EIPL HM150-H User manual

Page 1 of 12

Drawing : - TPC601

Issue : - 1

Date : - 08/06/23

HM150

HM150HM150

HM150-

--

-H

HH

H

DEHUMIDIFIER

DEHUMIDIFIERDEHUMIDIFIER

DEHUMIDIFIER

OWNER’S MANUAL

www.eipl.co.uk

Page 2 of 12

Drawing : - TPC601

Issue : - 1

Date : - 08/06/23

SAFETY INFORMATION

Children shall not play with the appliance.

This appliance can be used by children from 8 years and above and persons with reduced

physical, sensory or mental capabilities or lack of experience and knowledge if they have

been given supervision or instruction concerning use of the application in a safe way and

understand the hazards involved.

Cleaning and user maintenance shall not be made by children without supervision.

If the SUPPLY CORD is damaged, it must be replaced by the manufacturer, its service agent

or similarly qualified person in order to avoid hazard.

If the appliance is switched off at the mains power supply for any reason, the unit must be

allowed to stand at rest for at least three minutes before restarting.

Due to the high pressures within the refrigeration circuit, under no circumstances must direct

heat be applied to the evaporator coil in an attempt to remove the build-up of ice.

No attempt should be made to cut open any part of the refrigeration circuit due to high

pressures and gas involved.

If the appliance is switched off at the mains power supply for any reason, it must be allowed

to stand at rest for at least three minutes before restarting. Failure to do so may cause the

appliance to blow the fuses owing to the compressor due to there being a refrigerant

imbalance.

The Global Warming Potential (GWP) of refrigerants used in products manufactured by Ebac

Industrial Products Ltd is as follows: -

R290 – 3

R454c – 148

For type and weight of refrigerant contained in this appliance, please refer to the product data

label

Do not insert objects into any of the grilles on the machine.

Do no cover or obstruct airflow from the grilles.

Do not operate the unit with the covers removed

Do not stand on the unit

Do not attempt to lift heavy units unassisted.

Do check the plug on the unit matches the supply.

Do check the supply cord and power supply are earthed correctly

Do check the voltage selection before attempting to power up the unit (This is for dual voltage

units only).

Do use a residual current device “RCD” where possible

Page 3 of 12

Drawing : - TPC601

Issue : - 1

Date : - 08/06/23

The appliance uses R454c refrigerant gas. This gas is much

kinder to the environment as it is non-toxic with zero Ozone

Depletion Potential (ODP). This is a flammable gas and the

following warnings should be considered:

•The appliance uses a flammable refrigerant (see unit serial plate for

charge quantity). It is therefore part of a sealed system and any servicing

should only be carried out by EIPL service personnel.

•Do not pierce / puncture the appliance at any point, even when disposing

of. Before disposing all refrigerant should be evacuated and disposed of

as required by local environmental laws.

•If there is any damage to the appliance, DO NOT USE and contact EIPL.

•The appliance must not be used in a potentially explosive atmosphere.

•The appliance must not be used in an aggressive atmosphere e.g.

chemical environments.

•The appliance must not be used in a high dust environment.

•The appliance must not be used in a high solvent concentration

atmosphere.

•The appliance should not be used or stored in a space of 4M

3

or smaller.

•Do not use the appliance in a room with any continuous source of ignition

e.g. open flames or gas fires.

•R454c is an odourless gas.

•Anyone who does work on the refrigeration circuit must have the

appropriate qualifications / certification issued by a national accredited

organisation to ensure competence when handling flammable

refrigerants.

•Any parts to be replaced within the appliance should only be replaced with

EIPL approved parts.

Page 4 of 12

Drawing : - TPC601

Issue : - 1

Date : - 08/06/23

DEHUMIDIFIER PRINCIPLE

Dehumidifiers remove moisture from the air that is circulating through the

appliance.

The resulting reduction of relative humidity helps prevent rust, rot, mould,

mildew and condensation within the room, or other enclosed spaces where

the dehumidifier is used.

A dehumidifier consists of a motor-compressor unit, a refrigerant condenser,

an air circulating fan, a refrigerated surface, a means of collecting and

disposing the condensed moisture and a cabinet to house these components.

The fan draws air through the refrigerated surface and cools it below its dew

point, removing moisture which is collected and led away. The cool air then

passes the hot condenser, where it is reheated. With the addition of other

radiated heat, the air is discharged into the room at a higher temperature but

lower relative humidity than when the air entered the appliance. Continuous

circulation of the room air through the appliance gradually reduces the relative

humidity in the room.

The appliance is a rugged, reliable drying unit designed to operate effectively

over a broad range of temperature and humidity conditions.

An active hot gas defrost system guarantees positive de-icing, thereby

optimizing operation at low temperatures. Should the ambient temperature fall

below 15°C then ice will form on the evaporator coil as the air is passed over

it, and in turn the efficiency of the unit will drop. To prevent the buildup of this

ice on the evaporator coil an electronic timer is incorporated to energize the

hot-gas defrost valve. Operating the hot-gas valve causes the evaporator coil

to defrost and the water to drain down to the condensate well and then is

pumped out of the unit.

The appliance has been designed to work in ambient temperatures between

3°C and +35°C. Should the temperature in the room become excessive a

thermostat within the compressor casing will open and dehumidifying will stop,

until the thermostat resets itself.

UNPACKING

Carefully remove the appliance from its transit box and visually check for

signs of transit damage. If there is evidence of damage DO NOT attempt to

operate the appliance, call your supplier for advice. Do not discard the

packing; it will be useful when transporting the dehumidifier unit in the future.

Page 5 of 12

Drawing : - TPC601

Issue : - 1

Date : - 08/06/23

INSTALLATION

POSITIONING:

Position the appliance in the center of the room to be conditioned if at all

possible. However, if a damp patch is particularly apparent the outlet grille

should be pointed towards it.

NOTE: Both inlet grille and outlet grille of the appliance must have clear space

around them and not be obstructed in anyway. The unit must also be on a

level surface.

Appliance shall be installed, operated and stored in a room with a floor area

larger than 4M

2

.

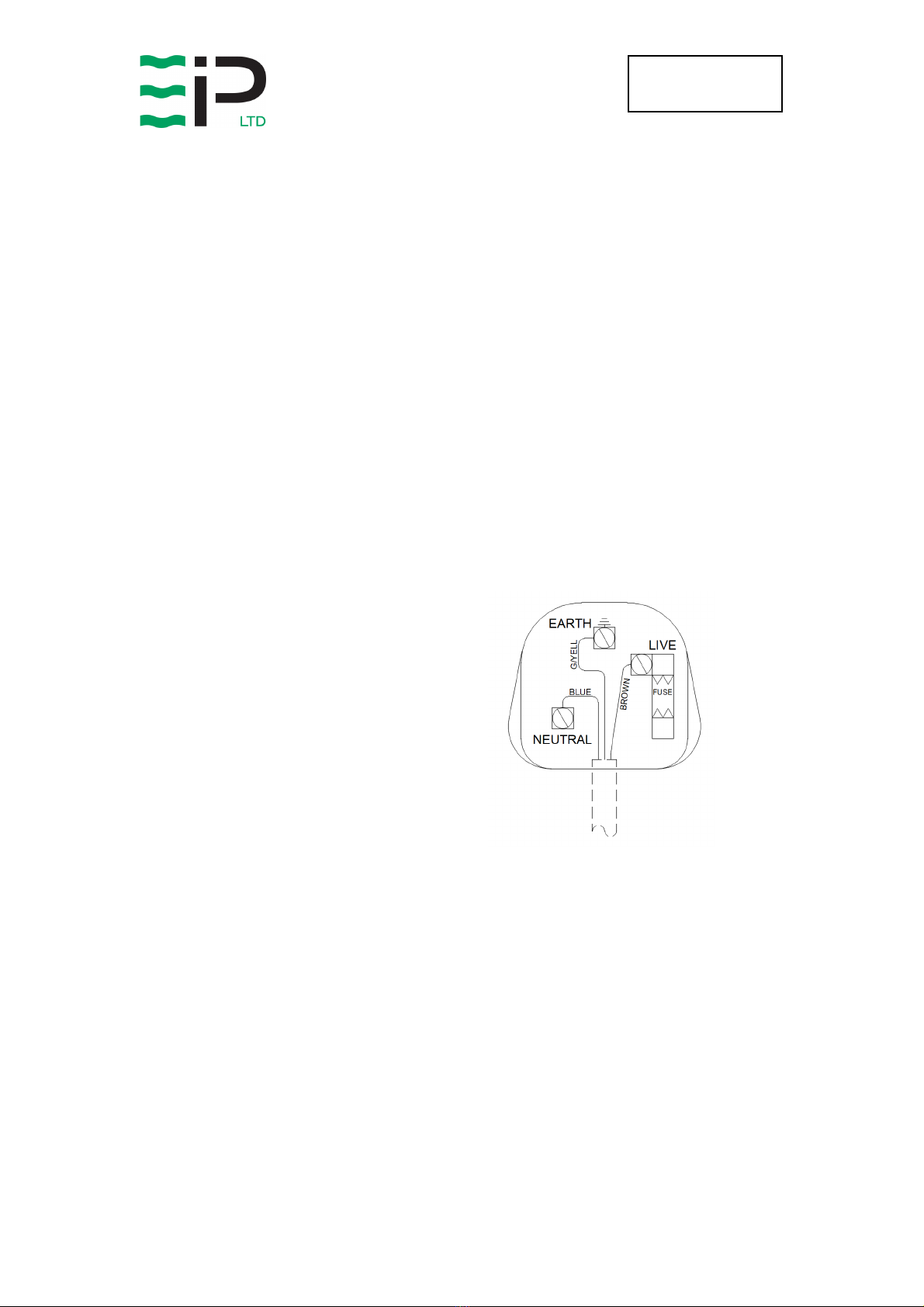

WIRING:

Connect the power mains cable to a 13 Amp power supply as follows: -

230V supply

Brown Live

Blue Neutral

Green/Yellow Earth (ground)

DRAINAGE:

The appliance is fitted with a condensate pump which collects all the

condensate. As the condensate pump fills with water it will automatically

activate and empty via the tube outlet located at the back of the dehumidifier,

this should be connected to a water container or permanent drain. If the pump

fails, then the dehumidifier will automatically switch off. NOTE: after the pump

has emptied there will still be a small amount of water standing in the pump

reservoir which will leak if the dehumidifier is not kept upright.

13 AMP 230V PLUG BS1363

13A

Page 6 of 12

Drawing : - TPC601

Issue : - 1

Date : - 08/06/23

HM150-H Dehumidifier Control Panel

Indicator

Function

Description

ON/OFF Red – Off

Green – On

Drying / Recirculation

Blue – Flashing – Drying Required

Blue – Solid – Drying On

Green – Solid – Recirculation Mode Fan Only)

Defrost Yellow – Flashing – Defrost mode selected

Yellow – Solid – Defrosting in progress

Alarm Green – Flashing – Pump Purging

Red – Solid – Fault, Pump Malfunction

Button / Ledgend Function Description

ON / OFF Switch the dehumidifier ON/OFF

Menu

Cycle through menu options and adjust the

desired set point. See below for list of menu

options

Recirculation Select recirculation fan or dehumidification

mode

Pump Purge Empty the integral water reservoir to prevent

spillage when moving / transporting

Navigation

Adjust the humidity set point UP/DOWN and

enter to confirm

Page 7 of 12

Drawing : - TPC601

Issue : - 1

Date : - 08/06/23

Menu Options

Pressing the Menu button cycles through the following pages of information.

Menu Options when dehumidifying mode is selected

Menu Display Information

1 Set RH Using the Up / Down Keys adjust the humidity to the desired

set-point, pressing the Enter key to accept and save.

2 Temperature Indicates the current room temperature.

3 Coil Temp Shows the current coil temperature. < -9degC display “—“)

4 Time To Start Displays the time to start drying mins) or “on” if already

drying

5 Time To Defrost

If defrost mode is selected, this option shows the remaining

time until defrost will occur. The yellow defrost light will be

flashing indicating a defrost is required.

If defrost is currently occurring, the yellow defrost light will be

solid, and the display will show the time remaining before

defrost ends.

Defrost not required or active the display will show “—“

Notes on Time values above

2 digits no decimal point indicates a time > 10mins

2 digits with a decimal point indicates mins and tenths of a min, ie 8.5 = 8mins 30 secs

Menu Options when recirculation mode is selected

Menu Display Information

1 Humidity Indicates the current room temperature.

Operation

Extend the short piece of tubing from the rear of the dehumidifier with the additional length

supplied using the “Quick Disconnect” coupling. Place the end of this tube into a suitable

drainage point, ie bucket, sink, toilet etc. Ensure the tube is not kinked or restricted.

Plug the unit into a suitable wall socket and power on.

Note the Power On Indicator shows Solid RED.

Press the ON/OFF button once to start the dehumidifier, pressing again will stop the

dehumidifier. To prevent the compressor starting too quickly after being powered down,

there is an inbuilt compressor off timer. This delayed start prevents the compressor for

restarting for 6 minutes after being switched off.

Page 8 of 12

Drawing : - TPC601

Issue : - 1

Date : - 08/06/23

The dehumidifier remembers the last mode of operation, and also the previously adjusted

set point.

Once the dehumidifier is started, the drying / recirculation light will indicate the selected

mode or operation.

Adjust the mode, as required. Recirculation or Drying).

In drying mode, the display will show the room humidity level.

In recirculation mode the display shows the current room temperature.

Using the Menu Key cycle through the menu options to the Set RH page, using the up/down

and enter keys adjust the humidity to the desired level.

The dehumidifier will now self-regulate to maintain the desired humidity level. The unit will

automatically defrost as needed. In warmer climates defrost is not required, allowing the

dehumidifier to continually dry.

Moving / ransporting the unit

The HM150-H has an inbuilt reservoir, which contains a small amount of water, therefore its’

advisable to allow any frost to melt, and empty this reservoir prior to moving.

Instructions / sequence

Switch the unit off by the control panel ON/OFF switch

Allow approximately 30mins for any frost / ice to melt

Press the Pump purge switch inorder to expel all water in the reservoir. The switch

may need pressing several times to ensure all water has been expelled

Remove from the plug from the wall socket and disconnect the drain tube

The unit is now ready to be moved / transported. Note the unit should be kept

upright at all times.

If, after carrying out the above procedures, the appliance does not

appear to function properly, refer to the Trouble Shooting section, which

follows, or contact EIPL.

Page 9 of 12

Drawing : - TPC601

Issue : - 1

Date : - 08/06/23

ROUTINE SERVICE

WARNING:

ENSURE THE POWER CORD TO THE APPLIANCE IS DISCONNECTED

BEFORE CARRYING OUT ROUTINE SERVICE. SERVICING AND REPAIR

SHOULD ONLY BE CARRIED OUT BY A SUITABLY QUALIFIED PERSON.

To ensure continued full efficiency of the appliance, maintenance procedures

should be performed as follows:

1. Clean the surface of the evaporator and condenser coils by blowing the

dirt out from behind the fins with compressed air. Hold the nozzle of the

air hose away from the coil (approx 6”) to avoid damaging the fins.

Alternatively, vacuum clean the coils.

WARNING:

DO NOT STEAM CLEAN THE REFRIGERATION COILS

2. Check that the fan is firmly secured to the motor shaft and that the fan

rotates freely. The motor is sealed for life and does not require any

lubrication

3. To check the refrigerant charge, run the appliance for 15 minutes. The

evaporator coil should be evenly frost coated across its surface. At

temperatures above 25°C, the coil may be covered with droplets of

water rather than frost. Partial frosting accompanied by frosting of the

thin capillary tubes, indicates loss of refrigerant gas or low charge.

4. Check all wiring connections.

TROUBLESHOOTING

S

YMPTOM

C

AUSE

R

EMEDY

Little or no airflow

1. Loose fan on shaft

2. Fan motor burnt out

3. Dirty refrigeration coils

4. Loose electrical wiring

5. Control humidistat either

set too high or

malfunctioning

1. Tighten fan

2. Replace the fan motor

3. See Routine Maintenance

4. Check the wiring diagram

to find fault and repair

5. Adjust humidistat as

required or replace

Little or no water

extraction

1. Insufficient air flow

2. Compressor fault

3. Loss of refrigerant gas

1. Check all of the above

2. Contact EIPL

3. Contact EIPL

Little or no defrost

when required

1. Faulty Timer

2. Faulty bypass timer

1. Contact EIPL

2. Contact EIPL

Page 10 of 12

Drawing : - TPC601

Issue : - 1

Date : - 08/06/23

SPECIFICATIONS

M

ODEL

:

HM150-H

H

EIGHT

:

470 mm (18.5 in)

W

IDTH

:

465 mm (18.3 in)

L

ENGTH

:

680 mm (26.8 in)

W

EIGHT

:

43Kg (95 lb)

A

IRFLOW

:

700 M

3

/Hr

P

OWER

S

UPPLY

:

230 V, 1 ph, 50 Hz

F

INISH

:

Rotational Moulded

polyethylene

R

EFRIGERANT

T

YPE

/Q

TY

:

R454c (See unit rating

label for quantity)

O

PERATING

R

ANGE

:

3°C – 35°C

Page 11 of 12

Drawing : - TPC601

Issue : - 1

Date : - 08/06/23

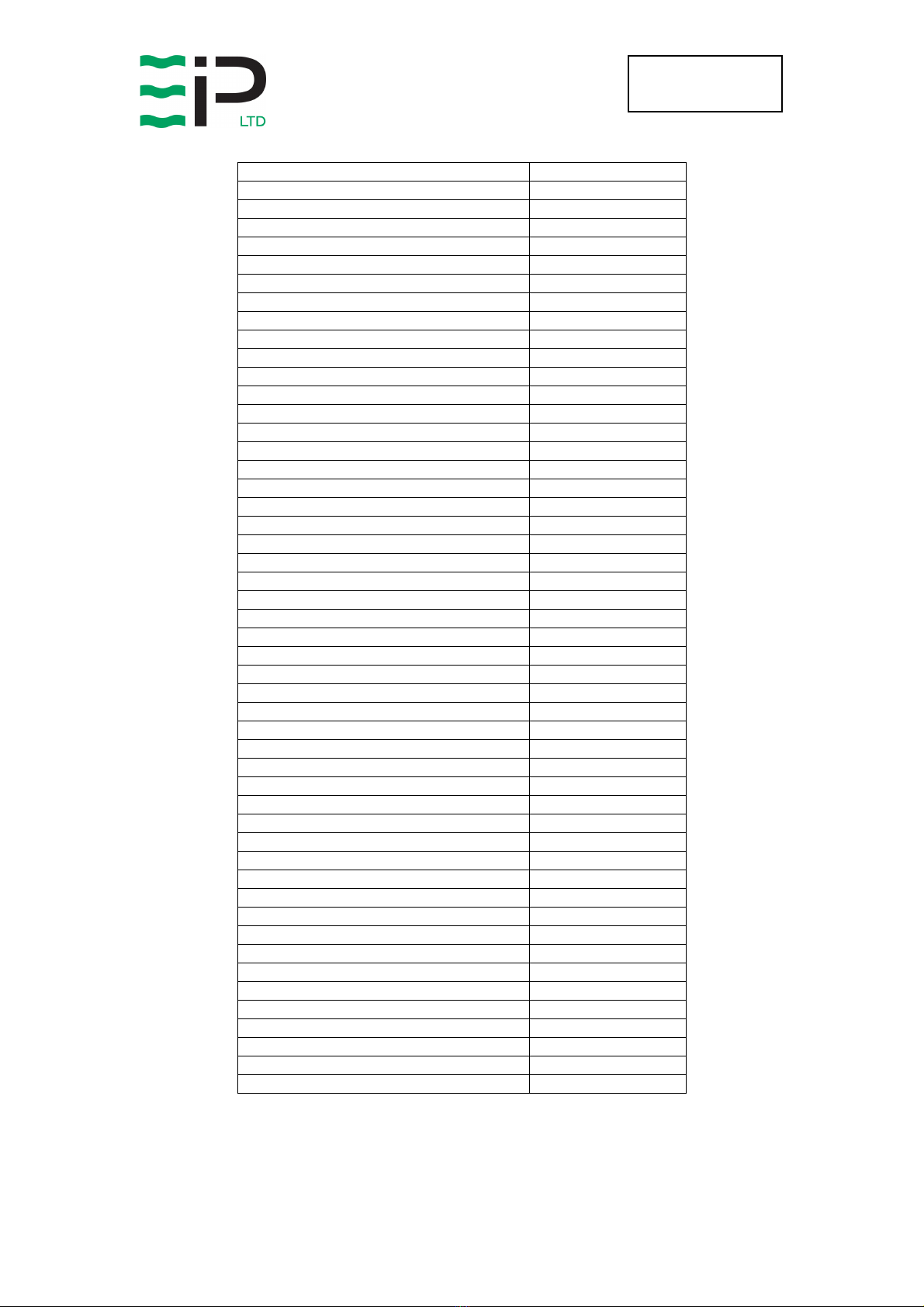

APPLIANCE SPARE PARTS LIST

Spare parts available online

www.EIPLDIRECT.com

Description

Part Number

Product Part Number

11580RH-GB

PCB - Timer

1619522

PCB - Humidity Sensor

1619526

PCB - Display

1619529

PCB Connecting Cable

2013748

Mains Cable

2029217

Foam Block

2056028

Refrigeration Coils

2158002

Keypad Label

2158028

Filter

2158036

Charge Valve

3014215

Capillary Tube

3014254

Foam Tape (Inseal)

3015199

Reversing Valve

3020833

Filter Dryer

3020958

Solenoid Coil

3030454

20mm Open Grommet

3032101

3/8” Open Grommet

3032102

12.5mm Open Grommet

3032104

25mm Open Grommet

3032111

Mains Lead Klambush

3032501

Pump High Level Float Switch

3033043

Mains Supply Filter

3033618

Coil Sensor

3035142

Humidity Sensor Housing

3035164

Circuit Board Jumper

3035834

Fan

3040280

Fan Inlet Ring

3040284

Wheel

3050125

Knurled Hand Wheel – M4

3080190

Starlock Washer Uncapped

3082610

Starlock Washer Capped

3082611

Hose Snapper Clip (SNP6)

3086136

Quick Release Tube Coupling

3086144

Hose Snapper Clip (SNP8)

3086146

Handle Spacer Washer

3087727

Handle Pivot Bolt

3088580

Handle Pivot Nut

3088594

Handle Retainer Catch

3088595

Circuit Board Support

3101413

Non Return Valve

3160157

Condensate Pump

3160162

Solid State Relay

3931320

LED Light Pipes

3931732

Compressor Capacitor

3933604

Humidity Sensor Cable

3935420

Condensate Outlet Tube

3944110

Condensate Reinforced Pump Tube

3944113

Compressor

3944965

Page 12 of 12

Drawing : - TPC601

Issue : - 1

Date : - 08/06/23

UK Head Office

Ebac Industrial Products Ltd

St Helens Trading Estate

Bishop Auckland

County Durham

DL14 9AD

Tel: +44 (0) 1388 664400

Fax: +44 (0) 1388 662590

www.eipl.co.uk

American Sales Office

Ebac Industrial Products Inc

700 Thimble Shoals Blvd.

Suite 109, Newport News

Virginia, 23606-2575

USA

Tel: +01 757 873 6800

Fax: +01 757 873 3632

www.ebacusa.com

Table of contents

Other EIPL Dehumidifier manuals