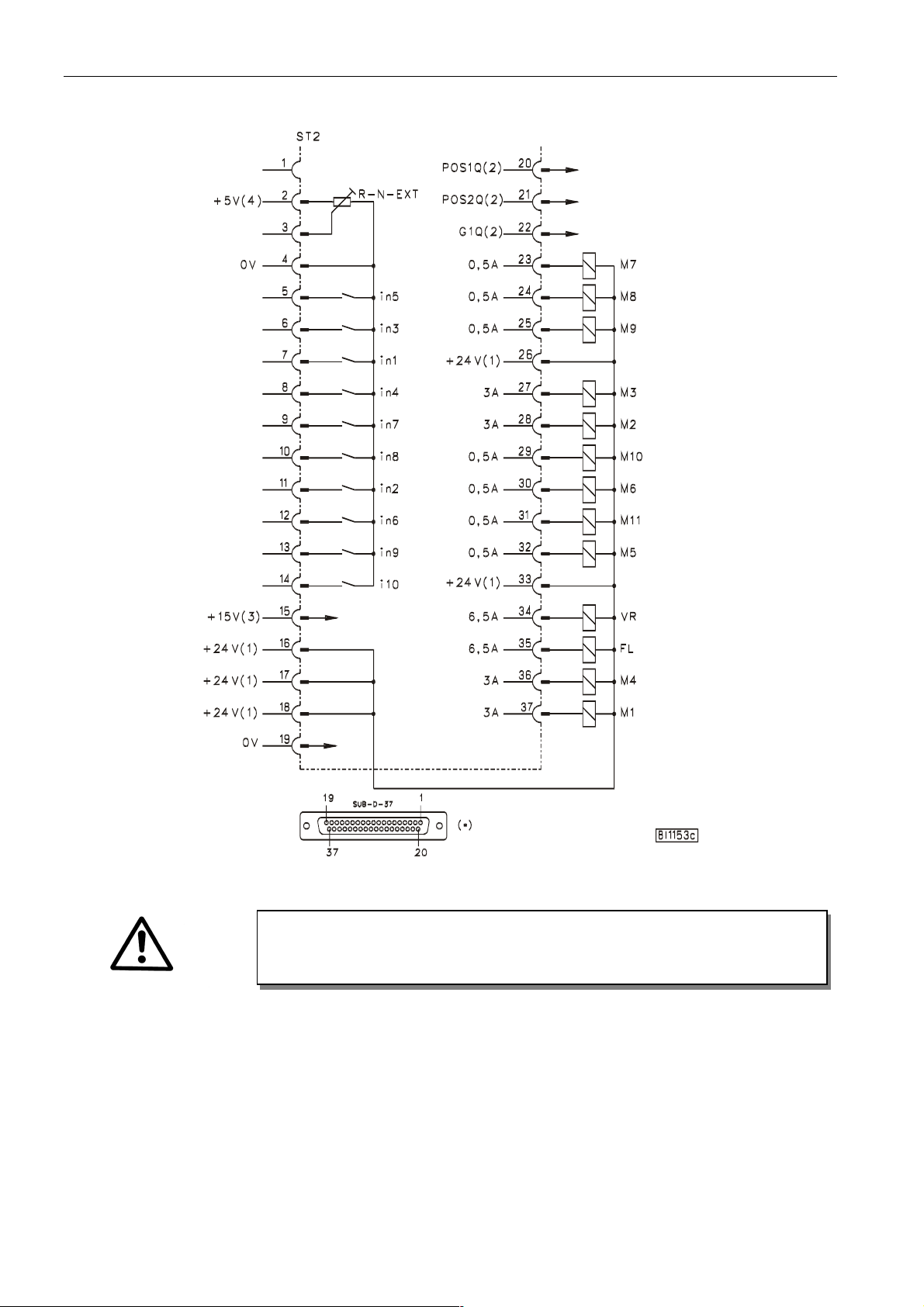

EFKA AB323A5221 10

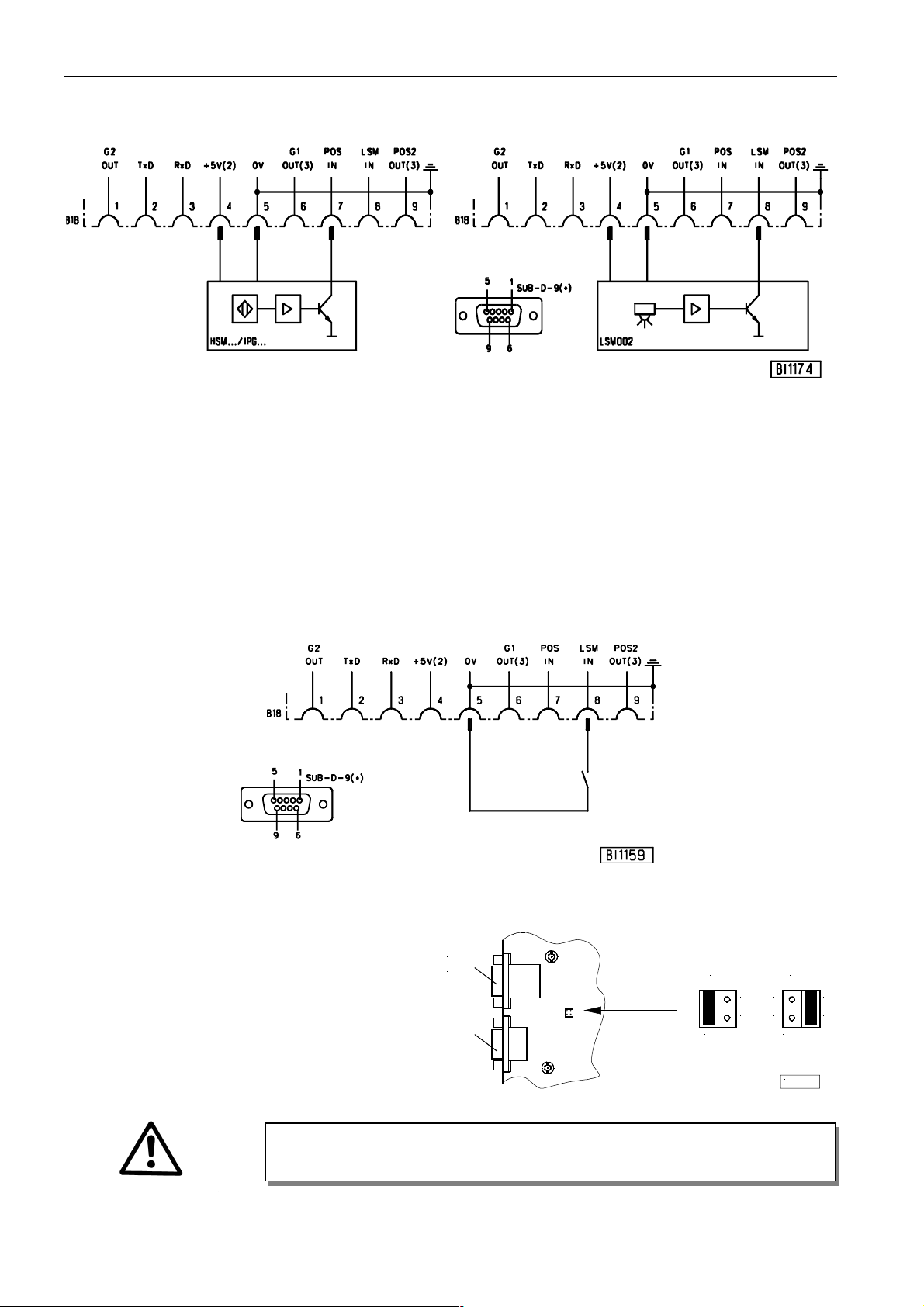

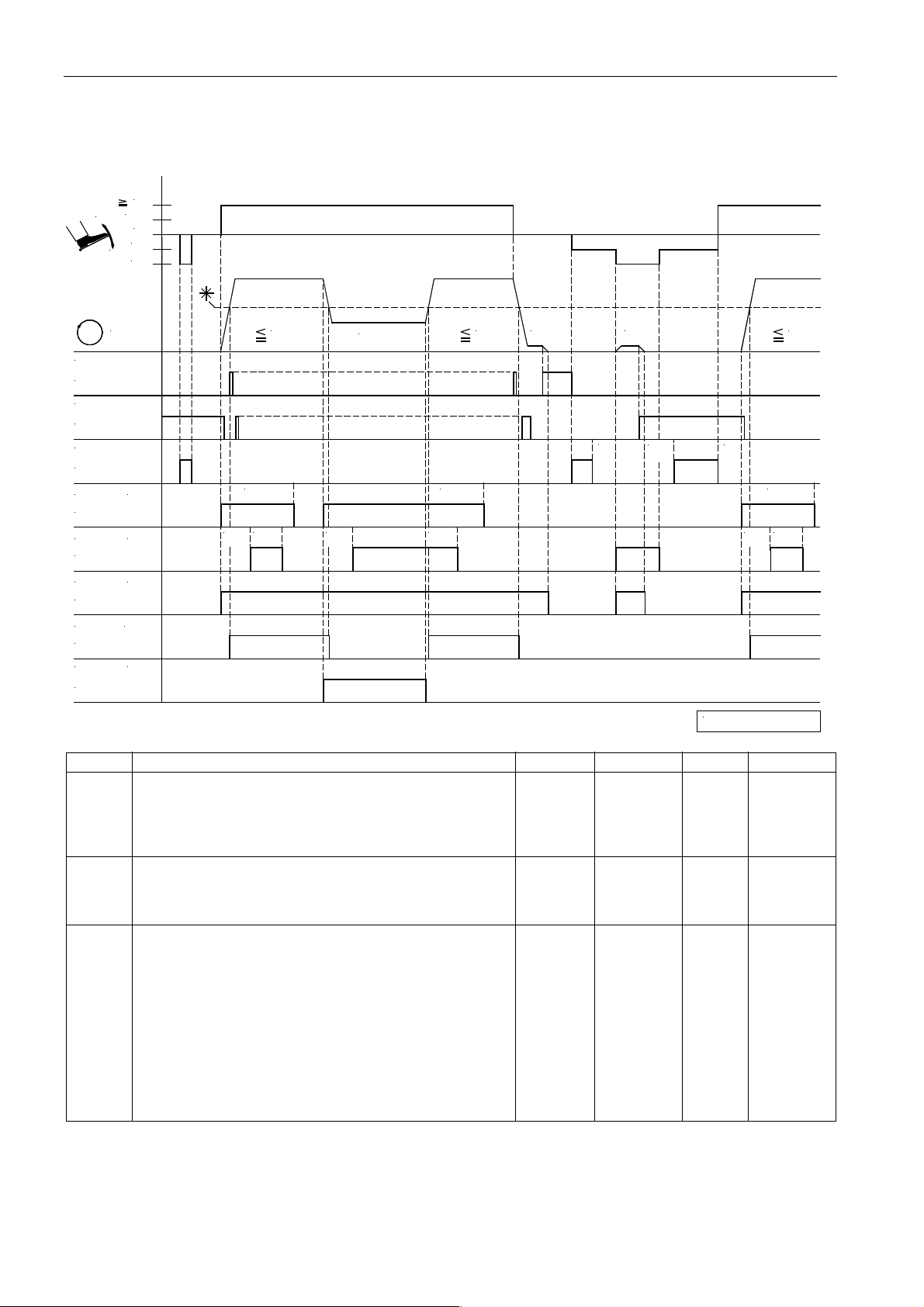

Connection of a HSM001 Hall sensor module Connection of a LSM002 light barrier module

or an IPG001 pulse encoder

Adapter cord 1113229 in case of multiple assignment of socket B18!

POS2 OUT - Output for position 2

POS IN - Input for positions

G1/G2 OUT - Output of generator impulses

TXD/RXD - Serial transmission lines

LSM IN - Possibility of connecting a light barrier module to socket B18/8

(If parameter 239 = 0, the light barrier function is selected.

Identification of the signal when switched to 0V.)

LSM002 - Reflection light barrier module

HSM... - Hall sensor module

IPG... - Pulse encoder

If parameter 239 is set to >0, a key can be operated on the input of socket B18/8.

There is a supply voltage of +5V for external devices on the B18/4 socket. After opening the cover, this voltage can be

changed to +15V by replugging a multipole connector J1 on the printed circuit board.

+5V = Connect lefthand pins 1 and 2 with jumper

(factory setting)

+15V = Connect righthand pins 3 and 4 with jumper

1) Nominal voltage +15V, 100mA (repluggable to +5V, 100mA)

2) Transistor output with open collector max. 40V, 10mA

*) Front view of the socket (component side) and/or rear view of the plug (soldering side)

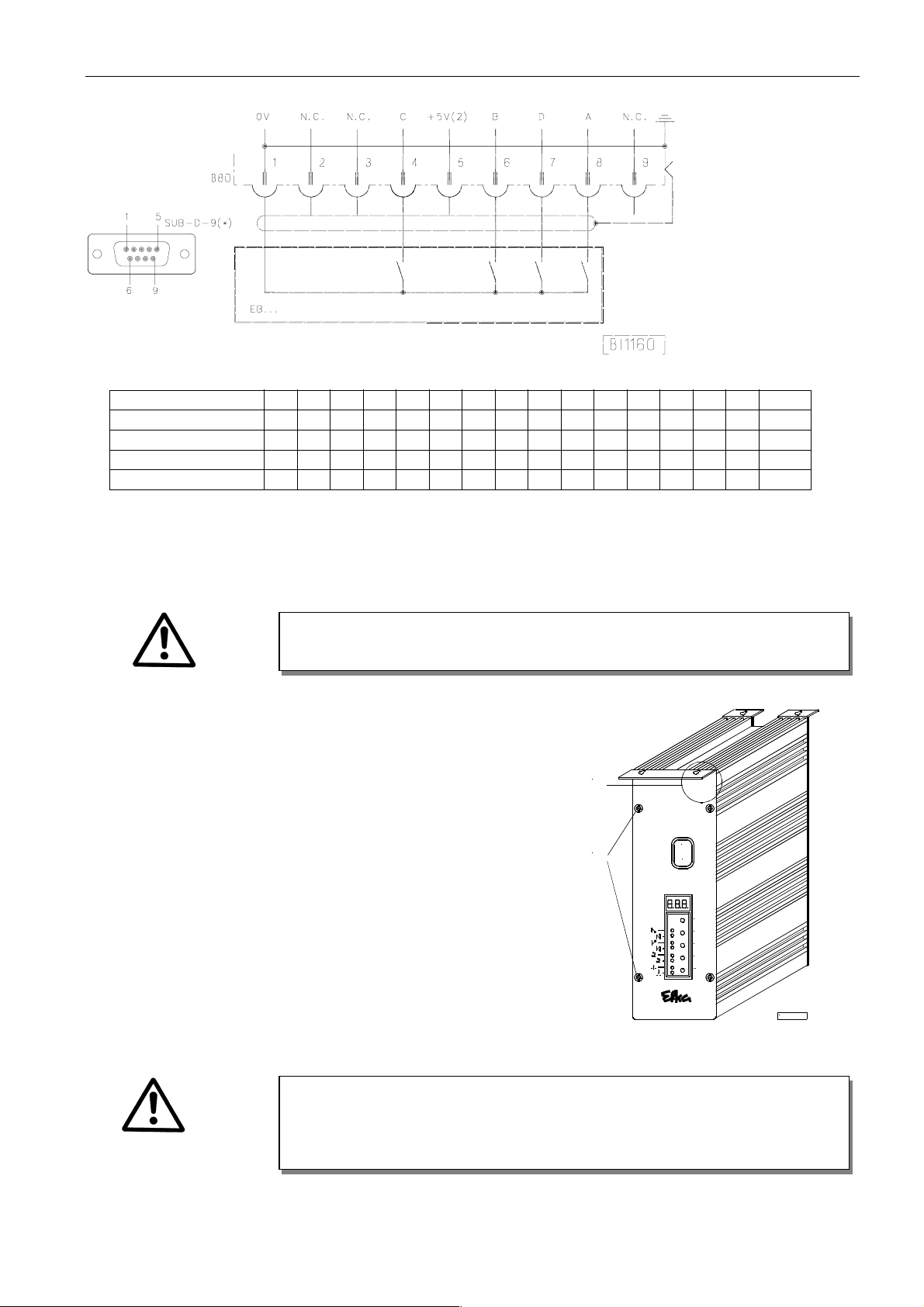

TTENTION!

Before opening the cover, turn power off!

B80

B18

B2

J4 31

+5V

42

J4

1 3

4

+15V

2

KL2351

J4