4

Before using the machine, damaged parts or protective devices should be carefully checked to make sure they work

soundly and full the designated function. Check alignment, connections and attachment of moving parts. Also check

if parts are broken. Parts or protective devices that are damaged should, if nothing else is mentioned in these operating

instructions, only be exchanged or repaired by qualied personnel. The same applies to defective switches and valve

triggers. If the machine cannot be switched on or off with the valve trigger, it should not be used.

The use of other accessories, or other additional items than recommended in these operating instructions, may

include the risk of bodily injury.

Only operate the tool after a thorough training or under supervision of a trainer.

Never exceed the maximum operation pressure.

Follow the valid national provisions in the country of application.

ATTENTION! Never use the hydraulic hose as a lifting handle!

USE

INTENDED USE

The machine is designed for drilling into concrete and masonry. The machine is intended to be used by professional

operators. Only authorized and trained personnel may use, maintain and repair the machine. The personnel has to be

especially instructed on the potential dangers. The working environment can be: construction site, factory, renovation,

rebuilding and building. Manipulation or modications to the machine are not allowed. Observe the instructions

regarding the operation, care and maintenance in the operation instruction. Dangers can come from the machines and

the auxiliary materials, if improperly handled or used.

IMPROPER USE

Any use deviating from the intended use as described is considered to be improper use. Working without personal

protection equipment.

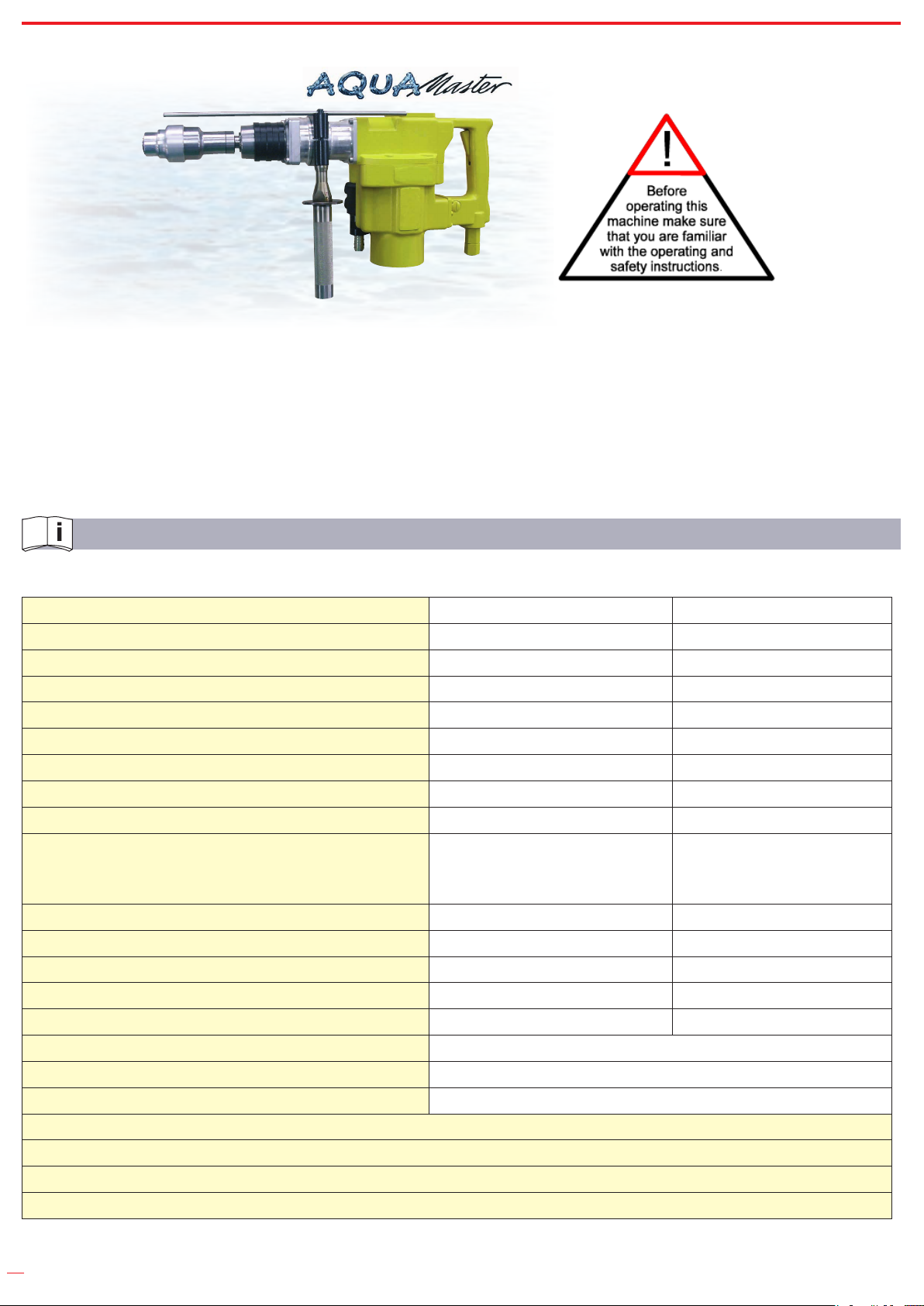

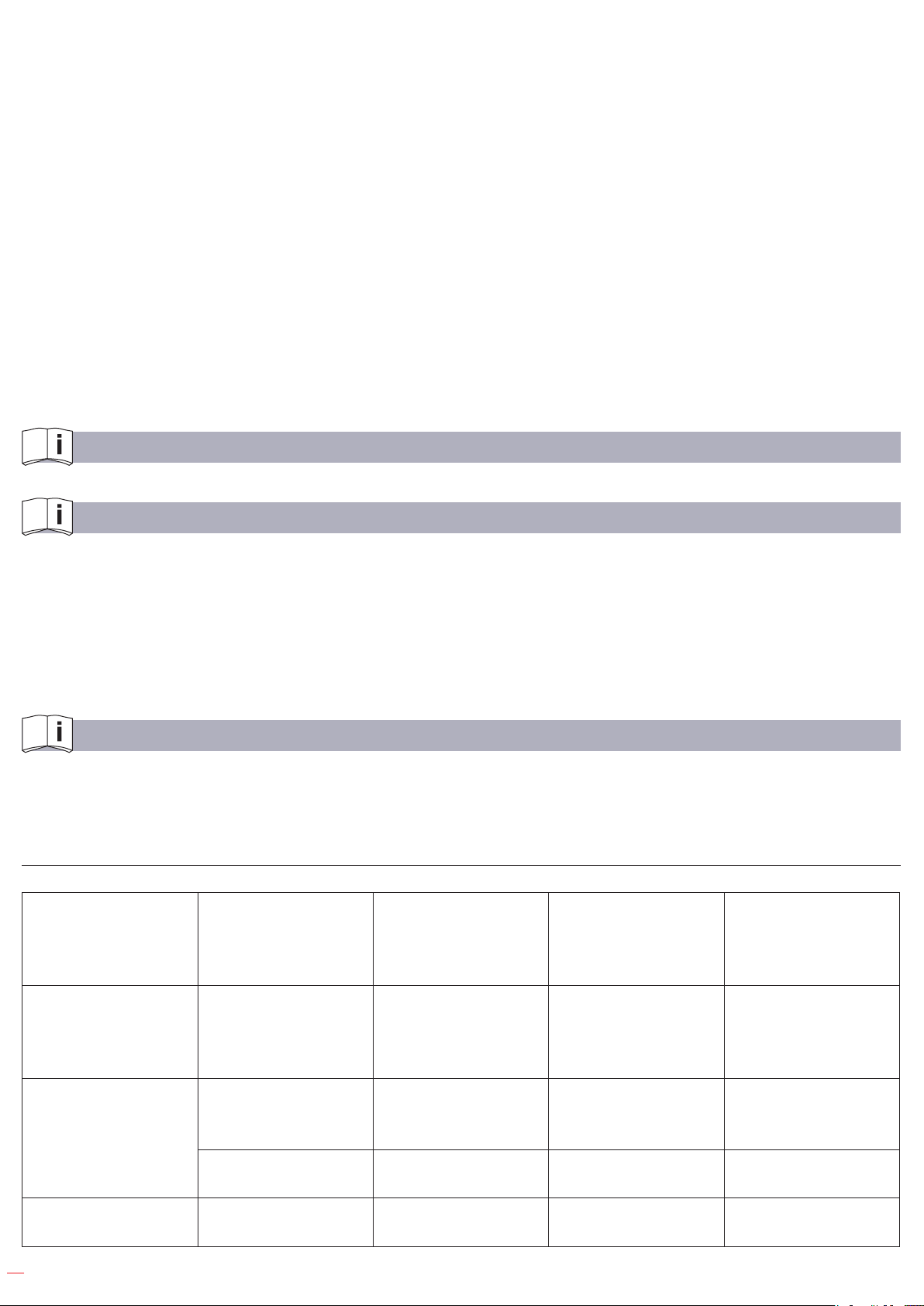

Danger Zones

Operational

condition

--------------------

Life phase

Normal function Malfunction Improper use Expected use

Transport

Transport of

the machine in

an inoperable

condition

Drop of the

machine

Transport of the

machine in an

operable condition

unknown

Operation

Machine only works

with actuated valve

Machine runs

without actuated

valve

Switch is blocked in

actuated condition unknown

Machine moves the

tool Tool blocks unknown unknown

Maintenance Operation at a

maintenance unit

Breakdown of the

machine unknown unknown