10

Once the 26D style Stitcher Head has been threaded

and the wire straightness has been obtained, it is time

to begin stitching. Activate the stitcher machine to

load one piece of wire in the Swivel (9038M). Even

though the 26D Stitcher Heads have been tested

at the factory, the wire draw adjusted and the legs

equalized, the following are directions to make these

adjustments if necessary.

If the staple is off-center, meaning one leg is

longer than the other, the length of the left leg has

to be changed. Loosen, do not remove, the Wire

Guide Spring Bracket Screw (9075) and the Wire

Guide Adjustment Lock Screw (090330). Using a

screwdriver, turn the Wire Guide Adjustment Screw

(9076) clockwise if a shorter left leg is necessary and

counter-clockwise if a longer left leg is necessary. A

slight turn of the Adjusting Screw will usually prove

sufficient to achieve the desired length. A quarter

turn of the Adjusting Screw will make a considerable

difference in the length of the staple’s leg. Once the

desired length has been achieved, tighten the Wire

Guide Spring Bracket Screw and the Adjustment

Lock Screw. At this point, the left leg should be

approximately one half the width of the crown.

NOTE: If the staple leg has been lengthened,

meaning the Wire Guide Adjustment Screw (9076) has been turned counter-clockwise, tap

down on the Wire Guide Spring Bracket Assy. (CAAA9074A2) before tightening the Wire Guide

Spring Bracket Screw (9075).

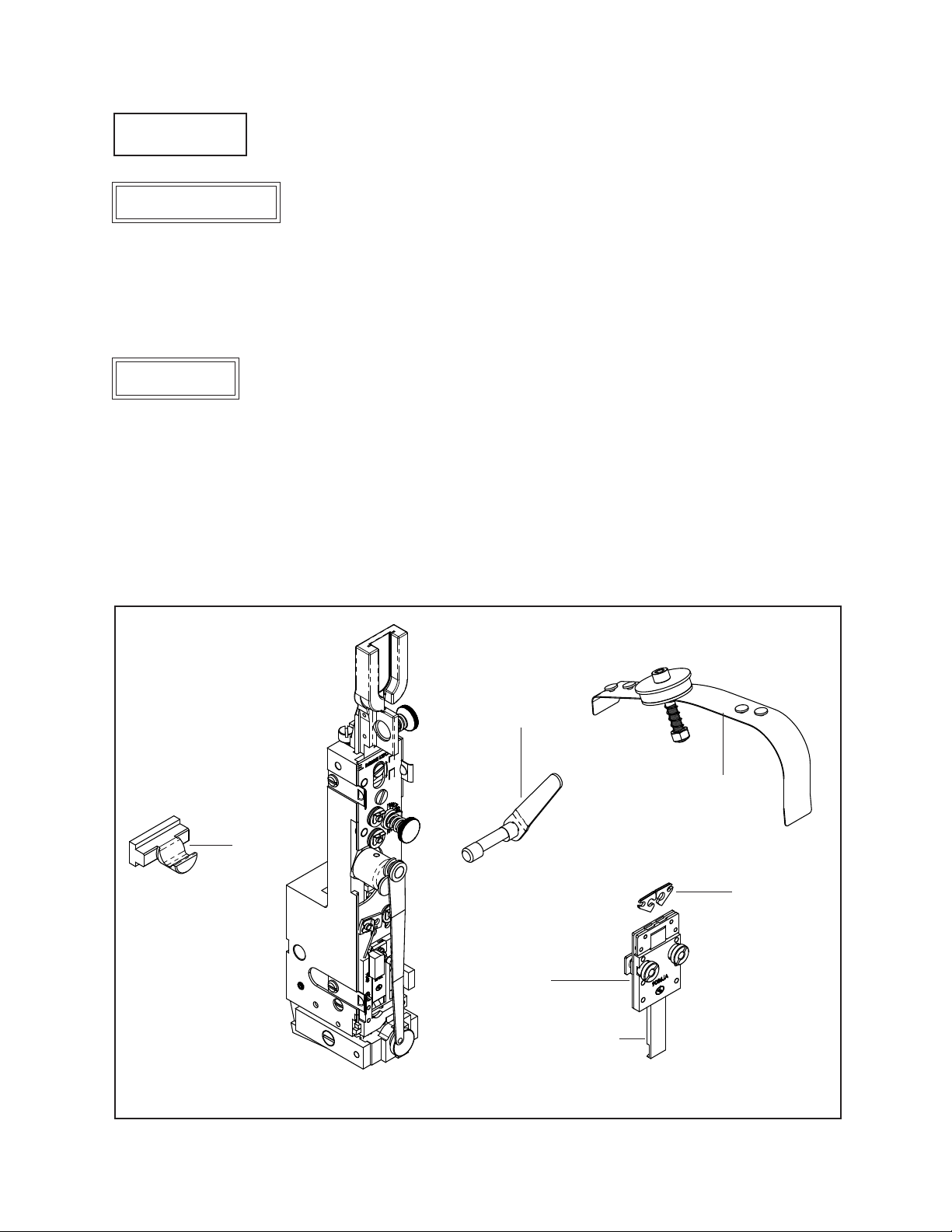

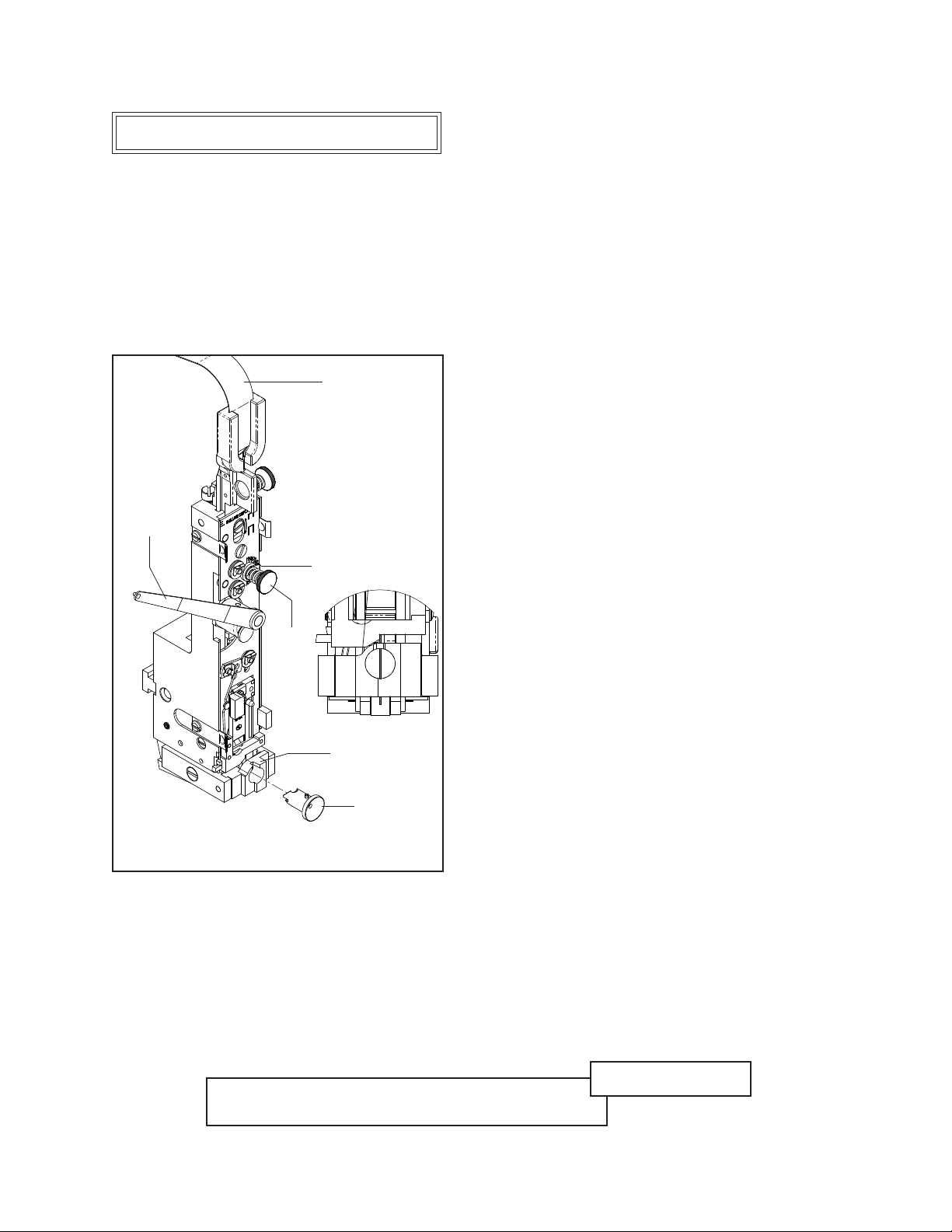

Adjusting the Length of the Left Leg (Figure 6)

Figure 6 - Adjusting the Left Leg

9076

9075

CAAA9074A2

shorter

leg

longer

leg

9038M

090330

The overall length of the stitch is controlled by the amount of wire that is drawn from the spool

after each stroke of the stitcher machine. To change the overall length of the stitch, the stitcher head’s

Face Plate has be to be raised or lowered accordingly.

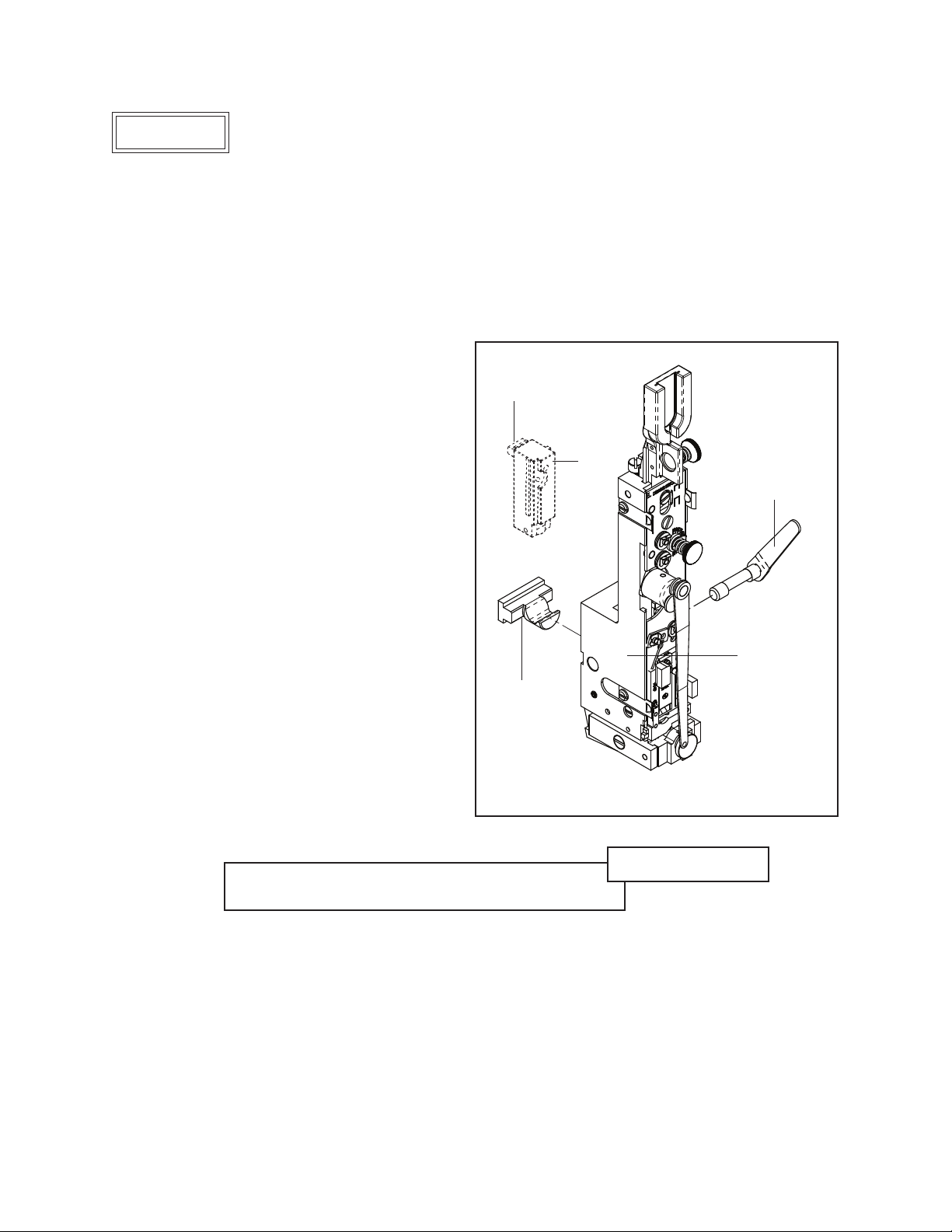

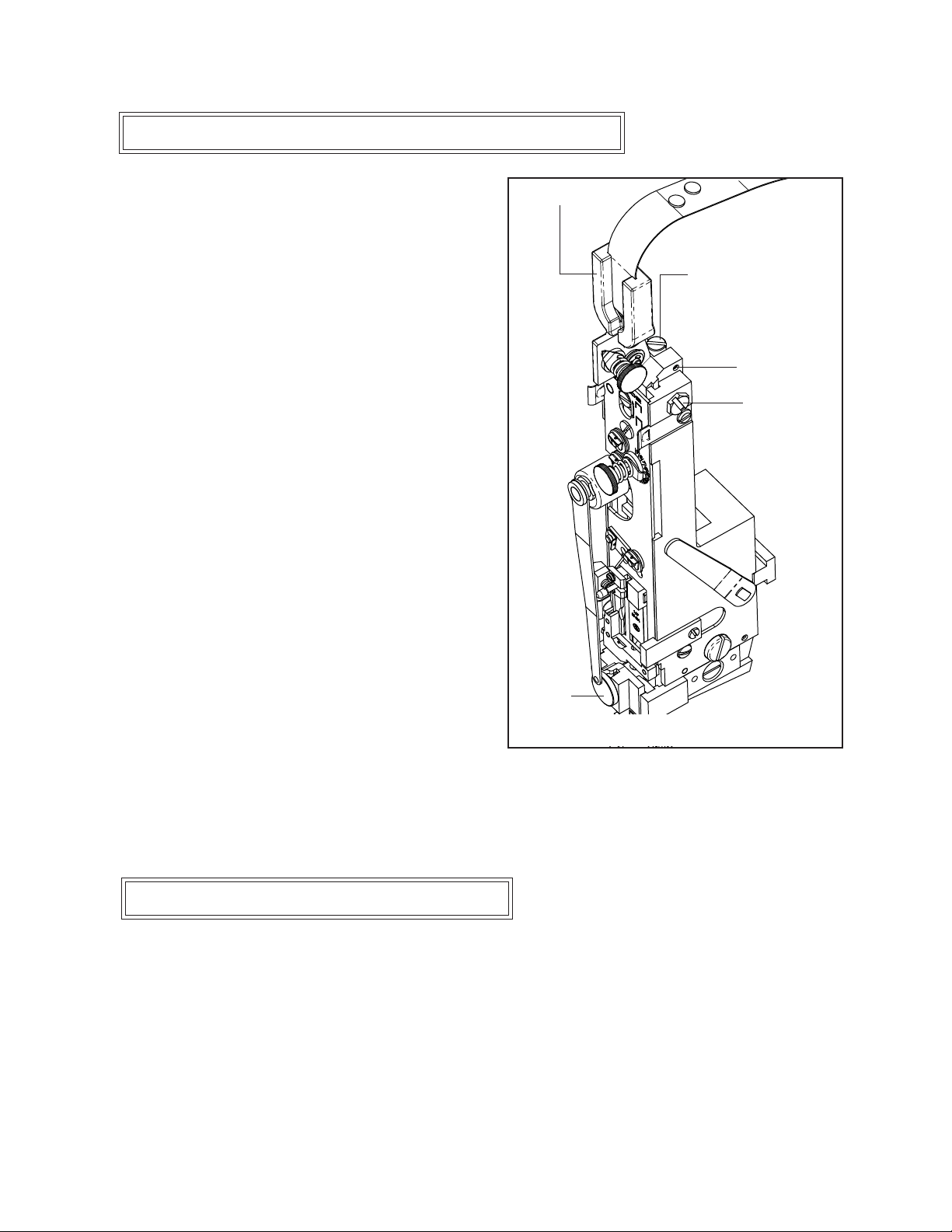

2601DDPHD Series Head (Figure 7)

Loosen the Face Plate Adjusting Slide Nut (2608) found in the center of the Face Plate (2146MA).

To increase the overall length of the stitch, raise the Face Plate slightly by applying pressure at the

bottom edge of the Face Plate. Use a large screwdriver as a lever under the Wire Cutter Housing area

Adjusting the Wire Draw (Figure 7)