-2-

Contents

SERVICE MANUAL ................................................... 1

Contents ........................................................................ 2

Safety Instructions......................................................... 3

Safety Precautions ..................................................... 3

Product Safety Notice................................................. 3

Service Personnel Warning........................................ 3

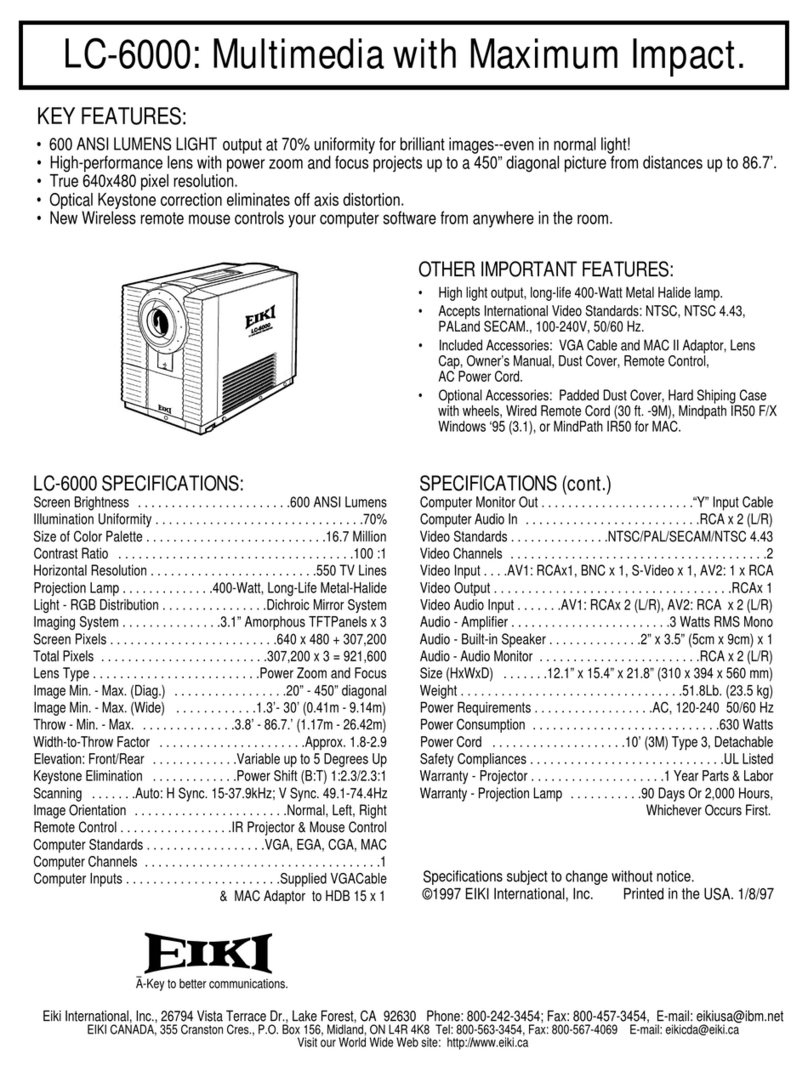

Specifications ................................................................ 4

Circuit Protections ......................................................... 5

Fuse............................................................................ 5

Thermal protectors (SW902) ...................................... 5

Mechanical sensor switches (SW901, SW1891)......... 6

Temperature sensors, wind sensors........................... 7

Power failure and fan lock detection........................... 8

Maintenance.................................................................. 9

Replacing the Filter Cartridge..................................... 9

Lamp Replacement ...................................................11

How to check Lamp Used Time ............................... 12

Quick maintenance................................................... 13

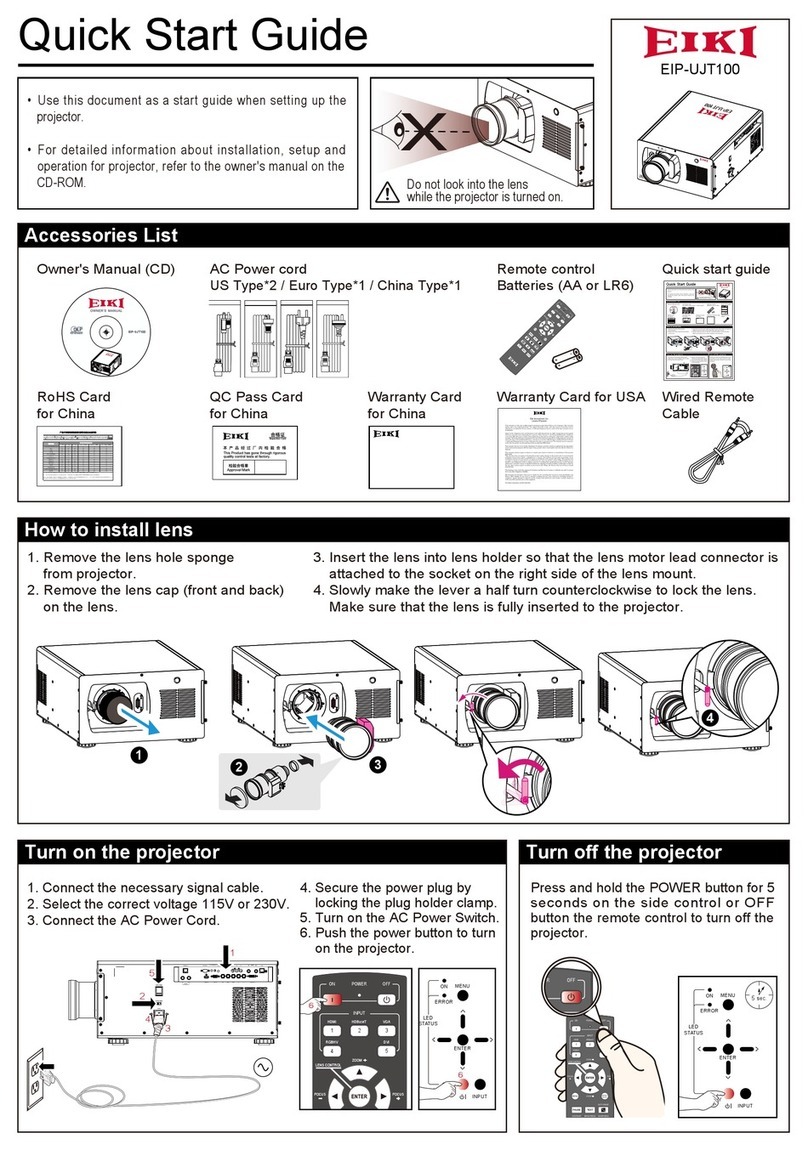

Lens Installation........................................................ 14

Using the Lens Antitheft screw................................. 15

Cleaning ................................................................... 16

Cleaning the Projection Lens ................................... 16

Cleaning the Projector Cabinet................................. 16

Security Function Notice ............................................. 17

Mechanical Disassembly............................................. 18

Optical Parts Disassembly .......................................... 27

Adjustments................................................................. 33

Adjustments after Parts Replacement...................... 33

Note on Main Board Replacement ........................... 33

Service Adjustment Menu Operation ....................... 34

Optical Adjustment ...................................................... 35

1. Optical axis adjustment ........................................ 36

2. Contrast adjustment ............................................. 40

Electrical Adjustments ................................................. 41

Circuit Adjustments................................................... 41

Test Points and Locations ........................................ 45

Service Adjustment Data Table ................................ 46

Troubleshooting........................................................... 65

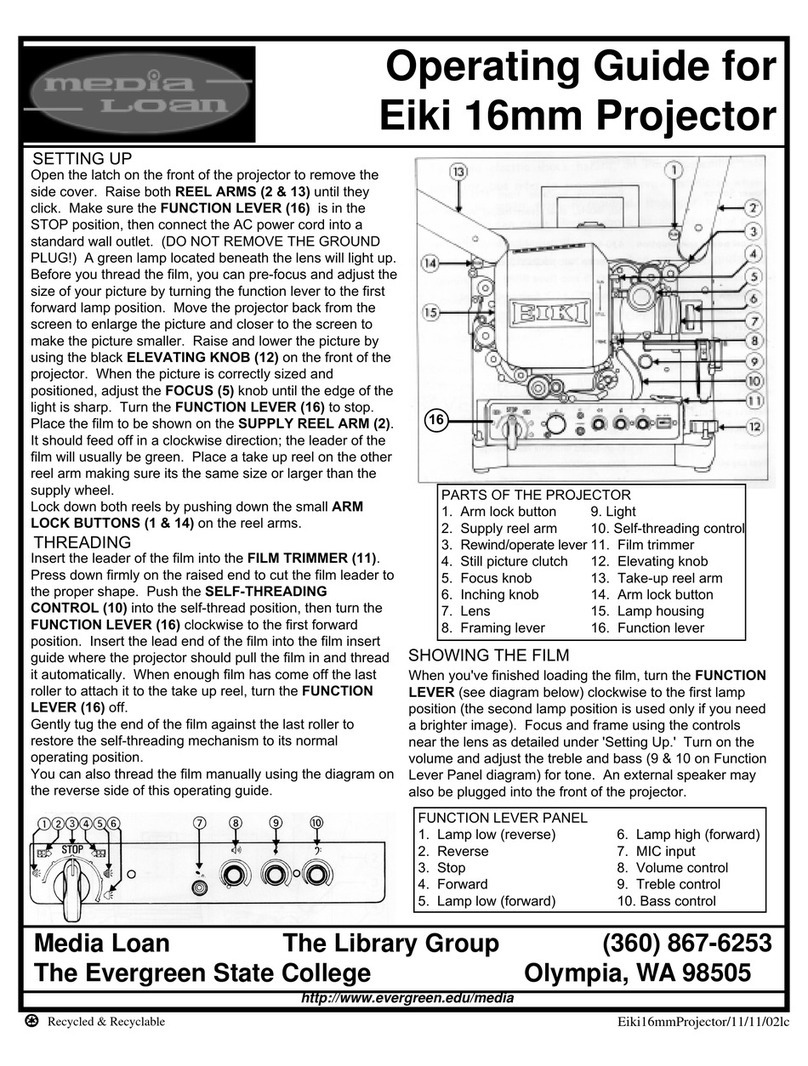

Chassis over view..................................................... 65

No Power.................................................................. 66

No Power (Power supply) ......................................... 67

No Power (Power supply) ......................................... 68

No Power (Fan control)............................................. 69

No Power (Lamp control).......................................... 70

Temperature Abnormality ......................................... 71

No Picture................................................................. 72

No Sound.................................................................. 73

Motor control problems............................................. 74

Bus control................................................................ 75

LED drive & RC control ........................................... 76

Indicators and Projector Condition ........................... 77

Power failure detection system ................................ 80

Diagnosis of Power Failure with RS-232C port ........ 84

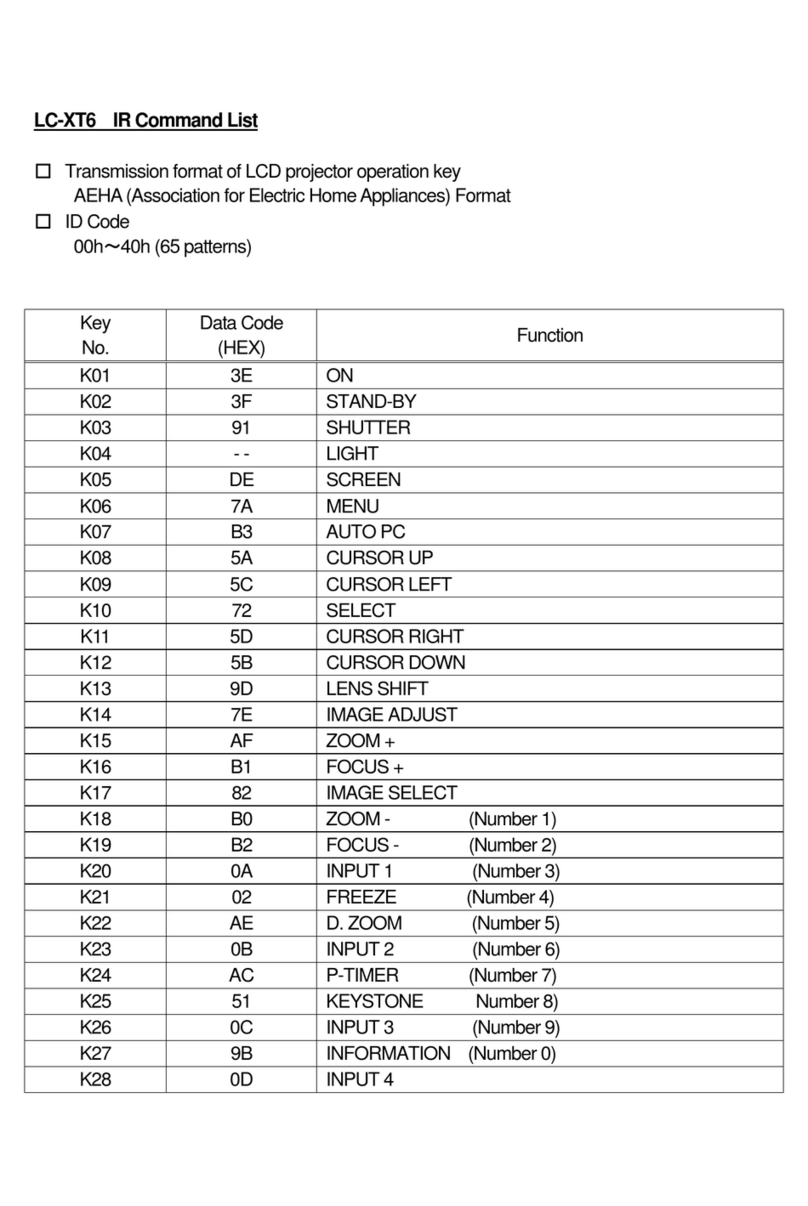

Serial Control Interface............................................. 85

Control Port Functions................................................. 87

IC Block Diagrams....................................................... 90

Parts Location Diagrams ........................................... 100

Mechanical Parts List ................................................ 109

Electrical Parts List.....................................................111

Diagrams & Drawings.................................................. A1

Parts description and reading in schematic diagram ..A2

Schematic Diagrams ...................................................A3

Printed Wiring Board Diagrams................................. A13

Pin description of diode, transistor and IC................. A17

Note on Soldering...................................................... A18