Ekckom XC8602ME-B User manual

XC8602ME-B

Optical Receiver Manual

Optical Receiver Specification

-1 -

1. Product Summary

XC8602ME-B outdoor optical receiver is a new 860MHz optical receiver. With wide

receiving optical power range, high output level, low power consumption and compact

structure. It is very easy to install. It is the ideal equipment to build the high-

performance NGB network.

2. Performance Characteristics

■High responsivity PIN photoelectric conversion tube.

■860MHz bandwidth design.

■Optimized circuit design, preceding stage adopts SMT process and post stage adopts

typical module amplifier circuit, make the photoelectronic signal transmission more

smooth.

■Power doubler output, with high gain and low distortion.

■Optical AGC control, when the input optical power range is -7~+2dBm, the output

level, CTB and CSO basically unchanged.

■Can be extended with remote network management, easy to access the network

management system.

■The fiber port and network management port can be selected external (I type) or internal

(II type).

3. Technique Parameter

3.1 Link testing conditions

The technique parameters of this manual according to the measuring method of GY/T

194-2003 <Specifications and methods of measurement on optical node used in CATV

systems>, and tested in the following conditions.

Testing conditions:

Forward path optical receiver part: with 10km standard optical fiber, passive optical

attenuator and standard optical transmitter composed the testing link. Set 59 PAL-D analog

TV channel signal at range of 45/87MHz~550MHz under the specified link loss. Transmit

digital modulated signal at range of 550MHz~862MHz, the digital modulated signal level

(in 8 MHz bandwidth) is 10dB lower than analog signal carrier level. When the input optical

power of optical receiver is -1dBm, the RF output level is 108dBμV, with 8dB output tilt,

measure the C/CTB, C/CSO and C/N.

Note: When the rated output level is the system full configuration and the receiving optical

power is -1dBm, equipment meets the maximum output level of link index. When the system

configuration reduce (that is, actual transmission channels reduce), the output level of

equipment will be increased.

Friendly Notice: Suggest you setting the RF signal to 6~9dB tilt output in the practical

engineering application to improve the nonlinear index (behind the node) of the cable system.

-2 -

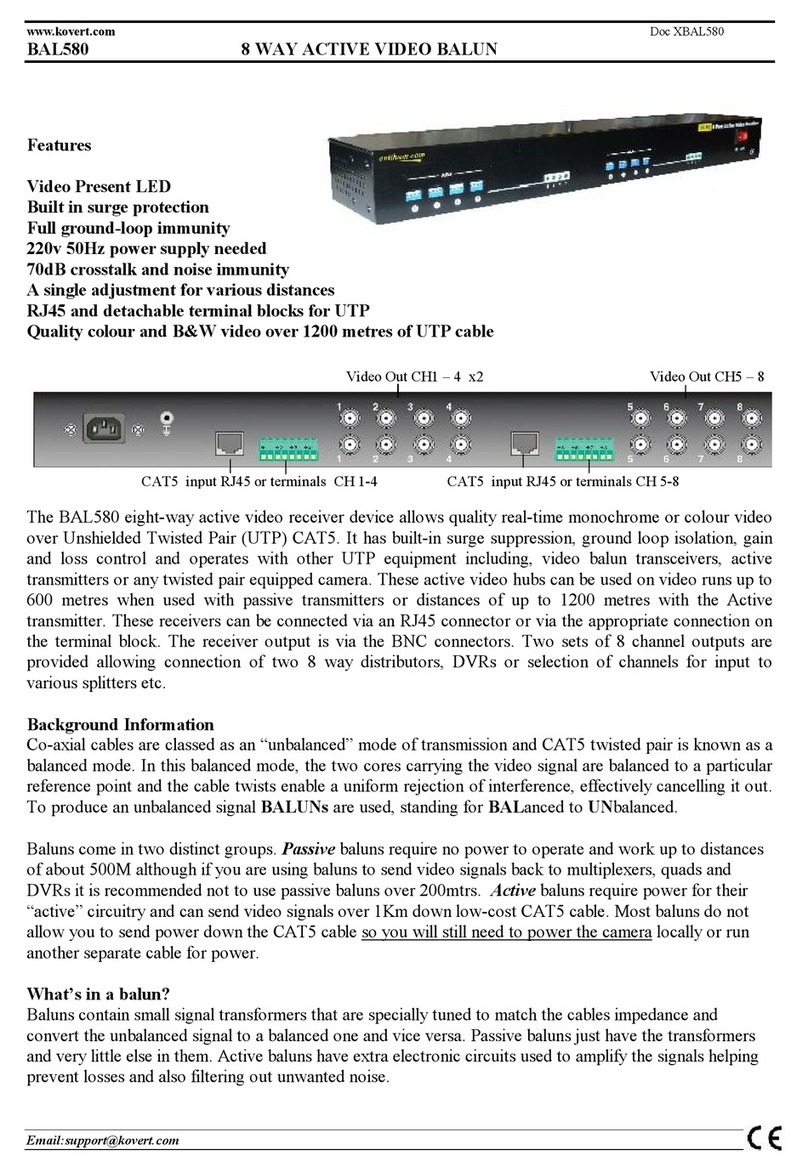

3.2 Technique Parameters

Item

Unit

Technique Parameters

Optical Parameters

Receiving Optical Power

dBm

-7 ~ +2

Optical AGC Control Range

dBm

+2 ~ -7

Optical Return Loss

dB

>45

Optical Receiving

Wavelength

nm

1100 ~ 1600

Optical Connector Type

SC/APC or specified by the user

Fiber Type

Single Mode

Link Performance

C/N

dB

≥ 51

EQ 8dB, output level

108dBμV (FZ110)

C/CTB

dB

≥ 65

C/CSO

dB

≥ 60

RF Parameters

Frequency Range

MHz

45 ~862

Flatness in Band

dB

±0.75

Rated Output Level

dBμV

≥ 108

Max Output Level

dBμV

≥ 116 (-7 ~ +2dBm optical power received)

Output Return Loss

dB

≥16

Output Impedance

Ω

75

EQ Range

dB

0~20

ATT Range

dB

0~20

Generic Characteristic

Power Voltage

V

A: AC (150~265)V B: AC (35~90)

V

Operating Temperature

℃

-40~60

Consumption

VA

≤18

Dimension

mm

220 (L) * 205 (W) * 65 (H)

Note: The forward RF parameters are tested under the condition of using NEC module. Use

other module, the parameters will be slightly different.

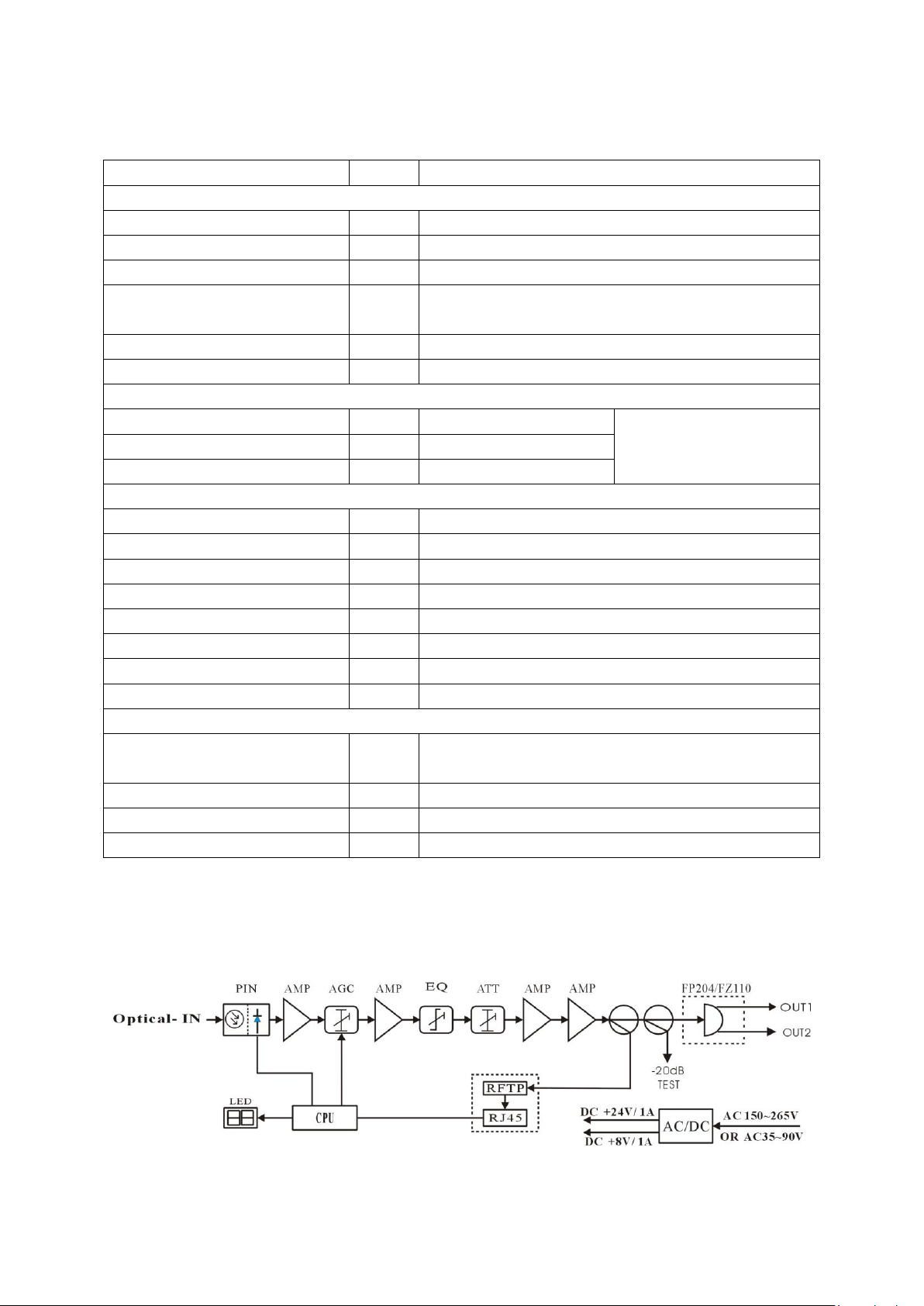

4. Block Diagram

-3 -

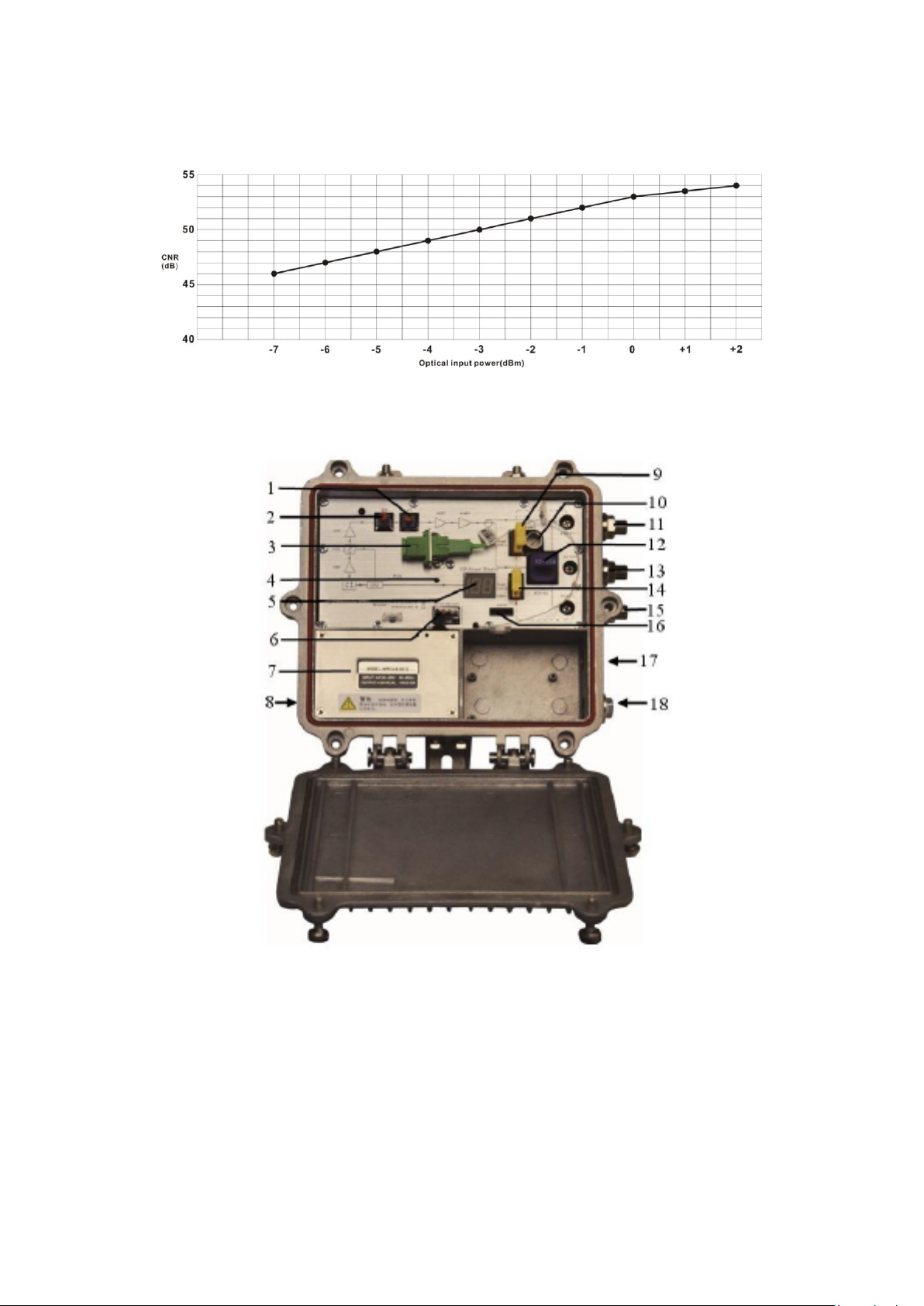

5. Relation Table of Input Optical Power and CNR

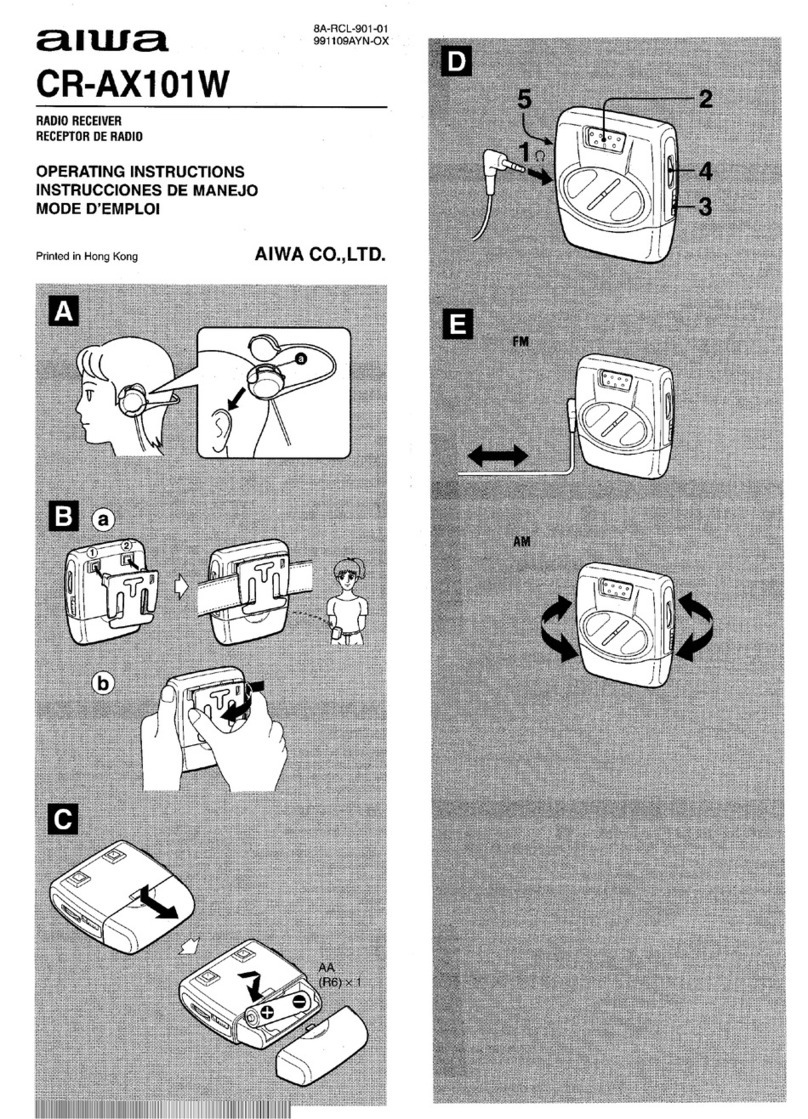

6. Structure Description

1. Adjustable ATT knob

2. Adjustable EQ knob

3. Optical receiving port (or external, optional)

4. Working indicator

5. Optical power display tube

6. Power interface

7. Switching power supply

8. Power cord in

9. AC60V power-pass inserter

10. Output -20dB test port

11. Output 1

12. FZ110 or FP204

13. AC60V feed

14. AC60V power-pass inserter

15. Output 2

16. Network management interface

17. Fiber in

18. Network cable in

-4 -

7. NMS setup instructions

If users configured the network management transponder, need to do the following

settings:

Transponder IP setup instruction:

Network management directly modify:

1. Default IP is 192.168.1.168, default gateway is 192.168.1.1, default subnet mask is

255.255.255.0

2. Connect the computer and transponder (can be direct connected), and change the

computer IP to 192.168.1.XXX (XXX is any number from 0 to 255 except 168); start

upper computer network management software, then search the device and log in.

3. Right-click device icon and choose modify the device IP.

4. Enter new IP address, gateway and subnet mask.

5. Click modify, then exit, it is done. There will show new IP address and gateway on

operational logbook.

6. Reboot the transponder, the new IP take effect (Click the reboot button in the network

management software or power on again)

-5 -

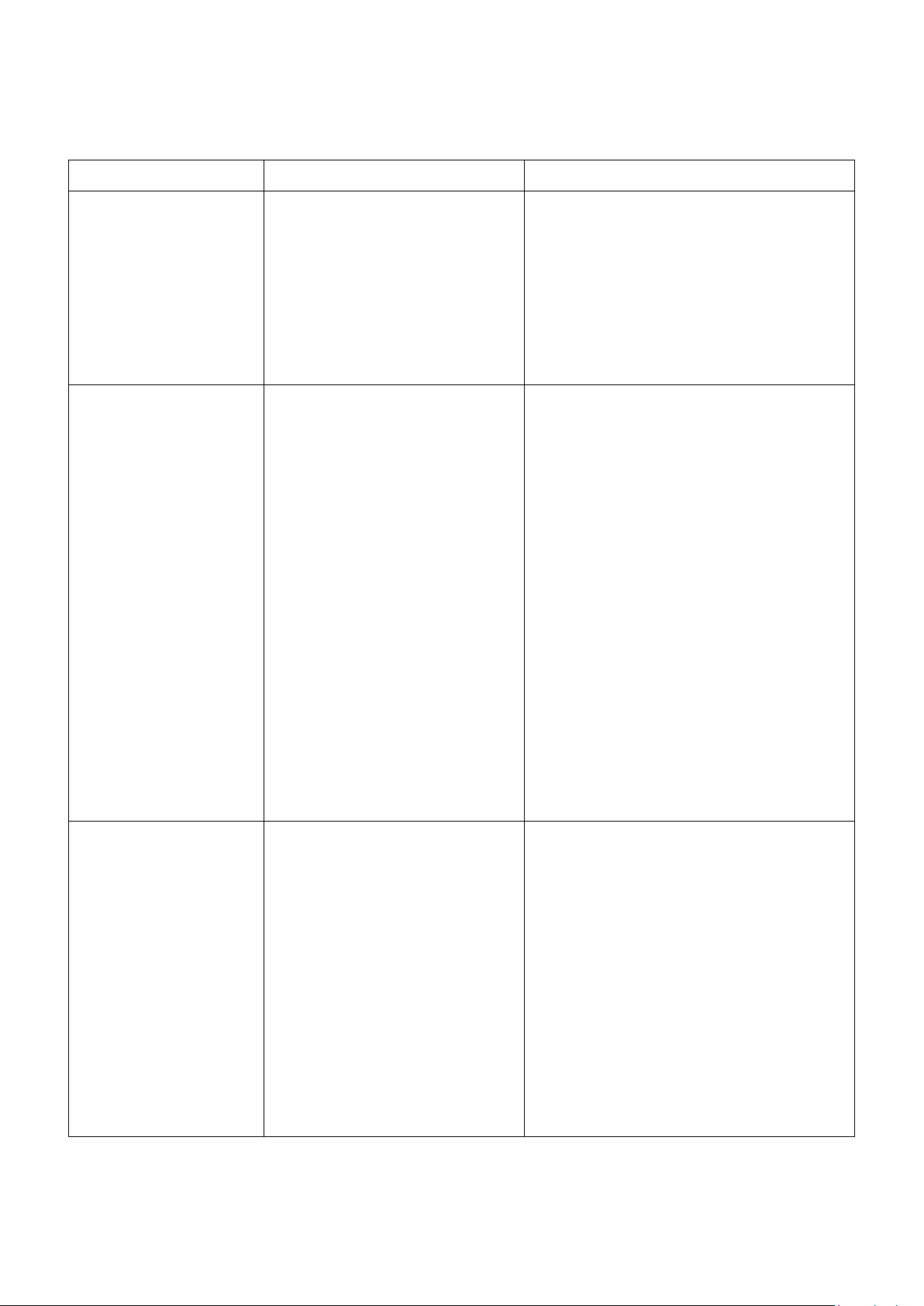

8. Common Failure Analysis and Troubleshooting

Failure phenomenon

Failure cause

Solution

After connecting the

network, the image of

the optical contact point

has obvious netlike

curve or large particles

highlights but the image

background is clean.

1. The optical input power of the

optical receiver is too high, make

the output level of the optical

receiver module too high and RF

signal index deteriorate.

2. The RF signal (input the optical

transmitter) index is poor.

1. Check the optical input power and make

appropriate adjustments to make it in the

specified range; or adjust the attenuation of

optical receiver to reduce the output level

and improve index.

2. Check the front end machine room optical

transmitter RF signal index and make

appropriate adjustments.

After connecting the

network, the image of

the optical contact point

has obvious noises.

1. The optical input power of the

optical receiver is not high

enough, results in the decrease of

C/N.

2. The optical fiber connector or

adapter of the optical receiver has

been polluted.

3. The RF input signal level of the

optical transmitter is too low,

make the modulation degree of the

laser is not enough.

4. The C/N index of system link

signal is too low.

1. Check the received optical power of the

optical contact point and make appropriate

adjustments to make it in the specified range.

2. Improve the optical received power of the

optical contact point by cleaning the optical

fiber connector or adapter etc methods.

Specific operation methods see “Clean and

maintenance method of the optical fiber

connector”.

3. Check the RF input signal level of the

optical transmitter and adjust to the required

input range. (When the input channels

number less than 15, should be higher than

the nominal value.)

4. Use a spectrum analyzer to check the

system link C/N and make appropriate

adjustments. Make sure the system link

signal C/N﹥51dB.

After connecting the

network, the images of

several optical contact

points randomly appear

obvious noises or bright

traces.

The optical contact point has open

circuit signal interference or

strong interference signal

intrusion.

1. Check if there is a strong interference

signal source; change the optical contact

point location if possible to avoid the

influence of the strong interference signal

source.

2. Check the cable lines of the optical contact

point, if there is shielding net or situation

that the RF connector shielding effect is not

good.

3. Tightly closed the equipment enclosure to

ensure the shielding effect; if possible add

shielding cover to the optical contact point

and reliable grounding.

-6 -

After connecting the

network, the images of

several optical contact

points appear one or two

horizontal bright traces.

Power supply AC ripple

interference because of the bad

earth of equipment or power

supply.

Check grounding situation of the equipment,

make sure that every equipment in the line

has been reliably grounding and the

grounding resistance must be﹤4Ω.

After connecting the

network, the received

optical power of the

optical contact point is

unstable and changes

continuously. The

output RF signal is also

unstable. But the

detected optical output

power of the optical

transmitter is normal.

The optical fiber connector types

do not match, maybe the APC

type connect to PC type.

The optical fiber connector or

adapter may be polluted seriously

or the adapter has been damaged.

1. Check the type of optical fiber connector

and adopt the APC type optical fiber

connector to ensure the normal transmission

of optical signal.

2. Clean the polluted optical fiber connector

or adapter. Specific operation methods see

“Clean and maintenance method of the

optical fiber connector”.

3. Replace the damaged adapter.

9. Clean and maintenance method of the optical fiber active connector

In many times, we consider the decline of the optical power as the equipment faults, but

actually it may be caused by that the optical fiber connector was polluted by dust or dirt.

Inspect the fiber connector, component, or bulkhead with a fiberscope. If the connector is

dirty, clean it with a cleaning technique following these steps:

1. Carefully pull off the optical fiber active connector from the adapter. The optical fiber

active connector should not aim at the human body or the naked eyes to avoid accidental

injury.

2. Wash carefully with good quality lens wiping paper or medical degrease alcohol cotton.

If use the medical degrease alcohol cotton, still need to wait 1~2 minutes after wash, let

the connector surface dry in the air.

3. The cleaned optical fiber active connector should be connected to optical power meter to

measure output optical power to affirm whether it has been cleaned up.

4. When connect the cleaned optical fiber active connector back to adapter, should notice to

make the force appropriate to avoid the ceramic tube in the adapter crack.

5. If the output optical power is not normal after cleaning, should pull off the adapter and

clean the other connector. If the optical power still low after cleaning, the adapter may be

polluted, clean it. (Note: Be carefully when pull off the adapter to avoid hurting inside

fiber.)

6. Use the dedicated compressed air or degrease alcohol cotton bar to clean the adapter.

When use the compressed air, the muzzle of the compressed air tank should aims at the

ceramic tube of the adapter, clean the ceramic tube with compressed air. When use

degrease alcohol cotton bar, carefully insert the alcohol cotton bar into the ceramic tube

to clean. The insert direction should be consistent, otherwise can not reach ideal cleaning

effect.

Table of contents

Other Ekckom Receiver manuals