MANUAL

MANUAL MANUAL

MANUAL

ILARIA ILARIA

ILARIA

ILARIA

7.3.1. Ignition phase

The stove is started by pressing the ON/OFF button for a few seconds. The procedure starts

by activating the ignition heater and continuously filling the pellets using the screw. The display

shows, in sequence, the messages ACCENDE [IGNITION], CARICA PELLET [FEEDING PEL-

LETS] and ATTESA FIAMMA [AWAITING FLAME]. After around 50 seconds (parameter Pr55), the

gear motor stops and the exhaust fan is started (at the speed set by parameter Pr16). Once the

pellets have been ignited and the flue gas temperature reaches 50°C (parameter Pr13), the heater

switches off and the flame stabilisation phase starts. The ignition phase ends when the tempera-

ture reaches 50°C, however for safety reasons and to protect the heater, this phase can last a

maximum of 16 minutes (parameter Pr02). If the pellets are not ignited, that is, the stove does

not reach 50°C in the 16 minutes available, the display will show the “MANCATA ACCENSIONE”

[FAILED IGNITION] alarm.

7.3.2. Flame stabilisation phase

In this phase, the screw conveyor feeds the pellets at the preset speed (parameter Pr05). When

the flue gas temperature exceeds 110°C (parameter Pr11) with a ramp of 3°C/minute, the stove is

ignited. In this flame stabilisation phase, the flue gas exhaust fan reaches the preset speed (pa-

rameter Pr17) and the temperature is measured to make sure it remains stable for a certain time

(parameter Pr02); after this, the operating phase starts. The initial start-up phases can be skipped

by holding button P2 (increase heat) for around 3 seconds; this automatically skips to the normal

operation phase.

7.3.3. Operating phase

The board has an input for an external thermostat. The operating mode of the stove changes ac-

cording to the external thermostat setting, the room thermostat setting and the room temperature

measured.

T

Amb

:

room temperature measured by the probe

T

SetAmb

:

room temperature set for the SET TEMP AMBIENTE [ROOM SET TEMP]

T

SetTerm

:

room temperature set on the external thermostat

• :

External thermostat closed (TAmb > TSetTerm): The display shows the message “ton” and the

stove works at the set heat output until the thermostat opens.

• :

External thermostat open (TAmb < TSetTerm): The stove works at the set heat output until

reaching TSetAmb (TAmb < TSetAmb), after which the economy phase starts (TAmb > TSetAmb).

-15- -16-

-15- -16-

7.3.1. Ignition phase

The stove is started by pressing the ON/OFF button for a few seconds. The procedure starts

by activating the ignition heater and continuously filling the pellets using the screw. The display

shows, in sequence, the messages ACCENDE [IGNITION], CARICA PELLET [FEEDING PEL-

LETS] and ATTESA FIAMMA [AWAITING FLAME]. After around 50 seconds (parameter Pr55), the

gear motor stops and the exhaust fan is started (at the speed set by parameter Pr16). Once the

pellets have been ignited and the flue gas temperature reaches 50°C (parameter Pr13), the heater

switches off and the flame stabilisation phase starts. The ignition phase ends when the tempera-

ture reaches 50°C, however for safety reasons and to protect the heater, this phase can last a

maximum of 16 minutes (parameter Pr02). If the pellets are not ignited, that is, the stove does

not reach 50°C in the 16 minutes available, the display will show the “MANCATA ACCENSIONE”

[FAILED IGNITION] alarm.

7.3.2. Flame stabilisation phase

In this phase, the screw conveyor feeds the pellets at the preset speed (parameter Pr05). When

the flue gas temperature exceeds 110°C (parameter Pr11) with a ramp of 3°C/minute, the stove is

ignited. In this flame stabilisation phase, the flue gas exhaust fan reaches the preset speed (pa-

rameter Pr17) and the temperature is measured to make sure it remains stable for a certain time

(parameter Pr02); after this, the operating phase starts. The initial start-up phases can be skipped

by holding button P2 (increase heat) for around 3 seconds; this automatically skips to the normal

operation phase.

7.3.3. Operating phase

The board has an input for an external thermostat. The operating mode of the stove changes ac-

cording to the external thermostat setting, the room thermostat setting and the room temperature

measured.

T

Amb

:

room temperature measured by the probe

T

SetAmb

:

room temperature set for the SET TEMP AMBIENTE [ROOM SET TEMP]

T

SetTerm

:

room temperature set on the external thermostat

• :

External thermostat closed (TAmb > TSetTerm): The display shows the message “ton” and the

stove works at the set heat output until the thermostat opens.

• :

External thermostat open (TAmb < TSetTerm): The stove works at the set heat output until

reaching TSetAmb (TAmb < TSetAmb), after which the economy phase starts (TAmb > TSetAmb).

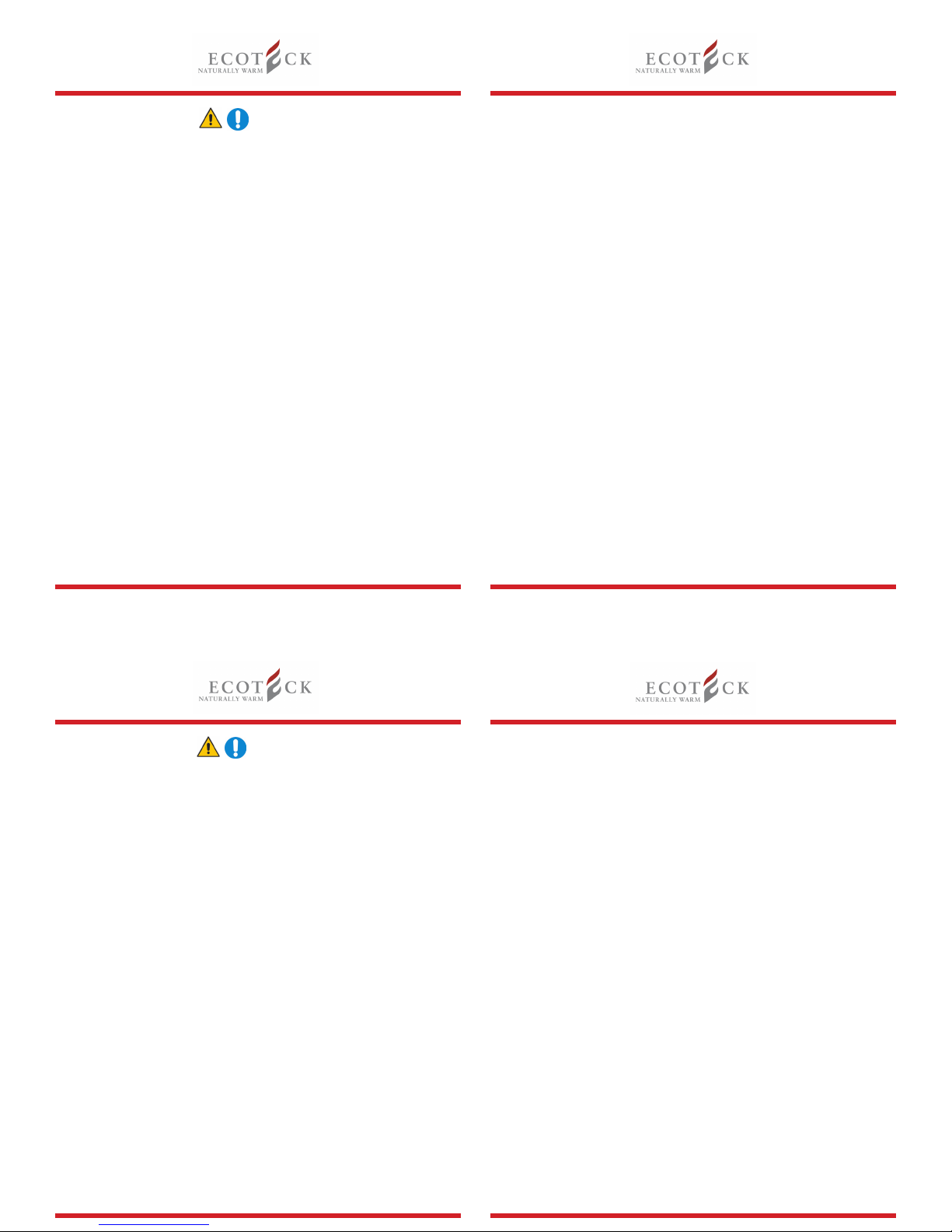

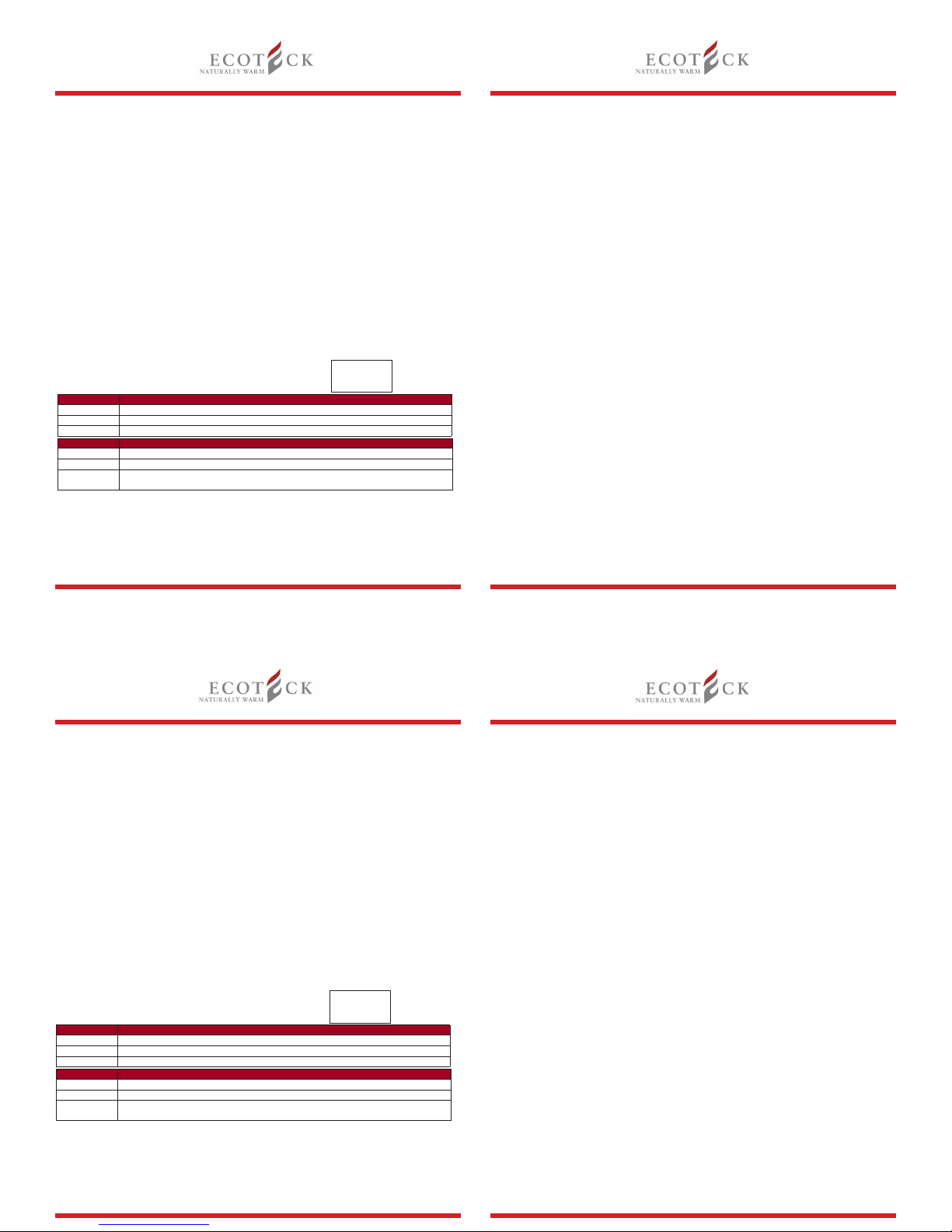

Display

The LCD shows all the messages required for the operation of the stove.

IR Receiver

IR receiver for remote control (optional).

7.2. User functions

7.2.1. Setting the heat output

The heat output is set using buttons P1 and P2 on a value between 1 (minimum) and 5

(maximum). The selected value is shown on the display. The setting can be made at any time,

both before the ignition of the stove and when the stove is in operation, but not in the economy

phase (see the paragraph on Economy phase).

7.2.2. Setting the temperature

The temperature setting can be made using buttons P4 and P5, between a minimum value of 7

and a maximum value of 40. The selected value is shown on the display. The setting can be made

at any time, both before the ignition of the stove and when the stove is in operation.

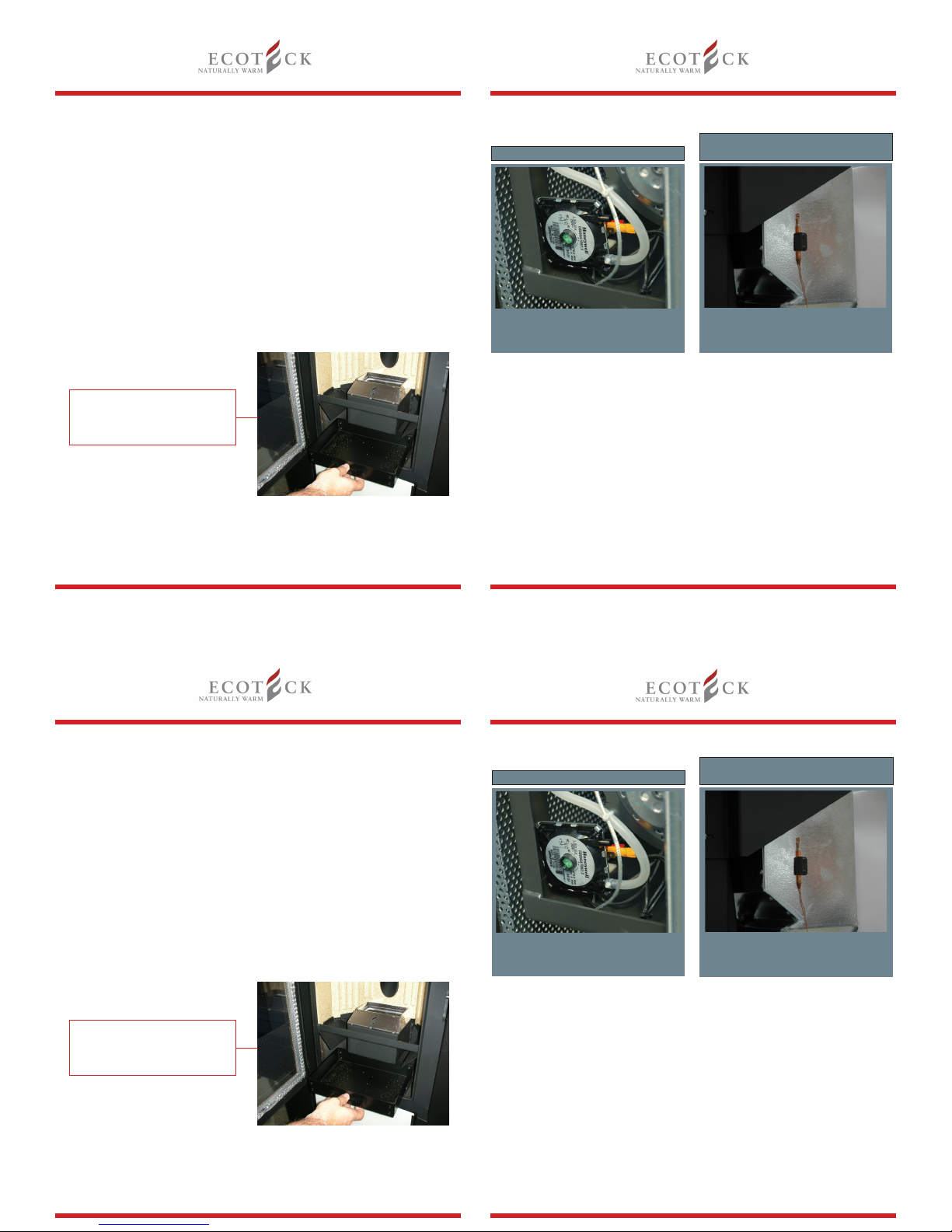

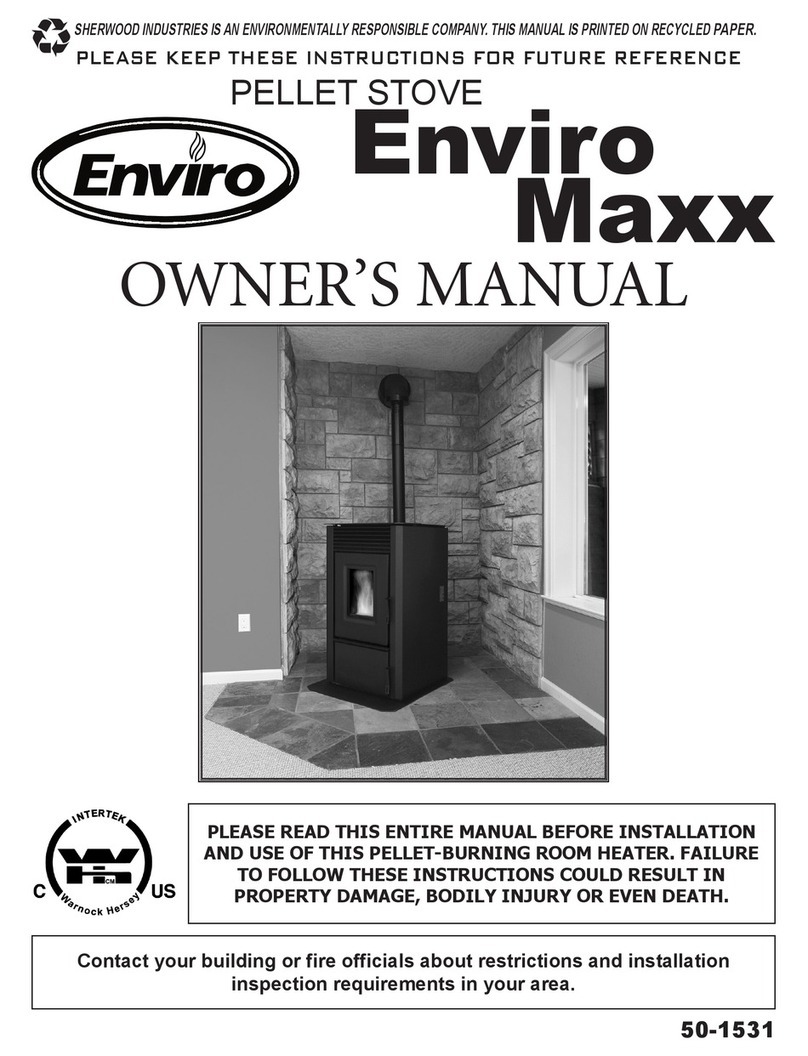

7.2.3. Settaggio della miscela pellet-aria.

Setting the air - pellet blend allows the speed of both the smoke engine and the pellet feeding

screw to be changed simultaneously. This allows combustion to be adjusted according to the

stove’s draught and according to the hardness of the pellet. To access adjustment press P6 and

P7 together until “0 PELLET 0 DRAUGHT” appears.

The quantity of pellet is changed with keys 4 and 5.

The speed of the smoke engine is changed with keys 6 and 7.

This screen will appear on the display

N.B. They are two independent headings!

7.3. Staring the stove

The stove is started and stopped manually by pressing button P3 (ON/OFF) for a few seconds. A

complete operating cycle usually involves five separate phases (ignition, flame stabilisation, normal

operation, economy and shutdown) which alternate according to the flue gas temperature measured

and other operating parameters. These phases are explained in detail below.

0

PELLET

0

DRAUGHT

Valori Pellet

From 0 to -5 i decrease the pellet load

0 Default value that considers the set combustion as excellent

From 0 to 5 i increase the falling pellet

Valori Tiraggio

From 0 to -5 To be carried out when there is too much draught and when there is no ame in the stove

0 Default value that considers the set combustion as excellent

From 0 to 5 To be carried out when the pellet to be used is too hard and a stronger draught is required

in the combustion chamber

Display

The LCD shows all the messages required for the operation of the stove.

IR Receiver

IR receiver for remote control (optional).

7.2. User functions

7.2.1. Setting the heat output

The heat output is set using buttons P1 and P2 on a value between 1 (minimum) and 5

(maximum). The selected value is shown on the display. The setting can be made at any time,

both before the ignition of the stove and when the stove is in operation, but not in the economy

phase (see the paragraph on Economy phase).

7.2.2. Setting the temperature

The temperature setting can be made using buttons P4 and P5, between a minimum value of 7

and a maximum value of 40. The selected value is shown on the display. The setting can be made

at any time, both before the ignition of the stove and when the stove is in operation.

7.2.3. Settaggio della miscela pellet-aria.

Setting the air - pellet blend allows the speed of both the smoke engine and the pellet feeding

screw to be changed simultaneously. This allows combustion to be adjusted according to the

stove’s draught and according to the hardness of the pellet. To access adjustment press P6 and

P7 together until “0 PELLET 0 DRAUGHT” appears.

The quantity of pellet is changed with keys 4 and 5.

The speed of the smoke engine is changed with keys 6 and 7.

This screen will appear on the display

N.B. They are two independent headings!

7.3. Staring the stove

The stove is started and stopped manually by pressing button P3 (ON/OFF) for a few seconds. A

complete operating cycle usually involves five separate phases (ignition, flame stabilisation, normal

operation, economy and shutdown) which alternate according to the flue gas temperature measured

and other operating parameters. These phases are explained in detail below.

0

PELLET

0

DRAUGHT

Valori Pellet

From 0 to -5 i decrease the pellet load

0 Default value that considers the set combustion as excellent

From 0 to 5 i increase the falling pellet

Valori Tiraggio

From 0 to -5 To be carried out when there is too much draught and when there is no ame in the stove

0 Default value that considers the set combustion as excellent

From 0 to 5 To be carried out when the pellet to be used is too hard and a stronger draught is required

in the combustion chamber