EDER Maschinenbau Bark Stripper ESG-C User manual

Original

409001_01 | 12.2020

Operating instructions

EDER attachments with chain drive

Chainsaw attachment for working logs and wood

EN

1

Attachments with chain drive

409001_01 | 12.2020

Content

About this guide............................................................................2

Validity......................................................................................3

Warranty...................................................................................3

Presentation of the warning notes.............................................4

Symbols used in this manual.....................................................5

Safety instructions.........................................................................5

Intended use.............................................................................6

Improper use ............................................................................6

Qualification of the personnel....................................................6

Points to observe......................................................................7

Safety instructions for the workplace.........................................7

Behaviour in an emergency.......................................................7

Safety devices..........................................................................8

Personal protective equipment..................................................8

Design and function ......................................................................8

Function ...................................................................................8

EDER Bark Stripper Head ESG-C 400200............................8

EDER Flat Planer EPH-C 400600.........................................9

EDER Curved Planer ERH-C 400700 ...................................9

EDER Contour Planer EKH-C 401900 ................................10

EDER Groove Cutter ENF-C 400800..................................10

EDER Wire Brush ERB-C 401500.......................................10

EDER Bark Beetle Cutter EBF-C 400900............................11

Scope of delivery ........................................................................11

Check completeness of the delivery........................................11

Check transport damage.........................................................11

Transport................................................................................12

Assembly....................................................................................13

Mounting the attachment.........................................................13

Commissioning and operation.....................................................16

409001_01 | 12.2020

Attachments with chain drive

2

EN

Starting the engine..................................................................17

Operation....................................................................................17

Changing and adjusting the knives..........................................19

EDER Bark Stripper ESG-C................................................19

EDER Flat Planer EPH-C / EDER Curved Planer ERH-C....20

EDER Contour Planer EKH-C.............................................21

EDER Groove Cutter ENF-C...............................................22

EDER Wire Brush ERB-C...................................................23

EDER Bark Beetle Cutter EBF-C ........................................24

Cleaning .....................................................................................25

Maintenance...............................................................................26

Decommissioning and disposal ...................................................26

Faults..........................................................................................26

Technical data ............................................................................27

Accessories and spare parts...................................................27

Grooving knife for bark beetle control..................................28

EDER Bark Stripper ESG ...................................................29

EDER Flat Planer EPH.......................................................30

EDER Curved Planer ERH..................................................31

EDER Contour Planer EKH.................................................32

EDER Groove Cutter ENF ..................................................33

EDER Wire Brush ERB.......................................................34

Declaration of conformity.............................................................36

3

Attachments with chain drive

409001_01 | 12.2020

About this guide

Validity

These instructions apply to attachments (accessories) to be mounted on

chainsaws for debarking andmilling treetrunks andwood in thefollowing

variants:

EDER Bark Stripper ESG-C

EDER Flat Planer EPH-C

EDER Curved Planer ERH-C

EDER Contour Planer EKH-C

EDER Groove Cutter ENF-C

EDER Wire Brush ERB-C

EDER Bark Beetle Cutter EBF-C

They are aimed at forestry professionals and private individuals with

basic knowledge of wood processing.

The instructions contain important information on how to properly mount

the attachments on a chainsaw, start them up, operate them, use them,

maintain them and rectify simple faults yourself.

Warranty

Attachments are covered by the statutory warranty period. The seller

must be notified immediately of any defects that can be proven to be due

to material or assembly errors. Proof of purchase ofthe attachmentmust

be provided by presenting the invoice and receipt when making a claim

under the warranty. The warranty is excluded with regard to the parts if

the defects are caused by natural wear and tear, temperature, weather

conditions as well as defects resulting from faulty connection,

installation, operation, lubrication or force. Furthermore, no warranty is

given for damage caused by unsuitable improper use of the machine,

e.g. improper modifications or repair work carried out by the owner or

third parties under his or her own responsibility, or in the case of

deliberate machine overload. The manufacturer does not accept any

warranty for:

•Parts which are subject to natural wear and tear

•Non-compliance with the operating instructions and insufficient or

incorrect care

•The consequences of improper maintenance and servicing

•Damage from improper handling and incorrect operation

Guarantee

The warranty period shall be 24 months from the date of delivery for

exclusively private use, and 12 months for commercial or professional

use or application or for rental. The statutory warranty remains

unaffected. Warranty claims must always be proven by the buyer by

409001_01 | 12.2020

Attachments with chain drive

4

EN

means of the original purchase receipt. A copy of this is to be enclosed

with the warranty application. The buyer's address and machine type

must be clearly identifiable for professional or commercial use. Any

defects occurring within the warranty period due to material or

manufacturing faults must be remedied by repair if they have occurred

despite proper operation and care of the machine.

No guarantee or warranty

Using the chainsaw with the attachments will invalidate the chainsaw

warranty.

Eder Maschinenbau GmbH is not liable for any damage to the chainsaw

used. Use the chainsaw with the attachments at your own risk.

Wear items such as chains, sprockets, knives and guide bars are

excluded from the warranty.

Presentation of the warning notes

SIGNAL WORD

Type and source of the danger!

Consequences

➢Danger prevention

•The warning sign (warning triangle) draws attention to danger of

life or injury.

•The signal word indicates the severity of the danger.

•The paragraph "Type and source of danger" indicates the type or

source of danger.

•The paragraph "Consequences" describes the possible

consequences of not observing the warning.

•The paragraph "Danger prevention" indicates how to avoid the

danger. It is imperative that you comply with these measures for

averting danger!

!

5

Attachments with chain drive

409001_01 | 12.2020

The signal words have the following meaning:

Warning

word

Meaning

DANGER!

Indicates a hazard that will certainly lead to death

or serious injury if you do not avoid the danger.

WARNING!

Indicates a hazard that can lead to death or

serious injury if you do not avoid the danger.

CAUTION!

Indicates a hazard that can lead to minor or

moderate injury if you do not avoid the danger.

ATTENTION!

Indicates possible damage to property. The

environment, material assets or the plant itself can

be damaged if you do not avoid the danger.

Symbols used in this manual

Symbol

Meaning

If this information is not observed, this can lead to

deterioration in the operating process.

>

Instruction for action: Describes actions that must

be carried out.

Safety instructions

The attachments for chainsaws were manufactured in accordance with

the generally recognised rules of technology. Nevertheless, there is a

risk of personal injury and damage to property if you do not observe the

following basic safety instructions and the warnings preceding

instructions in this manual.

> Read these instructions thoroughly and completely before working

with the chainsaw attachment.

> Keep the manual in a legible condition.

> Make sure that the manual is always accessible to all users.

> Always pass on the chainsaw attachment to third parties together

with this manual.

i

409001_01 | 12.2020

Attachments with chain drive

6

EN

Intended use

The attachments are designed as interchangeable equipment for

mounting on chainsaws.

Only chainsaws that have been tested by Eder Maschinenbau GmbH for

compatibility with Eder attachments may be used as drive motors. An

overview can be found at www.eder-maschinenbau.de/

produkte/anbaugeraete-fuer-motorsaegen-produkte

The various attachments can be interchanged with each other. You may

only use the chainsaw attachments for the activities described in these

instructions. You must always respect the performance limits of the

device.

The attachments are approved for use in forestry as well as for private

use. It is designed exclusively for operation by one person. Never allow

two or more persons to work on one device.

Intended use also implies that you have read and understood this

manual in its entirety and in particular the chapters "Safety instructions"

and "Design and function".

Improper use

Any use not in accordance with the intended use is not permitted. The

following is considered improper use:

•removing or modifying safety devices,

•using the attachment in any other way than described in the chapter

"Intended use",

•mounting the attachment in any other way than described in the

chapter "Assembly",

•using the attachment under operating conditions that differ from those

described in this manual.

If the device is not used as intended, all warranty claims will become

void.

The manufacturer is not liable for damage to the device and for personal

injury resulting from improper use.

Qualification of the personnel

The attachments for chainsaws may only be mounted, operated,

maintained and repaired by persons who have familiarised themselves

with the device and the associated dangers by means of these

instructions.

Persons who assemble, operate, disassemble or maintain the

attachments must not be under the influence of alcohol, other drugs or

medicines that affect their ability to react, nor must they be tired, ill or

irritable.

7

Attachments with chain drive

409001_01 | 12.2020

Persons under the age of 18 may only use the device under the

supervision of a qualified person.

Points to observe

General safety instructions

> Always follow the instructions in this manual to avoid hazards and

prevent damage.

> Observe the relevant accident prevention regulations and other

generally recognised safety and occupational health rules.

> Only carry out repair, set-up, maintenance and cleaning work and

transport the device when the drive is switched off and the tool is

stationary.

> Operate the device exclusively with the protective equipment fitted

or provided by the manufacturer.

> Never leave the device unattended during operation.

> If you have long hair, wear a hairnet when working with the device.

> Do not smoke while refuelling or while working with the device.

> When using the device, observe the information on vibrations and

sound level given in the chapter Technical data.

Safety instructions for the workplace

> Ensure that the workplace and the traffic routes required for

transporting the wood to and from the site are safe.

> Keep the working area free of wood debris, obstacles and tripping

hazards. Eliminate slippery and smooth areas. Do not use sawdust

or wood ash for this purpose, otherwise there is a risk of slipping.

> Ensure adequate lighting at the workplace.

> Ensure that a level and step-resistant area with sufficient freedom of

movement is available for working.

> When using chainsaws with combustion engines, only work in well-

ventilated environments and not in enclosed spaces. Exhaust fumes

contain toxic carbon monoxide.

> Do not allow persons to approach the running device. Keep persons

and animals away from the workplace. Children, animals and adults

must keep at least 10 metres away from the running device.

> Never work in the rain as the stability in wet conditions is impaired.

> Do not leave the device standing in the rain.

Behaviour in an emergency

If, for example, malfunctions or dangerous situations pose an immediate

risk of injury to persons or damage to the device:

> Switch off the device to which the attachment is mounted.

409001_01 | 12.2020

Attachments with chain drive

8

EN

> Have the malfunctions eliminated by your specialist dealer.

Safety devices

Attachments may only be used with the protective and safety equipment

(e.g. protective plate) provided for the intended use. Protective and

safety equipment must never be disabled and must be cleaned if

necessary.

Personal protective equipment

> Always wear the following personal protective equipment when

operating the machine:

•Safety shoes with steel toecap

•Tight-fitting clothing, a hair net if necessary

•Suitable work gloves

•Safety helmet with face protection

•Hearing protection

•Cut-resistant trousers

The personal protective equipment must comply with

the applicable accident prevention regulations.

Design and function

Function

With the different versions of the attachment you can achieve different

contours when working the wood. The individual attachments can be

exchanged for another attachment in a few easy steps.

EDER Bark Stripper Head ESG-C 400200

Design: The ESG-C bark stripper head is mounted on a bar that

matches the chainsaw and is driven by a chain just like a normal

chainsaw. No modifications are required to the chainsaw.

Field of application: For peeling logs of any diameter.

The design of the cylinder results in high cutting performance with

minimum effort.

Tungsten carbide pins placed directly behind the knives are designed in

such a way that the distance between the knives and the log is

maintained automatically and independently of the bark thickness over

i

9

Attachments with chain drive

409001_01 | 12.2020

the entire length of the log. Knots and thin branches are easily and

cleanly milled off.

The cylinder is straight and mills a flat surface similar to that of the

peeling knife. This allows you to use the device at an angle or crosswise

when working on the side of the trunk and when peeling root knots.

For the processing of robinia wood we recommend the use of

the contour planer EKH.

EDER Flat Planer EPH-C 400600

Design: The EPH-C flat planer is mounted on a bar that matches the

chainsaw and is driven by a chain just like a normal chainsaw. No

modifications are required to the chainsaw.

Field of application: For planing flat or round wood surfaces from 30

cm diameter.

The design of the cylinder results in high cutting performance with

minimum effort.

The knives mounted on the rotating cylinder are continuously adjustable,

allowing you to set both the cutting radius and the cutting depth

according to the desired chip thickness.

On the cylinder there are four knives distributed on two levels, which

produce a smooth surface without vibrations.

EDER Curved Planer ERH-C 400700

Design: The ERH-C curved planer is mounted on a bar that matches

the chainsaw and is driven by a chain just like a normal chainsaw. No

modifications are required to the chainsaw.

Field of application: For planing round, flat or curved wood surfaces up

to 30 cm diameter.

The design of the cylinder results in high cutting performance with

minimum effort.

The knives mounted on the rotating cylinder are continuously adjustable,

allowing you to set both the cutting radius and the cutting depth

according to the desired chip thickness.

On the cylinder there are four knives distributed on two levels, which

produce a smooth surface without vibrations.

i

409001_01 | 12.2020

Attachments with chain drive

10

EN

EDER Contour Planer EKH-C 401900

Design: The EKH-C contour planer is mounted on a bar that matches

the chainsaw and is driven by a chain just like a normal chainsaw. No

modifications are required to the chainsaw.

Field of application: For planing straight and wavy wooden surfaces,

e.g. when building log houses, children's playgrounds, bonanza fences

and similar projects. Well suited for very hard woods such as robinia

wood.

The design of the cylinder results in high cutting performance with

minimum effort.

The adjustable minimum knife projection setting effectively prevents the

log from splitting. As one rotation of the cylinder means only one cut at

working width, the reaction forces are kept to a minimum. Knots and thin

branches are easily and cleanly planed off.

EDER Groove Cutter ENF-C 400800

Design: The ENF-C groove cutter is mounted on a bar that matches the

chainsaw and is driven by a chain just like a normal chainsaw. No

modifications are required to the chainsaw. Up to three knives of 10mm

width each can be used to achieve cutting widths up to 30mm.

Field of application: For milling channels and grooves in wood

surfaces, e.g. when building log houses, children's playgrounds, carving

sculptures and in similar projects.

The design of the milling head results in high cutting performance with

minimum effort.

Up to three knife discs can be mounted on the support, producing a

smooth surface without vibration.

EDER Wire Brush ERB-C 401500

Design: The ERB-C wire brush is mounted on a bar that matches the

chainsaw and is driven by a chain just like a normal chainsaw. No

modifications are required to the chainsaw.

Field of application: For processing and cleaning wood surfaces,

metallic surfaces such as steel or iron and for removing rust or old paint.

The EDER Wire Brush ERB is exceptionally suitable for working out the

natural structure of the wood grain on boards, beams and round timber,

e.g. during construction, restoration and maintenance work on log

houses, children's playgrounds, park benches, wooden fences, on

weathered and rotten wood and similar projects.

11

Attachments with chain drive

409001_01 | 12.2020

EDER Bark Beetle Cutter EBF-C 400900

Design: The EBF-C bark beetle cutter is mounted on a bar that matches

the chainsaw and is driven by a chain just like a normal chainsaw. No

modifications are required to the chainsaw.

Field of application: The device is suitable for carving the bark of trees

to destroy the habitat of bark beetles. Resin bleeds from the carved

areas and hardens on thesurface. This hinders thedevelopment of bark

beetle larvae. Furthermore, the decomposition of the scratched tree

trunk is promoted because it dries out less quickly than after debarking.

In addition, fungal spores and microbes find plenty of surface area to

attack in the scratches.

Scope of delivery

Check completeness of the delivery

The scope of delivery of the selected attachment includes:

•1x attachment

•1x Allen wrench 6 mm

•1x pin wrench

•1x setting gauge (ESG-C, EPH-C, ERH-C, EKH-C,)

•1x operating instructions

•1x groove nut wrench (EBF) / 2x groove nut wrenches (ERB)

The bar, chain and drive sprocket are not included in the scope of

delivery, as these must be selected depending on the chainsaw used.

Check transport damage

Visible transport damage can be recognized by packaging damage or

by scratched and deformed parts on the device.

> Be sure to make a note of the damage on the delivery note: both

on the copy you receive and on the one that you must sign.

> Make sure that the deliverer (driver) countersigns.

If the deliverer refuses to confirm the transport damage, you should

refuse to accept the delivery and inform us immediately. A claim in

retrospect, without a direct note on the delivery note, will not be

accepted either by the carrier or by the transport insurer.

If you suspect latent transport damage:

409001_01 | 12.2020

Attachments with chain drive

12

EN

> Report concealed transport damage within two days at the latest,

which means that you must have checked your delivered goods

within this period. Reporting damage after this time is usually not

accepted.

> Make a note on the shipping documents in any case: "Goods are

accepted subject to concealed transport damage".

Insurance companies of carriers often react very suspiciously and

refuse to provide compensation. Therefore, try to prove the damage

clearly (send a photo if possible).

Transport

CAUTION

Risk of injury by the attachment head!

The cutter head of the attachment has sharp-edged tools that can

cause injuries.

> Ensure that there is sufficient distance between thecutter head

of the attachment and persons.

> Carry the motorised handheld device with the cutter head of

the attachment facing backwards and the exhaust pipe turned

away from the body.

ATTENTION

Danger from leaking fuel!

If thefuel tank inlet isnot properlyclosed, fuelmay leak and pollute

the environment.

> Before transportation, check whether the fuel tank inlet is

correctly closed.

> When transporting the device on vehicles, secure it against

tipping over.

!

13

Attachments with chain drive

409001_01 | 12.2020

Assembly

WARNING

Danger during assembly with the drive motor running!

This may result in injury.

> Switch off the drive motor before assembling the unit and

secure the device against being switched on again.

Danger from changes to the device!

This may result in injury.

> Only carry out assembly work described in this manual.

> Do not adjust the support, the chain, the knives or the milling

head while the engine is running. The chain must be correctly

tensioned.

> Only use original spare parts. These can be ordered directly

from Eder Maschinenbau GmbH or from your dealer (see back

page for address)

Converting and using the chainsaw with the Eder

attachments voids the chainsaw's warranty. Eder

Maschinenbau GmbH accepts no liability for damage to the

chainsaw!

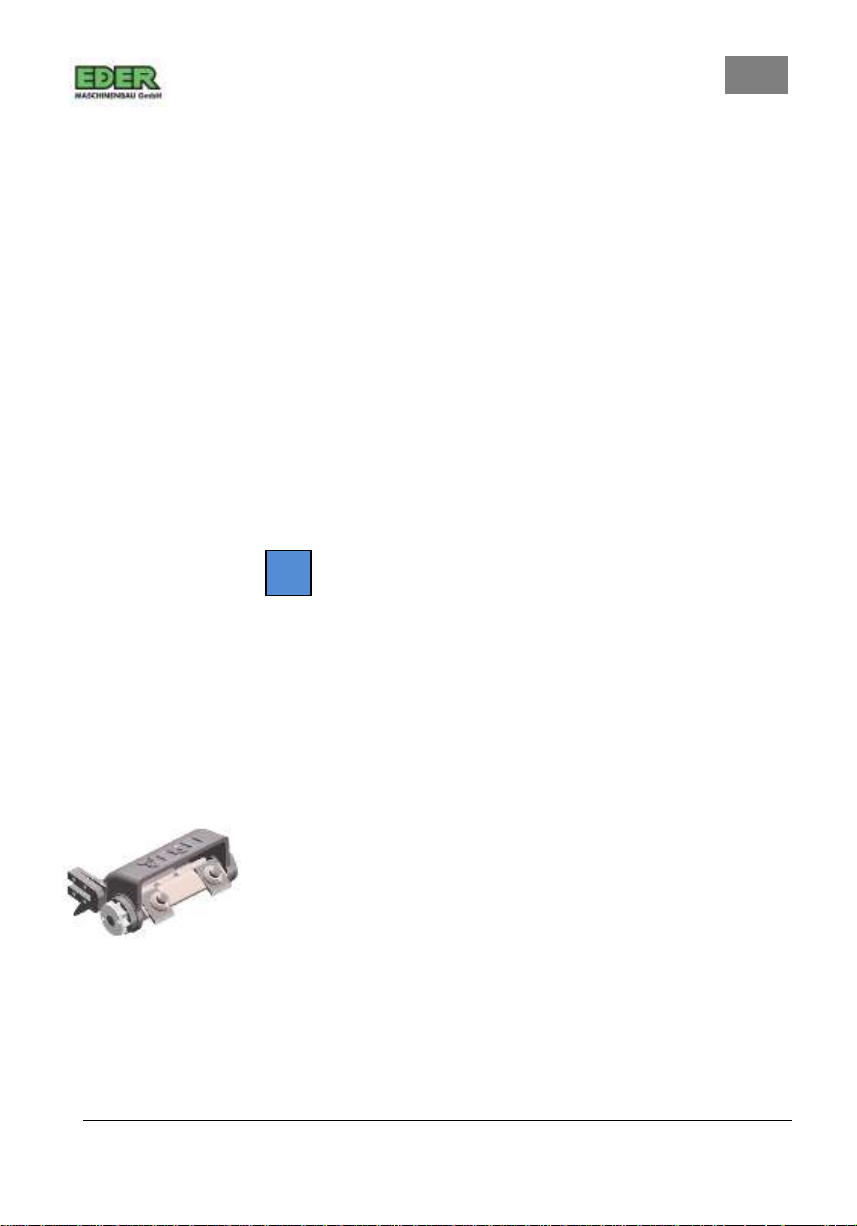

Mounting the attachment

ATTENTION

> Use a new sprocket on your chainsaw before using the

attachment. Retracted sprockets/chainrings can lead to

damage or higher wear on the drive chain.

> The sprocket/chainring used on the drive motor must have a

maximum of 7 teeth.

> When fitting, make sure you have the correct designation for

your sprocket/chainring. 3/8 LP, 3/8 Micro, 3/8 Hobby, 3/8

Picco etc. are not compatible with 3/8".

409001_01 | 12.2020

Attachments with chain drive

14

EN

> Place the guide bar (1 - Fig.1) between the screws (2 - Fig.1) in the

same way as a normal chainsaw bar.

> Note that the bar is not symmetrical. The oil holes are in different

positions on the two sides of the bar. Choose the correct side of the

guide bar depending on the chainsaw used.

> Check that the oil hole of the guide bar is on the oil groove of the

chainsaw - if not, turn the guide bar over. (To check the position,

clean the saw around the oil groove and apply some oil in the oil

groove. Then place the guide baragainst the chainsaw in its intended

position and carefully remove it again. The oil in the groove then

leaves a mark on the bar).

> The hole (3 - Fig.1) in the support must be located at the chain

tensioner driver. Depending on the type of chainsaw, this is mounted

on the motor side or in the cover (4 - Fig.1).

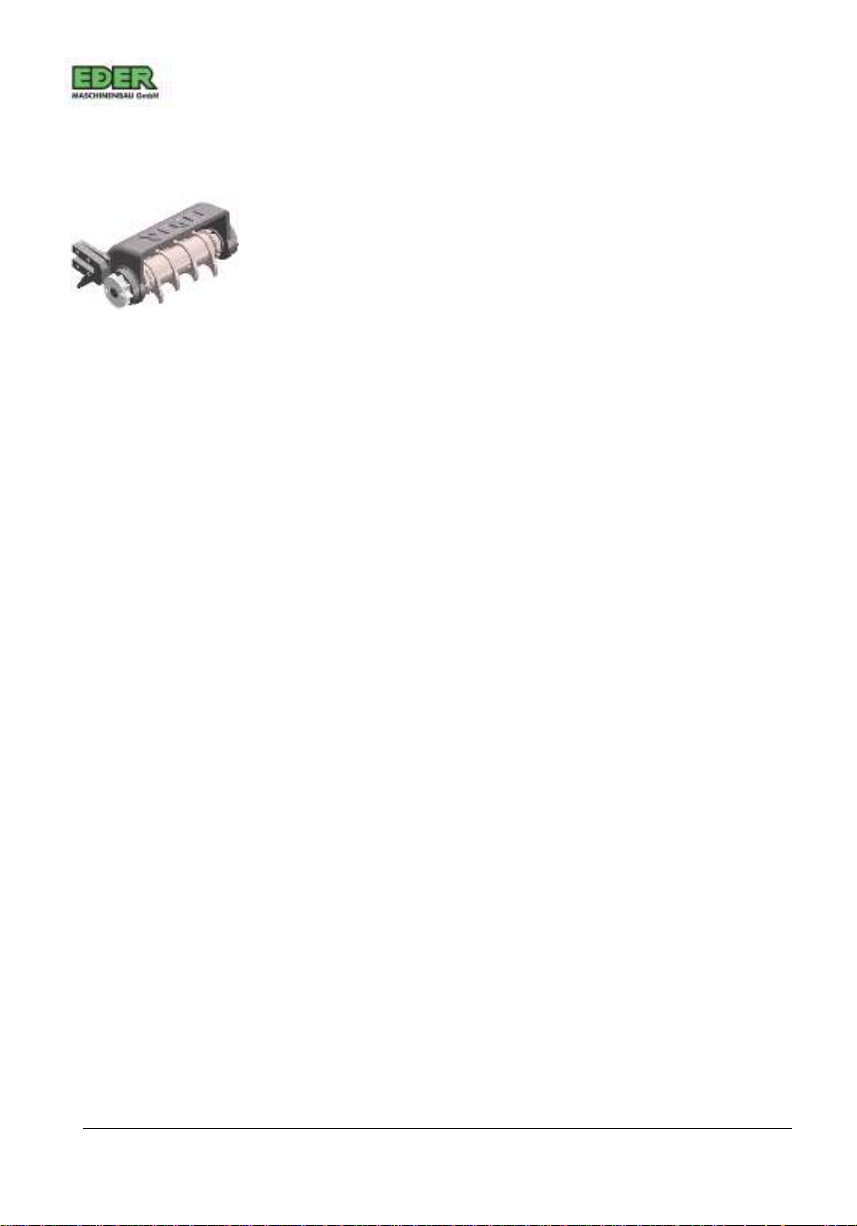

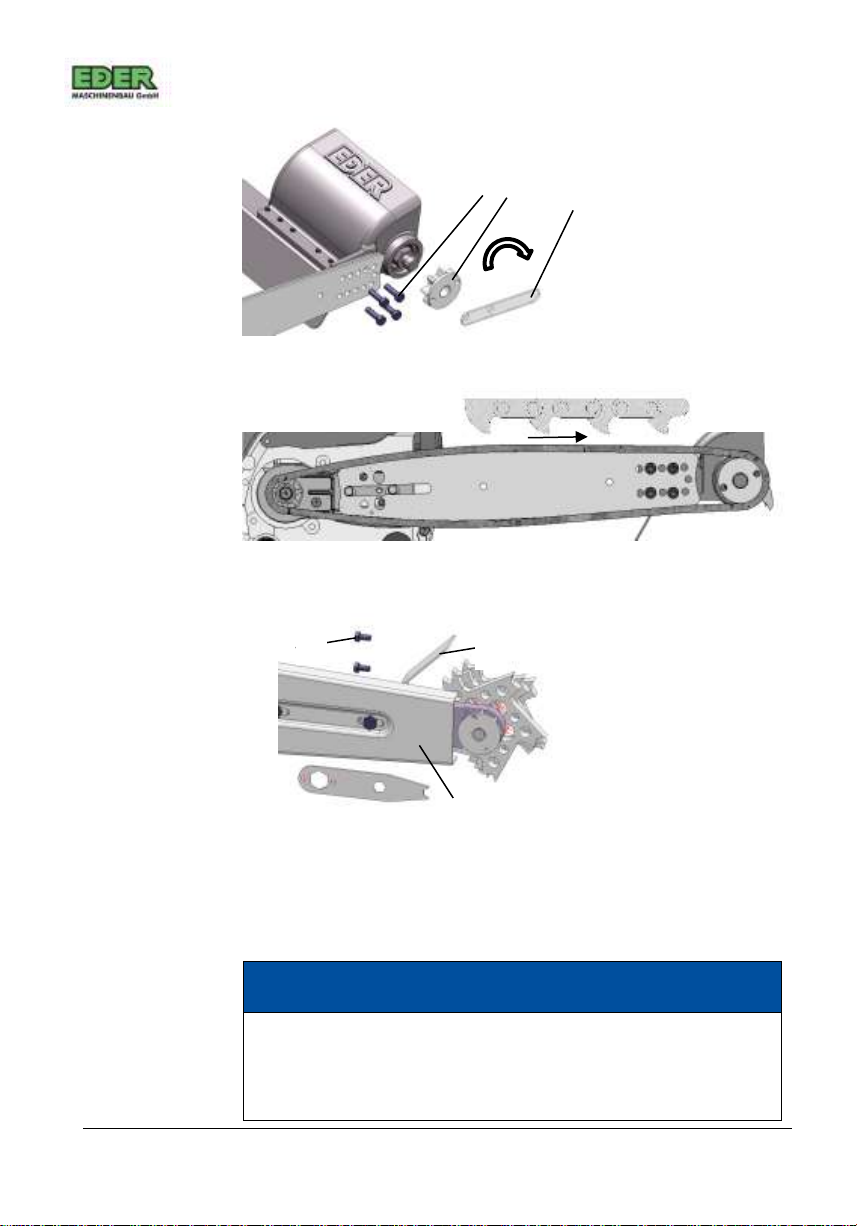

> Screw the head you want to use with the 4 M6x20 screws (1 - Fig.

2). Check the screws regularly for tightness. The head can be

screwed on in different positions depending on the chainsaw model.

The correct position is the one that allows the drive chain to be

sufficiently tensioned and re-tensioned.

> Screw the drive sprocket onto the housing (2 - Fig.2) and tighten it

with the pin wrench (3 - Fig.2).

> Now place the chain around the chainsaw sprocket and around the

drive sprocket. Insert the drive links into the rail. Make sure that the

chain is running in the correct direction (Fig. 3

Fig. 1: Mounting the support

2

1

3

4

15

Attachments with chain drive

409001_01 | 12.2020

Fig. 2: Fastening the peeling head to the support

Fig. 3: Putting on the chain

> Fit the protective plate to the guide bar (1 –Fig. 4).

Fig. 4.: Mounting the protective plate

> The groove cutter has another protective plate (2 -Fig.4). This

is screwed to the housing with two hexagonal screws (3 - Fig.4).

ATTENTION

Chain and drive sprocket pitch

Only use chains and drive sprockets matching the chainsaw and

having the same pitch.

1

2

3

3

3

1

3

1

409001_01 | 12.2020

Attachments with chain drive

16

EN

ATTENTION

> Put the side plate back on the device, slightly fasten it and tension

the chain. A new chain needs to be retensioned more often. Check

the chain tension more often.

> Tighten the screws of the side plate firmly.

ATTENTION

Chain tension

> Check the chain regularly for correct chain tension. To do this,

always switch off the engine!

> The chain is correctly tensioned if you can pull it slightly out of

the guide bar by hand with the chain brake released. The

chain must not be lifted more than 4 mm from the guide bar.

Commissioning and operation

ATTENTION

Damage to knives and tools!

Nails, adhering sand and other foreign bodies can damage the

knives and tools of the attachment.

> Check the logs to be worked before each use. If necessary,

remove nails, sand and other foreign objects before milling.

Before starting the motorised handheld device, make sure you have safe

working conditions. Check that

> the attachment has been correctly mounted,

> the chain is sufficiently tensioned and not damaged,

> the chain brake is functional,

> all knives and tools are correctly mounted and firmly seated

(tightening torque 35 Nm)

> the handles are clean and dry,

17

Attachments with chain drive

409001_01 | 12.2020

> both the fuel tank and the device are located outside of flammable

environments. Note that closed, empty fuel tanks may contain

explosive vapours.

Starting the engine

CAUTION

Danger of injury due to rotating tools!

After you have released the throttle trigger, the device will continue

to rotate for a short time (freewheel).

> Before starting the engine, make sure that all protective

housings and protective plates are fitted to the attachment.

> Place the motorised handheld device on the ground so that the

device does not touch any foreign objects.

> Never start the device in a hanging position.

> Keep the device away from your body during work.

> Make sure that no one is in the working area of the device.

Operation

WARNING

Risk of injury due to unsafe standing position!

There is a risk of injury if your standing position is not stable or if

you work overhead.

> Always take a safe and stable position.

> Never work on icy or wet surfaces, as there is a risk of slipping.

> Never work on ladders or in unstable positions.

> While working, hold the device firmly with both hands so that

no parts of the body can approach the chain, the tool head or

the exhaust pipe. Grasp firmly the throttle handle with your

right hand and the front handle with your left hand. This also

applies to left-handed persons.

> Do not hold the device above your head when working and

always use both hands when working.

> Work calmly and carefully with good visibility and adequate

lighting.

Risk of injury!

409001_01 | 12.2020

Attachments with chain drive

18

EN

WARNING

If you do not observe the following points, injuries are possible due

to rebounding of the device.

> Only work on wood with the device (except for the Wire Brush

ERB-C).

> During work, make sure that the cutter head does not touch

any foreign objects (stones, glass, metal objects, etc.) that

could damage the cutter head or the chain

> When the engine is running, place the cutter head or wire

brush on the trunk surface only at operating speed.

> Make sure that the throttle trigger is not blocked by the throttle

lock when working with the device, as in this case it is not

possible to control the rotation.

> Check that the knives are firmly seated before each use.

> Switch off the device before putting it down.

ATTENTION

Chain brake

> On some models, frequent use of the chain brake at high

speeds can damage the drive motor.

> Only use the chain brake in emergency and dangerous

situations, with the engine running idle or when the engine is

switched off

ATTENTION

Lubrication

> After each replacement of the guide bar, check whether oil is

being pumped through the groove of the bar. To dothis, switch

the engine off again after a short running time.

> Note that the chain and the guide bar may be hot.

19

Attachments with chain drive

409001_01 | 12.2020

Changing and adjusting the knives

ATTENTION

Damage due to blunt knives

Regularly check the cutting edges of the knives

> Working with blunt knives can damage the knives and the

bearing.

> If necessary, sharpen the knives or replace them.

Suitable tool

> Use a suitable torque wrench to tighten the knives. Never

tighten them with an extension wrench or using a hammer.

EDER Bark Stripper ESG-C

Sharp knives are required for optimal work with the EDER Bark Stripper

ESG-C. Blunt knives can be sharpened manually using normal grinding

wheels. Cutting edge angle is 40°.

The required knife setting depends on the type of wood to be peeled.

Adjust the knives from case to case.

The smaller the knife protrusion, the less wood is removed and

the smoother the surface becomes.

Fig. 5: Knife adjustment

The tungsten carbide pins on the knife discs serve as depth limiters. All

four knives must therefore have the same setting and the same distance

to the carbide pins. The knives must not protrude beyond the tungsten

carbide pins.

All four knives are replaced and adjusted in the same way. Proceed as

follows for each knife:

> Loosen the Allen screw of the knife with a 6 mm Allen wrench.

i

i

3

2

1

This manual suits for next models

13

Table of contents

Popular Chainsaw manuals by other brands

Poulan Pro

Poulan Pro 1980-02 owner's manual

Husqvarna

Husqvarna 439 Operator's manual

Makita

Makita UC 4001A instruction manual

Husqvarna

Husqvarna 55 Rancher Operator's manual

Sievert Crane & Hoist

Sievert Crane & Hoist LITTLE MULE FEL Series Operating and maintenance manual

Ryobi

Ryobi OCS1830 Original instructions