EIPL EBAC PD200 User manual

PD2

0

0

OWNERS MANUAL

Drawing No. :- TPC369

Issue :- 5

Date

:

-

24/11/16

EBAC MODEL PD200

INDUSTRIAL DEHUMIDIFIER

OWNER’S MANUAL

www.eipl.co.uk

PD2

0

0

OWNERS MANUAL

Drawing No. :- TPC369

Issue :- 5

Date

:

-

24/11/16

UNPACKING

Carefully remove the PD200 dehumidifier unit from its transit box and visually check for signs

of transit damage. If there is evidence of damage DO NOT attempt to operate the unit, call your

supplier for advice. Do not discard the packing, it will be useful when transporting the

dehumidifier unit in the future.

INTRODUCTION

The Ebac PD200 industrial dehumidifier removes moisture from the air through the refrigeration

process.

The Ebac PD200 is basically comprised of:

1) A compressor

2) A refrigerant evaporator coil

3) A refrigerant condenser coil

4) One circulation fan

5) A remote humidistat

6) A cabinet to house the above components

The fan draws the moist air through the cold evaporator coil which cools the air below its dew

point. Moisture forms on the evaporator coil and is collected in the condensate tray which is

equipped with a permanent drain. The cooled air then passes through the hot condenser coil

where it is reheated using the same energy removed during the cooling phase, plus the additional

heat generated by the compressor. The air is therefore discharged from the dehumidifier at a

slightly higher temperature with a lower absolute humidity than with which it entered.

Continuous circulation of air through the dehumidifier gradually reduces the relative humidity

within the area.

The PD200 dehumidifier is a rugged, reliable drying unit designed to operate effectively over a

broad range of temperature and humidity conditions.

The PD200 dehumidifier uses a remotely mounted adjustable humidistat to enable you to select

the level of dryness.

PD2

0

0

OWNERS MANUAL

Drawing No. :- TPC369

Issue :- 5

Date

:

-

24/11/16

SPECIFICATIONS

M

MM

M

ODEL

ODELODEL

ODEL

:

::

:

Ebac PD200

H

HH

H

EIGHT

EIGHTEIGHT

EIGHT

:

::

:

441mm

W

WW

W

IDTH

IDTHIDTH

IDTH

:

::

:

683mm

D

DD

D

EPTH

EPTHEPTH

EPTH

:

::

:

658mm

W

WW

W

EIGHT

EIGHTEIGHT

EIGHT

:

::

:

70.5Kg

A

AA

A

IR

IRIR

IRFLOW

FLOWFLOW

FLOW

:

::

:

Low 450 M

3

/hr

High 850 M

3

/hr

H

HH

H

ORSEPOWER

ORSEPOWERORSEPOWER

ORSEPOWER

:

::

:

3

P

PP

P

OWER

OWER OWER

OWER

S

SS

S

UPPLY

UPPLYUPPLY

UPPLY

:

::

:

230V/50Hz/1ph

F

FF

F

INISH

INISHINISH

INISH

:

::

:

Powder-coated Epoxy

R

RR

R

EFRIGERANT

EFRIGERANT EFRIGERANT

EFRIGERANT

T

TT

T

YPE

YPEYPE

YPE

/Q

/Q/Q

/Q

TY

TYTY

TY

:

::

:

R407c

PD2

0

0

OWNERS MANUAL

Drawing No. :- TPC369

Issue :- 5

Date

:

-

24/11/16

INSTALLATION

POSITIONING:

Position the dehumidifier unit in the center of the room to be conditioned if at all possible.

However if a damp patch is particularly apparent the outlet grille should be pointed towards it if

possible.

This unit can also be used in a duct system where applicable, please see the diagrams on the

following pages which identify the overall sizes of the unit and also the mounting points.

NOTE: Both inlet grille and outlet grille of the dehumidifier unit must have clear space around

them and not be obstructed in anyway. For correct installation and operation the unit inlet and

outlet must have a clearance of 0.5M from all adjacent surfaces and or structures.

Before connecting this unit to the relevant power supply the following must be carried out.

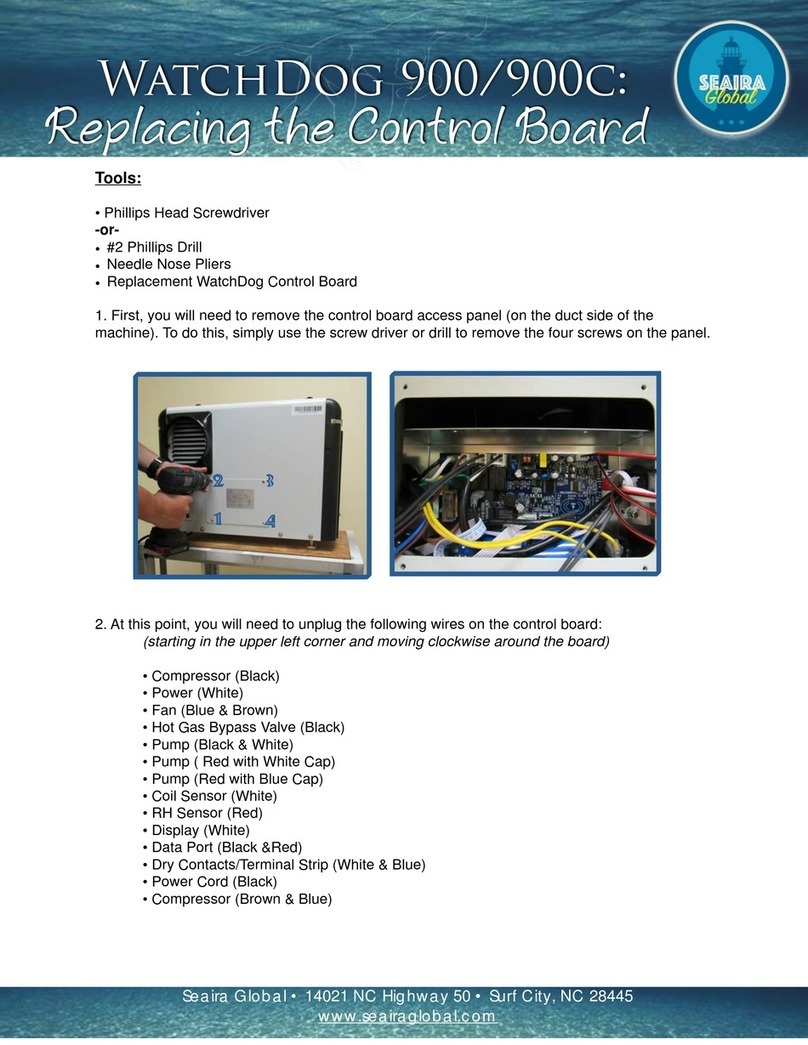

Selecting the correct fan speed – The PD200 has a low fan speed and a high fan speed and the

required speed must be chosen before installation. To select the correct fan speed firstly remove

the air inlet cover via the 10off M4 hex head bolts, then remove the electrical box cover via the

4off M4 hex head bolts. Once the electrical box cover is removed the supplied link wire must be

wired between either the ‘C’ and ‘L’ or the ‘C’ and ‘H’ terminals on the terminal block. This is

shown below.

Before the unit will switch on it must have a low voltage humidistat wired into it with the NC

contacts wired to the terminal block inside the electrical box as shown below.

PD2

0

0

OWNERS MANUAL

Drawing No. :- TPC369

Issue :- 5

Date

:

-

24/11/16

OPERATION

The following procedures should be followed to test the PD200 for correct operation:

1) After unpacking, examine all external features to confirm damage-free shipment. Report all

defects and damage at once. Connect the power cable to a grounded power source.

2) Connect the drainage outlet to a suitably sized hose and run the hose to a permanent drain.

Caution: Do not operate the machine without the covers for any longer than necessary. Do

not remove/ replace the covers when the unit is in operation.

Check dehumidification process as follows:

A. Place unit on a level surface.

B. Start up unit as follows:

i.Ensure fan speed selection has been chosen as mentioned in previous pages and also

that the humidistat has been wired in.

ii.Rotate humidistat control knob to fully counter clockwise, minimum setting.

iii.Plug unit into power supply and rotate humidistat knob clockwise to desired setting.

C. Check that the compressor is running.

D. Leave the machine running for 15 minutes.

E. Observe the evaporator coils behind the filter on the air inlet end of the unit to confirm

frost formation.

i.If the air temperature is below 70ºF, an even coating of frost should cover the entire

evaporator coil, except for the last one or two coils.

ii.If the air temperature is about 70ºF, frost and/or droplets of condensed water should

cover the entire evaporator coil.

F. As the drain tray fills, the condensate will automatically drain by gravity.

If after carrying out the above procedures, the unit does not appear to function properly, refer to

the Trouble Shooting section or contact the Factory Service Center.

WARNING:

•Due to the high pressures within the refrigeration circuit, under no circumstances must direct

heat be applied to the evaporator coil in an attempt to remove the build up of ice.

•No attempt should be made to cut open any part of the refrigeration circuit due to high

pressures and gas involved. If the unit is switched off at the mains power supply for any

reason, the unit must be allowed to stand at rest for at least five minutes before restarting.

Failure to do so may cause the unit to blow the fuses owing to the compressor due to there

being a refrigerant imbalance.

PD2

0

0

OWNERS MANUAL

Drawing No. :- TPC369

Issue :- 5

Date

:

-

24/11/16

ROUTINE SERVICE

WARNING: ENSURE THAT THE POWER CORD TO THE MACHINE

HAS BEEN DISCONNECTED BEFORE CARRYING OUT

ROUTINE SERVICE. THE SERVICING AND REPAIR OF

THIS UNIT SHOULD ONLY BE CARRIED OUT BY A

SUITABLY QUALIFIED PERSON

To ensure continued full efficiency of the dehumidifier, maintenance procedures should be

performed as follows:

1. Clean the surface of the evaporator and condenser coils by blowing the dirt out from

behind the fins with compressed air. Hold the nozzle of the air hose away from the

coil (approx 6”) to avoid damaging the fins. Alternatively, vacuum clean the coils.

WARNING: DO NOT STEAM CLEAN REFRIGERATION COILS.

2. Check that the fan is firmly secured to the motor shaft and that the fan rotates freely.

The fan motor is sealed for life and therefore does not need oiling.

3. To check the refrigerant charge, run the unit for 15 minutes and briefly remove the

cover. The evaporator coil should be evenly frost coated across its surface. At

temperatures above 70°F, the coil may be covered with droplets of water rather than

frost. Partial frosting accompanied by frosting of the thin capillary tubes, indicates

loss of refrigerant gas or low charge.

4. Check all wiring connections.

I

F ANY OF THE PRECEDING PROBLEMS OCCUR

,

CONTACT THE

E

BAC

S

ERVICE

C

ENTER PRIOR TO

CONTINUED OPERATION OF THE UNIT TO PREVENT PERMANENT DAMAGE

.

PD2

0

0

OWNERS MANUAL

Drawing No. :- TPC369

Issue :- 5

Date

:

-

24/11/16

REPAIRS

1. Should an electrical component fail, consult the Factory Service Center to obtain the

proper replacement part.

2. If refrigerant gas is lost from the machine, it will be necessary to use a refrigeration

technician to correct the fault. Contact the Factory Service Center prior to initiating

this action.

Any competent refrigeration technician will be able to service the equipment. The

following procedure must be used:

a. The source of the leak must be determined and corrected.

b. The machine should be thoroughly evacuated before recharging.

c. The unit must be recharged with refrigerant measured accurately by weight.

d. For evacuation and recharging of the machine, use the crimped and brazed

charging stub attached to the side of the refrigerant compressor.

The charging stub should be crimped and rebrazed after servicing. N

EVER

allow

permanent service valves to be fitted to any part of the circuit. Service valves may

leak causing further loss of refrigerant gas.

3. The refrigerant compressor fitted to the dehumidifier is a durable unit that should give

many years of service. Compressor failure can result from the machine losing its

refrigerant gas. The compressor can be replaced by a competent refrigeration

technician.

Failure of the compressor can be confirmed by the following procedure:

a. Establish that power is present at the compressor terminals using a voltmeter.

b. With the power disconnected, check the continuity of the internal winding by

using meter across the compressor terminals. An open circuit indicates that the

compressor should be replaced.

c. Check that the compressor is not grounded by establishing that a circuit does not

exist between the compressor terminals and the shell of the compressor.

PD2

0

0

OWNERS MANUAL

Drawing No. :- TPC369

Issue :- 5

Date

:

-

24/11/16

TROUBLESHOOTING

S

YMPTOM

C

AUSE

R

EMEDY

Unit inoperative 1. no power to unit 1. Check the power from the power

supply panel

Little or no airflow

1. Loose fan on shaft

2. Fan motor burnt out

3. Dirty refrigeration coils

4. Loose electrical wiring

1. Tighten fan

2. Replace the fan motor

3. See Routine Maintenance Section

4. Check the wiring diagram to find

fault and repair

Little or no water extraction

1. Insufficient air flow

2. Compressor fault

3.

Loss of refrigerant gas

1. Check all of the above

2. Contact the Factory Service Center

3.

Contact the Factory Service Center

Unit vibrates excessively 1. Loose compressor mounts

2. Damaged fan

1. Tighten the nuts on the compressor

mounts

2. Replace fan

Water flooding inside the

machine

1. Drain pipe blocked/frozen

2. Drain pipe too high

1. Clear the obstruction

2. Ensure that no section of the drain

hose is above the level of the water

outlet

PD2

0

0

OWNERS MANUAL

Drawing No. :- TPC369

Issue :- 5

Date

:

-

24/11/16

WARNINGS

This appliance can be used by children from 8 years and above and persons with

reduced physical, sensory or mental capabilities or lack of experience and knowledge if

they have been given supervision or instruction concerning use of the application in a

safe way and understand the hazards involved.

Children shall not play with the appliance.

Cleaning and user maintenance shall not be made by children without supervision.

If the SUPPLY CORD is damaged, it must be replaced by the manufacturer, its service

agent or similarly qualified person in order to avoid hazard.

This product contains fluorinated greenhouse gases covered by the Kyoto Protocol.

The refrigeration system is hermetically sealed.

The Global Warming Potential (GWP) of refrigerants used in products manufactured by

Ebac Industrial Products Ltd is as follows

R134a – 1300

R407c – 1610

For type and weight of refrigerant contained in this unit, please refer to the product data

label

Due to the high pressures within the refrigeration circuit, under no circumstances must

direct heat be applied to the evaporator coil in an attempt to remove the build-up of ice.

No attempt should be made to cut open any part of the refrigeration circuit due to high

pressures and gas involved.

If the unit is switched off at the mains power supply for any reason, the unit must be

allowed to stand at rest for at least three minutes before restarting.

AIRFLOW

AIRFLOW

WALL

PD120 / PD200 PD120 / PD200

INLET END DISCHARGE END

1

1

2

2

3

3

4

4

5

5

6

6

A A

B B

C C

D D

DIMENSIONS IN m.m.

OTHERWISE STATED

ANGULAR

TOLERANCES UNLESS

0.0

IF IN DOUBT ASK

DO NOT SCALE

0.00

3RD ANGLE PROJECTION

1993

0.

0.25

0.5 DEGREE

0.05

TITLE

MATERIAL

FINISH

BISHOP AUCKLAND

ENGLAND

LIMITED

SHEET

DRAWN :

CAD SCALE :

DRG.NO.

OF

1

PD120 / 200 DUCTED

INSTALLATION

N/A

N/A 1028260

W DAGLISH

NTS

1

1

DISCHARGE END

INLET END

FILTER INSERTED

INLET DUCT DISCHARGE DUCT

305mm

ALLOWFOR

SERVICECLEANER

THERMOSTAT AND POWERCORD

TOP VIEW SIDE VIEW

607 X 302 FLANGED 213 X 133 FLANGED

THERMOSTAT AND POWERCORD

ISS. DATE COMMENTS

1 23/10/08 ORIGINAL

AIR INTAKE END

AIR DISCHARGE END

58 286 280

72

257.5

9 OFF M8 X 1.25 MOUNTING NUTS

10431

102

119

388 200.5

683

308

49

33 578 658

CONDENSATE OUTLET 1/2" O/D

THERMOSTAT AND POWER CORD OUTLET

The above diagrams show the overall sizes of the unit, the positionng of the air inlet

aperture, the positioning of the air discharge aperture and the M8 mounting points

on the base of the unit.

Once the unit is in the desired location a 1/2" flexible pipe must be connected to the

condensate drainage outlet which is positioned under the air inlet aperture as

shown above. This should then be used to drain away condensate water into a

permanent drain or a water collection container.

257.5

555

PD2

0

0

OWNERS MANUAL

Drawing No. :- TPC369

Issue :- 5

Date

:

-

24/11/16

UK Head Office

Ebac Industrial Products Ltd

St Helens Trading Estate

Bishop Auckland

County Durham

DL14 9AD

Tel: +44 (0) 1388 664400

Fax: +44 (0) 1388 662590

www.eipl.co.uk

sales@eipl.co.uk

American Sales Office

Ebac Industrial Products Inc

700 Thimble Shoals Blvd.

Suite 109, Newport News

Virginia, 23606-2575

USA

Tel: +01 757 873 6800

Fax: +01 757 873 3632

www.ebacusa.com

sales@ebacusa.com

German Sales Office

Ebac Industrial Products Ltd.

Gartenfelder Str. 29-37

Gebäude 35

D-13599, Berlin

Germany

Tel: +49 3043 557241

Fax: +49 3043 557240

www.eip-ltd.de

sales@eip-ltd.de

Table of contents

Other EIPL Dehumidifier manuals