EHC FUSION COMET 24 kW User manual

2

GB-031C_f.625

Please read and follow the installation and operating instructions

carefully, to ensure the long life and reliable operation of this

appliance.

The Electric Heating Company may make minor changes

if necessary in the appliance that will not be shown in the

operating instructions, so long as the main features of the boiler

remain the same.

All boilers come with a 24 month warranty that covers all

defects originating from faulty materials and workmanship in the

manufacture of the boilers.

The warranty covers the replacement of any faulty parts and

labour costs.

The warranty will not cover any damage to the boiler from poor

or incorrect installation work.

The warranty will not cover any call out charges that have not

been organised by the Electric Heating Company Ltd.

The warranty will not cover water leaks into the boiler. All

plumbing joints must be checked.

The warranty card must be completed and sent back to The

Electric Heating Company as soon as possible for registration.

An internal Magnetic Filter is fitted to the Boiler and it must be

cleaned at least annually. (Note: Failure to clean the Magnetic

Filter may result in boiler shutdown). Warranty calls will not be

covered for this repair.

INTRODUCTION 2

PREPARATION 3

INSTALLATION 4

ELECTRICAL CONNECTIONS AND CONTROLS 8

EXTERNAL CONTROL WIRING 10

CONTROL PANEL CONNECTIONS 11

EXTERNAL BOILER WIRING 12

BOILER DIMENSIONS 12

USER INSTRUCTIONS 14

FAULT FINDING 15

TECHNICAL SPECIFICATIONS 15

3

GB-031C_f.625

This appliance must be fitted in accordance with the following

instructions.

The Local Building Regulations

The Building Regulations

The Building Standards, (Scotland-consolidated) Regulations.

Local water bylaws. British Standards- code

of practice

Heating systems in buildings. Design for water-based heating sys-

tems.

Heating systems in buildings. Method for calculation of the de-

sign heat load

Heating systems in buildings. Installation and commissioning of

water based heating systems

Requirements for electrical installations. IEE Wiring Regulations.

Seventeenth edition.

Closed expansion vessels with built-in diaphragm for installation

in water

Materials used in the manufacture of this appliance are non-haz-

ardous and no special precautions are required when fitting or

servicing this appliance.

A load check should be taken into consideration when install-

ing high output boilers.

The boiler must be fitted on a wall that will provide an adequate

fixing, and should be fitted in a location that the boiler and

pipe-work are not subject to frost and damp conditions.

Detailed recommendations are given in BS EN 12828:2003,

BS 6700: 2006+A1: 2009 and CP 342-2:1974

Pipes forming part of the useful heating surface should be in-

sulated to prevent any potential heat loss or frost damage (BS

6700:1997).

Drain valves should be fitted at the lowest point of the system

pipe work in an accessible position.

Drain valves should be in accordance with BS 2879: 1980 and

copper tube to BS EN 1057: 1996. is recommended.

The boiler can be installed in almost any location within a do-

mestic or commercial property, however consideration should be

given to future maintenance. Never leave the boiler switched off

if there is danger of having temperatures below 0°C in the room

where it is located.

We recommend that a minimum clearance of 450 mm should be

allocated for the removal of the front cover and adequate access

to the boiler plumbing and the internal electrical connections. A

50 mm allowance should be made at either side of the boiler to

allow free flow air into the boiler case and allow access to screws

on the boiler case.

4

GB-031C_f.625

All Fusion Electric Boilers have a 22mm compression connection

at the boiler’s flow and return pipes. Please note that the boilers

are supplied with blank washers fitted for transit purposes. These

must be removed before connections to pipe-work can be made.

The flow (red) and return (blue) are clearly marked on the external

case and under no circumstances should these connections be

reversed. Hot connections are not recommended at the boiler for

future maintenance and boiler disconnection. Lockshield valves

are recommended.

Remove outer screws at the bottom of the boiler and pull the front

cover outwards taking care to remove internal earth connections.

Earth connections must be re-connected before the boiler case is

re-installed.

We recommend that lockshield isolation valves are fitted on the

flow and return pipework. Such valves must be „full way” and

not „ball valves”. The installation of „ball valves” in the flow and

return pipework will reduce the recommended flow rate through

the boiler and promote premature boiler shutdown.

An auto air vent is integral within the boiler however an addi-

tional auto air vent must be fitted at the cylinder coil if the boiler

is being used for central heating and domestic hot water.

Calculate the „space heating” requirements in accordance with

BS EN 12831 and BS EN 14336. If the boiler is to heat the do-

mestic hot water, an additional allowance of 3kW (10,239 Btu’s)

should be made to the ‘space heating’ calculation.

Where practical, and if at all possible, we recommend that all

pipe-work be insulated, in particular the primary pipe-work

with-in a boiler cupboard. This is to reduce heat loss and reduce

high cupboard temperatures from exposed pipe-work. (BS 6700:

2006+A1: 2009).

The boiler has an integral automatic bypass valve fitted which

should be set to the relevant settings to allow the minimum flow

rates to pass through the boiler (8 l/min) when all radiator thermo-

stats and zone valves are closed.

Allowance should be made for a radiator to be installed within

the heating circuit and locked open. This will be located in the

room that has the room thermostat installed.

To comply with building regulations, Part L and Part J (in Scot-

land), room and cylinder stats must be fitted.

the heating system (sealed systems). Reference should be made

to BS EN 14336 for the method of filling and make up of water.

There must be no direct connection between the boilers central

heating system and the main water supply. When mains water is

required to fill the system directly, all local water bylaws must be

observed, and any connection made must be disconnected after

use.

The system to within 10% of mains water PPM

to ensure that no debris is trapped in the flow sensor as this may

result in boiler failure. Where existing radiators and pipe-work

are utilized a power flush must be carried out to remove debris.

All boilers are tested to 4.0 bar. The normal working pressure of

the boiler should be set to approx 1.0 / 1.5 bar. All sealed sys-

tems should comply with the relevant building regulations and

standards, including BS EN 13831 – Specification for Expansion

Vessels.

In order to protect the Flow Sensor located within the boiler, it is

imperative that the pre-installed magnetic filter is removed and

cleaned at least annually. Failure to carry out this action will in-

crease contamination of the boiler by system residue.

The Fusion Comet range of boilers can be used in various system

designs. Please refer to The Electric Heating Company for more

details on our Fusion Boiler for under floor heating. We are able

to supply a heat pack that contains the relevant control valves,

cylinder and room thermostats required to configure an „S” plan

heating system. The heat pack has all the necessary components

that you need to connect the systems controls and plumbing con-

figurations for „S” Plan design.

We recommend the use of thermostatic radiator valves on all ra-

diators except in the room that has the wall thermostat fitted. This

radiator should be fitted with lock shield valves and left in the

fully open position.

The boiler has an integral automatic bypass valve fitted which

should be set to the relevant settings to allow the minimum flow

rates to pass through the boiler (8 l/min) when all radiator thermo-

stats and „zone valves are closed”.

Systems should be designed to meet the current building regula-

tions in force at the current time.

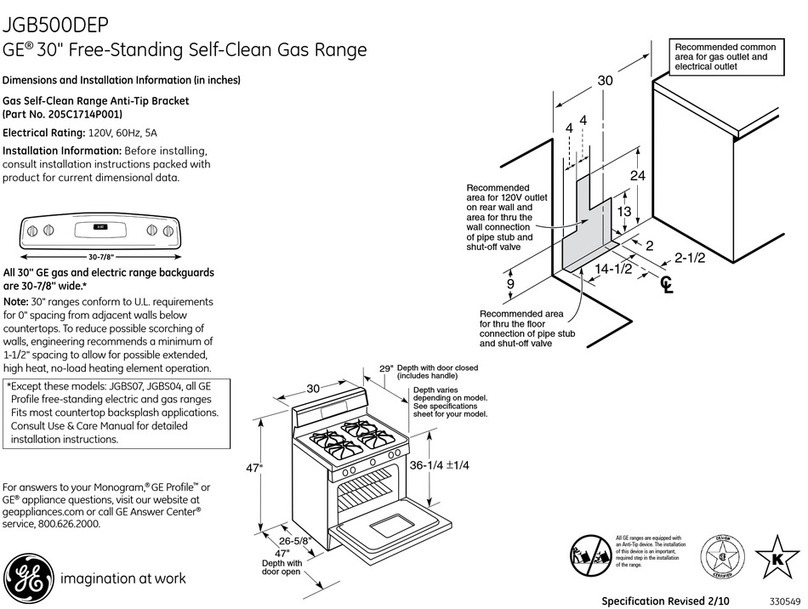

1. Hang the boiler in a vertical position on the fixing points and

screws provided, with the flow and return connections to the

bottom of the boiler, maintaining the clearances as per Figure

12 of this manual.

2. Connect the boiler to a heating system that is equipped with

isolation valves (see Figures 4 & 5).

3. Fill the heating system with treated water, which will substan-

tially extend the life of the heating coils. See item 14 „System

Protection” below.

4. Connect the boiler to the „mains” electrical system as per

Figures 6, 8, 9 & 11 using conductors sizes as per as specified

in the Technical Specification on page 17 of this document.

5. Connect the room thermostat / Programmer using the two

control conductors marked RP as in Figure 7 & 10.

6. For all other electrical connections refer to the ELECTICAL

CONNECTIONS & CONTROL section of this manual.

5

GB-031C_f.625

[1] - StainlessSteelHeatExchanger

[2] - FlowSensor

[3] - PressureSensor

[4] - SafetyValve

[5] - CirculatingPump

[6] - SafetyTemperaturelimiter

[7] - Returnconnection

[8] - Flowconnection

[9] - PowerBoard

[10] - ControlModule

[11] - AutomaticVent

[12] - ExpansionVesselandconnection

[13] - By-passValve

[14] - MagneticFilter

PF - Internal„mains”phaseconnectionsfromthePNconnectionblock

PN - Incoming‘mains’cableconnectionblock

WP - Electriccableaccess

M - Boilerfixingpoints

RP - RoomThermostatvoltfreeconnection

Electrical ‘mains’ input

6

GB-031C_f.625

Failure to protect the system will invalidate the manufacturer’s

warranty.

After the system has been installed the cleansing and inhibiting

procedure must be carried out as follows:

1. Fill the system with cold mains water to the recommended

pressure 1.5 bar and check for leaks, then drain the system

thoroughly making sure all drain cocks are fully open and that

the system is completely drained.

2. Add Fernox Heavy Duty restorer through the header tank or

via filling loop at the recommended dose. One bottle must be

used as a minimum per dwelling. If you are unsure of the cor-

rect dose rate, contact Fernox.

3. Re-fill the system and circulate the Heavy-Duty Restorer prior

to the boiler being fired up, then commission the system in

the normal way. The cleansing agent must be in the system

for a minimum 1 hour with the system at normal operating

temperature. A longer period of time would be more beneficial

to the cleansing process especially if excess flux was used.

4. Drain and flush the system thoroughly to remove the cleaning

agent and any debris or contaminant. This is a critical part of

the cleaning process and must be carried out correctly. Use a

rinse test meter (TDS), such as the Fernox CTM. The reading

must be within 10% of the mains ppm value.

5. Then add the Fernox Protector (Copal MB1 or Super concen-

trate). This will protect against the formation of scale, corrosion

and microbiological growths. It is crucial however, that for

the protector to work correctly, the system must be properly

cleansed and flushed.

6. The label included within the Fernox Protector carton should

be completed and attached adjacent to the boiler.

7. We recommend inhibitor levels are checked on an annual basis

(usually during the service) or sooner if the system content is

lost. This should be carried out using a Fernox inhibitor Test

Kit.

8. Fernox Technical Service Helpline on 0870 870 0362 for further

assistance.

1. Ensure the system is filled with water and correctly vented.

2. Check if the appropriate system installation pressure is

reached(see the “TECHNICAL DATA” section). By using

or

but-tons whilst the control panel is off, the pressure value

will be displayed. When the installation pressure is too low The

“A’’indicator flickers (see “Operating’’ section). This doesn’t

concern open vented system installations.

3. Set the external controls to call for heat. Disconnect the flow

sensor wiring plug on the control panel.

4. Switch the boiler on (press button).

5.

Check the pump is set to the correct mode (see table below).

Todo this, press button for no more than 2 seconds. The

LED’sshould signal an operating mode at the place pointed by

arrow.

6. If the LEDs are signaling a different operating mode than rec-

ommended in the table below, set the appropriate mode ac-

cording to the following instructions: press button for longer

than 2 seconds, but less than 10 seconds (LED’s will start to

flash),the pump then switches to the settings mode. LEDs glows

to indicate the current settings. To change the settings of the

pump in accordance with the table below, you can set the right

combination of glowing LEDs by pressing

the button. Once

LED combination is set correct, by not pressing

the button for

10 seconds the pump will remember this setting and will exit

from setting mode back to performance view.

7. Ensure adequate flow through the boiler is reached (the

„H”indicator is on with a constant light). The pump should

self vent after a short period of running. if necessary assist the

venting process in the following way;

• close the isolation valve on the outlet,

• leave boiler running for 15 sec.

• open the isolation valve.

8. Switch the boiler off (hold button for 3 seconds).

9. Reconnect the flow sensor plug to the control panel.

10. Switch the boiler on (press button).

11. Set the boiler to the required system temperature, see the “Op-

erating” section.

LED

1

2

3

4

5

LED

Rated

power

[kW]

Pump lifting

height [m]

LED 1

red

LED 2

yellow

LED 3

yellow

LED 4

yellow

LED 5

yellow

4● ●

6-9 5 ● ● ●

9-12 6 ● ● ● ●

14 - 24 7 ● ● ●

If the pump has detected one or more alarms, the bicolored LED 1

switches from green to red. When an alarm is active, the LEDs indi-

cate the alarm type as defined in the table below. If multiple alarms

are active at the same time, the LEDs only show the error with the

highest priority. The priority is defined by the sequence of the table.

When there is no active alarm anymore, the user interface switches

back to operation mode.

One red LED + one

yellow LED (LED 5)

Rotor is

blocked.

Trying to start

again every 1,5

seconds

Wait or

deblock the

shaft.

One red LED + one

yellow LED (LED 4)

Supply volt-

age too low

Only warning

pump runs

Control the

supply volt-

age

One red LED + one

yellow LED (LED 3)

Electrical

error

Pump is stopped

because of low

supply voltage or

serious failure

Control the

supply voltage

/Exchange the

pump

7

GB-031C_f.625

Temporary

Filling Loop

Mains Water

Supply

Temporary

Filling Loop

Mains Water Supply

8

GB-031C_f.625

„”

The recommended protection for hard wired boilers are as fol-

lows:

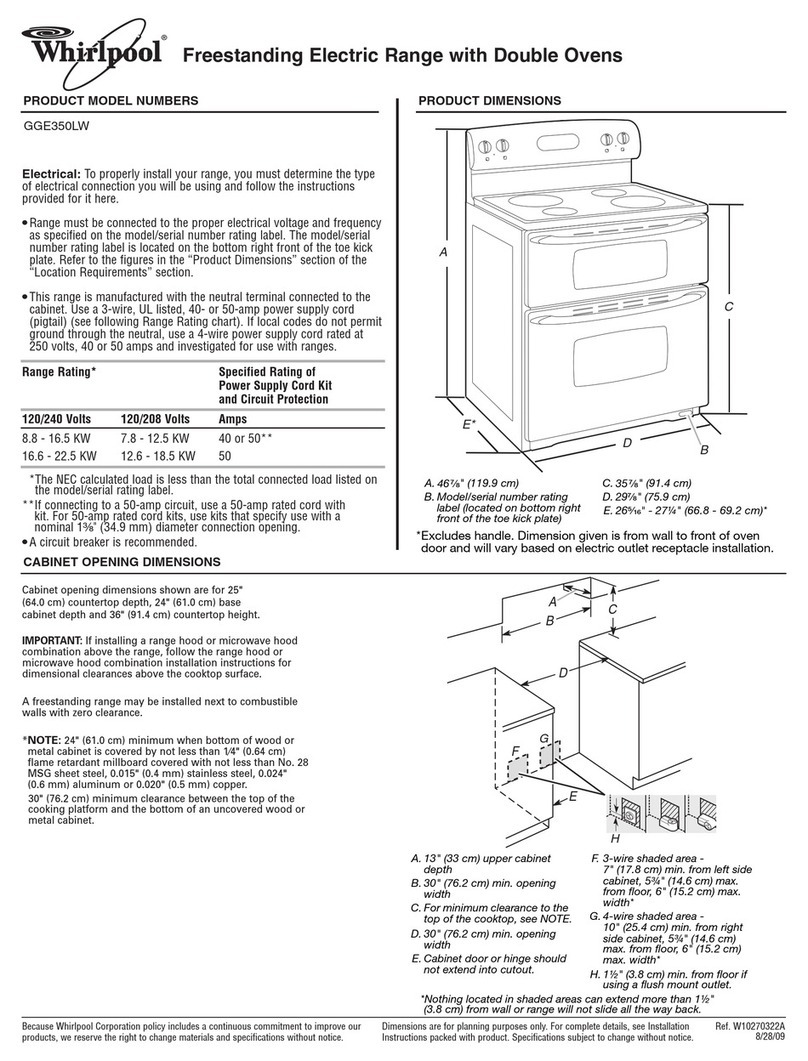

Model No Boiler size Protection (per phase)

FUSION 24 kW 24kW BOILER 40 AMP Protection

FUSION 14.4kW 14.4kW BOILER 80 AMP Protection

FUSION 12kW 12kW BOILER 63 AMP Protection

FUSION 9kW 9kW BOILER 50 AMP Protection

FUSION 6kW 6kW BOILER 32 AMP Protection

We recommend the use of the EHC SINGLE CHANNEL PRO-

GRAMMER and EHC ROOM THERMOSTAT for heating only

installations.

For Heating and Hot water installations, we recommend the use

of the TWIN HEAT PACK which includes the EHC ROOM THER-

MOSTAT & AN EHC 2 CHANNEL PROGRAMMER.

The TWIN HEAT PACK will incorporate all the relevant parts to

comply with current building regulations i.e. Motorized valves to

control the heating and hot water circuits and Room and cylinder

thermostats to control the room and water temperatures. This will

also provide boiler interlock. The use of TRV’s alone will not pro-

vide boiler interlock.

We recommend the use of TRV’s, however they must not be used

in the room that has the room thermostat fitted.

Load check must be taken into consideration when installing high

power boilers. This will be carried out by a qualified electrician.

There may be an additional requirement to upgrade the incoming

main fuse supplying the property if other high power devices are

used within the property. E.g Electric Showers. If an electric shower

is present we recommend that a Shower Sensor is installed within the

system. This will cause an interrupt to the boilers control signal when

the shower is in use. It will disable the boiler protecting the electrical

system from overload.

All boilers must be protected at the meter position with a 30mA dou-

ble pole RCD with a minimum of 3mm contact separation accom-

panied by a suitably rated MCB. If the boiler is not fitted local to the

meter position then an additional isolation switch must be fitted local

to the boiler for each supply.

All pipe-work must be earthed in accordance with the IEE BS7671

Wiring Regulations.

After completion of all electrical works, an electrical safety check

should be carried out i.e. short circuit, earth continuity, resistance to

earth and polarity check, and all relevant Test Certificates completed

and issued to the customer.

Never open the front cover of the boiler until all power supplies to the

boiler have been disconnected.

The boiler connections are clearly marked inside the boiler L N E

(24hr LIVE).

The 24hr live is the permanent Feed connection to the boiler from

the mains supply. External controls will require an independent fused

spur supplied from the consumer unit, however this fused spur should

be supplied by the same power source & protected by the same RCD

as the boiler itself, the control circuit should be protected by a 6Amp

MCB. The Boiler & control circuit RCD should be independent of all

other domestic circuits. The boiler supply cable should be calculated

by the means of a cable calculation in accordance with BS7671 by a

suitably qualified electrician.

9

GB-031C_f.625

After the cleansing and protection of the system has been carried out,

set the external controls to the customers selected times.

If an off-peak electric meter has been installed by an Electricity Com-

pany to supply OFF-peak rate electricity at selected times, the ap-

propriate settings should be entered into to the system programmer to

take advantage of the OFF-peak rate electricity.

The boiler has an inbuilt pressure sensor. If the boiler has been

switched on with a low or no water content, the system will sense

this and prevent the boiler from sending power to the main elements.

After the system has been filled with water and has had a cold flush

the Fernox cleanser should be added, the system filled with water,

purged of air and set to the correct pressure of 1.5 bar (sealed sys-

tems). At this point the main power may be switched on.

At this stage you may carry out the cleansing and protection of the

system. Refer to the installation section of this manual. (See page 7).

The boiler PCB has a voltage free connection for the controls (RP) &

(NA). Under no circumstances should 240V be connected to these

controller block connections as this will damage the boiler’s PCB and

Void the Manufacturers warranty.

The stat / programmer connections are clearly marked within the

boiler.

Only after all connections have been made and checked should the

system be filled with water and set to the proper pressure 1.5 bar

(Sealed systems).

Check the system for leaks. If water leaks into the boiler this may

damage the boiler electrics and the manufacturers warranty will be

invalid.

Under no circumstances should the boiler be switched on when the

system is dry.

„”

„”

10

GB-031C_f.625

SINGLE CHANNEL PROGRAMMER ROOM THERMOSTAT

VOLT FREE CONTROL

CONNECTIONS

TWIN CHANNEL PROGRAMMER DUAL CYLINDER THERMOSTAT ROOM THERMOSTAT

VOLT FREE CONTROL

CONNECTIONS

3A Switched

Fuse Isolator

6 Amp

3A Switched

Fuse Isolator

6 Amp

11

GB-031C_f.625

„”„”„”

12

GB-031C_f.625

Return Inlet Flow Outlet

13

GB-031C_f.625

R

F

P

ControlPanelKey

A - Waterpressureindicator(bar)

B - Waterflowrateindicator(l/min)

C - kWindicator

D - Watertemperatureindicator(°C)

E - Digitaldisplay

F - SummerMode

G - CallforHeat

H - Pumpoperationindicator

I - Returntemperatureflowindicator

J - Flowtemperatureindicator

K - Boilerheatingindicator

Heat Indicator.

• „on” – calling for heat,

• „off” – the required temperature has been reached – no call for heat is required,

• Flickers – NA entry is open – (external boiler interrupt active).

P Pump Indicator.

• „on” – pump is active, proper flow rate of water has been reached,

• Flickers – lack of flow or insufficient flow rate of water – heating elements are off.

Temperature Indicator.

• Red light – Boiler is in heating mode.

• Green light – Boiler temperature has been reached in radiators.

Indicator flickers – water pressure is not sufficient (below 0.5 bar).

When boiler is in Summer Mode (i.e. switched off) indicator will blink.

Indicator flickers – relative temperature sensor failure.

Indicator flickers – relative temperature sensor failure.

Messages on electronic display – data record error.

– parameter out of range or a temperature sensor failure.

14

GB-031C_f.625

Unlike other system boilers such as Gas, Oil and Propane the

FUSION „Comet” range of electric boilers require no ignition or

lighting sequence to be executed by the end user. All the end user

is required to do is ensure that the system is filled with water and

the room thermostat or programmer is calling for heat.

2.1 Switch the boiler on by pressing the button. (Note: When

switching the boiler off use the same button by pressing

and holding it in for 3 seconds.).

2.2 The recommended Water Pressure is approx 1.0/1.5 bar and

this can be checked by pressing the button until indicator

A is illuminated. The water pressure can be adjusted by con-

necting the external filling loop and pressurizing to the desired

pressure. Note: the filling loop must be disconnected after the

system has been re -pressurized.

2.3 First set the required Boiler Temperature (we recommend

a setting of 65

0C) by pressing the button until only indicators

D and K are illuminated. Press the button or the button

until the desired temperature setting is achieved.

2.4 Ensure the room thermostat is switched on and is calling for

heat. If the boiler is not yet at the desired heat setting then

indicators D, G, H, I, J & K will be illuminated with indictor K

illuminated in red. Once the room has reached the required

setting the K indicator should change from red to green. Refer

to the Control Panel diagram above to learn how to adjust to

the right temperature to make the boiler work comfortably and

economically.

2.5 The boiler Flow Rate is set at 8 l/min during the installation

of the boiler. To check this setting then press the button a

number of times until only indicator B is illuminated and then

read the figure on the digital display. If the figure is well below

the 8 l/min figure then call a Service Engineer for assistance.

2.6 To check the amount of kW energy being used by the boiler at

any point in time then press the button a number of times

until only indicator C is illuminated and then read the figure

on the digital display.

2.7 When indicator H is illuminated the pump is running.

We recommend the boiler temperature be set to 65°C. Raise or

lower the temperature in your installation with the buttons on

the right hand side of the control panel as per 2.3 in the previous

section.

„”

The customer has the option to switch the boiler onto „stand-

by” mode during summer months and this can be carried out by

pressing the „button and holding this in for 3 seconds”.

All indicators will go off except the F indicator which will inter-

mittently illuminate.

In the „stand-by” mode all the boiler functions are switched off

except the circulation pump. This is activated for 15 minutes

each day which protects the boiler and the whole central heating

system from being blocked and silted up. In this „stand by” mode

the circulation pump will run each day at the same time. (e.g. If

you switch the boiler to „stand by” at 6pm then the circulation

pump will run every day at 6pm for 15 minutes) To return to a

„Winter” mode setting then press and hold the button for 3

seconds again.

In the Winter mode setting the digital display will be active and

will show the temperature of the water at various points within

the boiler. Those indicators which are illuminated will show the

current status of the boiler. If the boiler is being called for heat

by the thermostat then the G, H, I, J & K indicators will be illumi-

nated. In the winter mode both the two port valves are active and

they will direct heat as required.

NB: Voltage free control connections

Width 418 mm

Height 710 mm

Depth 251.5 mm

15

GB-031C_f.625

The indicators and LCD display

on the front panel are off

No power to the boiler Check electricity mains power supply

Main over heat stat cut-out Check the temperature safety cut-out investigate cause

- possibly fault / return sensors or power board

The „A” indicator flickering

Insufficient water pressure

Check water pressure in display panel and increase to 1.5 bar

Pressure Sensor failure Check water pressure in display panel and if display shows

„- -” then replace Pressure Sensor

The „H” indicator flickering

Pump is blocked

Free Pump by setting the Pump on the highest gearing – See

Figure 3 then unscrew the screw on the Pump housing –

See Figure 2. Move Pump rotor manually.

Water is not circulating through the

Boiler Vent the system: Radiators, Pump and Boiler

Pump not running

Check power available at Pump head, if power available

replace as necessary. If power not available check fuse on

Controller Module and replace if necessary

Flow sensor not operating Check the flow sensor and replace as necessary

„G” indicator is flashing but

boiler digital display operating „NA” connection open circuit Ensure „NA” connection is closed or if using external con-

trol (e.g. Shower Sensor) that this is working correctly

„G” indicator flashing „NA” connection open circuit Check „NA” connection - should be closed

„K” indicator flickers Failure of inlet temp sensor Replace inlet temp sensor

„L” indicator flickers Failure of outlet temp sensor Replace outlet temp sensor

„G” „H” & „K” Indicators lit but

boiler not heating

No supply to heating coils from

Power Board.

Check outputs „G1” „G2” & „G3” on Power Board if

230Volts not present to all replace Power Board

„G” „H” & „K” Indicators lit but

boiler only partially heating

One or more heating coils have no

voltage supply from Power Board

Check outputs „G1” „G2” & „G3” on Power Board if

230Volts not present to all replace Power Board

Boiler range Fusion Comet 6kW

(EHCCOM6KW)

Fusion Comet 9kW

(EHCCOM9KW)

Fusion Comet 12kW

(EHCCOM12KW)

Fusion Comet

14.4kW

(EHCCOM15KW)

Fusion Comet 24kW

(EHCCOM24KW)

Pipe entry from boilers Bottom Bottom Bottom Bottom Bottom

Central heating flow & return pipes 22 mm

Min water pressure 1 bar

Max water pressure 3 bar

Expansion vessel 6 lt.

Maximum system water volume about 60 litres at initial system pressure 1,5 bar

Vessel charge pressure 1,5 bar

Safety Class IP22

Dry weight 25kg

Electrical supply 230V 1ph 50Hz

415V 3ph 50Hz

Load/current 26,0 Amp. 39,1 Amp. 52,2 Amp. 62,6 Amp. 3 x 34,8 Amp.

Minimum permitted cable diameter 6mm 10mm 16mm 10mm

Heating output 20484Btu 30726 Btu 40968 Btu 49161 Btu 81936 Btu

Temp setting (factory set) 85°C

Min temp setting 20 - 40°C

Overheat Protection 100°C

Pump included Yes

Recommended Pump settings Set to max

Protection 32 Amp. 50 Amp. 63 Amp. 80 Amp. 3 x 40 Amp.

The maximum allowed network impedance 0,39 Ω 0,32 Ω 0,24 Ω 0,22 Ω

Unit 40, Block 5

Third Road

Blantyre Industrial Estate

Blantyre

Glasgow

G72 0UP

Tel: 01698 820533 Fax: 01698 825697

www.electric-heatingcompany.co.uk

www.ehc-renewables.co.uk

This manual suits for next models

4

Table of contents

Popular Range manuals by other brands

Whirlpool

Whirlpool Gold GGE350LW Dimensions and installation information

GE

GE Monogram ZGU484NGP5SS installation instructions

Whirlpool

Whirlpool LWF5050 Instructions manual, installation and use guide

Cosmo

Cosmo F965NF user manual

Electrolux

Electrolux ICON Professional E36GF76JPS installation instructions

Whirlpool

Whirlpool RME2330 Use & care guide