3

Paragon 2

Smoke

If your engine is equipped with a smoke generator, DO

NOT OPERATE THE SMOKE UNIT WITHOUT SMOKE FLUID.

Doing so will damage the engine. The smoke unit heater

can be physically turned off using the switch located

beneath the cab (or behind the smokebox door on some

models). If the switch is on, the smoke can be turned

on and off using the AUX button on the DC Master or F7

on your DCC controller. Before using, add 6-8 drops of

uid to the smoke unit using the small plastic funnel that

came with your locomotive. Drop the uid directly into

the locomotive’s smokestack. If the smoke unit is hot,

do not lower the funnel too far into the smokestack as

you could accidentally contact the heating element. If you

melt plastic onto the heating element, your locomotive

will not be able to produce smoke. Whenever the smoke

starts to look thin, add another 3-4 drops (enough for 15-

20 minutes run time). There are 2 CV’s used to adjust the

smoke output by controlling the heat. CV236 controls the

level while moving, and CV 237 controls the level at idle.

Operation with a DC Power Pack

Your Paragon 2 Steam locomotive is ready-to-run. Simply

place the locomotive on a track powered by any DC power

pack with a variable output up to 16 volts DC. As you

increase the track voltage, the sound system will begin

functioning at around 7 volts DC. If you increase track

power slowly, you will hear the sound of a steam locomotive

starting. As you slowly increase track voltage, the engine

will start to move. There are a number of sounds the

locomotive will produce automatically to simulate the

sound of a full-size steam locomotive.

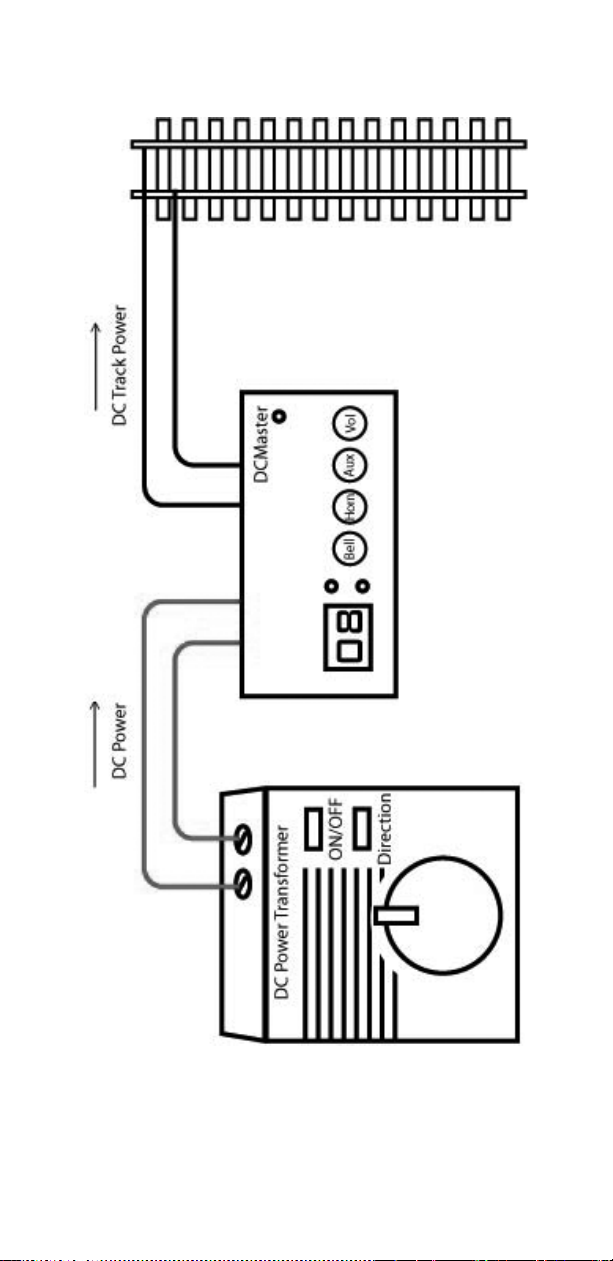

If you do not use DCC, the DC Master Analog Control

Module (BLI stk# 1011 or PCM stk# 1001), is required for

activation of the whistle, bell and some other sounds, and

to control the volume. It can also program CV’s without

a DCC system. The DC Master is shown in gure 1,

connected between the power pack and the track.

Figure 1 on following page.