EF Cypher 3D User manual

1

ASSEMBLY MANUAL AND SETUP GUIDE

Congratulations - you’ve just bought an electric powered helicopter with a

performance that’s going to amaze you! The Cypher 3D is here!

This lightweight 3D helicopter has a powerful brushless outrunner

motor and matching speed controller and features a 120° CCPM main

rotor control system, belt-driven tail rotor, autorotation unit as

standard, extensive use of ball races (20 pieces) and much more!

Combine this with your choice of lightweight micro servos, gyro, receiver

and Li-Po battery (not included) and prepare to be amazed at what this

versatile EP helicopter can do!

Kit Product Number EF006

Made in Taiwan

CYPHER 3D EP FEATURES

95% Factory-Assembled and Almost Ready to Fly

Stunning 3D Performance!

120° CCPM Main Rotor Control System

Belt Drive Tail Rotor with Ball Bearing Tensioners

Aluminium Centre Hub with Metal Operating Arms

Extensively Ball Raced

Composite Swashplate

One-Way Main Gear as Standard

3800Kv Brushless Motor & 40A Electronic Speed Controller Included

Strong, Pre-Painted Wooden Main Blades

•

•

•

•

•

•

•

•

•

•

All Contents Copyright © 2007,

Version 1 November 2007

DISTRIBUTED IN

EUROPE BY:

Ripmax Ltd.,

241 Green Street,

Eneld, EN3 7SJ.

United Kingdom.

DISTRIBUTED IN NORTH

AMERICA BY:

Global Hobby Distributors

18480 Bandilier Circle

Fountain Valley, CA 92708

2

TABLE OF CONTENTS

This assembly manual and setup guide is designed to guide you through the entire assembly and setup process of your new helicopter

in the least amount of time possible. Along the way you'll learn how to properly assemble your new helicopter and also learn tips that

will help you in the future. We have listed some of our recommendations below. Please read through them before beginning assembly.

●Please read through each step before beginning assembly.

You should nd the layout very complete and straightforward.

Our goal is to guide you through assembly without any of the

headaches and hassles that you might expect.

●There are check boxes next to each procedure. After you

complete a procedure, check off the box. This will help prevent

you from losing your place.

●Cover your work table with brown paper or a soft cloth, to protect

both the table and the parts.

●Keep a couple of small bowls or jars handy to put the small parts

in after you open the accessory bags.

●We're all excited to get a new helicopter in the air, but take your

time. This will ensure that you don't miss any assembly steps

and that your helicopter is set up correctly for its rst ight.

INTRODUCTION

This R/C helicopter is not a toy! If misused or abused, it can cause serious bodily injury and/or damage to property. Fly only in

open areas and preferably at a dedicated R/C ying site. We suggest having an experienced pilot carefully inspect your helicopter

before its rst ight. Please carefully read and follow all instructions included with this helicopter, your radio control system and any

other components purchased separately.

l Just because the Cypher 3D EP is small and powered by an electric motor doesn't mean that you shouldn't exercise caution when

ying and operating it. You must use the same amount of caution during use as when ying and operating a glow-powered

helicopter.

l We strongly suggest that when you rst begin ying the Cypher 3D EP that you perform only basic manoeuvres, until you are more

familiar with the setup and ight characteristics of the helicopter. This will give you time to feel comfortable with the way the helicopter

reacts to control inputs and power.

lYou must be cautious when plugging the battery into the helicopter. Unlike glow-powered helicopters that use a clutch assembly

to allow the engine to idle without the rotor blades spinning, an electric helicopter features no such clutch. You must be sure that

your transmitter is turned on and the power/collective control stick is in the full idle (throttle closed) position before plugging in the

battery. This will prevent any chance of the rotor blades spinning and harming you while plugging in the battery.

l To prevent unwanted radio signals from interfering with your transmitter and receiver, always turn on the transmitter rst, then plug

in the battery. After ying, always unplug the battery rst, then turn off the transmitter.

Introduction..............................................................................................2

Electric Helicopter Safety Warnings ........................................................2

Lithium Polymer Battery Safety Warnings ...............................................3

Customer Service Information.................................................................2

Items Needed for Assembly.....................................................................4

Installing the Cyclic Servos......................................................................5

Installing the Tail Servo............................................................................9

Installing the Electronic Speed Controller..............................................10

Installing the Gyro..................................................................................10

Installing the Receiver ........................................................................... 11

Connecting Up and Tidying the Wiring .................................................. 11

Installing the Battery..............................................................................12

Adjusting the Linkages ..........................................................................12

Installing the Main Rotor Blades and Body............................................13

Pre-Flight Set-Up...................................................................................14

Spare Parts............................................................................................15

3

CUSTOMER SERVICE INFORMATION

In the USA

Global Services

18480 Bandilier Circle

Fountain Valley, CA 92708

Phone: (714) 963-0329 Fax: (714) 964-6236

Email: service@globalhobby.net

Website: http://ef.globalhobby.com

l Li-Po batteries may explode or catch re. Serious injury can result from misuse.

l All instructions, warnings and cautions must be followed at all times. Failure to do so can lead to serious injury or re.

lDo NOT overcharge. Maximum voltage for each pack must be followed.

l Do NOT over-discharge. NEVER discharge below the minimum volts specied for the battery.

l Do NOT discharge at a rate greater than the maximum continuous discharge specied for the battery.

lDo NOT use or charge if the battery is hot.

lONLY use a charger made for Lithium Polymer (Li-Po) batteries.

lDo NOT charge at a rate higher than 1C. Example: if the battery’s rating is 2100mAH, then the charger’s charge rate must be

set at 2100mA or less.

lDo NOT leave in direct sunlight or in a hot car or storage area.

lDo NOT get wet or expose to moisture.

lDo NOT short-circuit the battery.

l ONLY discharge and charge the battery outdoors or in a re-safe container.

lDo NOT charge with reverse polarity.

lDo NOT leave the battery connected when not in use.

lDo NOT operate or charge unattended.

lDo NOT solder to the battery directly and do not get the battery hot in any way.

lAlways let the battery cool and "rest" between uses and charging.

lDo NOT charge inside your car or inside your house.

lInspect the battery before each use for swelling or other malformation. If the cell has ballooned, it MUST be discarded.

l Set the charger to 1C (charge at 1/2C or less for the rst 5 cycles).

lCheck polarity and then connect battery to charger.

lIn use, do not over-discharge or exceed maximum discharge.

lWhen handling the battery, remember not to poke, bend or damage the cell. The cell outer casing is soft and can be damaged.

lRemember, the cells must never exceed 160 degrees Fahrenheit for any reason.

In Europe:

Ripmax Ltd.,

241 Green Street,

Eneld, EN3 7SJ.

United Kingdom.

4

TOOLS AND SUPPLIES REQUIRED

Double-Sided

Foam Tape

Modelling

Knife

Needle Nose

Pliers

Small Phillips

Screwdriver

Adjustable

Wrench

This section describes our recommendations to help you in deciding which accessories to purchase for your new helicopter.

ITEMS NEEDED FOR ASSEMBLY

RECOMMENDED ITEMS FOR FLIGHT

lThe transmitter you choose must feature CCPM mixing capability.

lA factory-installed brushless motor is included, together with a matching brushless ESC.

lWe strongly suggest the use of ball raced servos.

Impulse Power

3 Cell 2100~2500mAh

Li-Po Battery

5 - 6 Channel

Transmitter with 120°

CCPM Heli MIxing

Futaba

S3154

Tail Servo

x 1

Micro Gyro

Cirrus 6 or More

Channel Micro Receiver

Pro-Peak

Prodigy II Li-Po

Battery Charger

Thread

Lock

Assorted Hex

Wrenches

Nylon Cable

Ties

Scissors

Cirrus

CS302BB

Servos x 3

Suitable

Connectors for

Battery to ESC

5

❑The swashplate is controlled by a 120° CCPM system. Choose three

identical servos - we are using ballraced Cirrus 302BBs.

❑Remove the servo horns

❑Trim the servo horns as shown using a pair of pliers or sidecutters. You

need to trim one arm off each of the left/right servo horns and three arms

off the fore/aft servo horn as shown.

INSTALLING THE CYCLIC SERVOS

SERVO INSTALLATION TIPS

●After installing the balls onto the servo horns, apply a drop of thin C/A to the ends of the threads to lock the screws into place

●Make sure that you install the servo horn retaining screws to secure the servo horns to the servos

●Make sure that the servos are centred and that you centre the servo horns and ensure that they're pointing in the correct direction

●Make sure that you install the balls the correct distances out from the centre of the servo horns

●Make sure that you install the servos with the servo output shafts pointing the correct direction

● Tighten the servo mounting screws gently, yet tight enough to hold the servos rmly in place

❑Locate three mounted balls and install them on the underside of the left/

right servo horns and on top of the the fore/aft servo horn as shown.

❑Note that all three balls are mounted exactly the same distance out from

the centre on each horn.

❑Beginners may need to reduce the measurement to 8mm (one hole further

in on the arm) to reduce the control throw.

❑ To give sufcient access to install the fore/aft servo, the main shaft needs

to be temporarily removed.

❑Using an Allen key, remove the lower shaft retaining bolt. Grip the nut on

the other side with a pair of pliers or adjustable wrench.

❑Loosen the grub screw in the upper retaining collar using the access point

in the main frames as shown. Do not remove the grub screw, just loosen

it.

6

❑Now remove the two forward screws that retain the swashplate

anti-rotation link.

❑The anti-rotation link can now be rocked backwards to clear the swashplate

as shown.

❑The complete shaft assembly can now be withdrawn from the model and

put to one side.

❑Slide the main gear out of the frames.

NOTE You do not need to remove the tail drive gear. If you leave it in

place it helps ensure that the tail drive belt cannot twist or fall

back into the boom.

❑The fore/aft servo can now be slid under the anti-rotation link and between

the main frames. Note the orientation of the servo.

❑The servo is installed into its mount as shown after pulling its lead through

the main frames.

7

❑Screw the servo into its mount using the screws supplied with the servo.

Do not use rubber mounting grommets.

❑ Centre the servo, then t the previously prepared servo horn at 90° to

vertical and pointing backwards as shown. Tighten the servo horn retaining

screw through the access point in the main frame.

❑This completes the installation of the fore/aft servo and the shaft assembly

can now be replaced as shown below.

❑Ensure the tail drive belt is located on its pulley and is not twisted.

❑Lift up the tail drive pulley and slde the main drive gear under it, ensuring

that the auto-rotation unit is below the main gear as shown.

❑Carefully slide the main shaft assembly through its bearing block in the

main frames and through the tail drive pulley.

❑Holding the main gear in mesh with the motor, the shaft can slide through

the auto-rotation unit and into the lower bearing block.

IMPORTANT Ensure the long arm on the rear of the swashplate aligns

with the slot in the anti-rotation link.

❑Rotate the shaft until the hole in the auto-rotation unit aligns with the hole

in the bottom of the shaft.

❑Replace the mounting bolt you originally removed using a drop of thread

locking compound on the retaining nut. Hold the nut with pliers or an

adjustable wrench as you tighten the bolt.

NOTE If necessary, slide a larger washer over each of the mounting

screws so that they retain the servo effectively with no risk of

them pulling through the mounting lugs.

8

❑Re-tighten the grub screw to retain the tail drive gear on the main shaft.

❑The ball-link from the rear of the swashplate can now be connected to

the mounted ball on the fore/aft servo.

❑Rock the anti-rotation link back into position and replace the two forward

screws that were previously removed.

❑Ensuring the servo is centred, attach the previously prepared servo horn

to the left cyclic servo with the mounted ball to the rear and at 90° to the

shaft as shown. Tighten the servo horn retaining screw securely.

❑Slide the servo into its mount.

❑The ball-link from the left-hand side of the swashplate can now be

connected to the mounted ball on the left cyclic servo.

❑Ensuring the servo is centred, attach the previously prepared servo horn

to the right cyclic servo with the mounted ball to the rear and at 90° to

the shaft as shown. Tighten the servo horn retaining screw securely.

❑Slide the servo into its mount, noting that the lead should be drawn back

through the sideframe.

NOTE We recommend the grub screw be removed and a drop of thread

locking compound applied before replacing it.

❑Screw the servo into its mount using the screws supplied with the servo.

Do not use rubber mounting grommets.

NOTE If necessary, slide a larger washer over each of the mounting

screws so that they retain the servo effectively with no risk of

them pulling through the mounting lugs.

9

❑Screw the servo into its mount using the screws supplied with the servo.

Do not use rubber mounting grommets.

❑The ball-link from the right-hand side of the swashplate can now be

connected to the mounted ball on the right cyclic servo.

❑Prepare the tail servo horn by removing one of the arms as shown.

❑Attach a mounted ball on the top of the servo horn 10mm out from the

centre.

❑Screw the tail servo into its mount using the screws supplied with the

servo. Do not use rubber mounting grommets.

❑Connect the tail linkage’s ball link to the servo.

❑Ensure that the pushrod is as straight as possible though the boom

mounted guides. Rotate the servo mount as necessary to achieve this,

then re-tighten the two retaining screws.

❑ Locate a ball end and screw it on to the pre-tted tail pushrod.

INSTALLING THE TAIL SERVO

NOTE If necessary, slide a larger washer over each of the mounting

screws so that they retain the servo effectively with no risk of

them pulling through the mounting lugs.

NOTE If necessary, slide a larger washer over each of the mounting

screws so that they retain the servo effectively with no risk of

them pulling through the mounting lugs.

10

❑Cut a length of Velcro (hook and loop material) from the strip supplied.

Peel off the backing paper from one side and attach it to the underside

of the ESC as shown

INSTALLING THE ELECTRONIC SPEED CONTROLLER

❑Now peel off the backing paper from the second side.

❑Slide the motor connectors through the sideframes.

❑Press the ESC into position between the frames as shown.

❑Connect the three motor wires from the ESC to the motor’s connectors.

❑Please refer to the separate instruction sheet for details on how to set-up

and use the ESC.

NOTE The motor wires are only temporarily connected at this stage as

two may need to be reversed to achieve the correct motor rotation

later.

❑Cut a length of double sided tape (not supplied) and attach to the underside

of your gyro.

❑Peel off the backing paper from the double-sided tape and attach the gyro

between the main frames on its mount behind the main shaft.

❑ Press the gyro down rmly in position.

NOTE If using a gyro without servo-reversing, make sure you install it

in the correct direction - see the installation instructions supplied

with your gyro for more information.

INSTALLING THE GYRO

11

❑Cut two pieces of Velcro (hook and loop material) from the strip supplied.

One piece attaches to the top of the receiver and the other is cut to match

the angled shape of the sideframes on the rear.

❑Peel off the backing paper from one side of each piece of Velcro and

attach them to the receiver as shown.

INSTALLING THE RECEIVER

❑Remove the remaining backing paper from both pieces of Velcro and slide

the receiver into its position to the rear of the main frames under the main

gear.

NOTE Do not mount the receiver too far forward to ensure that you still

have access to the crystal without removing the receiver.

❑Press the receiver into position between the frames as shown, ensuring

the Velcro on the top and rear of the receiver attach to the sideframes.

❑You can now connect your servos, ESC and gyro to the receiver using

the instructions supplied with your radio system for guidance as to which

channels operate which functions.

❑Use cable ties (not suplied) to secure the wiring to the main frames to

ensure that nothing can be drawn into any of the mechanical parts. This

is particularly important on a smaller helicopter where there are a lot of

wires in a restricted space.

❑Use a small band to retain the aerial to the vertical stabiliser ensuring it

cannot be drawn into the main or tail rotors. Do not shorten the aerial.

12

❑Solder on your choice of connectors onto the battery wires from the ESC

to suit the Li-Po battery you are using.

❑We are using an Impulse Li-Po, so have chosen 4mm gold connectors.

❑ The battery ts into the front of the main frames and is retained with a

combination of a strip of velcro (hook and loop material) and the velcro

strap supplied.

❑Attach a length of velcro to the top of the battery, remove the backing

paper and press the battery rmly in place as shown.

❑Wrap the velcro strap supplied around the battery, through the side frames

and over the top of the ESC to retain.

❑Test that the motor turns the correct direction. If you need to reverse the

motor direction, swap two of the three motor wires

IMPORTANT Observe the correct polarity when connecting the ESC

to the battery - red is positive (+) and black is negative

(-). Do not reverse these connections.

INSTALLING THE BATTERY

ADJUSTING THE FLIGHT CONTROL LINKAGES

CONTROL LINKAGE TIPS

When viewed from behind, the swashplate should rise and fall in a level attitude when the collective (throttle) stick is raised and lowered.

It should tilt to the left and right when corresponding aileron control inputs are made. When viewed from the side, the swashplate

should tilt forward for forward cyclic (down elevator) and backwards for rear cyclic (up elevator) control inputs. Use the transmitter

mixing instructions supplied with your radio system for reference.

lDouble-check that the servo horns are centred when the collective stick is centred

lDouble-check that the servo reversing settings in your transmitter are set properly, so that the servo horns move in the correct direction

lMake sure that your radio transmitter is set to heli mode and that 3 servo, 120° CCPM mixing is turned on

❑Turn on your radio control system and double-check that each servo horn

is centred and moving in the correct direction.

❑With the roll/pitch control stick, trim tabs and servo horns centred, check

to ensure that the swashplate is level when viewed from the front. If the

swashplate is not level, adjust the ball-end on the roll and pitch control

linkages until satised with the alignment.

❑Centre the throttle/collective control stick, then double-check that the trim

tab and the servo horn are centred. Check to ensure that the swashplate

is level from the side. If the swashplate is not level, adjust the ball-end on

the collective control linkage until satised with the alignment.

IMPORTANT Disconnect the motor so that you can complete the

set-up without risk of the blades turning. Beginners

should enlist the help of an experienced helicopter yer

to set-up the Cypher.

13

❑With the tail rotor servo and servo horn

centred, adjust the ball-end so that the

tail rotor pivot arm is aligned 90º to the

tail boom.

INSTALLING THE MAIN ROTOR BLADES AND BODY

❑Install the main rotor blades, making sure that the rounded leading edge

of both blades is facing the same direction as the rounded leading edge

of the paddles.

IMPORTANT The rotor blades are balanced from the factory. No balancing is required.

INSTALLING THE MAIN ROTOR BLADES

IMPORTANT Don't overtighten the socket-cap screws and lock nuts.

Tighten them, then back them off about 1/4 - 1/2 of a

turn to ensure that the blades are tight, but not binding.

They must be able to move slightly.

INSTALLING THE BODY

❑Slide the body over the front of the main frames.

❑Hook the lower edge over the undercarriage then spread the rear of the

body over the two aluminium body posts. Now push the pre-drilled hole

in each side of the body over the pin on the body post on each side of

the main frame.

IMPORTANT Double-check that no part of the body interferes with the

main gear or the swashplate assembly. If the t is too

close, trim the body slightly using a pair of scissors.

14

❑Double-check that the paddles are level when all of the controls are

centred. Both paddles should be even with each other, too.

Before ying your helicopter for the rst time, it's important to double-check everything once more and to make sure that you've set

the helicopter up properly for its rst few ights.

PREFLIGHT SETUP

❑Double-check that all of the screws used throughout assembly are tight. All screws should be secured in place using thread-lock

(if threaded into metal) or with a small drop of thin C/A if threaded into nylon or composite material. This will prevent the screws

from loosening during ight.

❑ Before each ight you should range-test your radio control system to ensure that it is functioning properly.

❑Double-check that you've installed the servo horn retaining screws in all of the servos.

❑Double-check that the main rotor blade screws and the tail rotor blade screws are snug, but not too tight.

❑Double-check that all of the controls are working properly and that they are moving in the correct direction.

Paddles parallel and

level with each other

ADJUSTING THE PITCH SETTINGS

❑First, centre all four control sticks and double-check

that the servo horns and the swashplate are centred, as

described previously.

❑Use a pitch gauge to adjust the collective pitch range

shown right. These gures should be used only as a guide

as the total pitch will be dictated by the battery you are

using.

IMPORTANT Before making adjustments, unplug the motor from the ESC. This will ensure that the motor doesn't turn on.

Pitch Degrees

(Positive) Full Positive Collective +8 ~ +9

Hovering Point +4 ~ +5

Neutral Collective 0

(Negative) Full Negative Collective -8 ~ -9

❑Mark the tip of one rotor blade with a coloured highlighter pen. This will

aid the identication of a high or low blade.

❑Smoothly open the throttle until the heli begins to lift off and watch the

rotational plane (tracking) of the rotor blades. The rotational plane of both

rotor blades should be the same. If they are not, adjustments need to be

made to one blade.

IMPORTANT When spinning, both blades should be even with each

other. They should not appear to waver or oscillate up and down.

CHECKING MAIN ROTOR BLADE TRACKING

❑To adjust the blade, disconnect the ball-end from the lower blade linkage

with the higher rotational plane and tighten the ball-end 1 full turn.

❑Reconnect the ball-end and test the rotational plane of the rotor blades

again. Repeat the procedure until satised with the alignment.

❑When completed, you can wipe off the highlighter pen mark.

Adjust links on

either side of the

head to correct

tracking errors

15

SPARE PARTS

CY0010 Main Frame Sides

CY0020 Main Frame Internal Structure

CY0030 Belt Guide Pulleys, Front

CY0060

Undercarriage Mounting Frames

CY0070 Undercarriage Set

CY0040 Motor Mount

CY0080 Centre Hub

CY0090 Flybar Carrier

CY0100 Flybar Mixing Arms

CY0110 Main Blade Holders

CY0120 Feathering Spindle Spacers

CY0130 Feathering Spindle

CY0140 Paddles

CY0150 Flybar

CY0170 Mixer Block

CY0180 Mixer Arm Set

CY0190 Swash Plate

CY0200 Anti Rotation Stay

CY0210 Main Belt Drive Pulley

CY0220 Main Gear

CY0230 Auto Rot’n Unit Hub W/Bearing

CY0240 Auto Rotation Drive Sleeve

CY0250 Main Shaft

CY0270 Tail Gearbox Case

CY0280 Tail Pitch Lever

CY0290 Tail Shaft with Gear

CY0300 Tail Control Arm

CY0310 Tail Rotor Hub

CY0320 Tail Rotor Blade Holders

CY0330 Tail Blades

CY0340 Tail Servo Mounts

CY0350 Tail Pushrod Guides

CY0360 Horizontal Stabiliser Mount

CY0370 Tail Fin Set

CY0380 Tail Boom

CY0410 Tail Pushrod Set

CY0420 Tail Belt

CY0450 Bearings 2 x 5 x 2.5

CY0460 Bearings 3 x 6 x 2.5

CY0470 Bearings 4 x 8 x 3

CY0480 Bearings 5 x 10 x 4

16

SPARE PARTS

CY0010

Main Frame Sides

CY0020

Main Frame Internal Structure

CY0030

Belt Guide Pulleys, Front

CY0040

Motor Mount

CY0050

Canopy Mounting Posts

CY0060

Undercarriage Mounting Frames

CY0080

Centre Hub

CY0070

Undercarriage Set

CY0090

Flybar Carrier

CY0100

Flybar Mixing Arms

CY0120

Feathering Spindle Spacers

CY0110

Main Blade Holders

CY0130

Feathering Spindle

CY0140

Paddles

CY0160

Flybar Control Arms

CY0150

Flybar

CY0170

Mixer Block

CY0180

Mixer Arm Set

CY0200

Anti Rotation Stay

CY0190

Swash Plate

CY0210

Main Belt Drive Pulley

CY0220

Main Gear

CY0240

Auto Rotation Drive Sleeve

CY0230

Auto Rot’n Unit Hub W/Bearing

17

SPARE PARTS

CY0250

Main Shaft

CY0570

Main Blades (Wood) - 315mm

CY0270

Tail Gearbox Case

CY0280

Tail Pitch Lever

CY0290

Tail Shaft with Gear

CY0300

Tail Control Arm

CY0320

Tail Rotor Blade Holders

CY0310

Tail Rotor Hub

CY0330

Tail Blades

CY0340

Tail Servo Mounts

CY0360

Horizontal Stabiliser Mount

CY0350

Tail Pushrod Guides

CY0370

Tail Fin Set

CY0380

Tail Boom

CY0400

Boom Support Ends

CY0390

Tail Boom Supports

CY0410

Tail Pushrod Set

CY0420

Tail Belt

CY0440

Linkage Balls (Long x 6, Short x 2)

CY0430

Control Rod Ends (Long x6, Short x2)

CY0260

Linkage Set

CY0450

Bearings 2 x 5 x 2.5

CY0470

Bearings 4 x 8 x 3

CY0460

Bearings 3 x 6 x 2.5

18

SPARE PARTS

CY0480

Bearings 5 x 10 x 4

CY0500

Brushless Motor 3800kv

CY0510

Brushless ESC 40A

CY0520

Battery Tie

CY0530

14T Pinion

CY0540

15T Pinion

CY0560

Instruction Manual

CY0550

16T Pinion

CY0580

Canopy with Screen & Decals

In North America

Your EF Helicopters Cypher 3D is warranted against manufacturer defects in materials and workmanship for a period of 90 days from the date of purchase. Warranty

service will be provided within 90 days of the date of purchase only if you are able to provide the original or a copy of the original dated sales receipt.

Your EF Helicopters Cypher 3D is warranted against manufacturer defects in materials and workmanship for a period of 1 (one) year from the date of purchase. Warranty

service will be provided within one (1) year of the date of purchase only if you are able to provide the original or a copy of the original dated sales receipt. This does not

affect your statutory rights.

EF Helicopters guarantees this kit to be free from defects in both material and workmanship, at the date of purchase. This does not cover any component parts damaged

by use, misuse or modication. In that EF Helicopters has no control over the

nal assembly or material used for nal assembly, no liability shall be assumed for any damage resulting from the use by the user of the nal user-assembled product

By the act of using the nal user-assembled product, the user accepts all resulting liability.

Table of contents

Popular Toy manuals by other brands

Faller

Faller TOILET HOUSE instructions

Fisher-Price

Fisher-Price Pixter owner's manual

Minicars

Minicars AN10300 manual

The Learning Journey

The Learning Journey Techno Gears Marble Mania Twin Twister instruction manual

Radio Flyer

Radio Flyer Glide & Go Balance Bike quick guide

Mattel

Mattel Barbie R4109 instructions

Mega Construx

Mega Construx POKEMON LAPRA manual

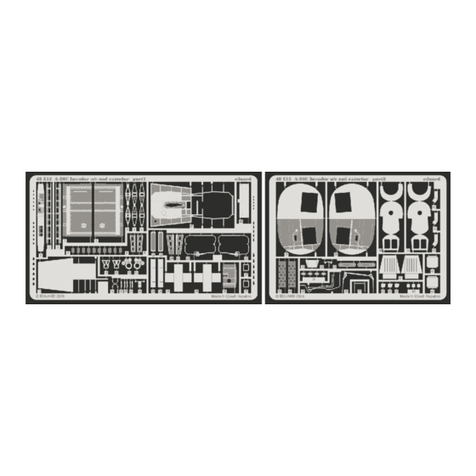

Eduard

Eduard A-26C Invader u/c and exterior quick start guide

Lionel

Lionel Little Lines Freight Set owner's manual

V-tech

V-tech Phonics Desk user manual

Mega Bloks

Mega Bloks Barbie Build'n Play Underwater Cove manual

THUNDER TIGER

THUNDER TIGER TTR4307 Assembly manual