EDI 210 Series User manual

THIS MANUAL CONTAINS TECHNICAL INFORMATION FOR THE FOLLOWING SERIES OF MODEL 210

CONFLICT/VOLTAGE SIGNAL MONITORS: 210-NY; Issue B,C,D. INCLUDED ARE GENERAL DESCRIPTION,

OPERATIONAL DESCRIPTION, INSTALLATION AND SPECIFICATIONS.

THE MODEL 210 SERIES SIGNAL MONITORS ARE DESIGNED AND MANUFACTURED IN THE U.S.A.

BY EBERLE DESIGN INC., PHOENIX, ARIZONA.

INFORMATION HEREIN CONTAINED IS PROPRIETARYTECHNICAL INFORMATION OF EBERLE DESIGN INC..

PUBLICATION, REPRODUCTION OR USE IN WHOLE OR PART IS NOT PERMITTED EXCEPT UNDER TERMS

AGREED UPON IN WRITING. 8COPYRIGHT 2000-2003 EDI

REV: June 2003

pn 888-1210-001

OPERATIONS MANUAL

═════════════

MODEL 210 SERIES

NYDOT

RMS SIGNAL MONITOR

TM

TM

<blank>

MAINTENANCE NOTE

EBERLE DESIGN INC. SIGNAL MONITORS HAVE BEEN CAREFULLY

INSPECTED AND TESTED TO ENSURE PROPER OPERATION. IT IS

RECOMMENDED THAT THE SIGNAL MONITOR BE TESTED AT LEAST

ANNUALLY TO ENSURE COMPLIANCE WITH THE PROPER

SPECIFICATIONS.

<blank>

TABLE OF CONTENTS

GENERAL DESCRIPTION..................................................................................................................................1

Introduction .....................................................................................................................................................1

Basic Functions...............................................................................................................................................1

Conflict Monitoring.....................................................................................................................................1

24VDC Monitoring.....................................................................................................................................1

Controller Watchdog Monitoring...............................................................................................................1

GENERAL CHARACTERISTICS........................................................................................................................3

Hardware Features.........................................................................................................................................3

AC Line Brown-out Detection.........................................................................................................................3

Minimum Flash Time.................................................................................................................................3

Recurrent Pulse (RP) Detection ....................................................................................................................3

Non-Volatile Fault Memory.............................................................................................................................4

Program Card Absent (PCA) Indication.........................................................................................................4

Configuration Change Monitoring..................................................................................................................4

Internal MPU Watchdog.................................................................................................................................4

Reset Input Detection.....................................................................................................................................5

LED Test.........................................................................................................................................................5

Memory Test...................................................................................................................................................5

Watchdog Monitoring Disabled Indicator.......................................................................................................5

Diagnostic Display Mode................................................................................................................................5

No Fault Diagnostic Display......................................................................................................................5

Fault Diagnostic Display............................................................................................................................5

INSTALLATION ...................................................................................................................................................7

Program Card Programming .........................................................................................................................7

Option Jumper Programming ........................................................................................................................7

Recurrent Pulse (RP) Disable Switch ......................................................................................................7

WD Timing Switch.....................................................................................................................................7

Select Jumper Programming.........................................................................................................................7

Watchdog Latch Select.............................................................................................................................7

Minimum Flash Enable Select..................................................................................................................7

Configuration Change Fault Select..........................................................................................................7

AC Line Brown-out Select.........................................................................................................................8

Watchdog Programming................................................................................................................................8

Watchdog Enable Switch..........................................................................................................................8

Watchdog Timing Option..........................................................................................................................8

Internal MPU Watchdog Latch Option...........................................................................................................8

FRONT PANEL DESCRIPTION..........................................................................................................................9

Indicators.........................................................................................................................................................9

Front Panel Controls ......................................................................................................................................9

THEORY OF OPERATION ...............................................................................................................................11

System Description.......................................................................................................................................11

Detailed Description of Circuit Operation.....................................................................................................11

Main MPU Logic ......................................................................................................................................11

Serial Peripheral Interface (SPI).............................................................................................................11

Internal MPU Watchdog..........................................................................................................................11

EEprom Memory.....................................................................................................................................12

24Vdc Logic Inputs..................................................................................................................................12

Display 12

Program Card and Switch Inputs............................................................................................................12

RMS-EngineTM.........................................................................................................................................12

Power Supply..........................................................................................................................................12

MAINTENANCE .................................................................................................................................................13

Preventive Maintenance...............................................................................................................................13

Trouble Shooting Sequence ........................................................................................................................13

SPECIFICATIONS..............................................................................................................................................15

Electrical........................................................................................................................................................15

Timing Functions ..........................................................................................................................................16

Mechanical....................................................................................................................................................16

Environmental...............................................................................................................................................16

WIRING ASSIGNMENTS...................................................................................................................................17

Monitor Unit Connector (P3).........................................................................................................................17

Program Card Connector (P4).....................................................................................................................18

210-NY RMS Signal Monitor

Operations Manual

Eberle Design Inc. Page 1

Section 1

GENERAL DESCRIPTION

1.1 INTRODUCTION

Thismanual covers the operation, equipment usage,and design considerationsof the 210-NYseriesSignal Monitor.It

provides the user with a general understanding of the operating principles necessaryto install and maintain the model

210-NY series Signal Monitor.

1.2 BASIC FUNCTIONS

The 210-NY series Signal Monitor is a device used in a traffic controller assembly to monitor traffic signals at an

intersection for conflicting proceed indications caused bymalfunctionsof the controller, load switches,field wiring and

loads, or mis-wiring of the cabinet.The 210-NY series Signal Monitor also provides error sensing of the cabinet24VDC

supplyand monitors the controller Watchdog output. The 210-NY series Signal Monitor isdirectlyinterchangeable witha

standard model 210 Signal Monitor and complies with all specifications outlined in New York State Transportation

Management Equipment Specifications (November 1, 1994) with addendum May 30, 1995.

When triggered by the detection of a fault condition which exists longer than the minimum period, the 210-NY series

Signal Monitor will enter the fault mode causing the Output relaycontactsto close and enablingtheStop-Time outputto

the controller. The cabinet assemblyshould be wired such that the closure of the conflictmonitor Outputrelaycontacts

will cause an automatic switching of the field signal outputsfrom normal operation to flashing operation. The 210-NY

series Signal Monitor will then displaythe appropriate fault indications. The 210-NY seriesSignal Monitor will remain in

this fault mode until a reset command isissued via the front panel RESET button or ExternalResetinput.ThelossofAC

Line power will not reset the fault mode unless the fault is WD FAULT or WD@LOW VOLT. In the event of AC Line

power loss the 210-NYseriesSignal Monitor will retain the status of all fault and channel indicatorsand will displaythe

correct fault and channel status upon restoration of AC Line power.

1.1.1 CONFLICT MONITORING

The 210-NY is capable of monitoring 16 channels. Each channel monitors a Green and Yellow field signaloutputatthe

field terminals. A Program Card is provided for assigning conflicting channels and inhibiting Yellow monitoring for

required channels.The 210-NY series Signal Monitor detectsthe presence of conflicting Green orYellowsignalson the

AC field terminations between any two or more channels assigned to conflict on the Program Card. The monitoring

circuitry is capable of detecting either full wave or positive and negative half-wave field signal outputs at the specified

voltage levels.

1.1.2 24VDC MONITORING

When the 24VDC inputfalls below the specified voltage levels the model 210-NYwill enter the fault mode causing the

Outputrelay contacts to close and enabling the Stop-Time output to the Controller. The 24VDC monitoring circuitryis

referenced to Logic Ground and is isolated from the rest of the monitor circuits.

1.2.1 CONTROLLER WATCHDOG MONITORING (WD FAULT & WD@LOW VOLT)

The Watchdog outputfrom the Controller Unitismonitored for logic transitions. When a logic transitionisnotsensedfor

the specified period (see Section 3.4.2) the model 210-NYwill enter the fault mode causing the Outputrelaycontactsto

close and enabling the Stop-Time output to the Controller. If the AC Line voltage is above 101 +_2 Vac when the

Watchdog fault is detected the WD FAULT indicator will be illuminated. If the AC Line voltageisbelow101

If the AC Line voltage drops below 88

+_2Vacwhen

the Watchdog fault is detected the WD@LOW VOLT indicator will be illuminated. The indicator statuswill be latched

until a reset command is issued.

+_2 Vac either Watchdog fault mode will be cleared when the AC Line voltage

restores above 88

If the AC Line voltage drops below 101

+_2 Vac and the unit detectswatchdog pulses from the Controller.Theindicatorwill remainilluminated

to indicate a Watchdog fault existed but was cleared by the power loss.

+_2 Vac or the Watchdog fault occurs while the AC Line voltage isbelow 101 +_2

Vac (WD@LOW VOLT), the Watchdog fault mode will be cleared when the AC Line voltage goes above 101 +_2 Vac

and the unit detectswatchdog pulses from the Controller. To clear the fault, 650 +_100 transitionsof theWatchdoginput

210-NY RMS Signal Monitor

Operations Manual

Eberle Design Inc. Page 2

are required. The indicator will remain illuminated to indicate a Watchdog fault existed but was cleared by the power

loss.

The WDT Latch option (see section 3.3.1) determines whether this WD FAULT or WD@LOW VOLT fault mode is

latched through an AC Line brownout or not. If the WDT Latch option is notselected, anACLinebrownoutconditionwill

reset either WD FAULT or WD@LOW VOLT fault mode when the AC Line is restored as described above.

If the WDT LATCH option is selected, the WD FAULT or WD@LOW VOLT fault mode is maintained until a Reset

command is applied.

210-NY RMS Signal Monitor

Operations Manual

Eberle Design Inc. Page 3

Section 2

GENERAL CHARACTERISTICS

The following extended features are provided on the 210-NYseriesSignal Monitor to provide additionalfaultmonitoring

functions, to increase the reliability of the monitor operation, and enhance the diagnostic capabilities offered to the

service technician.

2.1 HARDWARE FEATURES

The model 210-NYseries Signal Monitor isa dual microprocessor based unit.All monitoring functionsandfeaturesare

firmware programmable which permits upgradesor modifications bysimplyreplacingtheEPROMdevicecontainingthe

firmware with the upgraded version. Thus, most changes to the 210-NY series Signal Monitor specifications may be

accommodated without modifying the hardware.

Since all critical timing functions are accomplished bythe microprocessor,the quartz crystal based accuracyresultsin

very precise and repeatable measurements. This accuracy is maintained on functions from timing fault conditions to

implementing a unique firmware based digital sampling and filtering algorithm. Thisalgorithm isappliedto all ACfield

signals to help eliminate false detection in a "noisy" AC line environment.

Input voltages are measured using a true Root Mean Squared (RMS) technique. A dedicatedRMS-Enginecontrolsthe

analog to digital (A/D) hardware which samples each AC input voltage 32 times per cycle. The RMS-Engine then

calculates the true RMS voltage value producing accurate results which are veryinsensitive to changes in frequency,

phase,wave shape, and distortion. Voltage references are temperature compensated for constantvoltagelevelswithin

the operating temperature range.

A nonvolatile EEPROMdevice is utilized to retain fault statusinformation in the event of an AC Line power interruption.

The correct fault indications will be displayed upon restoration of AC Line power. This EEPROM device requires no

battery back-up.

2.2 AC LINE BROWN-OUT DETECTION

When the AC Line voltage is below the "drop-out" level the 210-NY series Signal Monitor will suspend all fault monitoring

functions,close the Outputrelay contacts,and enable the Stop-Time output to the controller.TheACPOWERindicator

on the front panel will extinguish to indicate the brown-outstatus.When the AC Line voltage returns abovethe"restore"

level the monitor will resume normal operation and the AC power indicator on the front panel will remain illuminated.

The AC Brownout dropout and restore voltage levels are selected by the AC Line Brown-out Select jumper labeled

SEL5. See Section 3.3.4.

If the AC Line voltage isdetected above 135 +_

2.2.1 MINIMUM FLASH TIME

2 Vrms,the AC POWER indicator will flash at a 2 Hz rate.Thisindication

will be latched until a reset command is issued.

A Minimum Flash time option can be selected (see section 3.3.2) which provides a flash interval of at least6 seconds

and at most 10 seconds in duration following a power-up, an AC Line interruption, or a brownout restore. During this

interval the unit will suspend all fault monitoring functions and close the Output relay contacts.

The minimum flash interval will be terminated after at least 6 seconds if the Watchdog input has made 5 transitions

between the True and False state and the AC Line voltage is greater than the restore level.

2.3 RECURRENT PULSE (RP) DETECTION

This error detection function supplements the normal Conflict monitoring algorithm for sensing faults which are

intermittent or pulsing in nature. The RMS-Engine is designed to filter out short term transients commonlyfoundonthe

electrical service and provide noise immunityagainst false signal detections. The Recurrent Pulse detectionfunctionis

designed to respond to fault conditions which are intermittent in nature and do not meet the continuous timing

requirements of the normal detection algorithms, yet maystill produce improper signal displays. Theseinputconditions

are differentiated by their longer time constant and fault response times.

210-NY RMS Signal Monitor

Operations Manual

Eberle Design Inc. Page 4

Figure 2-1 shows an example of a recurrent Conflict fault. Channel 2 Green isdetected active due to a malfunction of

the load switch which caused the output to Aflicker@On for 100 ms approximately every 200 ms. Since normal Conflict

detection requires a continuous fault of at least 350 ms typical, this event could go undetected. The Recurrent Pulse

detection algorithm will combine these pulsesinto one event and trigger a Conflict fault once thelonger recurrenttiming

threshold is exceeded.

When triggered bya recurrent fault condition, the 210-NYwill enter the fault mode, transfer the Outputrelaycontactsto

the Fault position, enable the Stop-Time output to the controller, and illuminate the CONFLICT indicator along withthe

RP DETECT indicator. The unitwill remain in the fault mode until reset bythe Reset button or the ExternalResetinput.

Fault response timeswill varydepending on the pulse width and frequencyof the recurrent inputs, butwill range from

1000 ms minimum to 10.4 seconds maximum. Recurrent Pulse detection can be disabled with the RP DISABLEoption

switch (SW3-2), see Section 3.2.1.

2.4 NON-VOLATILE FAULT MEMORY

The 210-NY series Signal Monitor stores the fault and channel indicator status atthe time the fault occurs into a non-

volatile EEPROMdevice. Should an AC Line power interruption occur while the monitor is in the fault mode, then upon

restoration of AC Line power,the Output relayand Stop-Time output will remain in the fault mode and the correct fault

and channel indicators will be illuminated.

2.5 PROGRAM CARD ABSENT (PCA) INDICATION

If the Program Card is absent or notseated properly in the edge connector, the 210-NYseriesSignal Monitor will enter

the fault mode causing the Output relay contacts to close and enabling the Stop-Time output to the controller. The

CONFLICT indicator will illuminate to indicate this condition.A manual or external Resetisrequired afterthe Program

Card is properly seated.

2.6 CONFIGURATION CHANGE MONITORING

The 210-NY series Signal Monitor maintains an internally calculated CRC value of the current configuration settings.

These settings include the permissive diode matrix, Yellow Disable switches, Option switches, SEL1 through SEL10

jumpers, and the Watchdog Enable switch. On power-up,reset, and periodicallyduring operation,theunitwillcompare

the current configuration settings with the previously stored value. If the settings have changed, the 210-NY series

Signal Monitor will automatically log the new setting.

When the Configuration Change Fault select option is jumpered (see section 3.3.3), any change in the configuration

parameters will cause the 210-NY series Signal Monitor to enter the fault mode causing the Output relay contacts to

close and enabling the Stop-Time output to the controller. To indicate this fault mode the IF indicator will flashata4Hz

rate. Depressing the Reset button for 5 full seconds will clear this fault and log the new configuration parameters.

2.7 INTERNAL MPU WATCHDOG

The 210-NY series Signal Monitor generates an internal watchdog pulse from itsmicroprocessor.Thisoccurs atleast

once per line cycle. If the internal hardware doesnot detect a watchdog pulse withinapproximately325milliseconds,the

210-NYseries Signal Monitor will enter the fault mode causing the Output relaycontactstocloseandenablingtheStop-

Time output to the controller. The IF indicator on the front panel will illuminate to indicate a monitor hardware and/or

firmware failure.

210-NY RMS Signal Monitor

Operations Manual

Eberle Design Inc. Page 5

This type of failure isconfigured aslatching.With latching operation, only a lossof AC Line will restore operation. If the

microprocessor resumes operation the unit will not return to normal operation. If non-latching operation is desired,

jumper E5 may be removed. See Section 3.5.

2.8 RESET INPUT DETECTION

A reset command from either the front panel Reset button or External Reset input will causeaone-timeresetcommand

to the monitor. If the reset command is maintained longer than 500 milliseconds, the monitor will resume monitoring

functions and the Reset command will then provide input to the Diagnostic Display mode (see Section 2.12).

2.9 LED TEST

The monitor will illuminate all front panel indicators for 1000 milliseconds when a Resetcommand isissued bythefront

panel Reset button or External Reset Input. This function provides a means to verify the operation of all front panel

indicators.

2.10 MEMORY TEST

The 210-NY series Signal Monitor verifies the proper operation of the memory devices (RAM, EPROM, & EEPROM)

required to operate the monitor. This test is performed when AC Line power is applied, a Reset Command isissued to

the monitor, and periodically during operation. If a memory error is detected, the 210-NY series Signal Monitor will

attempt to update the front panel displayand then execute a STOP instruction. This will cause theOutputrelaycontacts

to close and enable the Stop-Time output to the controller. The IF indicator on the front panel willilluminatetoindicatea

monitor hardware and/or firmware failure. Due to the nature of these hardware or firmware failures, other fault

indicators that may be concurrently illuminated may not be valid for trouble shooting purposes.

2.11 WATCHDOG MONITORING DISABLED INDICATOR

When the WD ENABLEswitch is in the OFF position to disable Watchdog Monitoring of the cabinet Controller,the210-

NY series Signal Monitor will extinguish the WD FAULT indicator on the front panel.

2.12 DIAGNOSTIC DISPLAY MODE

The 210-NY series Signal Monitor provides two means of displaying the individual Green and Yellow field status.The

No Fault Diagnostic Display mode shows the individual colors while the monitor is not in the fault mode (intersection

operating). The Fault Diagnostic Display mode shows the individual colors which were active at the time the monitor

triggered to the fault mode (intersection in flash).

2.12.1 NO FAULT DIAGNOSTIC DISPLAY

When the 210-NY series Signal Monitor is not in the fault state, the unit can display the active Green and Yellow field

status individually. To enter this display mode depress and hold the Reset button. Each time the Reset button is

activated and held, the next set of colors will be displayed on the channel status indicators. The displaywill continue to

showthe selected color as long as the Resetbutton isactivated. Thismode onlyaffects the monitor displayand normal

fault processing will continue to occur. The sequence is as follows:

Reset Fault Status LEDs

#1 (G) AC POWER LED flashes Green field status 1-16

Channel Status LEDs

#2 (Y) WD FAULT LED flashes Yellow field status 1-16

... (repeats back to top)

2.12.2 FAULT DIAGNOSTIC DISPLAY

Once the 210-NYseries Signal Monitor has been triggered by a fault, the Green and Yellow field inputstatusactive at

the time of the current fault maybe displayed individually. This status is not resetbyan AC Line power interruption. To

enter this display mode remove the Program Card. The sequence is as follows:

Reset Fault Status LEDs

--- Current Fault Status Current channel status

Channel Status LEDs

#1 (G) AC POWER LED flashes Green field status 1-16

#2 (Y) WD FAULT LED flashes Yellow field status 1-16

... (repeats back to top)

210-NY RMS Signal Monitor

Operations Manual

Eberle Design Inc. Page 6

To enter thisdisplaymode remove the Program Card.Depressing the Resetbuttonadvancesthedisplaymodefromthe

normal mode to the Green field input display. The (G) AC POWER LED will pulse ON once per second to indicate this

mode. The channel display LEDs will show the Green channels active at the time of the fault.

Depressing the Reset button again advances the display mode from the Green displaymode to the Yellow field input

display. The (Y) WD FAULT LED will pulse ON once per second to indicate this mode. The channel displayLEDs will

show the Yellow channels active at the time of the fault.

To exitthisdisplaymode,replace the Program Card. If the Program Card is removed while the model 210-NYunithas

not been triggered by a fault, the fault status display mode will show the Green and Yellow channels active when the

Program Card was removed.

210-NY RMS Signal Monitor

Operations Manual

Eberle Design Inc. Page 7

Section 3

INSTALLATION

3.1 PROGRAM CARD PROGRAMMING

Thiscard provides the means to assign conflicting channels and to disable sensing of Yellow input signals.The card is

initially supplied with 120 diodes mounted on the card. Thispermits all channels to conflict with all other channels. To

program a NON-CONFLICTING channel pair, remove the appropriate diode from the program card. To DISABLE

sensing of a Yellow signal on a channel, solder a wire jumper between the hole pairs labeled for that channel.

Example:

If the Program Card is removed or notseated properlyin the edge connector, the210-NYseriesSignal Monitorwill enter

the fault mode causing the Output relay contacts to close and enabling the Stop-Time output to the controller. The

CONFLICT indicator will illuminate to indicate this condition. A manual Reset is required after the Program Card is

properly seated.

If channel 2 Green or Yellow is permissive with channel 6 Green or Yellow,disconnectthediodelabeled"2-6".

To disable Yellow signal sensing on channel 9, a jumper wire must be soldered in between the pair of holeslabeled"9"

in the area designated "YELLOW DISABLE" on the program card.

3.2 OPTION JUMPER PROGRAMMING

The 210-NY series Signal Monitor provides jumper options to modify the monitor operation. The Option jumpers are

labeled OPTIONS (SW3) and are located near the program card edge connector. Option jumpers SW3-1, SW3-4

through SW3-8 are not used.

3.2.1 RECURRENT PULSE (RP) DISABLE SWITCH (RP DISABLE)

Jumper #2 of SW3 is labeled "RP DISABLE". When this jumper is in position, the Recurrent Pulse detection mode is

disabled. See Section 2.3.

3.2.2 WD TIMING SWITCH

Jumper #3 of SW3 is labeled "WD 1.0 SEC".When thisjumper isin position,the Watchdog fault time isset to 1.0 _+0.1

seconds. When this jumper is NOT in position, the Watchdog fault time is set to 1.5

3.2.3 SELECT JUMPER PROGRAMMING

_+0.1 seconds.

The 210-NY series Signal Monitor also providesjumper options to modify the monitor operation. The Select jumpers

are labeled SEL1 through SEL10. SEL6 through SEL10 are reserved for EDIconfiguration programming and should

not be modified except by the factory.

3.2.4 WATCHDOG LATCH SELECT (SEL1)

The WDT Latch select determines whether the WD FAULT or WD@LOW VOLT fault mode is latched through an AC

Line brownoutor not. If the WDT Latch select is notjumpered,an AC Line brownoutcondition willresettheWDFAULT

or WD@LOW VOLT fault mode when the AC Line is restored. The WD FAULT or WD@LOW VOLT indicator will

remain illuminated until a Reset command is issued via the front panel RESET button or External Reset input. See

section 1.2.3.

If the WDT LATCH select is jumpered, the WD FAULT or WD@LOW VOLT fault mode is maintained until a Reset

command is applied.

3.2.5 MINIMUM FLASH ENABLE SELECT (SEL2)

When jumpered,the Minimum Flash function provides a flash interval of at least 6 seconds and at most 10 seconds in

duration following a power-up, an AC Line interruption, or a brownout restore. See section 2.2.1.

3.2.6 CONFIGURATION CHANGE FAULT SELECT (SEL3)

When jumpered,the Configuration Change Fault function will be enabled causing the 210-NYseries Signal Monitor to

enter the fault mode if any configuration parameter is changed. If the Configuration Change Fault Select jumper isnot

installed, the unit will not set the fault mode. See section 2.6.

210-NY RMS Signal Monitor

Operations Manual

Eberle Design Inc. Page 8

3.2.7 AC LINE BROWN-OUT SELECT (SEL5)

When jumpered,the AC Line Brown-outlevels will be set for the 2010 serieswith Adropout@at98+_2VrmsandArestore@

at 103 +_2 Vrms with timing at 400 +_50 ms. When not jumpered, the AC Line Brown-out levels will besetforthe210-NY

series with Adropout@at 82 +_2 Vrms and Arestore@at 88 +_2 Vrms with timing at 80

3.3 WATCHDOG PROGRAMMING

_+17 ms. See section 2.2.

3.3.1 WATCHDOG ENABLE SWITCH

The toggle switch SW2 labeled "WD ENABLE" providescontrol for the Watchdog Monitoring function.Whentheswitch

is in the ON position, the Watchdog Monitoring function is enabled. When the switchisintheOFFposition,theWatchdog

Monitoring function is disabled.

3.3.2 WATCHDOG TIMING OPTION

Jumper #3 of the OPTIONS switch (SW3) is labeled "WD 1.0 SEC". When thisjumper isin position,theWatchdogfault

time is setto 1.0 _+0.1 seconds. When this switch is NOT in position, the Watchdog fault time is set to 1.5

3.3.3 INTERNAL MPU WATCHDOG LATCH OPTION

_+0.1 seconds.

The internal MPU Watchdog circuit can be configured as a latching function. To enable the latchingfunctionasoldered

wire jumper should be placed into jumper holes labeled "E5". See Section 2.7.

210-NY RMS Signal Monitor

Operations Manual

Eberle Design Inc. Page 9

Section 4

FRONT PANEL DESCRIPTION

4.1 INDICATORS

The AC POWER indicator will illuminate when the AC Line voltage level is above the brown-out "restore" level.

The indicator will extinguish when the AC Line voltage is below the "drop-out" level. If the AC Line voltage is

detected above 135

(G) AC POWER Indicator

+_

If the unit isin the Diagnostic Displaymode,the AC POWER indicator will flashONoncepersecondto indicatethe

Channel Status display is showing Green channel status. See Section 2.12.

2 Vrms, the AC POWER indicator will flash at a 2 Hz rate. See Section 2.2.

The WD FAULT indicator will illuminate when a Controller Watchdog fault isdetected while theAC Linevoltageis

greater than 101

(Y) WD FAULT Indicator

+_

If the unit isin the Diagnostic Displaymode, the (Y) WD FAULT indicator will flash ON once persecondtoindicate

the Channel Status display is showing Yellow channel status.

2 Vac. If the unit is not in the fault mode the indicator will display the state of the Watchdog

input.

The WDF@LOW VOLT indicator will illuminate when a Controller Watchdog fault is detected while the AC Line

voltage is between 88

WD@LOW VOLT Indicator

+_2 Vac and 101 +_2 Vac.

The DC POWER ON indicator will extinguish when a 24VDC fault condition is detected. This indicator remains

illuminated if the monitor has not been triggered by a 24VDC fault.

DC POWER ON Indicator

The CONFLICT indicator will illuminate when a conflicting proceed signal fault is detected. The CONFLICT

indicator will also illuminate if the Program Card is not in place.

CONFLICT Indicator

The RP DETECT indicator will illuminate when the Recurrent Pulse detection function has triggered a Conflict

fault. See Section 2.3.

RP DETECT Indicator

The IF indicator will illuminate when an internal hardware or firmware test function has failed. This indicator is

intended to inform the service technician of a monitor hardware or firmware failure. Due to the nature of these

hardware or firmware failures, other fault indicators that may be concurrently illuminated may not be valid for

trouble shooting purposes.

IF Indicator

If the unit is in the Configuration Change Fault mode, the IF indicator will flash at a 4 Hz rate (see section 2.6).

During normal operation the Channel Statusindicators will display all active proceed signals(GreenorYellow).In

the fault mode the Channel Status indicators will display all proceed signals active at the time of the fault.

CHANNEL STATUS Indicators

4.2 FRONT PANEL CONTROLS

Depressing the Resetbutton resets the 210-NY series Signal Monitor after it hasbeen triggered bya fault. In the

eventof a monitor hardware or firmware fault (IF) the Reset button maynot resetthe monitor. A power-up restart

RESET Button

210-NY RMS Signal Monitor

Operations Manual

Eberle Design Inc. Page 10

may be required. The Reset button also provides control of the Diagnostic Display mode. For a complete

description of Diagnostic Display operation see Section 2.12.

210-NY RMS Signal Monitor

Operations Manual

Eberle Design Inc. Page 11

Section 5

THEORY OF OPERATION

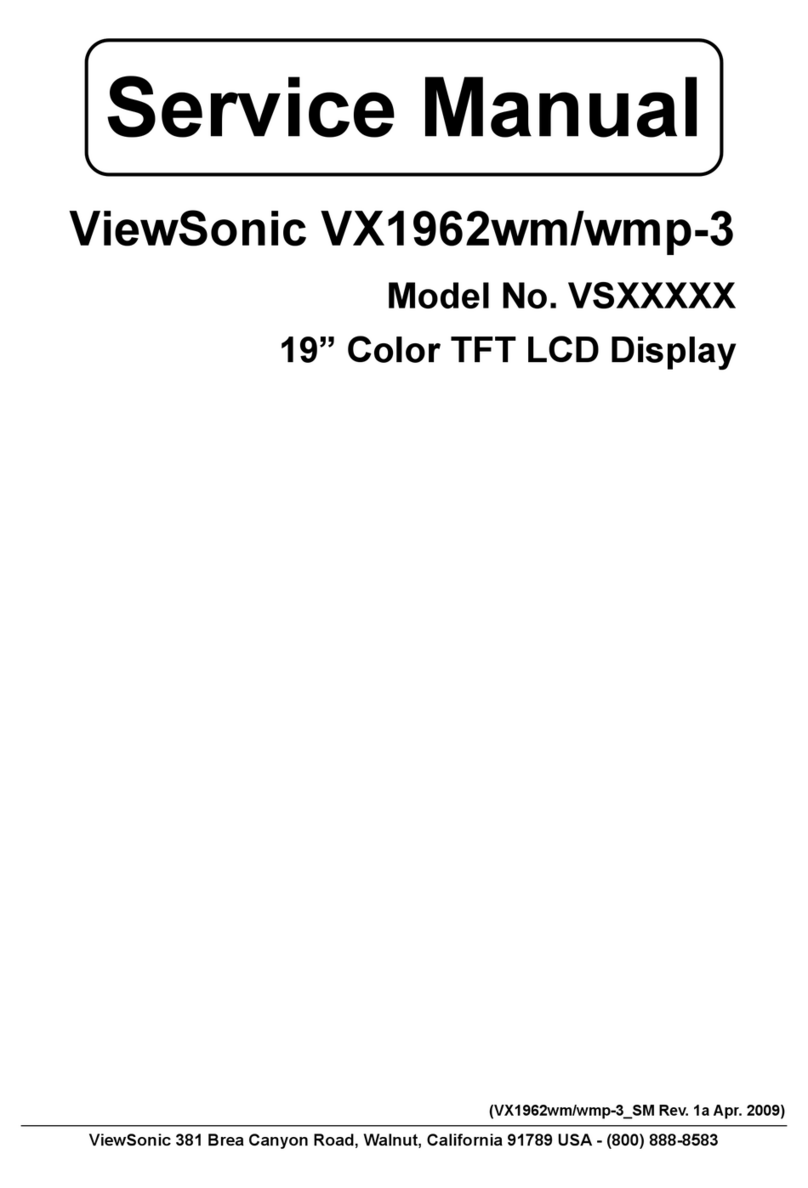

5.1 SYSTEM DESCRIPTION

The 210-NY series Signal Monitor uses a dual microprocessor architecture consisting of an MC68HC11D0 main

microprocessor unit (MPU) and a Microchip PIC17C43 based RMS-Engine. The RMS-Engineisa dedicatedsingle-chip

high speed micro-controller used to sample the AC field inputs and calculate the true Root Mean Squared (RMS)

voltage. This true RMS voltage information is then transmitted to the main microprocessor for fault processing.

The MC68HC11D0 main microprocessor uses a high speed synchronous serial I/O system called theSerialPeripheral

Interface (SPI) to exchange data with the peripheral circuit blocks. It controls all functions of the unit except for thoseof

the RMS-Engine.

68HC11

MPU

17C43

RMS

ENGINE

ANALOG

MUX

ARRAY

RAM

ROM

MEMORY

OUTPUT

DRIVERS

24 VOLT

LOGIC

INPUTS

PROGRAM

CARD &

SWITCH

INPUTS

DISPLAY

DRIVERS

A/D

AC

FIELD

INPUTS

MOSI

Data

Addr

Out Relay

Fault Leds

Ch Leds

MISO

Stop Time

MPU WD

5.2 DETAILED DESCRIPTION OF CIRCUIT OPERATION

5.2.1 MAIN MPU LOGIC

The MC68HC11D0 main microprocessor (U8) operates in the Expanded Multiplexed mode which allows for external

memory devices. The program firmware is contained in the 29F010B CMOS Flash device (U12) and program data

storage is contained in the SRM2264 8Kx8 static RAM(U18). The expanded address and data bussisusedto link the

memory devices with the microprocessor. A 74HC137 (U9) selector also resides on the buss to generate chip select

signals for the SPI devices.

5.2.2 SERIAL PERIPHERAL INTERFACE (SPI)

The Serial Peripheral Interface (SPI) is a high speed synchronous serial I/O system used to interconnect the main

microprocessor to the following circuit blocks: EEprom (U20), 24Vdc Logic Inputs (U25), Display Multiplexer (U2, 3),

Program Card and Switch inputs (U34-37), and the RMS-Engine (U38).

Data is clocked out of the main microprocessor on the MOSI pin (U8.18) while data is clocked in on the MISO pin

(U8.17). The SCLK signal (U8.19) provides the synchronous clock. A peripheral device mustbeselectedbyU21before

SPI transfers may take place.

5.2.3 INTERNAL MPU WATCHDOG

Circuit U4A and U4B comprise the internal MPU Watchdog circuit. If this circuit does receive an input from the main

microprocessor for at least 325 ms, the circuit will trigger and force the Output relayto the fault mode, enabletheStop-

210-NY RMS Signal Monitor

Operations Manual

Eberle Design Inc. Page 12

Time output, and illuminate the DIAGNOSTIC indicator. This indicatesthatthe microprocessor hasfailed tooperateits

program loop. Under normal conditions the microprocessor will clock this circuit every 20 ms.

If jumper E5 is installed this fault mode will only be reset bya complete power down cycle.

5.2.4 EEPROM MEMORY

The 25C320 Serial EEprom (U20) device provides 4096 bytes of nonvolatile memory. It is interfaced to the main

microprocessor through the SPIport. No battery is required to maintain the data in this device.

5.2.5 24VDC LOGIC INPUTS

The Cabinet 24Vdc input, CU Watchdog input, and External Reset input are thresholded by comparator U47 to

determine true/false input status. Opto-couplersU42-45 provide electrical isolation betweenLogicGroundandNeutral.

The 74HC165 (U25) shift register uses the SPI port to transfer this data to the main microprocessor.

5.2.6 DISPLAY

The front panel LED display is multiplexed by the row driver U3 and the column driver U2. The scan rate is

approximately 60 Hz. Displaydata isshifted into U3 while individual columns are selected byU2usingtheSPIinterface.

5.2.7 PROGRAM CARD AND SWITCH INPUTS

The program card and configuration switch inputs are scanned through a diode matrixusing row driversU34 and U35.

Column drivers U36 and U37 select the column to be read. These devicestransfer data to the main MPU through the

SPI interface.

5.2.8 RMS-ENGINE

The RMS-Engine is a Microchip PIC17C43-16I/P single-chip high performance RISC microcomputer executing

proprietary firmware that calculates true RMS voltages for each inputchannel. The resulting data is transferred to the

main MPU via the SPI interface. The analog to digital converter U39 provides the voltage measurement data for the

RMS-Engine approximatelyevery6 microseconds. Analog multiplexers (74HC4051N) select the appropriate channel

for sampling. Op amp circuits U46A, U46B, and U46C perform a full wave rectification circuit.

5.2.9 POWER SUPPLY

The switching power supplyisbased on a MIC38C43 (U22) fixed frequencycurrent-modePWMcontroller.The ACLine

is full wave rectified and charges capacitor C72 to approximately170 Vdc. The PWM controller switches current from

C72 through the transformer T1 using transistor Q3 atapproximately 200 KHz. The transformer couples this energyto

the secondaries and provides the following output voltages: VDD=+5 Vdc, VCC=+8 Vdc, VGG=-8 Vdc, VEE=-5 Vdc,

VCCL=+16 Vdc, and VDDS=+5 Vdc. Opto-coupler U24 provides feedback to the controller for regulation.

210-NY RMS Signal Monitor

Operations Manual

Eberle Design Inc. Page 13

Section 6

MAINTENANCE

6.1 PREVENTIVE MAINTENANCE

No adjustments or alignments are required. It is recommended that the signal monitor be tested at least annually to

ensure compliance with the proper factory and agency specifications.

6.2 TROUBLE SHOOTING SEQUENCE

Will not power on

SYMPTOMS:

A) Blown fuse

CAUSES:

B) Internal power supply is low

C) No AC input to the monitor

A) Remove the fuse and verify with an Ohm meter. Replace if necessary with a fuse with the same current rating.

SOLUTIONS:

B) Check the unregulated voltage across filter capacitor C72 with an oscilloscope or volt meter. It should read

approximately 170 Vdc when the AC Line is equal to or greater than 110 Vrms. If the regulated supply(VDD) is

less than 4.5 Vdc the internal power supply monitoring circuit (U19) will hold the MPU in reset and the

DIAGNOSTIC indicator on the front panel should illuminate. Measure the regulated voltageacrosscapacitorC22.

If it measures lower than 5 _+

C) If the fuse is not blown then the monitor may not be getting AC Line or Neutral to the edge connector of the

monitor.

0.5 Vdc the regulated supply may be overloaded or shorted to ground.

Faults when AC power is applied

SYMPTOMS:

A) Program card is absent or not seated properly

CAUSES:

B) AC Line level is low

C) Memory device fault

D) No internal watchdog pulses

A) The CONFLICT indicator on the front panel will illuminate. Re-insert the program card with the diode side of the

card facing the front panel slot and depress the RESET switch. The rear edge oftheprogram cardshouldbeflush

with the front panel.

SOLUTIONS:

B) Measure the AC Line voltage level with a volt meter. If it is below the required "drop-out" level, the monitor will

transfer the Outputrelay contacts and enable the STOP TIME outputto the controller. The AC POWER indicator

on the front panel will extinguish to indicate the "brown-out" condition.

C) The memory devices are verified when AC Line power is applied or a Reset command is issued. If a memory

fault is detected the MPU executes a STOP instruction.This causes all MPU activitytocease.Refer toSection

2.10.

D) Absence of internal watchdog pulses may result from the MPU not executing or completing the program loop or

the hardware detecting the internal watchdog pulses is not functioning. Place an oscilloscope probe on U4.2. If

210-NY RMS Signal Monitor

Operations Manual

Eberle Design Inc. Page 14

there are no pulses, depress the front panel reset switch to re-start the MPU. If the watchdog pulses are now

present on U4.2 then trace the remaining pulse detection hardware for the required waveforms.

Required channels will not conflict

SYMPTOMS:

Diode on the Program Card is open or absent

CAUSES:

Check the program card to verifythat the required diode is in place. If the diode ispresent then verifyallconnectionsare

good and the diode is working correctly.

SOLUTIONS:

Other manuals for 210 Series

1

Table of contents

Other EDI Monitor manuals