Elcon EL-32 User manual

ELcon

Consulting & Engineering

Brunnhaldenstrasse 8

3510 Konolfingen

Switzerland

Phone

E-Mail

Shop

+41 (0) 31 792 04 61

info@elcon.ch

http://shop.elcon.ch

EL-32

Digital replacement display kit

incl. CTCSS function for the

YAESU FT-221R

Construction, operating and functional description

from SW-Version 2.0e

January 18, 2024

Page2 / 36 January 18, 2024, © Elcon, Switzerland EL-32_V3.0a_en.docx

Table of Contents:

1Introduction ..................................................................................................................................... 3

2Assembly of the display module ..................................................................................................... 3

2.1 Parts lists................................................................................................................................ 5

2.2 Step by Step assembly and testing of printed circuit boards................................................. 7

2.2.1 Assembling the PCB.......................................................................................................... 7

2.3 Plug assembly........................................................................................................................ 8

2.3.1 Initial test of the PCB ....................................................................................................... 10

2.4 Converting the FT-221 ......................................................................................................... 10

2.4.1 Removing the analog display from the FT-221................................................................ 10

2.4.2 Installation of the new digital display board in the FT-221............................................... 13

2.5 Start-up and adjustments..................................................................................................... 15

2.5.1 Adjusting the voltage measurement circuit...................................................................... 15

2.5.2 Adjustment of the frequency measuring circuit................................................................ 16

2.5.3 Test of the CTCSS encoder............................................................................................. 18

2.5.4 Adjustment of the CTCSS encoder.................................................................................. 18

2.5.5 Assembly.......................................................................................................................... 19

3Operation and functions................................................................................................................ 21

3.1 Display.................................................................................................................................. 21

3.2 Communication with the display module.............................................................................. 21

3.3 Menu structure ..................................................................................................................... 22

3.4 Operating modes.................................................................................................................. 23

3.4.1 Frequency Display ........................................................................................................... 23

3.4.2 Voltage Display................................................................................................................ 25

3.4.3 Morse readout of frequency............................................................................................. 25

3.4.4 Morse readout of voltage ................................................................................................. 25

3.4.5 Sound settings ................................................................................................................. 26

3.4.6 CTCSS (Continuous Tone Coded Squelch System)....................................................... 26

3.4.7 CTCSS memory for repeater operation........................................................................... 27

4Software Update ........................................................................................................................... 29

4.1.1 Installing the USB-updater software on the PC............................................................... 29

4.1.2 Installing the USB driver software.................................................................................... 29

4.1.3 Transferring the software updates in the EL-32............................................................... 31

5Appendix....................................................................................................................................... 32

5.1 Specifications ....................................................................................................................... 32

5.2 Rulers................................................................................................................................... 32

5.3 Repair / Warranty ................................................................................................................. 33

5.4 Disclaimer of liability............................................................................................................. 33

5.5 PCB assembly...................................................................................................................... 34

5.6 Schematic............................................................................................................................. 35

5.7 Notes.................................................................................................................................... 36

Important!

Advices or tips for the correct function of the EL-32.

Caution!

The instructions must be observed carefully.

EL-32_V3.0a_en.docx January 18, 2024, © Elcon, Switzerland Page3 / 36

1 Introduction

The old YASEU FT-221R VHF (2m-band) transceiver (ca. 70s) is still popular because of its

very good reception. Unfortunately, it only has an analog frequency display. A digital display

of the frequency is only possible with the FY-221. Today this frequency display is no longer

available, or only at exorbitant prices, e.g. on eBay.

Today, modern microcontroller-controlled transceivers can be purchased. However, many ra-

dio amateurs still want to keep - perhaps their first device - alive and use it. But an analog

frequency display is no fun when repeater stations are becoming increasingly narrow-band

and require higher frequency accuracy when transmitting.

Replacing the mechanical display unit with a 7-digit digital frequency display is easy with this

kit.

A display module has been developed that can be installed directly in the FT-221R and has

useful additional functions, such as CTCSS for repeater operation.

The design is simple, as almost only wired components are used.

2 Assembly of the display module

For the assembly you need the following tools and additional material:

♦50 to 80W pencil-style soldering iron

♦solder Ø 0.5mm flux-core

♦small needle nose pliers

♦several screwdrivers (Phillips)

♦tweezers

♦fine side cutter

♦multi meter (ohmmeter, voltmeter)

It is advisable to study carefully and print out this documentation as a reference when you as-

semble the device. It allows you to control each implemented step.

Make sure the workspace is safe and free of static electricity, so that the installed elements

are not damaged. It might be helpful to wear an antistatic bracelet. The illustrations on page

5 continued should help to identify the shapes and colors of the individual components.

The components, PCB and all mechanical elements corresponding to the component list

(Table 2) are packed in a bag. Open the bag carefully, so that no components are lost or

damaged.

Soldering is one of the most important aspects of setting up this device. A bad solder

joint - even with a carefully assembled kit - can make it impossible to operate the unit

and lead to frustration.

Page4 / 36 January 18, 2024, © Elcon, Switzerland EL-32_V3.0a_en.docx

It's easy to create a good solder joint, if the following rules are observed:

1. Use a temperature-controlled pencil-style soldering iron with about 50 to 80 watts. A 1

to 2 mm wide chisel or pyramid tip works best.

2. Set the temperature for lead-free solder to a maximum of 320°C (608°F) and for

leaded tin to a maximum of 360°C (680°F).

3. The tip must always be clean and well tinned. Wipe the tip often on stainless steel

wool (to be found in the cleaning-products department at a supermarket), never on a

wet sponge. Otherwise, the soldering iron tip cools off unnecessarily, and there is not

enough heat at the solder joint.

4. Do not use solder pastes, but good quality solder wire with a flux-core.

5. Keep the soldering iron tip only once, but long enough (approximately 2 to 3 seconds),

to the soldering joint, so that the solder can flow well. During this time enter very little

solder between solder joint and tip.

6. Never touch the soldering pads on the board; otherwise, a good soldering will not be

possible. Should this happen anyway, clean the PCB with a lint-free cloth and benzine.

7. For multi-pole components such as IC sockets, plugs, etc. solder only 2 pins on diago-

nally opposite corners. This has the advantage that the elements can still be adjusted

and afterwards soldered definitively. Subsequently, all other connections can be sol-

dered.

Always make sure that you do not burn the already soldered components with the sol-

dering iron.

The resistors in the parts list show the respective color coding (see also Table 1). If you are

not familiar in dealing with the color coding, it is better to measure the resistance value with

an ohmmeter prior to soldering.

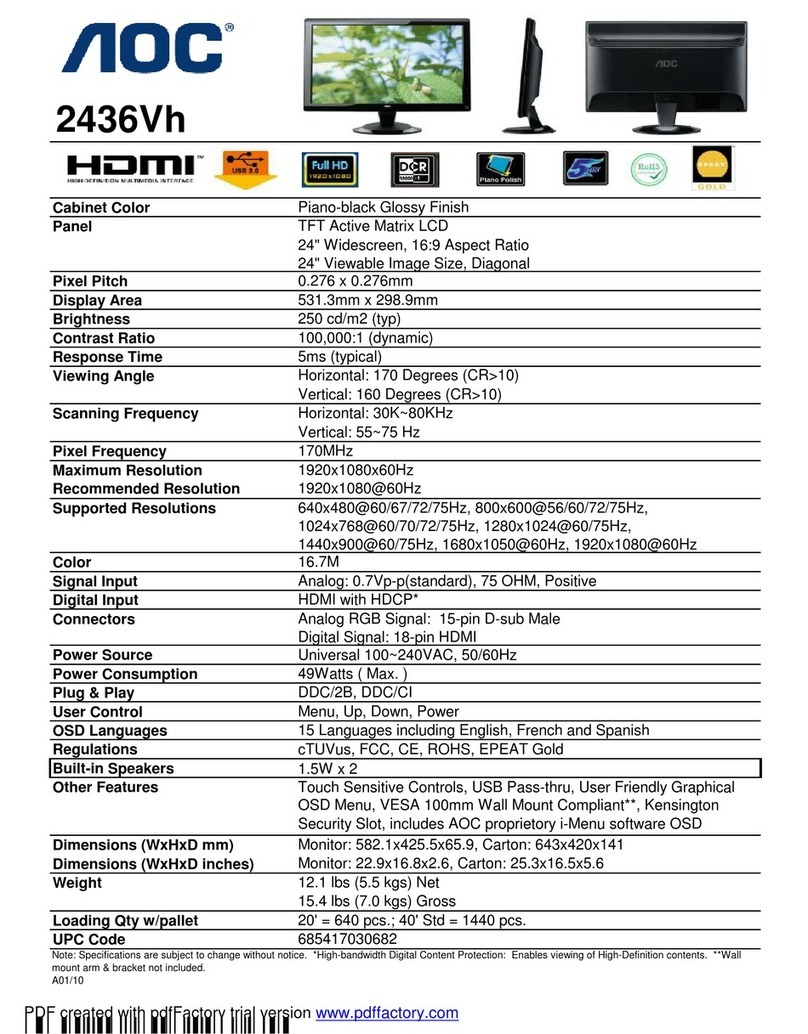

Color coding of resistors with 4 rings

Color

Resistance in Ω

Tolerance

1st ring

(1st digit)

2nd ring

(2nd digit)

3rd ring

(multiplier)

4th ring

none

-

-

-

±20%

silver

-

-

10-2 = 0.01

±10%

gold

-

-

10-1 = 0.1

±5%

black

-

0

100= 1

-

brown

1

1

101= 10

±1%

red

2

2

102= 100

±2%

orange

3

3

103= 1’000

-

yellow

4

4

104= 10’000

-

green

5

5

105= 100’000

±0.5%

blue

6

6

106= 1’000’000

±0.25%

violet

7

7

107= 10'000’000

±0.1%

gray

8

8

108= 100'000’000

-

white

9

9

109= 1'000'000’000

-

Table 1

Note: all polarized components (diodes, transistors, capacitors, ICs, relays, etc.) must

have the correct mounting orientation.

EL-32_V3.0a_en.docx January 18, 2024, © Elcon, Switzerland Page5 / 36

2.1 Parts lists

EL-32 board

piece

components No.

Description

1

R1 (not installed)

22Ω 1/8 W (red-red-black) [Component 1]

1

R5 (not installed)

51Ω 1/8 W (green-brown-black) [Component 1]

2

R3, R14

100Ω 1/8 W (brown-black-brown) [Component 1]

2

R9, R13

10kΩ 1/8 W (brown-black-orange) [Component 1]

3

R6, R8, R11

22kΩ 1/8 W (red-red-orange) [Component 1]

1

R16

33kΩ 1/8 W (orange-orange-orange) [Component 1]

2

R4, R12

47kΩ 1/8 W (yellow-purple-orange) [Component 1]

3

R2, R7, R15

100kΩ 1/8 W (brown-black-yellow) [Component 1]

1

R10

10kΩ Trim potentiometer (blue) 3296P [Component 2]

4

C6, C7, C8, C11

1nF Ceramic marked with 102 [Component 3]

11

C2, C3, C4, C5, C10, C12, C13, C14,

C16, C17, C19

0.1uF Ceramic marked with 104 [Component 3]

3

C9, C15, C18

1uF/50V electrolyte [Component 14]

2

C1, C20

47uF/16V electrolyte [Component 14]

1

X1 (already installed)

20MHz TCXO SMDR0053-T-040-3 [Component 4]

7

U1, U2, U3, U4, U5, U6, U7

LSHD-A103, 7 Segment LED [Component 11]

1

U8

MAX7221CNG or AS1106PL [Component 8]

1

U9

PIC18F2550 I/SP programmed [Component 7]

1

U10 (already installed)

MC12093DG 1.1 GHz prescaler [Component 6]

1

U11

PIC12F1571 I/SP programmed [Component 9]

1

U12 (already installed)

MAX9203ESA 7ns, Voltage Comparator [Component 6]

1

U13

TSOP4838 IR-Rx [Component 12]

1

U14

L78L05ACZ Positive Voltage Regulator [Component 16]

1

D1

1N4148 Diode [Component 10]

1

D2

1N4148 Diode [Component 10]

1

B1

AT-1220-TT-5-R Buzzer [Component 13]

1

P1 (already installed)

USB-B mini jack (SMD) [Component 5]

1

P2

JST B7B-XH-A Socket connector [Component 23]

1

JST XHP-7 Plug housing [Component 24]

7

JST Socket contact SXH-001T-P0.6 [Component 25]

1

J1 (not installed)

Header 6 Pin [Component 18]

1

RF-In

Coaxial RG-316 Length 23 cm [Component 17]

1

Tone Out

Audio cable length 23 cm [Component 26]

5

Stranded wires

various lengths (see text) [Component 22]

3

Spacer bolt M3x12mm

[Component 19]

3

Screws M3x6mm

[Component 20]

1

Foil for display red

[Component 21]

1

Polarization film for display

[Component 27]

1

PCB EL-32

Board version 2.1b [Component 15]

Table 2

Page6 / 36 January 18, 2024, © Elcon, Switzerland EL-32_V3.0a_en.docx

Component 1

Component 2

Component 3

Component 4

Component 5

Component 6

Component 7

Component 8

Component 9

Component 10

Component 11

Component 12

Component 13

Component 14

Component 15

Component 16

Component 17

Component 18

Component 19

Component 20

Component 21

Component 22

Component 23

Component 24

Component 25

Component 26

Component 27

Component 28

Component 29

Component 30

Table 3

EL-32_V3.0a_en.docx January 18, 2024, © Elcon, Switzerland Page7 / 36

2.2 Step by Step assembly and testing of printed circuit boards

2.2.1 Assembling the PCB

For the placement drawings of the top and bottom of the PCB refer to Chapter 5.3 (Figure 32

and Figure 33). The SMD components are already assembled.

Populate the following components, using the parts list (Table 2).

R1 to R16, resistors R1 and R5 are not installed.

The trim potentiometer R10 is fitted on the back of the PCB.

C1 to 20, capacitors →Pay attention to the polarity of electrolytic capacitors!

U1 to U6, 7-segment LED display 10 pin→note installation direction!

The LEDs must be very accurately aligned in a straight line! Solder only 2 pins (diago-

nal) first, so that the alignment can still be corrected.

U8, IC MAX7221 or AS1106 LED Display-Driver 24 pin →note installation direction!

U9, IC PIC18F2550 microcontroller →note the installation direction!

U11, IC PIC12F1571 microcontroller →note the installation direction!

U13, IC TSOP4838 IR Receiver →leads have to be turned by 90°.

U14, IC 78L05 5V Voltage regulator, horizontally mounted →note installation direction!

B1, AT-1220 Buzzer

P2, the socket connector is fitted on the back of the PCB.

The connection (coaxial cable RF-In) is inserted into the circuit board at the rear and

soldered at the front.

An RG-216 coaxial cable is used to feed the VHF signal. Prepare the 23 cm long coaxial

cable as shown in Figure 1:

Remove 15mm of insulation.

Shorten the shielding and the inner conductor insulation to 5mm each.

A thin wire (wire cut-off from a resistor) is wrapped twice around the

shield and soldered.

Figure 1

Solder the prepared coaxial cable into the circuit board from the rear.

See Figure 2

Figure 2

Strip approx. 15 mm off the second end of the coaxial cable. Unbraid the shielding and

twist it together. Strip approx. 4 mm of insulation from the inner conductor. Tin both ends.

Page8 / 36 January 18, 2024, © Elcon, Switzerland EL-32_V3.0a_en.docx

2.3 Plug assembly

All connector housings and contacts are supplied to allow easy connection of power supply

and signals. Use only high quality, colored stranded wire. The colors of the wires should be

chosen to match the function, e.g. red + 13.8V power supply, blue or black for ground (GND)

and other colors for the signals PTT-In and RPT-In etc.

The connectors consist of two components; the connector housing and the contacts. To con-

nect a wire, strip the wire for about 2 mm, twist and tin it. Insert the tinned end of the wire into

the contact so that the wire is inside the inner and the insulation is inside the outer pair of

tabs.

Figure 3

Using a crimping tool or small needle nose pliers, carefully press the outer tabs around the

wire insulation to hold the wire in place. Repeat this with the inner tabs to hold the conductor

in place. Solder the conductor to the inner lugs, taking great care to ensure that no solder

flows into the contact.

Now insert the contact into the connector housing, with the small locking tab on the front of

the housing. Push the contact inwards until the locking tab snaps into place. If you need to

remove a contact, press carefully on the locking tab with a small screwdriver or the end of a

pair of pointed pliers. The contact is released and can be pulled out of the housing.

Figure 4

Pin1

Mark

EL-32_V3.0a_en.docx January 18, 2024, © Elcon, Switzerland Page9 / 36

The shielded audio cable is used for the CTCSS signal.

Prepare the 15 cm long cable. Crimp (or solder) the inner conductor and shield to one

crimp contact each.

Strip approx. 15 mm of insulation from the second end of the shielded audio cable. Un-

braid the shielding and twist it together. Strip approx. 4 mm of insulation from the inner

conductor. Tin both ends.

For the GND connection, strip approx. 2 mm of insulation from a 10 cm long black

stranded wire on both sides and crimp (or solder) the wire to a crimp contact on one side.

For the +8V supply, strip a 12cm long red stranded wire approx. 2mm on both sides and

crimp (or solder) the wire on one side to a crimp contact →This is connected to +8V of

the transceiver after the display board has been installed.

For the voltage measurement of the +13.8V rail, strip approx. 2mm of insulation from a

10cm long orange stranded wire on both sides and crimp (or solder) the wire on one side

to a crimp contact →This is connected to the 13.5V power supply of the transceiver after

the display board has been installed.

For the PTT-In signal, strip approx. 2 mm of insulation from both sides of an 11 cm long

yellow stranded wire and crimp (or solder) the wire on one side to a crimp contact →T

his is connected to TX8V of the transceiver after the display board has been installed.

For the RPT-In signal, strip approx. 2 mm of insulation from both ends of an 18 cm long

violet stranded wire (RPT-In) and crimp (or solder) the wire on one end to a crimp contact

→. This is connected to RPT8V of the transceiver after the display board has been in-

stalled.

Push the prepared cables with the contacts into the 7-pin connector housing in the order

shown in Figure 5.

Figure 5

Check all solder joints on the EL-32 display module very carefully! Check all components

for correct installation direction and value.

A magnifying glass can help here, because even the smallest, unwanted solder

bridges can have disastrous effects.

Mark

Pin1

Page10 / 36 January 18, 2024, © Elcon, Switzerland EL-32_V3.0a_en.docx

2.3.1 Initial test of the PCB

Once all the elements have been assembled, a first electrical test can be carried out.

Ensure that the workplace is clean so that the circuit board does not lie on cut pieces of

wire, which can create short circuits.

Connect the DC power supply unit to the black (-on P2 pin1 GND) and red wire (+on P2

pin2 +8V and P2 pin3 +13.8V) of the display board and set the voltage to approx. +8V.

If you have a power supply unit with current limitation, set this to a maximum current of

approx. 50mA.

Switch on the supply voltage.

The following text will appear on the 7-segment display:

. followed by the Morse code character "R" (di dah dit)

The digital display is then in frequency measurement mode. As no VHF signal is yet pre-

sent at J2, the display will show .

If the first test is successful, you can proceed with the conversion of the FT-221R.

2.4 Converting the FT-221

2.4.1 Removing the analog display from the FT-221

The mechanical conversion must be carried out strictly according to the following se-

quence, otherwise problems may occur.

Figure 6

EL-32_V3.0a_en.docx January 18, 2024, © Elcon, Switzerland Page11 / 36

Remove the cover of the device, which is fastened with four plastic rivets.

Disconnect the speaker connection cable.

Turn the device upside down and remove the 12 screws and the bottom cover.

Remove all 11 rotary knobs on the front panel.

Remove the 8 countersunk screws that secure the front frame to the cabinet and remove

the front frame.

Use a blunt object to release the two indicators CLAR and RPT through the front panel by

carefully pushing them out of the front cover and then remove the front panel.

Figure 7

Remove the 4 screws (two at the top and two at the bottom) with which the VFO is at-

tached to the front cabinet. (see Figure 8).

Figure 8

Remove the 4 screws (two on the left and two on the right) on the front cabinet and fold it

forward by 90°. Make sure that no wires break off. (see Figure 9)

Page12 / 36 January 18, 2024, © Elcon, Switzerland EL-32_V3.0a_en.docx

Figure 9

Remove the scale disk and the two screws of the scale cover as well as the two scale illu-

mination lamps. (see Figure 10)

Figure 10

Remove the PB-1471 circuit board (LED board) and then the two screws that secure the

coarse scale. Also remove the retaining bracket for the scale lamps and the scale wheel.

(see Figure 11)

Figure 11

Desolder the two scale lamps (four blue wires) on the connection block (see Figure 12)

and the PB1471 PCB (one violet wire) on the CHANNEL rotary switch.

EL-32_V3.0a_en.docx January 18, 2024, © Elcon, Switzerland Page13 / 36

Figure 12

2.4.2 Installation of the new digital display board in the FT-221

Screw three M3x12 spacer bolts into the corresponding threaded holes on the front of the

VFO gearbox as shown in Figure 13.

Figure 13

Take the assembled and tested EL-32 display module and fasten it to the spacer bolts us-

ing three M3x6 screws (with washer).

Caution! All connecting wires, the audio cable and the coaxial cable must be led out

downwards. The two lamps CLAR and RPT must protrude between the S-meter and

the new display module at the front (as shown in Figure 18).

Fold the front cabinet back up and secure it with 4 screws (two on the left and two on the

right). Make sure that no wires break off or become trapped.

Turn the device over, so that the bottom is facing upwards.

Reattach the VFO to the front cabinet with 2 screws.

Page14 / 36 January 18, 2024, © Elcon, Switzerland EL-32_V3.0a_en.docx

Solder the two prepared cables (black = Gnd and orange = +13.5V) of the display module

to the soldering points as shown in Figure 14.

Figure 14

Solder the prepared cables of the display module to the connector strips as shown in Fig-

ure 15.

•violet = RPT-In on J21-Pin 11 (TONE-BURST UNIT)

•yellow = PTT-In on J22-Pin 16 (MIC-AMP UNIT)

Figure 15

Solder the prepared cables of the display module according to

Figure 15 to the connector strip J22 (MIC AMP UNIT).

•Shielded audio cable: Tone to pin 20, shield (GND) to pin 19.

Make sure that the shielding does not cause a short circuit on the circuit board →Use

insulating or shrink tubing.

•8V supply of the display module: red = +8V at pin21.

J21

J22

EL-32_V3.0a_en.docx January 18, 2024, © Elcon, Switzerland Page15 / 36

Route the coaxial cable to the buffer board (PB-1671A) as shown in Figure 16 and solder

the shield and inner conductor parallel to the coaxial cable leading to the socket on the

back of the FT-221R. Make sure that the shielding does not cause a short circuit on the

circuit board →use insulating or shrink tubing.

Figure 16

Before you finish reassembling the device, it must be commissioned and calibrated.

2.5 Start-up and adjustments

You will need the following tools to calibrate the EL-32 display board:

♦Digital voltmeter with a range of DC 0 to 20V (resolution 10mV)

♦Frequency counter with a measuring range up to 150MHz and a resolution of 10Hz.

♦A PHILIPS, Sony, NEC or universal IR remote control, which you set to TV mode with

RC5, Sony or NEC protocol.

With the calibration routines implemented in the display board, the module can be calibrated

quickly and easily for all operating modes.

If you have set and saved incorrect values during calibration, e.g. for the voltage dis-

play, incorrect values will be displayed. However, you can repeat the calibration proce-

dure as often as you like and recalibrate the device.

2.5.1 Adjusting the voltage measurement circuit

Attention: The following measurements and calibration work are carried out at the open

device. Please note that certain parts, mainly on the bottom of the device, carry 230V

AC voltage. Always disconnect the power plug when handling the device (e.g. turning

the device, soldering, etc.). Never hold the appliance with your hands from the side of

the open cabinet, as this could result in an electric shock!

Page16 / 36 January 18, 2024, © Elcon, Switzerland EL-32_V3.0a_en.docx

Connect the multimeter (min. 3 ½ digits →resolution 10mV) to the 5-pin socket (Gnd =

Pin2, +13.5V=Pin5), see Figure 17.

Figure 17

Supply the FT-221R with 230V AC or 13.8V DC via the power cable.

Switch the device on with the POWER switch.

Use the multimeter to measure the supply voltage as shown in Figure 17.

Log the measured voltage _____________V

If the display shows .. select, the „Setup“-Mode, by pressing the VOL+

or VOL- button on the remote control.

Press the numeric key 4on the remote control. „Calibrate V“ will be displayed.

Use the VOL+ or VOL- buttons to calibrate the display to the voltage noted above,

e.g. . volts.

Press again the numeric key 4on the remote control. You are now back to the

mode, and the calibration value is stored in the memory of the microcontroller.

Select the display . volts by using the VOL+ or VOL- key.

The adjustment is completed. Switch off the appliance and unplug the mains plug.

2.5.2 Adjustment of the frequency measuring circuit

A precise frequency counter is required for the adjustment. It must be possible to

measure accurately in the frequency range of 130-140 MHz (<10 Hz accuracy).

Before the frequency adjustment can be done, the device must be prepared for it.

Mount three rotary knobs on the device (without front panel) as shown in Figure 18 and

set the BAND and CHANNEL switches to the 145.0 MHz or VFO position and all lever

switches must be in the horizontal position.

+13.5V

Gnd

EL-32_V3.0a_en.docx January 18, 2024, © Elcon, Switzerland Page17 / 36

Figure 18

Connect the frequency counter to the 5-pin socket (Gnd = Pin2, RF-Out=Pin1) on the

back of the FT-221 so that you can measure the exact frequency.

Figure 19

Now plug the appliance into the mains and switch it on using the POWER switch.

Allow the appliance to warm up for at least 15 minutes.

Now use the tune knob on the VFO to set the frequency on the frequency counter exactly

to 134.300.00MHz (Rx frequency - IF). →IF = 10.7MHz

Calibrate the frequency display as precisely as possible to 145.000.0 MHz using the fol-

lowing adjustment function from the "Setup" mode.

The current frequency display may show a frequency slightly different from 145.000.0

MHz due to the target frequency deviation of the temperature stabilized oscillator (TCXO)

on the EL-32. For example, .. MHz

Now use the remote control to select "Setup" mode using the VOL+ or VOL- but-

tons.

Press the numeric key 7on the remote control. . is displayed.

Press the VOL+ or VOL- buttons (10Hz steps) or the |<< or >>| buttons (100Hz steps)

several times until the display shows exactly ..

Press the numeric key 7(or OK button) on the remote control again. is displayed

again.

Press the VOL+ or VOL- buttons until .. is displayed

(last digit 100Hz).

This completes the frequency adjustment.

Switch the device off and disconnect the mains plug.

RF-OUT

BAND=145.0

Gnd

CHANNEL=VFO

All switches in

horizontal position

Page18 / 36 January 18, 2024, © Elcon, Switzerland EL-32_V3.0a_en.docx

2.5.3 Test of the CTCSS encoder

A frequency counter is required for the test. It must be possible to measure accurately

in the frequency range of 50-300Hz (<1Hz accuracy).

Now plug the appliance into the mains and switch it on using the POWER switch.

Now use the remote control to select "Setup" mode using the VOL+ or VOL- but-

tons.

Press the numeric key 8to switch to mode.

Press the OK button to switch to CTCSS frequency selection mode.

Use the VOL+ or VOL- buttons to select the corresponding CTCSS frequency.

Standard frequencies according to TIA/EIA-603-D from . to . can be

set.

Use the frequency counter on the audio cable (J22 pin 20) to measure the CTCSS fre-

quency. The measured frequency must correspond to the value shown on the display

(±1%).

Press the numeric key 8(or OK button) on the remote control again is displayed

again.

This completes the CTCSS test.

Switch off the device and disconnect the mains plug.

2.5.4 Adjustment of the CTCSS encoder

An FM deviation meter in the frequency range 144-148 MHz is required for this setting.

Repeater operation with the CTCSS encoder requires adjustment of the AF level.

Now plug the appliance into the mains and switch it on using the POWER switch.

Connect the transmitter output to a 50Ω dummy load that has a measurement output.

Connect the FM deviation meter to the measurement output of the dummy load (meas-

urement range 200 to 500Hz).

Select the following settings on the transceiver:

Frequency = 145MHz

Mode = FM

MIC-GAIN = completely counterclockwise

Now use the remote control to select "Setup" mode using the VOL+ or VOL- but-

tons.

Press the numeric key 8to switch to mode.

Press the OK button to switch to CTCSS frequency selection mode.

EL-32_V3.0a_en.docx January 18, 2024, © Elcon, Switzerland Page19 / 36

Use the VOL+ or VOL- buttons to select the CTCSS frequency .

Turn the VOX GAIN control counter-clockwise to the MOX position.

Adjust the AF level of the CTCSS signal on the EL-32 board using the trim potentiometer

(R10) until the FM deviation meter indicates approx. 400Hz.

Turn the VOX GAIN control clockwise to the PTT position.

This completes the CTCSS encoder setting.

Switch off the device and disconnect the mains plug.

2.5.5 Assembly

Important: For your safety, always remove the mains cable from the FT-221R.

Remove the scale window for the frequency display from the front panel.

Take the red filter film [Component 21], cut it to size, remove the cover film and stick it to

the inside of the scale window. Make sure that there are no air bubbles.

Once you have stuck on the red filter film and pressed it on with a cloth, remove the sec-

ond protective film.

Take the polarizing film [Component 27], cut it to size, carefully remove the cover foil with

the red stripe and do not touch the adhesive layer with your fingers.

Stick the polarizing film onto the red filter film. Make sure that there are no air bubbles.

Once you have applied the polarizing film and pressed it on with a cloth, remove the sec-

ond protective film.

Figure 20

Refit the scale window for the frequency display in the front panel.

Remove the three temporarily attached rotary knobs from the appliance.

Place the front panel in the front frame and reattach it to the cabinet using 8 countersunk

screws.

Fit all 11 rotary knobs to the front panel. Ensure that the switch positions are correct.

Turn the device, so that the bottom is up.

Page20 / 36 January 18, 2024, © Elcon, Switzerland EL-32_V3.0a_en.docx

Take the bottom cover and connect the speaker to the speaker cable.

Mount the bottom cover with 12 screws.

Turn the device over, so that the top is facing upwards again.

Place the cover on the appliance and secure it with the four plastic rivets.

Table of contents