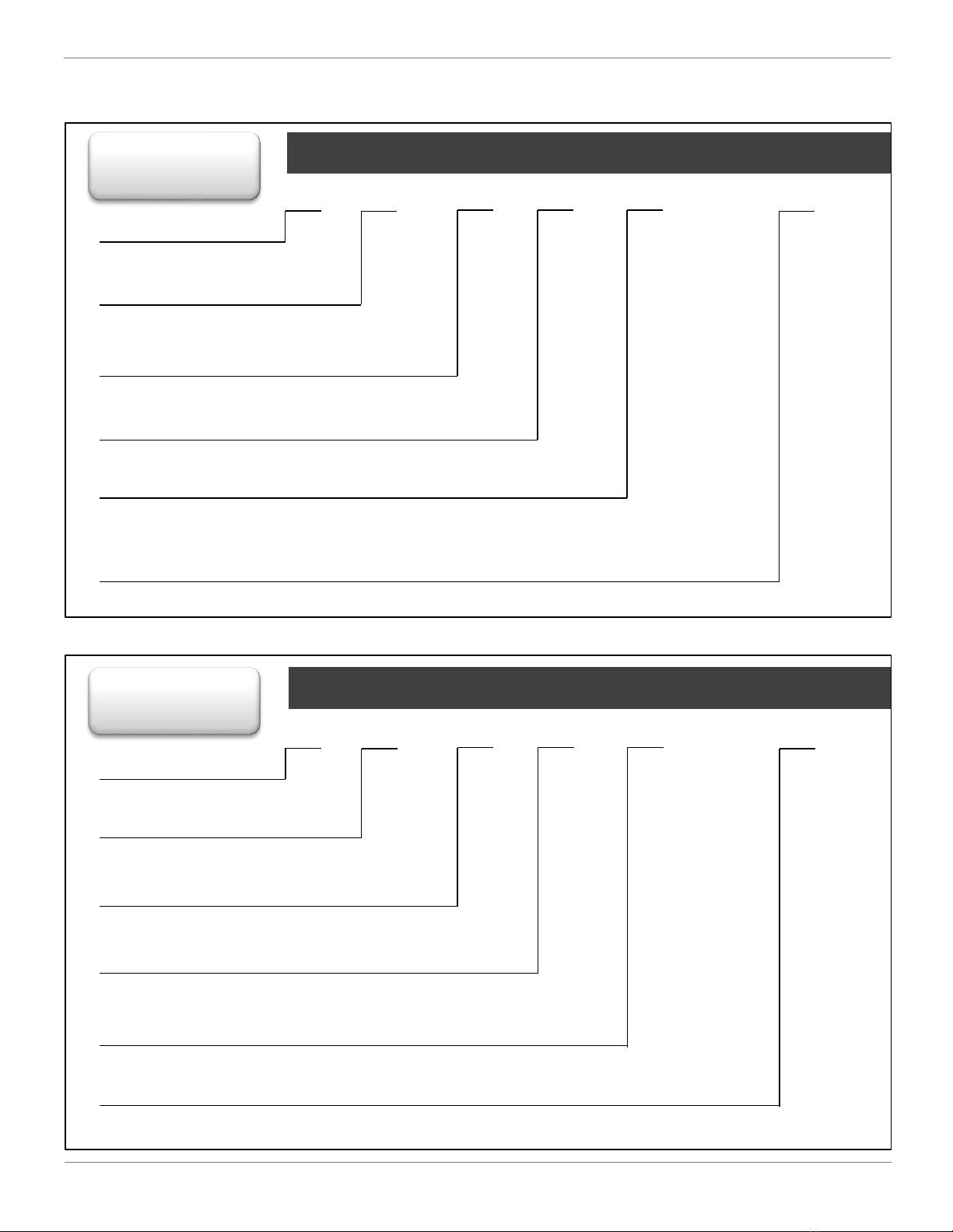

E OD A 18 H - 4860

1 2 3 4 5 6

Brand

E: Ecoer

Product Series

OD: Outdoor Condensing Unit

Model Letters

A: 208/230V-1Ph-60Hz

SEER

18: 18SEER Series

Type

H: Heat Pump C: AC only

Capacity

2436: up to 3Ton 4860: up to 5Ton

Condensing

Unit

E AH A T N - 36

1 2 3 4 5 6

Brand

E: Ecoer

Product Series

AH: Indoor Air Handler

Model Letters

A: 208/230V-1Ph-60Hz

Metering device

T: TXV

Communications

N: 24V Normal

Capacity

24=2Ton 36=3Ton 48=4Ton 60=5Ton

E series

Air Handler

3/62

ESI (Ultra) Service Manual www.ecoer.com

03.2021Manufacturer reserves the right to change specifications or designs without notice.

2.1 Refrigerant Circuit

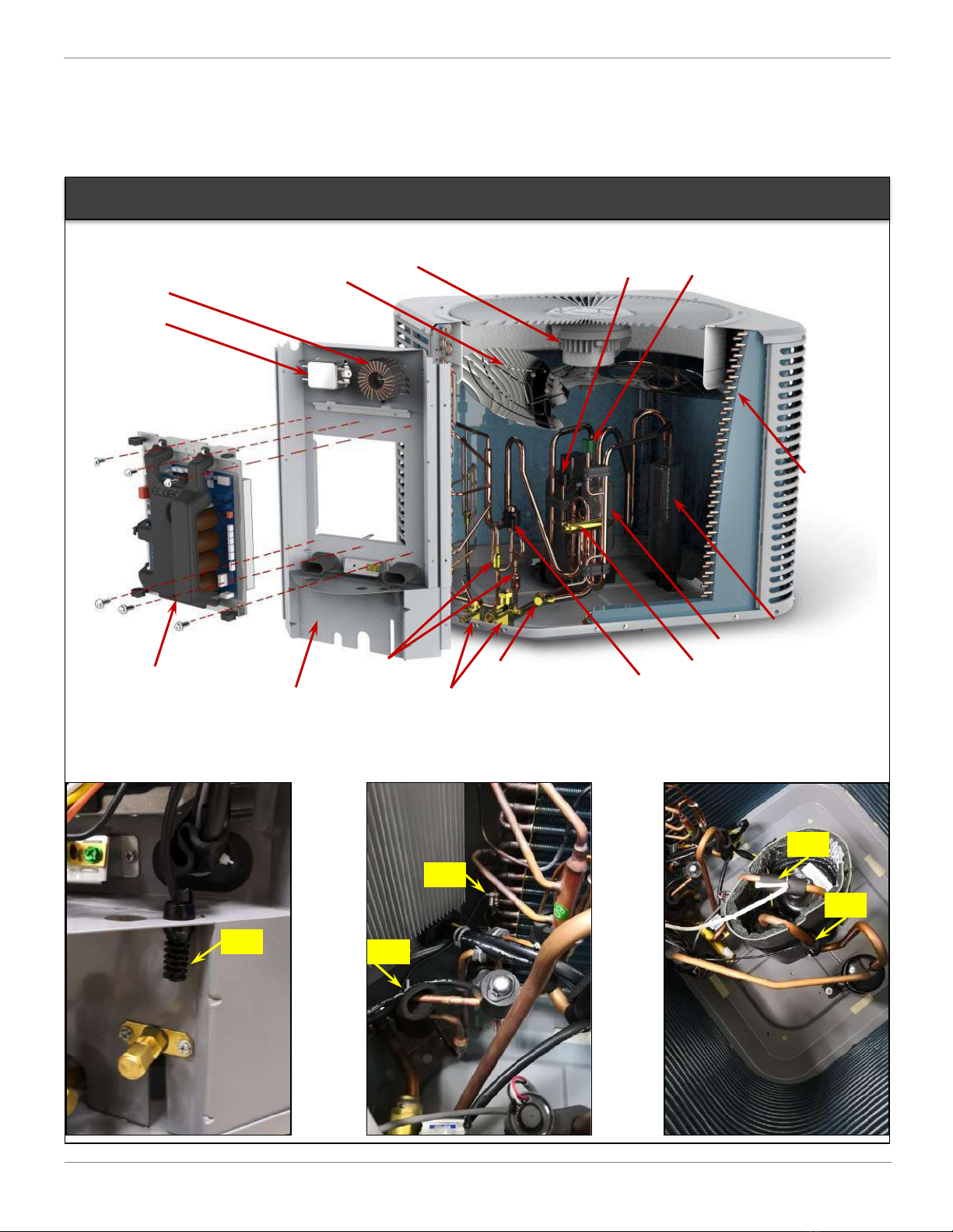

2.1.1 Functional Parts Layout of Condensing Units

2 ESI (Ultra) Unitary System

TH

TL

TS

TD

TA

DC Motor (FAN)

Main Control Board (PCB)

Accumulator (ACC)

Noise Filter

Inductance Fan Blades

Heat

Exchanger

Liquid / Gas Service Valve

Inverter Compressor (INV)

Reversing Valve (ST1)

Electronic Expansion

Valve (EEV)

Strainers Gauge Port

High Pressure

Sensor (HP) Low Pressure

Sensor (LP)

Lower Side Plate

EODA18H-2436

4/62

ESI (Ultra) Service Manual www.ecoer.com

03.2021Manufacturer reserves the right to change specifications or designs without notice.

TS

TD

TA

TA

DC Motor (FAN)

Main Control Board (PCB)

Accumulator (ACC)

Noise Filter

Inductance

Fan Blades Heat

Exchanger

Liquid / Gas Service Valve Inverter Compressor (INV)

Reversing Valve (ST1)

Electronic Expansion

Valve (EEV)

Strainers Gauge Port

High Pressure

Sensor (HP) Low Pressure

Sensor (LP)

Lower Side Plate

TIPS:

Remove screws to take away the lower

side plate to access TH / TL sensors.

A slotted screwdriver may be required to

open the plate from the condensing unit.

TH

TL

EODA18H-4860

5/62

ESI (Ultra) Service Manual www.ecoer.com

03.2021Manufacturer reserves the right to change specifications or designs without notice.

2.1.2 Major Components Functions and Refrigerant Circuits Diagram

HP TD

EEV

INV

TH

TA

ST1

(RV)

TS

TL

ACC

Liquid Service Valve

Heat Exchanger

Gas Service Valve

Gauge Port

FAN

LP

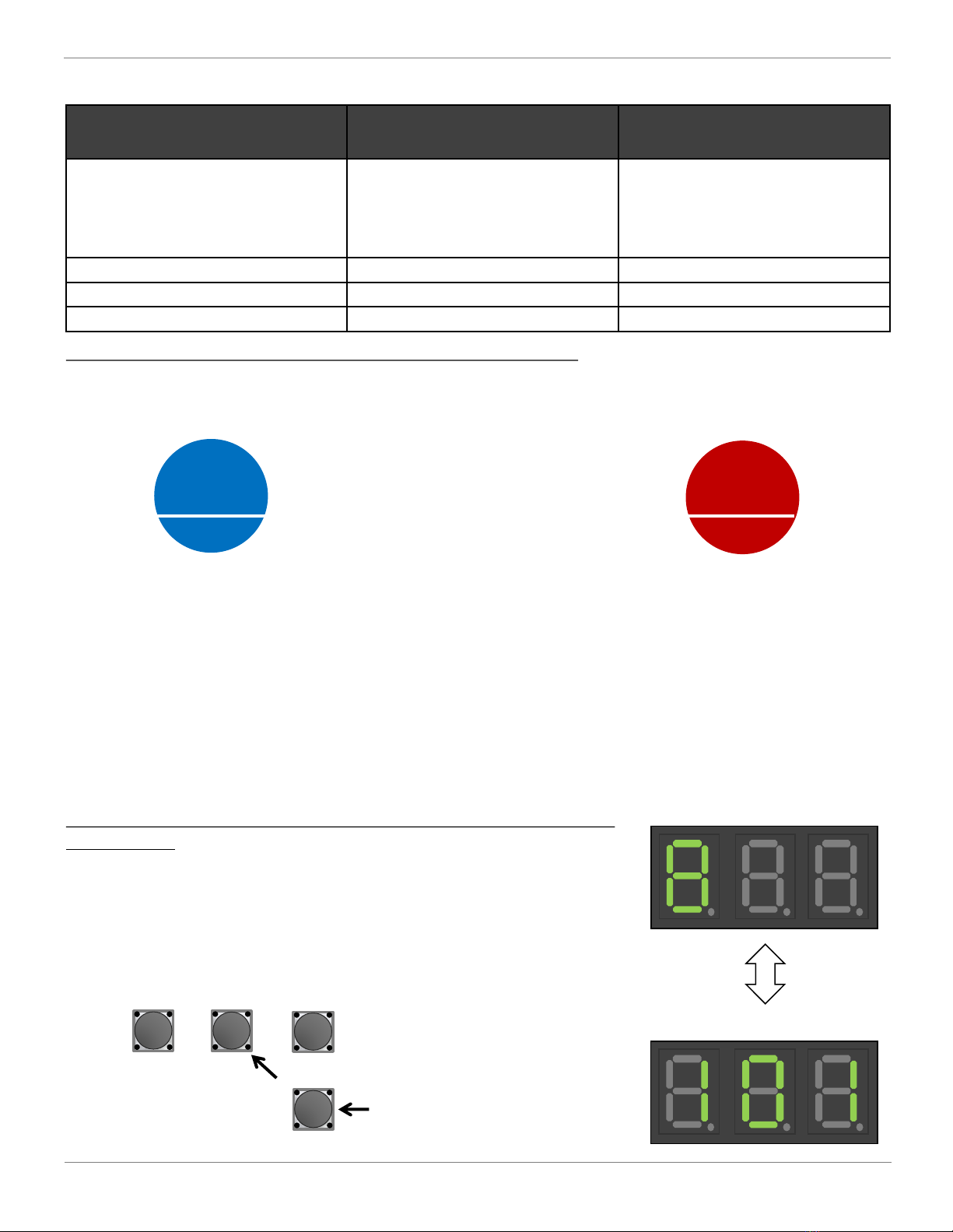

Name

Symbol

Function

Inverter compressor

INV Adjusts refrigerant flow rate by changing the compressor speed (RPS)

based on objective pressure.

DC motor FAN Outputs heat exchanger capacity by adjusting the motor rotation speed

based on operating pressure.

Electronic expansion

valve EEV 1) Fully open in cooling mode and defrost operation.

2) Control compressor discharge superheat in heating mode.

Reversing valve ST1

(RV)

Switches the operation mode between heating and cooling (including

defrost control).

Temperature sensor

TA Uses to detect outdoor air temperature and control fan speed.

TS Uses to detect compressor suction temperature and calculate compressor

suction superheat (SH).

TD Uses to detect compressor discharge temperature and calculate

compressor discharge superheat (DSH).

TH Uses to control defrosting during heating operation.

TL Uses to detect liquid line temperature and calculate sub-cooling (SC).

TF Uses to detect heat sink temperature of inverter module.

High pressure sensor

HP Uses to detect high pressure.

Low pressure sensor

LP Uses to detect low pressure.

Accumulator ACC Uses to store excess refrigerant.

6/62

ESI (Ultra) Service Manual www.ecoer.com

03.2021Manufacturer reserves the right to change specifications or designs without notice.

2.1.3 Refrigerant Flow of Each Operation Mode

Cooling Operation (including defrost operation and cooling oil return)

HP

TD

EEV

INV

TH

TA

ST1

(RV)

TS

TL

ACC

Liquid Service Valve

Heat Exchanger

Gas Service Valve

Gauge Port

TXV

Indoor Coil

High pressure Gas

High pressure Liquid

Low pressure Gas

Low pressure Mix.

FAN

LP

Strainer

Heating Operation (including heating oil return)

HP

TD

EEV

INV

TH

TA

ST1

(RV)

TS

TL

ACC

Liquid Service Valve

Heat Exchanger

Gas Service Valve

Gauge Port

TXV

Indoor Coil

High pressure Gas

High pressure Liquid

Low pressure Gas

Low pressure Mix.

FAN

LP

Strainer

7/62

ESI (Ultra) Service Manual www.ecoer.com

03.2021Manufacturer reserves the right to change specifications or designs without notice.

2.2 Function and Control

2.2.1 Operation Mode

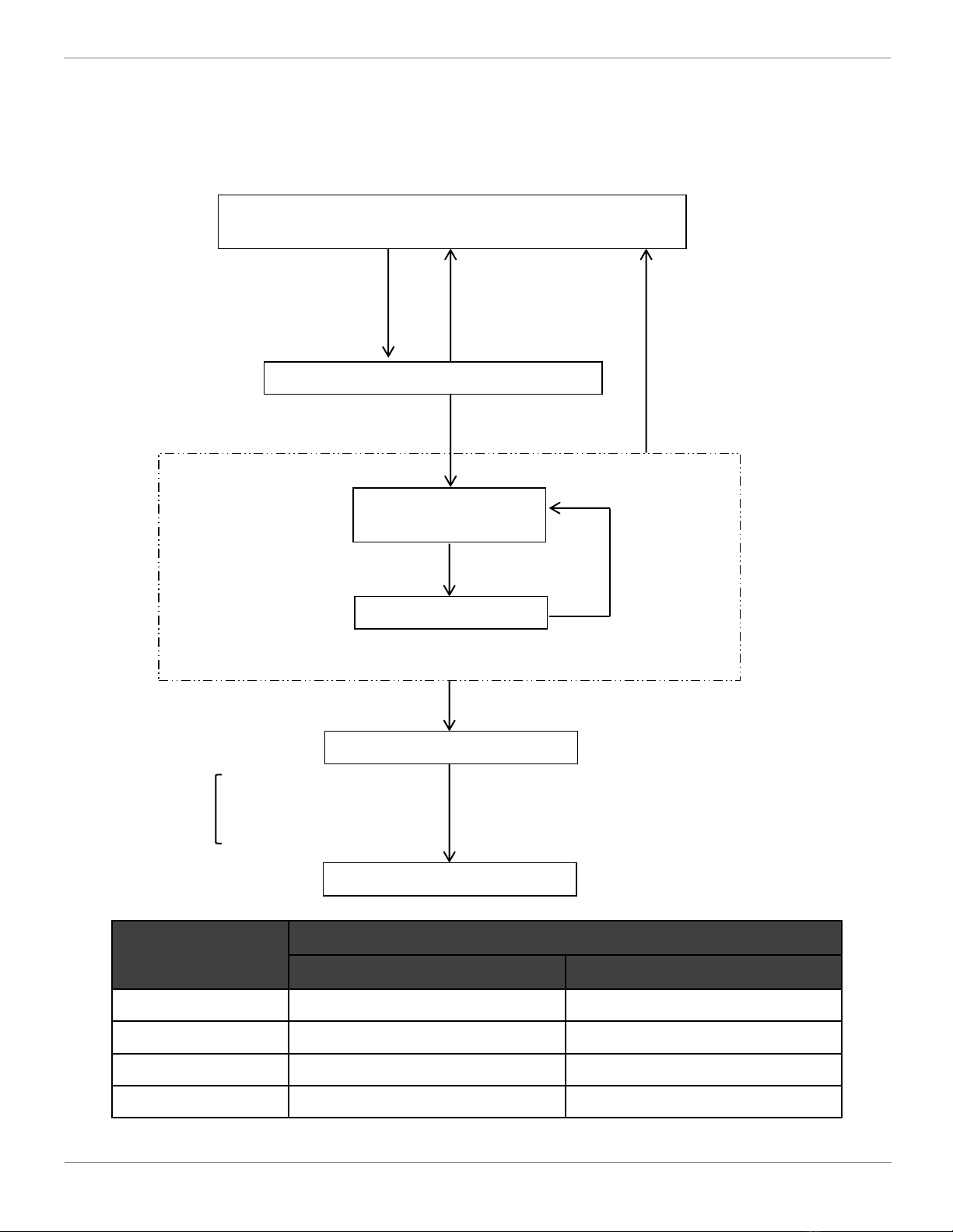

NOTES: The operation may be enforced to complete under some conditions.

Operation in stop mode

Pressure equalizing

prior to start-up

Thermostat ON (Y energized)

•Thermostat OFF

(Y de-energized)

•O signal change

Start-up control *NOTE

・Cooling start-up

(O energized)

・Heating start-up

(O de-energized)

Cooling or heating

operation

Oil return IN

conditions are met.

Defrost IN

conditions are met.

NO

NO

Oil return operation *NOTE

YES

Defrost operation *NOTE

YES

Normal operation

•Compressor PI control

•EEV PI control

•Fan motor control

•Protection control

Restart standby

(compressor stops)

Malfunction

MAX. 6 minutes

After 1 minute

8/62

ESI (Ultra) Service Manual www.ecoer.com

03.2021Manufacturer reserves the right to change specifications or designs without notice.

2.2.2 Basic control

2.2.2.1 Normal control

Input

Signal

Actuator

Cooling control

(including

cooling oil return)

Heating control

(including

heating oil return)

YCompressor (INV) Apply PI control to maintain Tes*1 Apply PI control to maintain Tcs*1

Y / O*2 Outdoor fan (FAN) Cooling fan control Heating fan control

O*2 Reversing valve (ST1) De-energized Energized (208/230VAC)

Y / O*2 Electronic expansion

valve (EEV) 480pls PI control to maintain discharge

superheat (DSH)

Remarks:

1. Tes: Target Te value (Varies depending on the load of space, mode choice, silent setting, etc.)

Te: Low pressure equivalent saturation temperature

Tcs: Target Tc value (Varies depending on the load of space, mode choice, silent setting, etc.)

Tc: High pressure equivalent saturation temperature

2. SW1_3=OFF (factory), condensing unit uses Y/C/O (O for cooling) signal to operate heat pump.

SW1_3=ON has been set, condensing unit uses Y/C signal to run cooling only.

2.2.2.2 Defrost control

This system carries out demand defrost control if any one of the following conditions satisfy.

I. The calculated temperature difference between ambient temperature (TA) and defrost

temperature (TH) is called Delta T. After Delta T is achieved and continues for 5 minutes.

II. After “Minimum Run Time” (MRT) is achieved.

III. The high pressure drops below 245psi for 20 minutes if TA is between 14°Fand 28°F.

IV. Manual defrosting can be chosen from n08 setting.

Defrost will be terminated once defrost temperature sensor (TH) reaches 64°F for one (1) minute or

the defrost time has exceeded eight (8) minutes. Defrost mode setting (n04) offers termination

options for different geographical conditions.

a) TA is between 41°F and 59 °F: TH ≤ 30°F, Delta T = 18°F

b) TA is between 19°F and 41°F: TH ≤ 30°F, Delta T = 12~18°F

c) TA is less than 19°F: TH < 9°F, accumulative compressor run time ≥ 80 minutes

TH back-up running: TA < 59°F and LP ≤ 90psi, accumulative compressor run time ≥ 60 minutes

a) MRT is 3.5 hours if TA is less than 23°F

b) MRT is 2 hours if TA is between 23°F and 43°F

Start-up control is enforced to complete, then wait another 5 minutes to activate the defrost operation.

a) Defrost in heavy snow area will extend defrost for one (1) minute, but reduce the heating time to

execute more defrost cycles.

b) Defrost in light snow area will reduce defrost for 30 seconds.

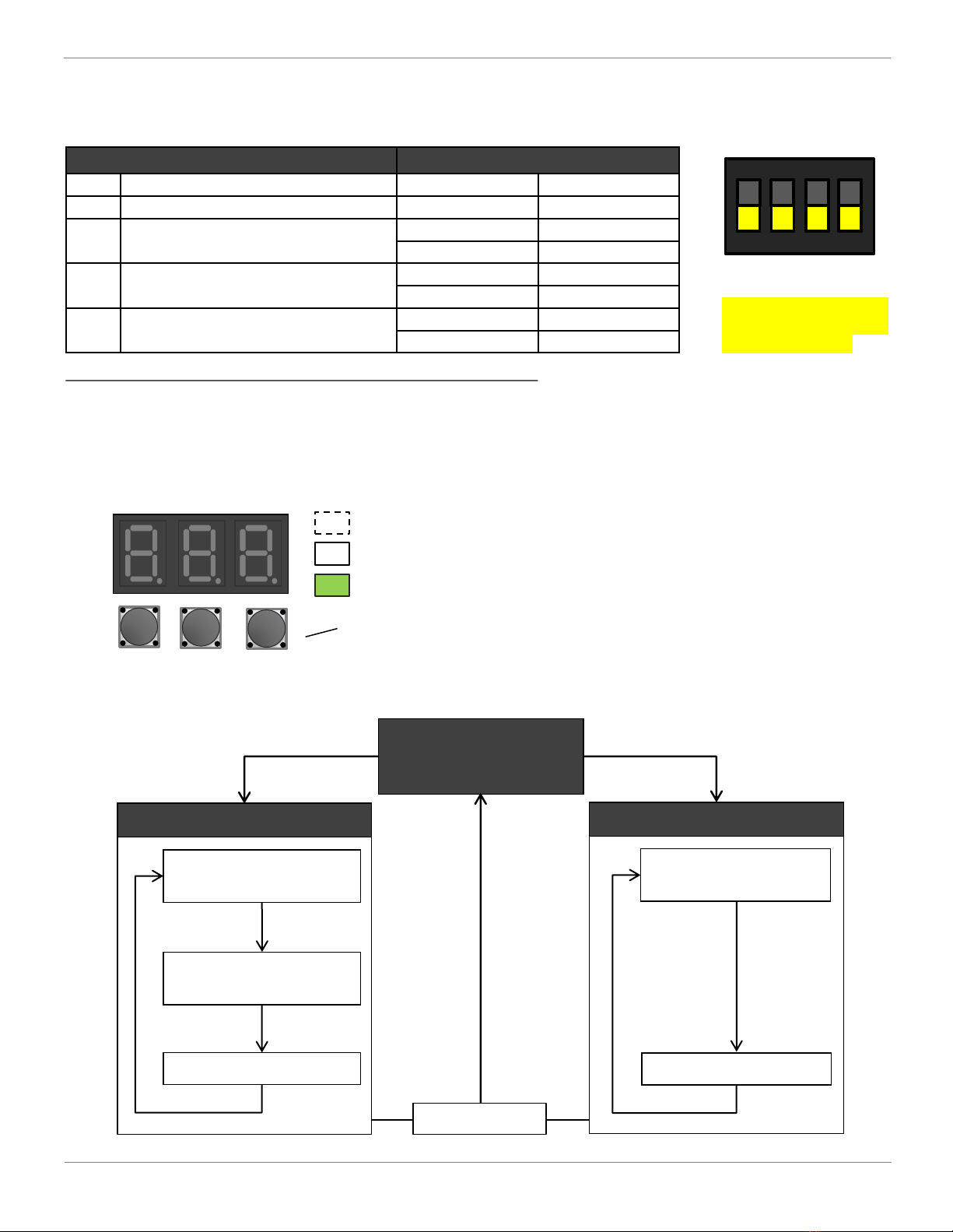

1 2 3 4

ON DIP

SW1 on ODU PCB

SW1_3: AC / HP

Switch

9/62

ESI (Ultra) Service Manual www.ecoer.com

03.2021Manufacturer reserves the right to change specifications or designs without notice.

2.2.2.3AUTO charge mode and pump down function

Actuator

AUTO charge mode OR

Pump down

in cooling

Pump down in heating

Compressor (INV)

2ton: 56rps→26rps

3ton: 66rps→36rps

4ton: 56rps→26rps

5ton: 66rps→36rps

2ton: 66rps→26rps

3ton: 80rps→36rps

4ton: 58rps→26rps

5ton: 70rps→36rps

Outdoor fan (FAN) Cooling fan control Heating fan control

Reversing valve (ST1) De-energized Energized (208/230Vac)

Electronic expansion valve (EEV) 480pls PI control to maintain DSH

AUTO charge mode locks the compressor speed in cooling. The LED will display the refrigerant

coefficient if both the liquid line sub-cooling (SC) and compressor suction superheat (SH) of ESI

system are proper. To keep the best Ecoer Smart Inverter (ESI) systems’ performance and reliability,

the following requirements should be followed in cooling.

•If the LED displays “--”in AUTO charge mode for more than 20 minutes, stop charging and use a

wrench to clockwise the TXV to ensure SH is no less than 7゜F.

•In case that the cooling performance is terrible due to improper superheat (i.e. SH >20゜F). Adjust

the system according to

1. Activate AUTO charge mode to fix compressor frequency (RPS) by press BS4 for 5 seconds on

outdoor PCB. Run the system for 15~20 minutes and check refrigerant coefficient number

from LED display or ESS Pro App, add refrigerant unless the coefficient number is less

than 0.6.

2. Open the front panel of the indoor unit, use a wrench to counterclockwise the TXV until SH

≤20゜F. This will make more refrigerant flow into indoor coil for better cooling performance.

Pump down locks the compressor speed depending on the

actual mode. On the thermostat, set coolingfor refrigerant recovery

to condenser or heating for refrigerant migration to indoor coil and

line sets. Hold and press BS4 button for 5 seconds until you see

blinking ‘7’, press BS2 button in one minute to get ‘8’.

Once pump down is activated. The low pressure will be displayed on

LED. *NOTE Low pressure protection is valid if LP <24.5psig.

SEG1 SEG2 SEG3

SEG1 SEG2 SEG3

SC

6~18゜FTarget SC and SH

in cooling SH

7~20゜F

BS1 BS2 BS3

BS4

10/62

ESI (Ultra) Service Manual www.ecoer.com

03.2021Manufacturer reserves the right to change specifications or designs without notice.

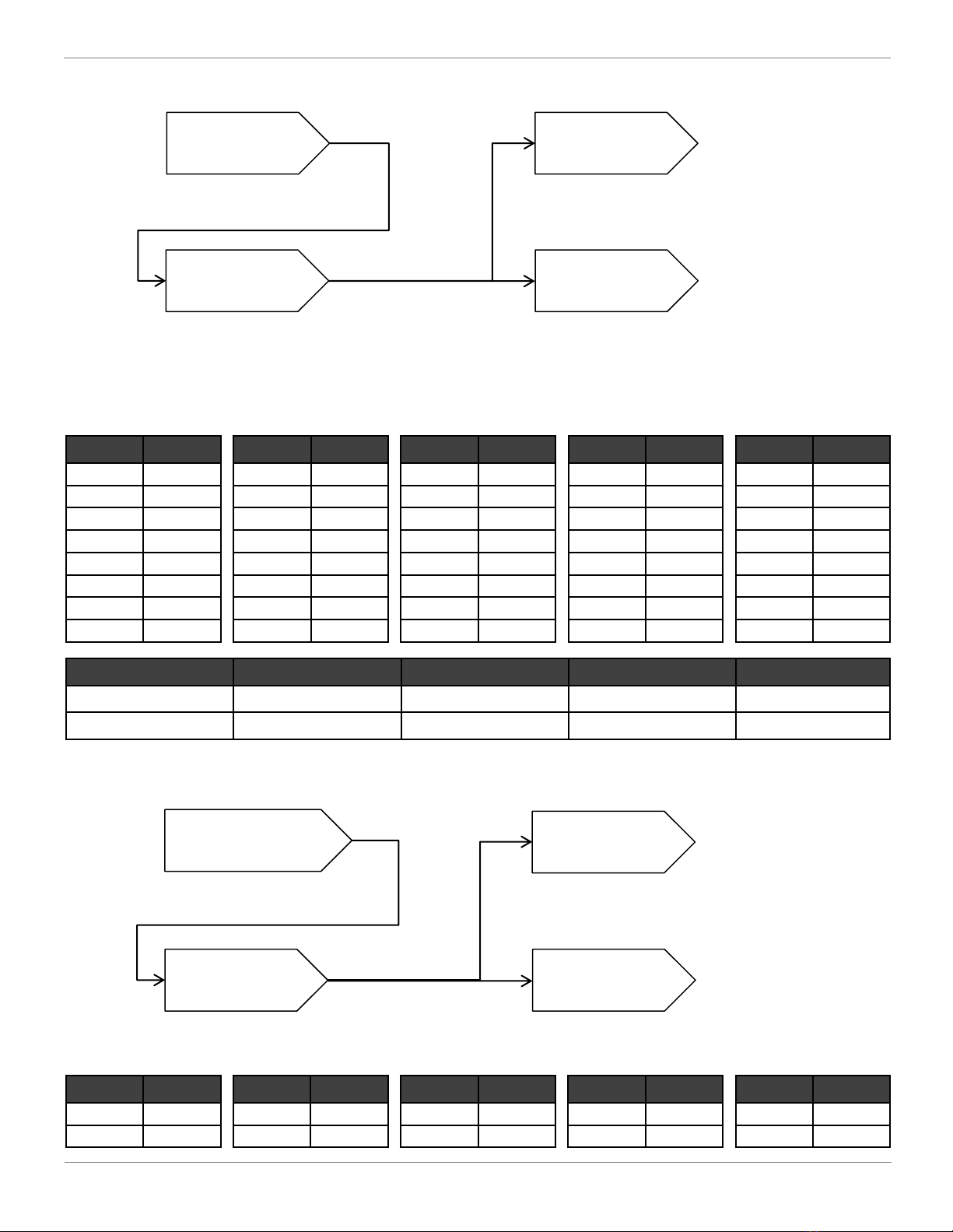

2.2.2.5 Fan control

[Fan RPM VS STEP]

STEP RPM STEP RPM STEP RPM STEP RPM STEP RPM

0 0 2 450 4680 6830 8930

1350 3550 5780 7880 9980

2.2.2.4 Compressor control

[Compressor RPS VS STEP]

STEP RPS STEP RPS STEP RPS STEP RPS STEP RPS

1 - 9 28 17 44 25 60 33 76

2 - 10 30 18 46 26 62 34 78

316 11 32 19 48 27 64 35 80

418 12 34 20 50 28 66 36 82

520 13 36 21 52 29 68 37 84

622 14 38 22 54 30 70 38 86

724 15 40 23 56 31 72 39 88

826 16 42 24 58 32 74 40 90

Outdoor Capacity

2Ton 3Ton 4Ton 5Ton

Cooling Max RPS 70 80 66 76

Heating Max RPS 80 90 80 90

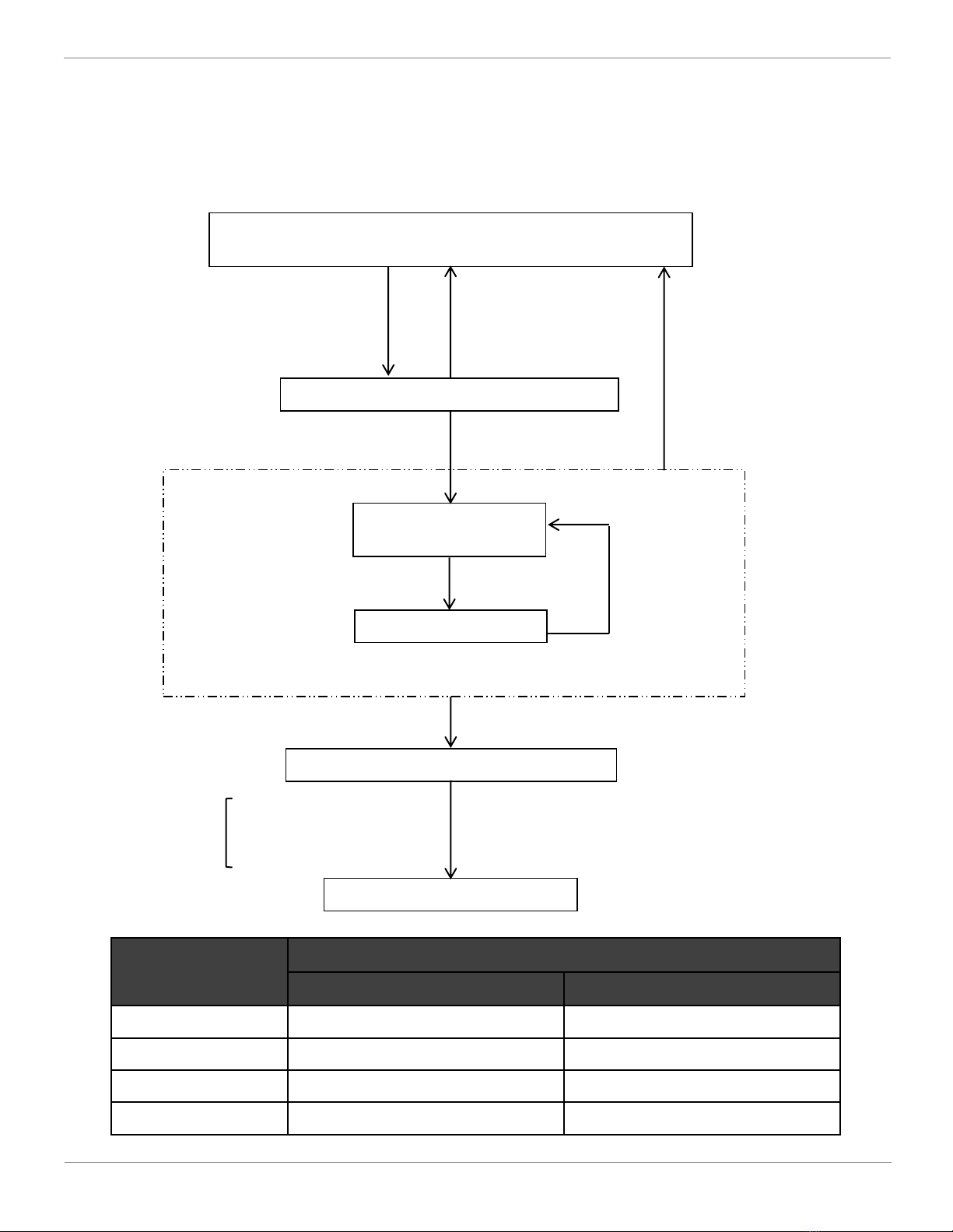

Start-up control

PI control

Directive control

•Pressure differential control

•MAX time (cooling) ≤ 10 minutes

•MAX time (heating) ≤ 45 minutes

Fixed speed

Depending on the load of the space.

Standby

MAX 6 minutes for pressure

equalization

Start-up control

Pressure control

Directive control

Standby after

getting start signal

MAX STEP •Cooling fan control by high pressure

•Heating fan control by low pressure

Fixed speed

11/62

ESI (Ultra) Service Manual www.ecoer.com

03.2021Manufacturer reserves the right to change specifications or designs without notice.

2.2.2.6 Electronic expansion valve (EEV) control

NOTE: Heating DSH should be between 25 ゜F and 50 ゜F with proper refrigerant level.

•Overcharged: DSH is less than 18 ゜F with EEV opening < 72pls.

•Undercharged: DSH is higher than 50 ゜F with EEV opening ≥ 460pls

2.2.2.7 Silent mode

In order to decrease the noises produced by condensing unit, the crucial noise resources should be

limited. Once the silent mode has been activated by n05, n06 and n07 (refer to field setting), both the

highest compressor frequency (RPS) and fan speed (RPM) are limited.

Max Fan Speed (RPM)

Condenser Capacity Standard Mode Silent Mode (Level 1) Super Silent Mode (Level 2)

2Ton 830 680 550

3Ton 930

Cooling: 830

Heating: 780

680

4Ton 880 830 780

5Ton 980 880 780

Cooling Max Compressor RPS

Condenser Capacity Standard Mode Silent Mode (Level 1) Super Silent Mode (Level 2)

2Ton 70 66 56

3Ton 80 76 70

4Ton 66 66 56

5Ton 76 68 58

Maximum compressor frequency

Maximum fan speed

Heating Max Compressor RPS

Condenser Capacity Standard Mode Silent Mode (Level 1) Super Silent Mode (Level 2)

2Ton 80 70 60

3Ton 90 78 72

4Ton 80 62 52

5Ton 90 70 60

Start-up control

PI control

Directive control

•Cooling: 480pls

•Heating: Temperature differential control

Fixed opening

Standby after

getting start signal

•Cooling: 360pls→480pls

•Heating: 360pls→0pls •Cooling: 480pls

•Heating: Depending on the compressor

discharge superheat (DSH). *NOTE

DSH

25~50゜F

12/62

ESI (Ultra) Service Manual www.ecoer.com

03.2021Manufacturer reserves the right to change specifications or designs without notice.

2.2.3. Protection controls

HP≥C

Normal operation

(Upper limit compressor step = Max. step)

HP<D

Upper limit compressor

step: Decrease 2step

Current step maintained

After 15 sec.

HP≥A

High pressure abnormal standby

HP≥B

Upper limit compressor step = Current step

HP≥B

Compressor restarts

HP<D

Symbol

EODA18H-2436/4860

Cooling Heating

A545psig [3.8MPa] 545psig [3.8MPa]

B493psig [3.4MPa] 479psig [3.3MPa]

C479psig [3.3MPa] 450psig [3.1MPa]

D464psig [3.2MPa] 421psig [2.9MPa]

2.2.3.1 High pressure protection control

High pressure (HP) protection control is used to prevent extremely high pressures in the system and

protect the compressor.

Restart permission=ON

and

HP<D

13/62

ESI (Ultra) Service Manual www.ecoer.com

03.2021Manufacturer reserves the right to change specifications or designs without notice.

LP<C

Normal operation

(Upper limit compressor step = Max. step)

LP≥D

Upper limit compressor

step: Decrease 2steps

Current step maintained

After 15 sec.

LP<A

Low pressure abnormal standby

LP<B

Upper limit compressor step = Current step

LP<B

Compressor restarts

LP≥D

Symbol EODA18H-2436/4860

A 24.5psig [0.17MPa]

B 43.5psig [0.30MPa]

C 61.0psig [0.42MPa]

D 72.5psig [0.50MPa]

2.2.3.2 Low pressure protection control in cooling mode

Low pressure (LP) protection control in cooling is used to protect compressor against the transient

decrease of low pressure.

Restart permission=ON

and

LP≥D

14/62

ESI (Ultra) Service Manual www.ecoer.com

03.2021Manufacturer reserves the right to change specifications or designs without notice.

2.2.3.3 Discharge temperature protection control

This discharge temperature (TD) protection control is used to protect the compressor internal

temperature against a malfunction or transient increase of discharge pipe temperature.

TD≥C

Normal operation

(Upper limit compressor step = Max. step)

TD<D

Upper limit compressor

step: Decrease 2steps

Current step maintained

After 15 sec.

TD≥A

Discharge temperature abnormal standby

TD≥B

Upper limit compressor step = Current step

TD≥B

Compressor restarts

TD<D

Symbol

EODA18H-2436/4860

Cooling Heating

A248°F (120°C) 230°F (110°C)

B230°F (110°C) 212°F (100°C)

C212°F (100°C) 194°F (90°C)

D194°F (90°C) 176°F (80°C)

Restart permission=ON

and

TD<D

15/62

ESI (Ultra) Service Manual www.ecoer.com

03.2021Manufacturer reserves the right to change specifications or designs without notice.

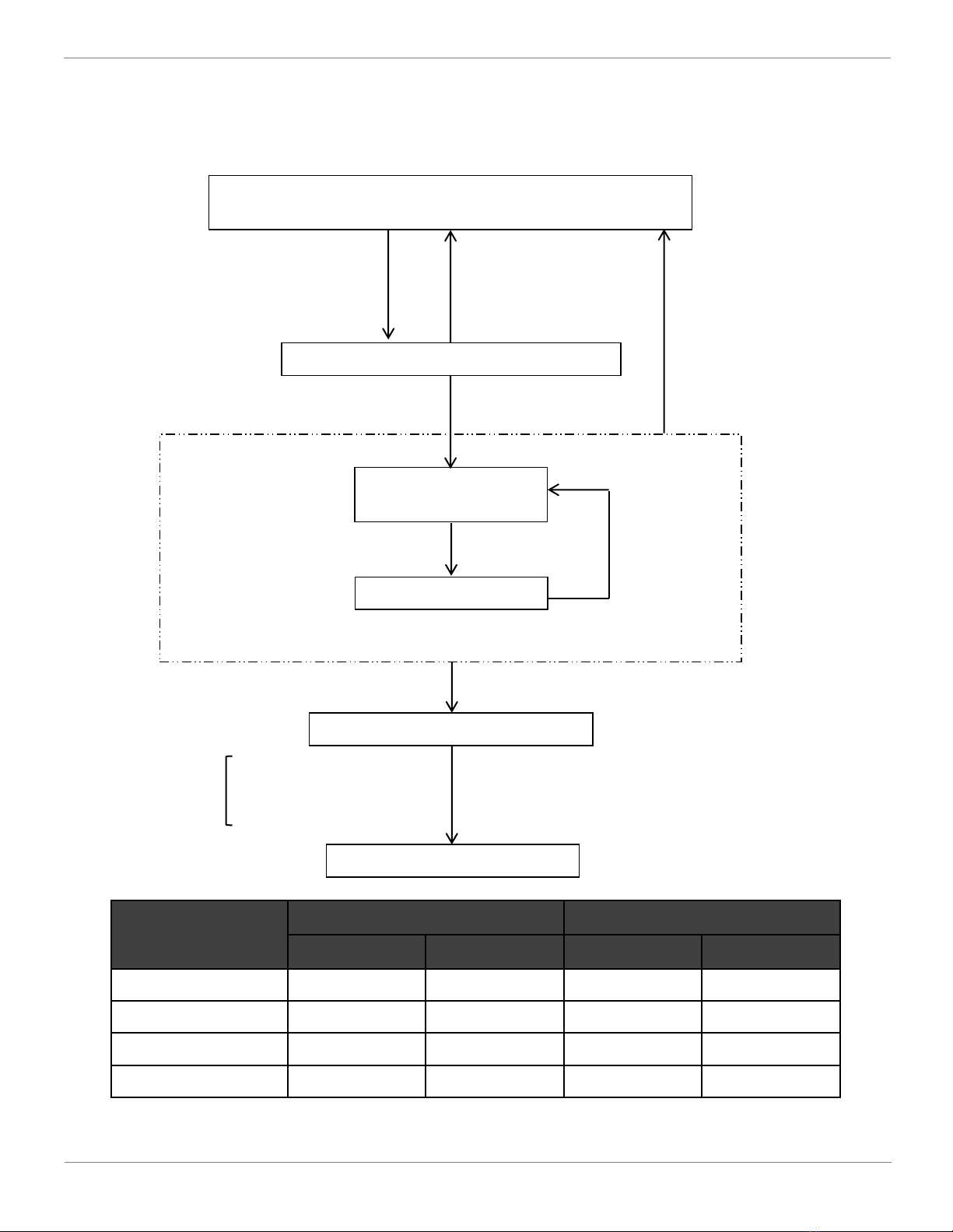

2.2.3.4 INV Module temperature protection control

Inverter module temperature (TF) protection control is performed to prevent tripping due to an

abnormal increase in temperature.

TF≥C

Normal operation

(Upper limit compressor step = Max. step)

TF<D

Upper limit compressor

step: Decrease 1step

Current step maintained

After 15 sec.

TF≥A

Inverter heat sink temperature abnormal standby

TF≥B

Upper limit compressor step = Current step

TF≥B

Compressor restarts

TF<D

Symbol

EODA18H-2436 EODA18H-4860

Cooling Heating Cooling Heating

A181°F (83°C) 181°F (83°C) 176°F (80°C) 167°F (75°C)

B174°F (79°C) 158°F (70°C) 158°F (70°C) 149°F (65°C)

C167°F (75°C) 153°F (67°C) 151°F (66°C) 142°F (61°C)

D162°F (72°C) 147°F (64°C) 145°F (63°C) 136°F (58°C)

Restart permission=ON

and

TF<D

16/62

ESI (Ultra) Service Manual www.ecoer.com

03.2021Manufacturer reserves the right to change specifications or designs without notice.

2.2.3.5 Compressor over-current protection control

This control is performed to prevent tripping due to an abnormal transient compressor current (IA).

IA≥C

Normal operation

(Upper limit compressor step = Max. step)

IA<D

Upper limit compressor

step: Decrease 1step

Current step maintained

After 30 sec.

IA≥A

Inverter current abnormal standby

IA≥B

Upper limit compressor step = Current step

IA≥B

Compressor restarts

IA<D

Symbol

EODA18H-2436 EODA18H-4860

Cooling Heating Cooling Heating

A16A 16A 20A 20A

B 9.2A 9.5A 12.1A 12.1A

C 8.6A 9.1A 11.7A 11.7A

D 8.0A 8.5A 11.2A 11.2A

Restart permission=ON

and

IA<D

17/62

ESI (Ultra) Service Manual www.ecoer.com

03.2021Manufacturer reserves the right to change specifications or designs without notice.

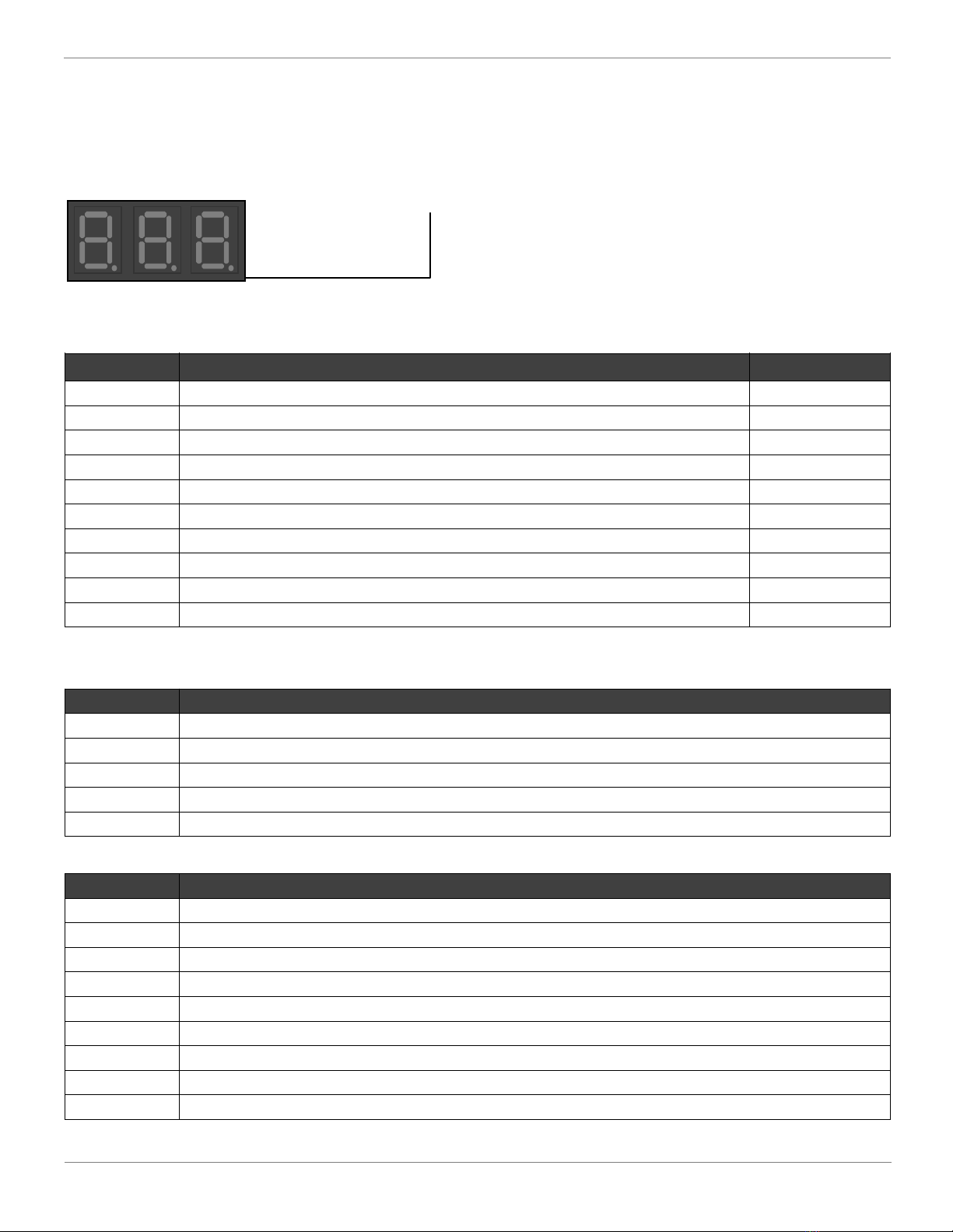

LED on main control board can display the operating status of outdoor unit (ODU).

2.3 Field Setting

2.3.1 Default display

SEG1: Normally blank, but it displays codes “0to 9”accordingly if there is damaged sensor and

command response.

SEG2: Normally blank, but it will display code accordingly as below if outdoor unit is running under

limited condition.

SEG3: It displays outdoor unit’s operation mode.

SEG1 Code

Description Time

0 Software is updating through IoT device About 5 min.

1 High pressure sensor (HP) fault back-up running 7 Days

2 Low pressure sensor (LP) fault back-up running 7 Days

3 Compressor discharge temperature sensor (TD) fault back-up running 7 Days

4 IPM module temperature sensor (TF) fault back-up running 7 Days

5 Ambient temperature sensor (TA) fault back-up running 120 Days

6 Defrost sensor (TH) fault back-up running 90 Days

7 Compressor suction temperature sensor (TS) fault back-up running 120 Days

8 Liquid line temperature sensor (TL) fault back-up running 120 Days

9 IoT command response -

SEG2 Code Description

0 Running under high pressure (HP) limit

1 Running under low pressure (LP) limit

2 Running under discharge temperature (TD) limit

3 Running under IPM module temperature (TF) limit

4 Running under compressor current limit

SEG3 Code Description

0 Stop (Y signal de-energized)

1 Ready to start-up (Y signal energized) *Note

2 Cooling

3 Heating

4 Oil return

5 Defrost

6 Manual defrost

7 AUTO charge mode in cooling

8 Pump down

Note: Compressor waits three to eight minutes to restart.

7 segment display instructions

SEG1 SEG2 SEG3

18/62

ESI (Ultra) Service Manual www.ecoer.com

03.2021Manufacturer reserves the right to change specifications or designs without notice.

Modes list (SEG3 Display)

SEG1 SEG2 SEG3

Stop or standby (Y signal de-energized)

SEG1 SEG2 SEG3

Ready to start-up (Y signal energized)

(6 to 8 minutes for pressure equalization to restart)

SEG1 SEG2 SEG3

Cooling

SEG1 SEG2 SEG3

Heating

SEG1 SEG2 SEG3

Oil return

SEG1 SEG2 SEG3

Defrost

SEG1 SEG2 SEG3

Manual defrost

SEG1 SEG2 SEG3

AUTO charge mode in cooling

SEG1 SEG2 SEG3

Pump down

19/62

ESI (Ultra) Service Manual www.ecoer.com

03.2021Manufacturer reserves the right to change specifications or designs without notice.

2.3.2 Setting by dip switches

2.3.3 Setting by pressing buttons

Query and setting operations can be done by pressing buttons on main control board.

SW1 dip switch Description

NO.Setting item Status Content

1Reserved - -

2Capacity selection ON 2 or 4 Ton

OFF (factory) 3 or 5 Ton

3AC only/Heat pump selection ON AC only

OFF (factory) Heat pump

4Command *response for IoT ON No

OFF (factory) Yes

* Remote field setting, troubleshooting, software updates and so on.

Condensing units’ functions can be applied by dipping switch and pressing buttons.

1 2 3 4

ON DIP

SW1

Use minor straight

screwdriver to dip switch.

Must power off the unit

for at least 2 minutes to

activate the change.

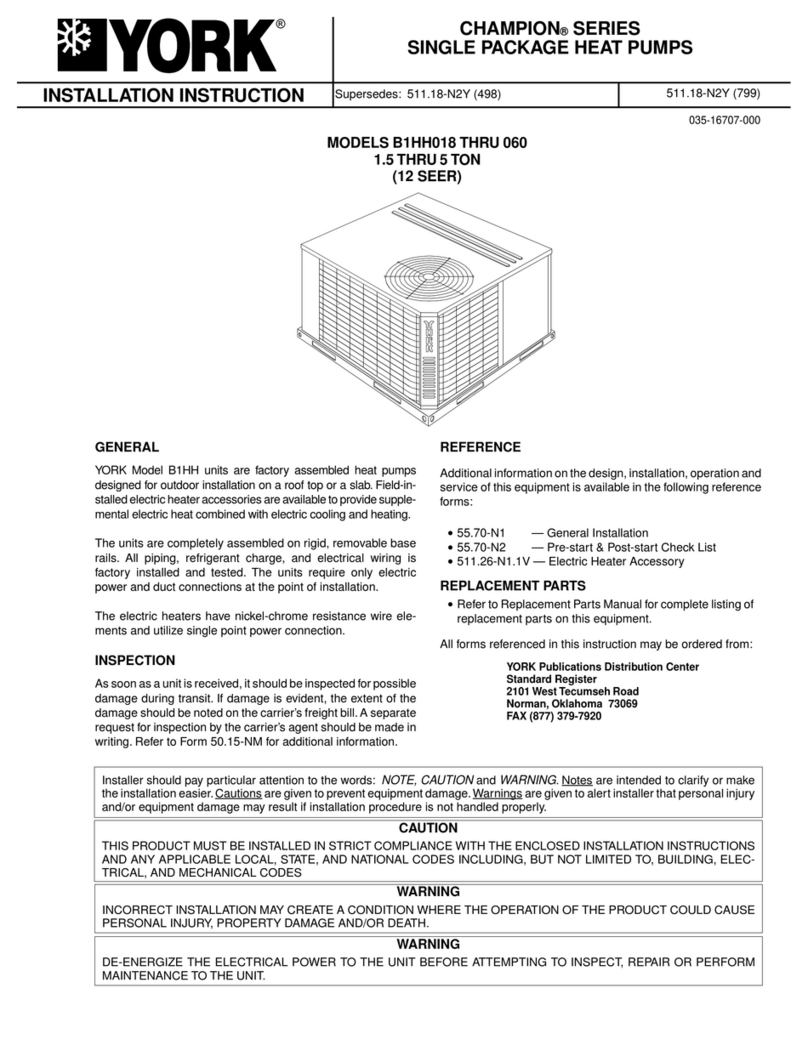

BS1

BS1: Menu or back button

BS2: UP button

BS3: Spot check and confirm button

Remarks: Press or tip any directions are valid.

BS2 BS3

Press buttons

Off

Blinking

On

SEG1 SEG2 SEG3

Setting mode

Default mode

(Press BS3 button to

spot check running data)

Press and hold BS1for 5 seconds

to set special functions.

Press BS3

Symbol selection by

pressing BS2 button

Setting item selection

by pressing BS2 button

Contents display

Press BS3

Press BS3

Query settings

Press BS3

Symbol selection by

pressing BS2 button

Contents display

Press BS3

Press BS1 once to query

current setting.

Press BS1 once

20/62

ESI (Ultra) Service Manual www.ecoer.com

03.2021Manufacturer reserves the right to change specifications or designs without notice.

System states can be showed on the 7 segments display (LED) of outdoor unit. Press BS3button to get

code number and corresponding detailed information with an interval of one second.

Example:

Code number Detailed information

Remark:

When multi-error codes exist at the same time, each code will be displayed one by one with an interval of one second.

SEG1 SEG2 SEG3 SEG1 SEG2 SEG3

Default mode (Spot check)

No. Number content Example Description

Default Refer to default display instructions 902

9: Command

0: Running under high pressure limit

2: Cooling mode

01-Outdoor unit type and capacity H3 H: heat pump C: AC only

3: 3Ton

02-Liquid line sub-cooling 10 10°F

03-Compressor suction superheat 18 18°F

04-Compressor speed 56 56RPS

05-Electronic expansion valve opening 360 360pls

06-Step of fan 8 The 8th step

07-Low pressure (LP sensor) 145 145psig

08-High pressure (HP sensor) 350 350psig

09-Outdoor ambient temp. (TA) 95 95°F

10-Compressor suction temp. (TS) 70 70°F

11-Compressor discharge temp. (TD) 170 170°F

12-Defrost sensor temp. (TH) 80 80°F

13-Liquid line temp. (TL) 70 70°F

14-Inverter module temp. (TF) 150 150°F

15-Target evaporating temp. (Tes) 43 43°F

16-Current evaporating temp. (Te)45 45°F

17-Target condensing temp. (Tcs)104 104°F

18-Current condensing temp. (Tc) 112 112°F

19-Compressor DC current 10.1 10.1A

20-Undercharged refrigerant signal 1 0: None 1: Level 1 2: Level 2 (severe)

21-Main software version A01 A01 version

22-Inverter software version b01 b01 version

23-Current fault E1 Display up to 5 *codes

24-The last fault F1 --: None

25-Fault before the last fault F2 --: None

Table of contents

Other Ecoer Heat Pump manuals

Popular Heat Pump manuals by other brands

Metro Therm

Metro Therm METROAIR I 8 Installer manual

POOLEX

POOLEX Nano Action Reversible Installation and user manual

York

York B1HH018 installation instructions

MICROWELL

MICROWELL HP 1000 GREEN Installation and user manual

Nortek

Nortek Q5RD Series installation instructions

Panasonic

Panasonic WH-MDC05H3E5 Service manual