Installation Manual and Owner’s Guide WHO-321064-NG, WHO-321064-LP

ECOHOT TM

11 of 27

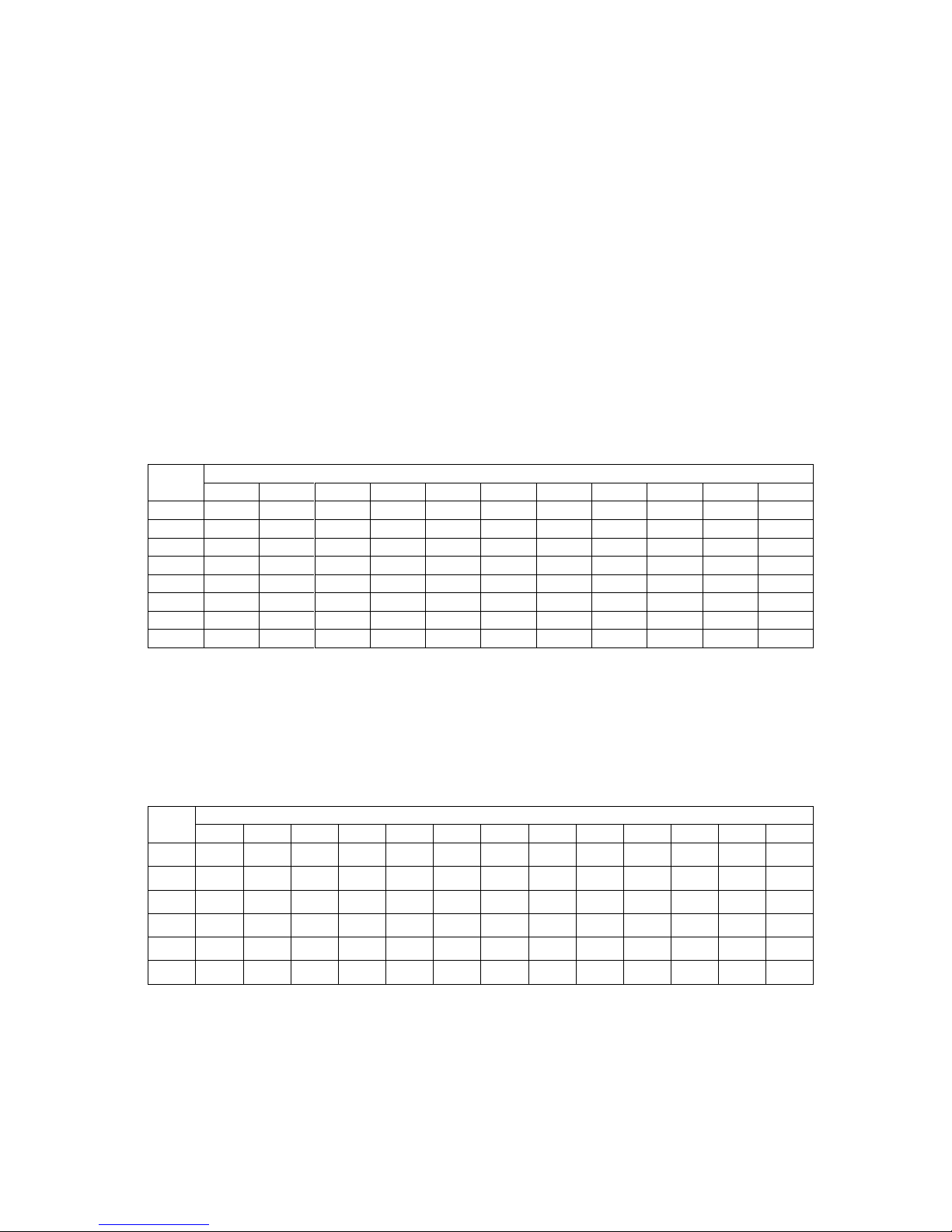

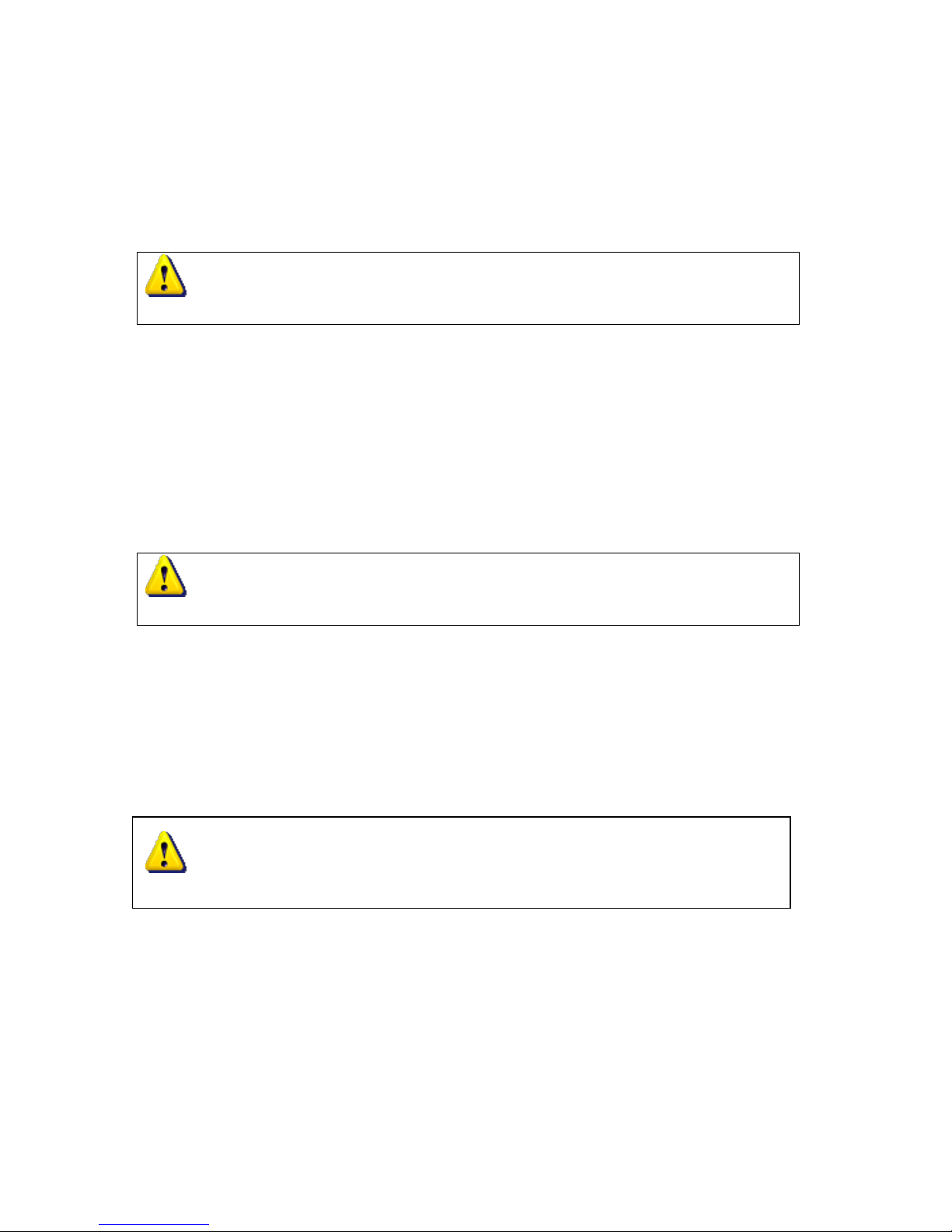

3. Minimum Manifold Pressure adjustment

◆Adjust Dip Switch 1 to OFF position,

◆Use a small crossing screw driver adjust The Adjustable Resistance of PCB which marked

“MIN”, to meet the data of De-rating Manifold Min. Pressure from the De-rating Manifold

Pressure Table.

◆Then adjust Switch 2 to OFF position.

4. Check Manifold Pressure

◆Shut off all water taps, and unplug water heater’s power cord.

◆Plug the power cord and turn on all water taps, check the Maximum and Minimum

Manifold Pressure again as Step 2 and Step 3.

◆Seal back Manifold Pressure measuring point.

Water Connections

When facing the heater, the cold water inlet is on your right and the hot water outlet is on your left.

Although water piping throughout your structure may be other than copper, we recommend that

copper piping be used for at least three feet before and after the heater (follow local codes). Keep

water inlet pipe to no less than 3/4” diameter to allow the full flow capacity.

Remember that water pressure must be sufficient to activate the heater when drawing hot water

from the top floor. If the hot and cold connections to the heater are reversed, the heater will not

function. 3/4’’Copper or brass fittings work best when connected to the connectors. (See Fig. 2) The

flexible type connectors will make instillation easier and seals to the water valve by means of a

union connection with a washer type gasket at the joint. No pipe dope or thread tape is to be used at

this joint. Be certain there are no loose particles or dirt in the piping. Blow out or flush the lines

before connecting to the ECOHOTTM. Full port valves should be installed on both the cold water

feed line and the hot water outlet line to facilitate servicing the heater. For installation on a private

well system, be sure that the water pressure is set between 30 and 50 PSI. (See Fig. 2) Plumbing

connections for the ECOHOTTM

Connecting the pressure relief valve (PRV) (PRV Must be Brass, ¾” and, rated at 150 PSI),

Install PRV discharge line 6” above floor drain or to exterior of home (check local building codes).

(See Figure 2) A listed pressure relief valve must be installed at the time of installation and needs to

be ¾” and 150PSI. No valve is to be placed between the PRV and the heater. No reducing coupling

or other restriction may be installed in the discharge line.

The discharge line must be installed such that it allows complete drainage of both the pressure relief

valve (PRV) and the line to a suitable place for disposal.

The location of the PRV must be readily accessible for servicing or replacement, and be mounted as

close to the water heater as possible. See Fig. 2. To install the PRV, a suitable fitting connected to an

extension on a “T”fitting can be sweated to the hot water line. (See Fig. 2)

(PRV is included with this water heater for Canada only).

OPERATING INSTRUCTIONS

Before proceeding with the operation of the heater make sure that the system is filled with water.