Ecoer 2436 User manual

Other manuals for 2436

3

This manual suits for next models

1

Table of contents

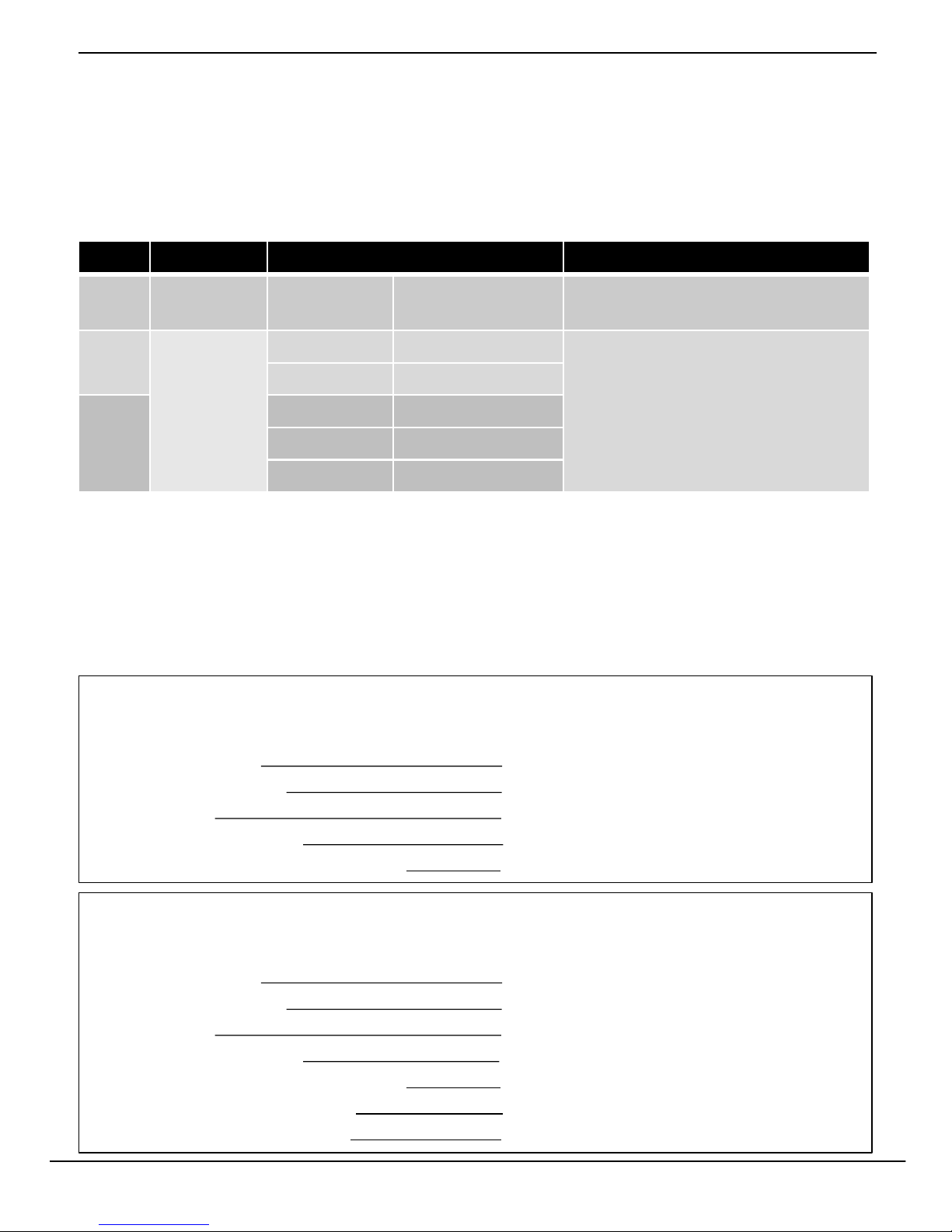

Other Ecoer Heat Pump manuals

Popular Heat Pump manuals by other brands

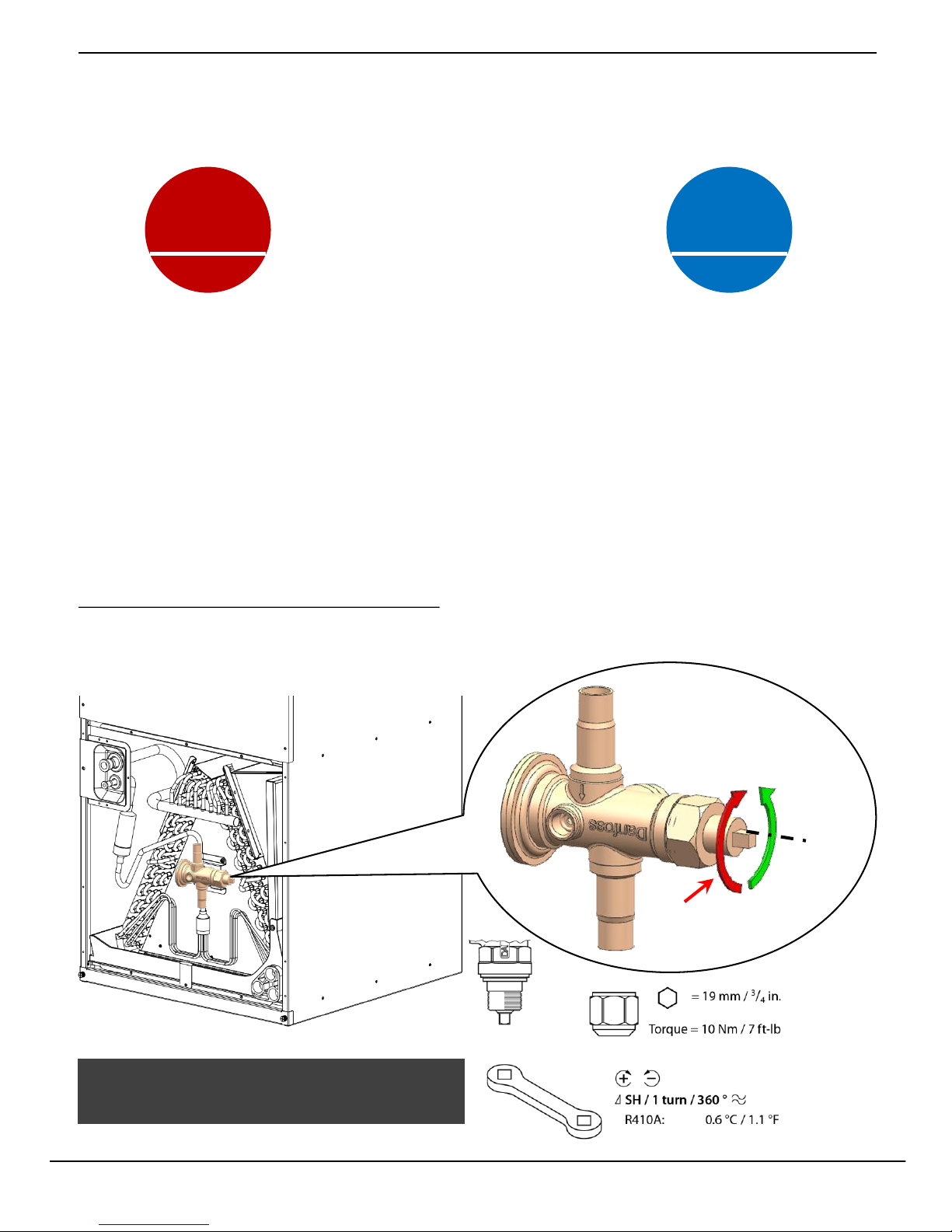

Danfoss

Danfoss Optyma OP-LPQE Series instructions

Viessmann

Viessmann Vitocal 100-A Series Assembly and servicing instructions

Panasonic

Panasonic WH-MXC09D3E5 operating instructions

TERSUS

TERSUS BCPI7 Installation & operation manual

Bitzer

Bitzer K033N operating instructions

Daikin

Daikin Super Multi NX FTXS20G2V1B Service manual

Dimplex

Dimplex SIH 90TU operating instructions

Gree

Gree GRS-Cm18PdRe/NhA-M owner's manual

Technibel

Technibel Liberty300 Solar Installation and operating instructions

Lennox

Lennox XP16 Brochure & specs

Allied

Allied 2HP13/14 Installation/start-up instructions/homeowners information manual

Raypak

Raypak HEAT-COOL RHP 115HC Brochure & specs

Panasonic

Panasonic WH-MDC09C3E5 Servise manual

Lennox

Lennox Signature XP15-024 installation instructions

DeDietrich

DeDietrich EASYLIFE Alezio G AWHP 4.5MR-EMC 24/28 MI... user guide

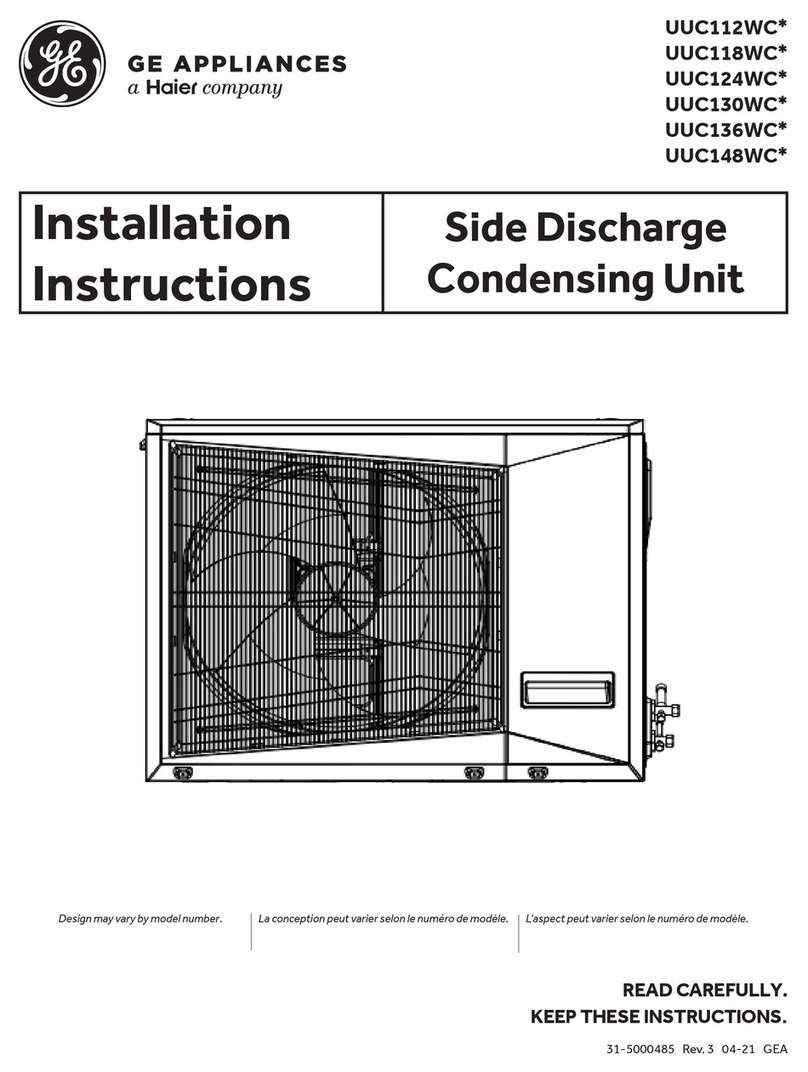

GE

GE UUC112WC Series installation instructions

DURASTAR

DURASTAR DRPTAC07Y41G1A Owners and installation manual

Arden

Arden BLN-006TC1 Service manual