Printed in USA

©1999

Page 2

E-ALRBS-IP-11/99

READ AND UNDERSTAND THE OPERATORS INSTRUCTION MANUAL THOROUGHLY BEFORE ATTEMPTING

TO OPERATE THIS EQUIPMENT. Death or serious injury could occur if this machine is used improperly.

EDCO AIR–RAM LONG REACH CHISEL SCALER - MODEL ALR-BS

OPERATORS INSTRUCTIONS

1When operating this equipment, the operator must

wear approved job related safety attire. Eye and

hearing protection must be worn at all times while

equipment is in use as sound levels exceed 92 dBA.

Steeltoe safety shoes should be worn. Head pro-

tection is required if work is performed overhead.

Wear proper dust mask based on material being

removed.

2Use the correct size air hose for the tool, ½ diam-

eter (minimum). Hose and fittings must be rated for

safe handling in excess of 100 PSI pressure. The

working pressure of this tool is 80-90 PSI and should

never be allowed to exceed 100 PSI.

3Limit the hose length to 30 feet (10 meters) maxi-

mum. Note: The pressure drop of ½” diameter hose

is approximately 1 PSI per 90 linear feet.

4A filter/water separator must be provided on the air

source to afford an adequate supply of clean, dry air

to this tool. A lubricator should also be used. If a

lubricator is unavailable, lubricate the tool daily by

putting 6 to 7 drops of lightweight machine oil in the

hose connector opening prior to connecting the air

supply. In cold weather, use graphite oil for lubrica-

tion.

5Disconnect the air supply before re-

moving or installing a chisel or ac-

cessory. Squeeze the hand lever to release all com-

pressed air from the tool. Use only genuine EDCO

chisels and accessories with this equipment. Fail-

ure to do so may result in serious bodily injury or

death.

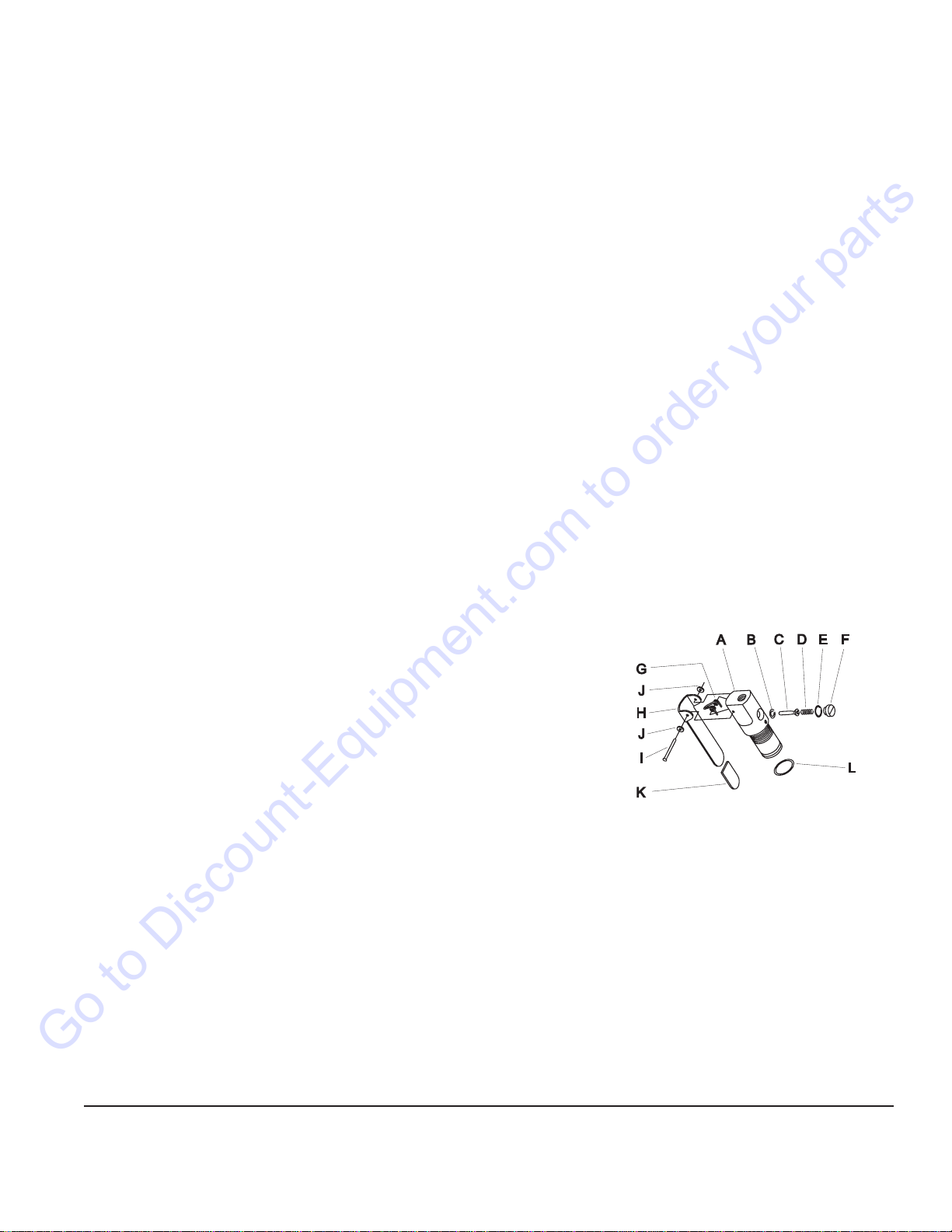

6To install or remove chisel: Disconnect the air sup-

ply. Squeeze the hand lever to release all com-

pressed air. Pull back on the spring loaded locking

collar and hold while removing the chisel. Hold back

on the spring loaded locking collar while firmly seat-

ing the new chisel in the holder. Release collar to

retain the chisel.

7 The appropriate accessory must be used for the job at

hand. DONOT force the tool into the work. The ham-

mering action of the tool will perform the work for you.

NEVERUSETHETOOLASAPRYBAR. Damage to

the equipment will result. If the tool does not seem to

perform the work to your specifications, try another

accessory or Contact Discount-equipment

8To activate tool, attach the air source, firmly grip the

tool then squeeze the hand lever on the air valve.

9After releasing the air valve hand lever,

the tool will continue to operate for

up to 15 seconds. This is a normal result of

stored pressure in the tool casing being re-

leased gradually. Be sure to firmly grip the tool

until ALL air leaves the chamber.

10 Remove the air source from the tool when not in

use.

11 This equipment will create dust from

the material being removed. That dust

may contain a chemical known to the state of Califor-

nia to cause cancer and/or birth defects or other re-

productive harm.As an example, paints and concrete

contain chemicals known to the state of California to

cause cancer and/or birth defects or other reproduc-

tive harm. Check the chemical properties of the ma-

terials to be removed.

12 It is the operator’s responsibility to keep

other people (workers, pedestrians, by-

standers, etc.) away during operation. Block off the

work area in all directions with roping, safety netting,

etc. for a safe distance. Failure to do so may result

in others being injured by flying debris or exposing

them to harmful dust and noise.

Go to Discount-Equipment.com to order your parts