TABLEOFCONTENTS

1PREMISE....................................................................................................................................................................................................................................3

1.1GeneralInformation......................................................................................................................................................................................................3

1.2IntendedUsers...............................................................................................................................................................................................................3

1.2.1UserQualifications...................................................................................................................................................................................................3

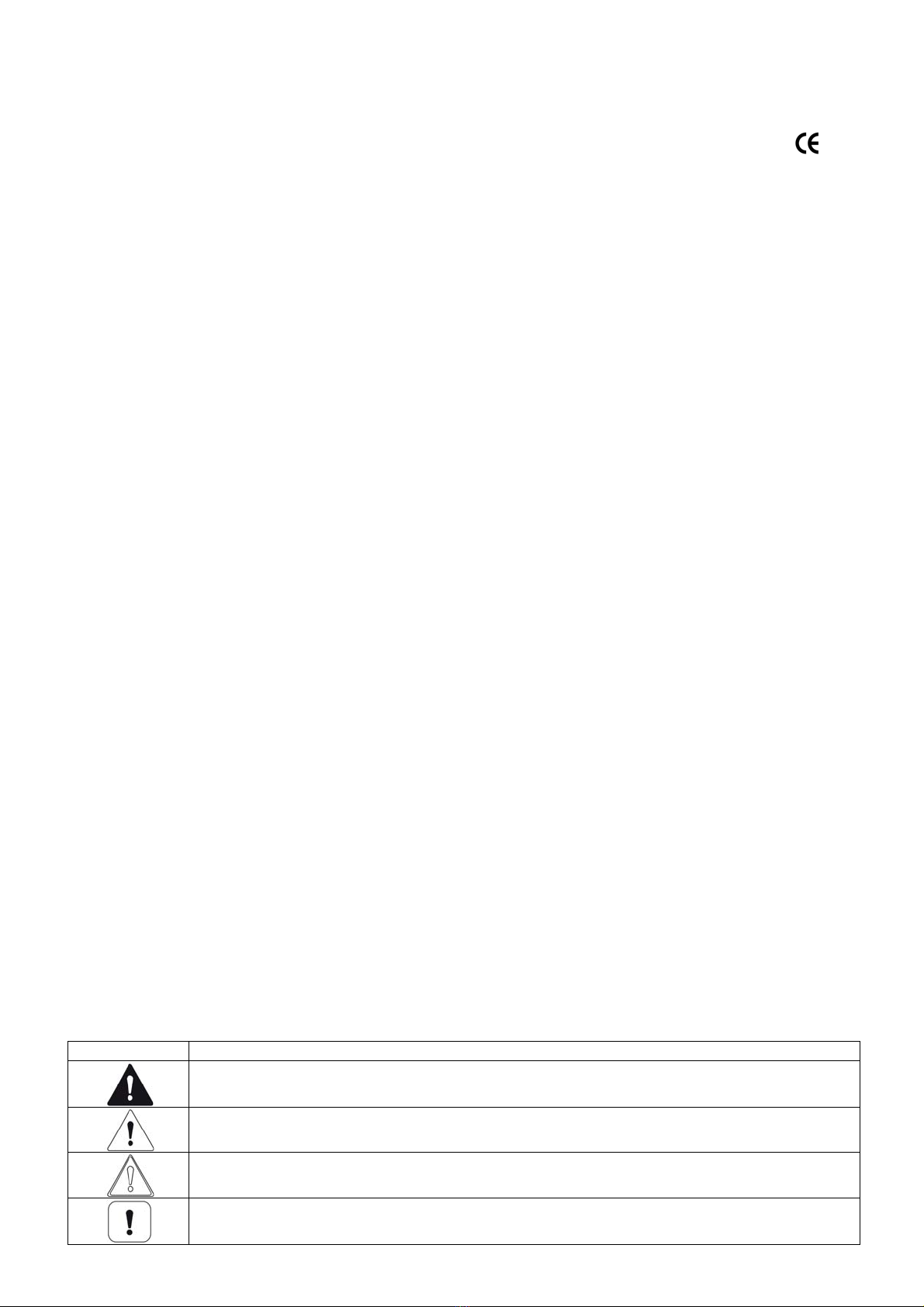

1.2.2Symbols....................................................................................................................................................................................................................3

2GENERALINFORMATION..........................................................................................................................................................................................................5

2.1ManufacturerIdentificationInformation.......................................................................................................................................................................5

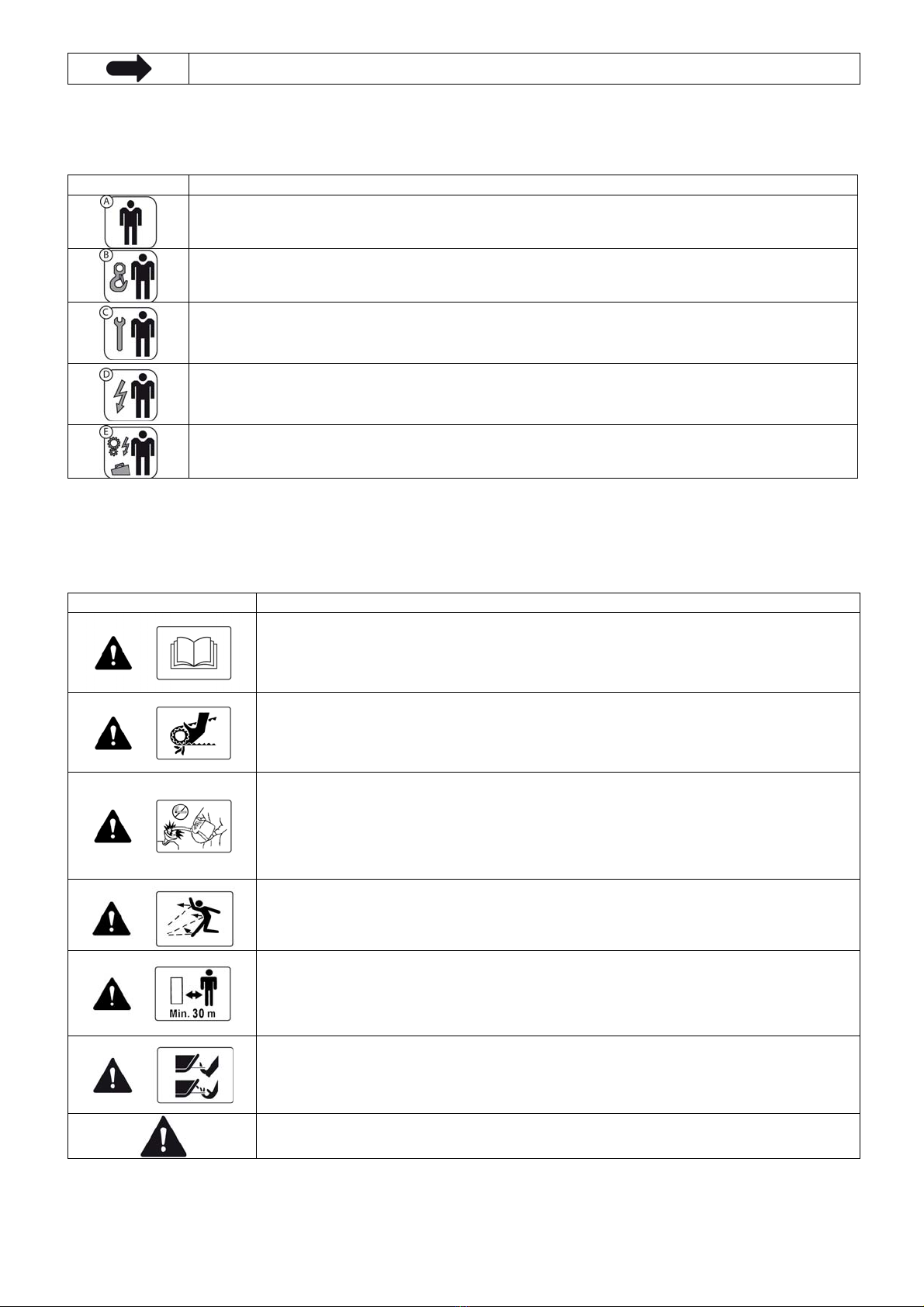

2.2Machineidentificationratingplatesanddata:..............................................................................................................................................................5

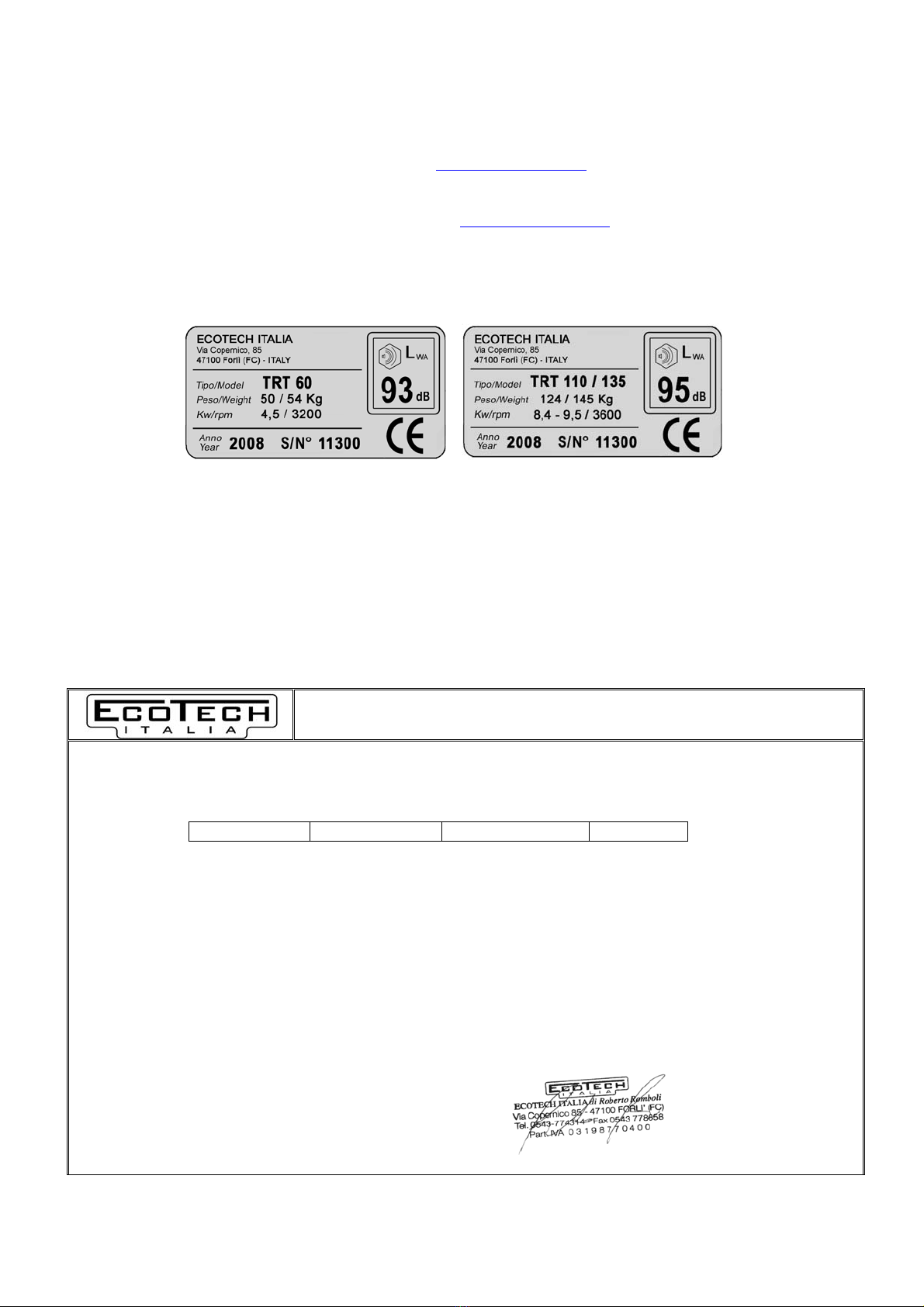

2.3Declarations...................................................................................................................................................................................................................

5

2.3.1DeclarationofConformity........................................................................................................................................................................................5

2.4SafetyRegulations.........................................................................................................................................................................................................6

2.5Guarantee......................................................................................................................................................................................................................6

2.6Attheexpenseoftheclient...........................................................................................................................................................................................6

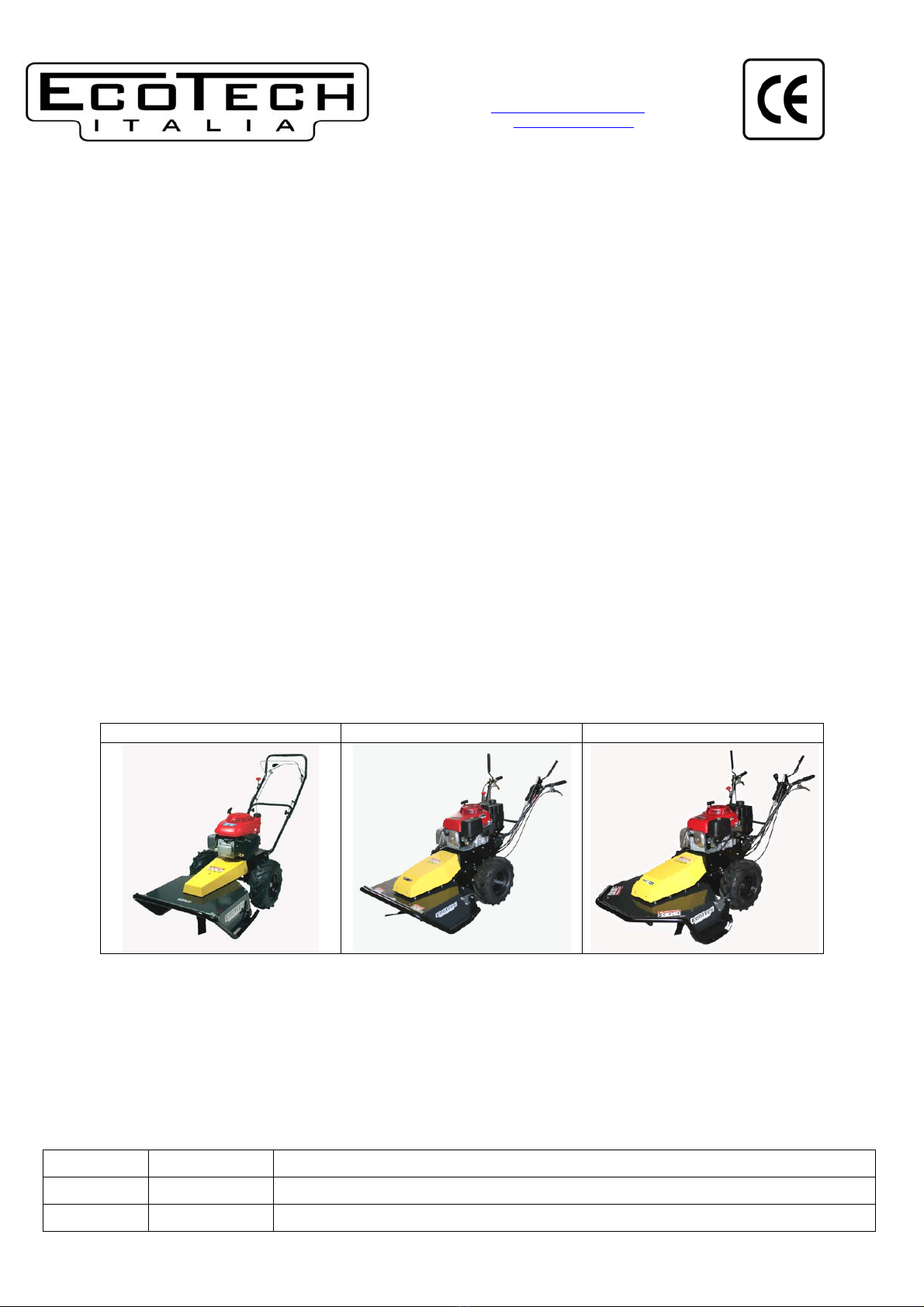

3DESCRIPTIONOFTHEMACHINE...............................................................................................................................................................................................6

3.1OperationalPrinciple.....................................................................................................................................................................................................7

3.1.1IntendedUse............................................................................................................................................................................................................7

3.2Dimensions....................................................................................................................................................................................................................7

3.3EnvironmentalConditions..............................................................................................................................................................................................7

3.4Lighting..........................................................................................................................................................................................................................7

3.5Vibrations.......................................................................................................................................................................................................................8

3.6Noiseemissions.............................................................................................................................................................................................................8

3.7TechnicalSpecifications.................................................................................................................................................................................................8

4INSTALLATION...........................................................................................................................................................................................................................8

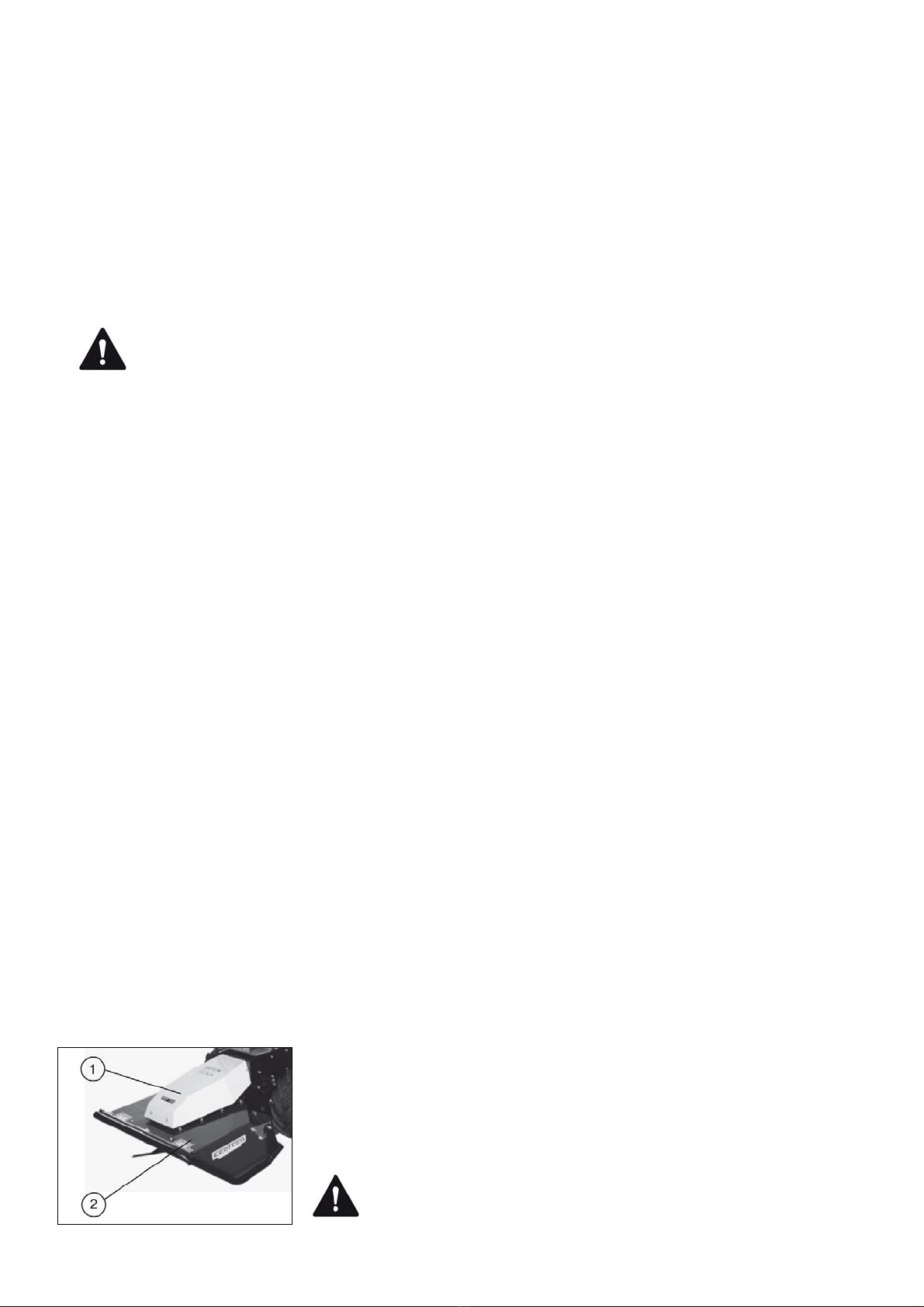

4.1TransportandHandling.................................................................................................................................................................................................8

4.1.1Packaging:.................................................................................................................................................................................................................8

4.2Storage...........................................................................................................................................................................................................................9

4.3Preliminarychecks.........................................................................................................................................................................................................9

4.4Scrapping.....................................................................................................................................................................................................................10

5SAFETY....................................................................................................................................................................................................................................10

5.1GeneralWarnings........................................................................................................................................................................................................10

5.2UseRestrictions...........................................................................................................................................................................................................10

5.3DANGERousZones.......................................................................................................................................................................................................10

5.4Safetydevices..............................................................................................................................................................................................................10

5.5Signs.............................................................................................................................................................................................................................11

5.6ResidualRisks...............................................................................................................................................................................................................11

6MACHINEUSE.........................................................................................................................................................................................................................11

6.1Adjustments.................................................................................................................................................................................................................11

6.2OperationalModes......................................................................................................................................................................................................12

6.2.1WORKINGONLEVELGROUND...............................................................................................................................................................................12

6.2.2WORKINGONASLOPE(onlyontheSwingversion)...............................................................................................................................................13

6.3Normalstop.................................................................................................................................................................................................................14

6.4Emergencystop...........................................................................................................................................................................................................14

7MAINTENANCE.......................................................................................................................................................................................................................14

7.1MaintenanceStatus.....................................................................................................................................................................................................14

7.2Cleaning.......................................................................................................................................................................................................................

15

7.3Lubrication...................................................................................................................................................................................................................15

7.4OrdinaryMaintenance.................................................................................................................................................................................................15

7.5ExtraordinaryMaintenance.........................................................................................................................................................................................15

7.6Diagnosticsandtroubleshooting.................................................................................................................................................................................16

8SPARESANDACCESSORIES.....................................................................................................................................................................................................17

8.1Service.........................................................................................................................................................................................................................17

8.2Spareparts...................................................................................................................................................................................................................17

9PURPOSEOFTHEINSTRUCTIONMANUAL..............................................................................................................................................................................17

9.1Conservationoftheinstructionmanual.......................................................................................................................................................................17

9.2InstructionManualupdatingmethods........................................................................................................................................................................18

9.3GLOSSARY....................................................................................................................................................................................................................18

9.3.1Glossary(AnnexIp.1.1.1Dir.2006/42/CE)............................................................................................................................................................18

9.3.2Otherdefinitions....................................................................................................................................................................................................18

Table1‐1:Symbolsconcerninginformationand/orprocedures..........................................................................................................................................................4

Table1‐2:Symbolsconcerningoperatorqualifications.......................................................................................................................................................................4

Table1‐3:Symbolsconcerningsafety..................................................................................................................................................................................................4

Table2‐1:ExtractoftheDeclarationofConformity............................................................................................................................................................................5

Table2‐2:SafetyRegulations..............................................................................................................................................................................................................6

Table3‐1:Dimensions.........................................................................................................................................................................................................................7

Table3‐2:TechnicalSpecifications......................................................................................................................................................................................................8

Table6‐1:Adjustments......................................................................................................................................................................................................................12

Table6‐2:Workingonaslope...........................................................................................................................................................................................................14

Table7‐1:ExtraordinaryMaintenance..............................................................................................................................................................................................15