ElectiQ eiQ52CANOPY User manual

USER MANUAL

CANOPY COOKER HOOD KITCHEN

EXTRACTOR FAN IN SILVER

eiQ52CANOPY

eiQ70CANOPY

Thank you for choosing your electriQ cooker hood. This instruction manual is

designed to provide you with all required instructions related to the installation, use

and maintenance of the appliance. In order to operate the unit correctly and safely,

please read this instruction manual carefully before installation and usage.

CONTENTS

SAFETY

3

INSTALLATION

5

OPERATION

7

CLEANING AND MAINTENANCE

7

FILTER INFORMATION

8

LIGHT INFORMATION

9

TROUBSLEHSOOTING

10

SUPPORT

10

PRODUCT FICHE

11

2

SAFETY PRECAUTIONS

Whilst this product is compliant with all safety requirements, incorrect or

inappropriate use can lead to both personal injury and potential

damage to property. Please read the contents of this instruction booklet

thoroughly before fitting or using this appliance.

• The cooker hood must be installed in accordance with the installation

instructions and all measurements followed.

• All installation work must be carried out by a competent person or

qualified electrician.

• The unit must be connected to an earthed power supply.

• If venting externally, make sure the ducting has no bends sharper

than 90 degrees as this will reduce the efficiency of the cooker hood.

• The cooker hood is for domestic use only and is not designed for

commercial use. It should only be used for the purpose it was intended

to extract vapours and cooking odours.

• Do not flambé or use an open flame under the cooker hood.

• Do not try to use the cooker hood without the grease filters or if the

filters are excessively greasy! They should be cleaned regularly (see

“Maintenance”) or replaced as necessary.

• The extraction fan must be level to avoid grease collection at one

end, as this could cause a potential fire risk.

• Do not leave frying pans unattended during use because overheated

fat or oils might catch fire.

• If the cooker hood is damaged, do not attempt to use it.

• If the supply cord is damaged, it must be replaced by the manufacturer,

its service agent or a similarly qualified person in order to avoid a

hazard.

• This appliance can be used by children aged from 8 years and above

and persons with reduced physical, sensory or mental capabilities or

lack of experience and knowledge if they have been given supervision

or instruction concerning use of the appliance in a safe way and

understand the hazards involved.

• Children shall not play with the appliance. Cleaning and user

maintenance shall not be made by children without supervision.

• Children should be supervised to ensure that they do not play with the

appliance. It is not a toy.

• The plug must be accessible after installation for isolation in case of an

emergency – or an appropriate fused switch if the unit is hard-wired to

the mains via a spur.

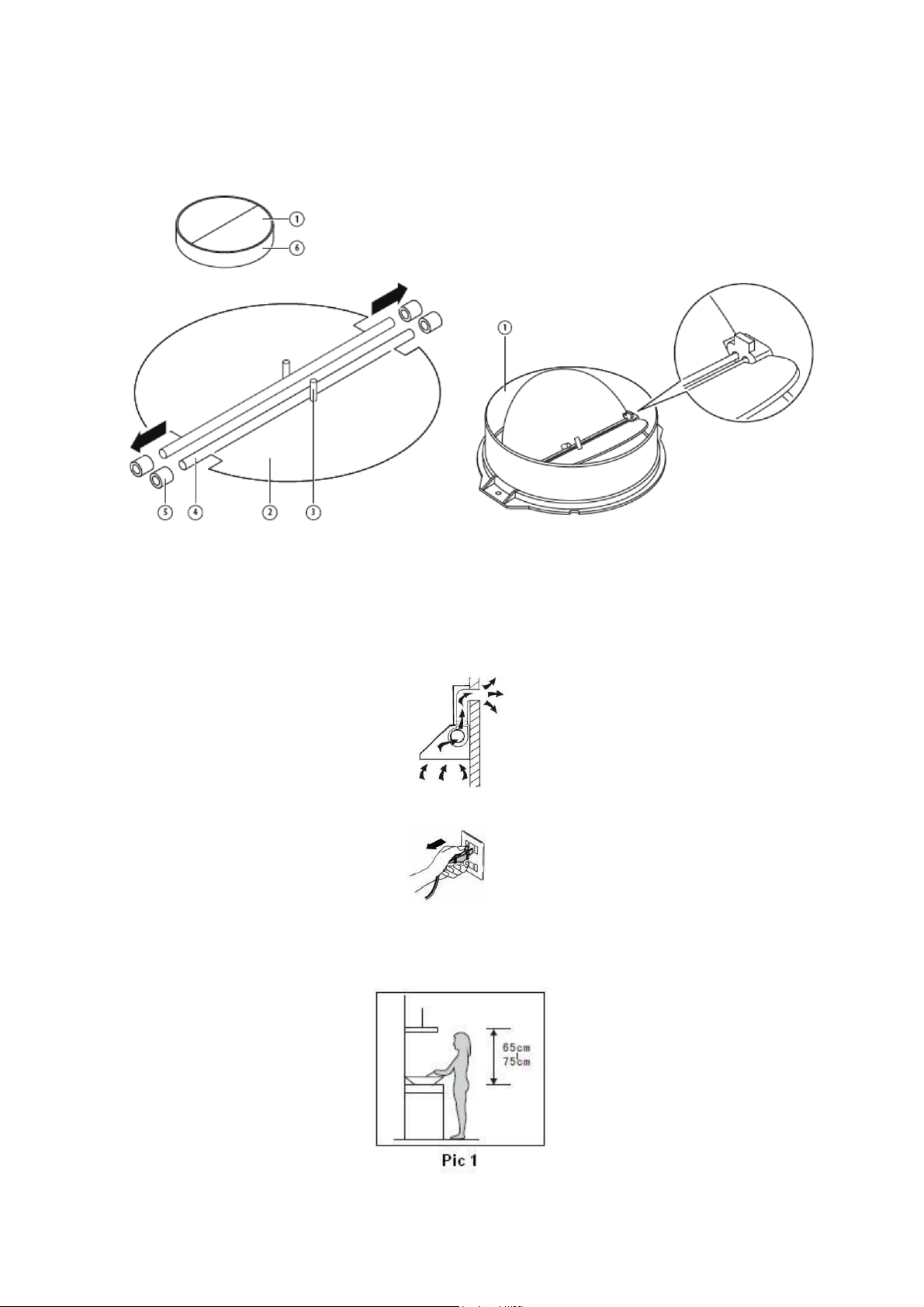

• The minimum distance between the surface of the hob and the lowest

part of the hood should be at least 65cm. A distance of between 65cm

3

and 75cm gives peak efficiency.

• The air must not be discharged into a flue that is used for exhausting

fumes from appliances burning gas or other fuels.

• When the hood is vented externally and used with appliances which

burn fuel (e.g. gas, oil, wood) the area must be sufficiently ventilated to

ensure safe operation. Fresh air must be allowed to freely enter the

room to prevent a partial vacuum.

• A partial vacuum can starve the heating appliance of oxygen, impairing

combustion. It can also prevent toxic fumes from leaving the room, or

can cause fumes to be sucked into the room from outside.

• Safe operation is only possible when the partial vacuum within the

working area does not exceed 4 Pa (0.04 mbar). This can be achieved

by ensuring air is able to enter the room from outside through a suitable

sized opening which cannot be sealed during operation. A number of

alternative solutions are available to ensure this. If in any doubt,

professional advice should be sought.

• Regulations concerning the discharge of air have to be fulfilled.

• There is a potential fire risk if cleaning is not carried out in

accordance with the instructions.

• Clean your appliance periodically by following the method given in the

chapter MAINTENANCE.

• If used in recirculation mode, the charcoal filters trap odours and must

be replaced at least once a year depending on how frequently the

cooker hood has been used.

• For safety reason, please use only the same size of fixing or

mounting screw, which are recommended in this instruction manual.

• Warning: Failure to install the screws or fixing device in accordance

with these instructions may result in electrical hazards

CAUTION: Accessible parts of the hood can become very hot during

use with cooking appliances, whether in use or not, due to heat

rising from the hob. Sufficient time should be allowed for the unit to

cool before touching either the housing or the grease filters.

4

V-FLAP INSTALLATION

INSTALLATION

If you have an outlet to the outside, your cooker hood can be connected as

below picture by means of an extraction duct (enamel, aluminium, flexible pipe or

non-flammable material with an interior diameter of 150/120mm).

1. Before installation, turn the unit off and ensure it is not plugged in.

2. The cooker hood should be placed at a distance of 65~75cm above the cooking

surface for best effect.

5

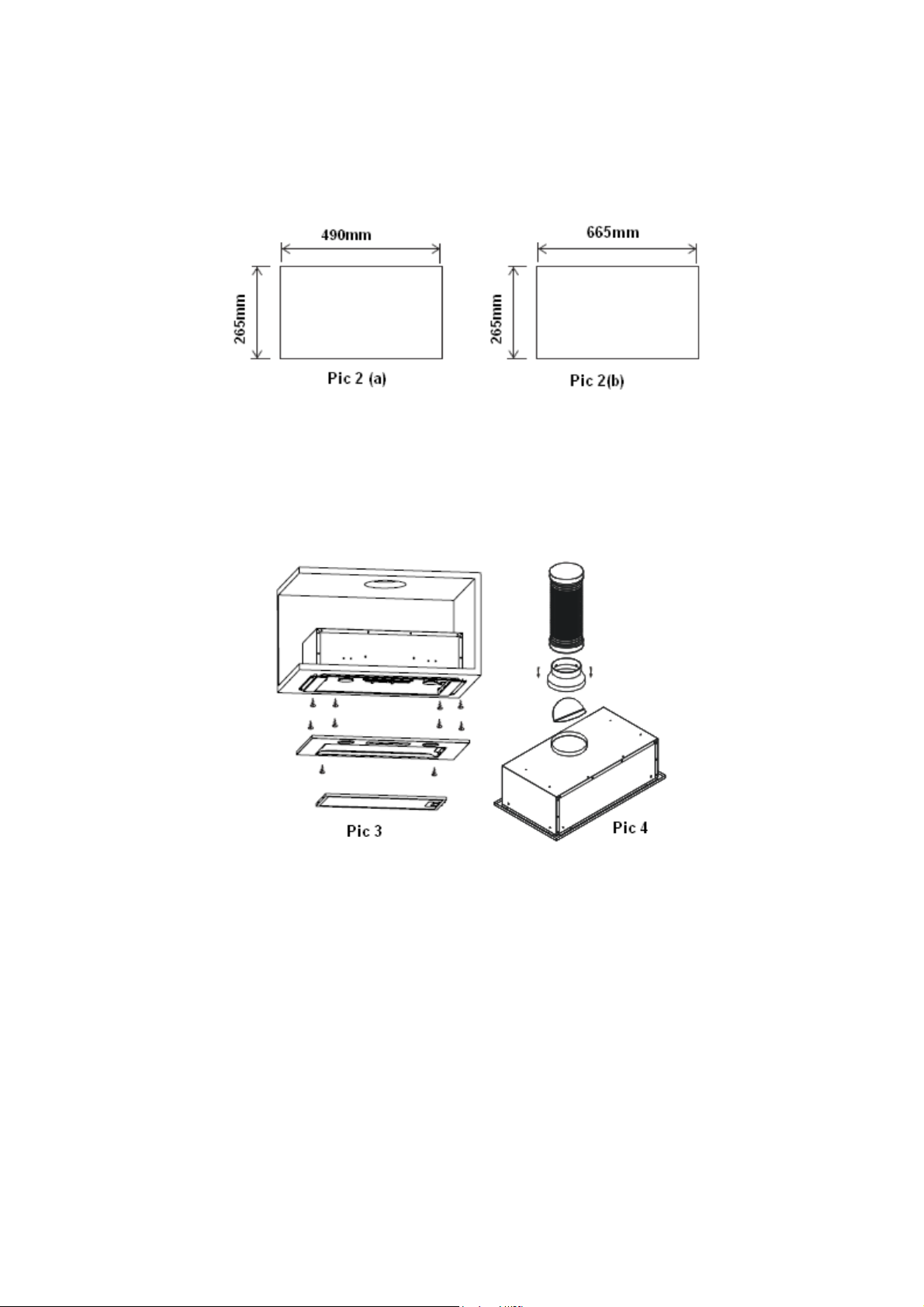

3. Drill a hole in the cupboard, with hole wide 490*265(mm)for 52CM, hole wide

665*265(mm) for 70CM.Refer to pic below. Make sure the distance between

the edge of the hole and the edge of the cupboard edge is at least 35mm.

4. Remove the aluminium filter and remove the two front panel screws.

5. Use a screwdriver to secure the 8pcs ST4*18 screws and fix the hood body to the

cupboard.

6. Replace the front panel with the two screws and replace the filter.

7. Install the v-flaps and converter to the outlet and fix the expansion pipe to the outlet

with cable tie.

Note: The expansion pipe is not included in the product.

6

OPERATION

1. LIGHT: Use the switch to turn the light ON/OFF

2. FAN SPEED: Use the switch to adjust the fan speed with 1 being the lowest, 3

being the highest and 0 being off.

CLEANING MAINTENANCE

Before cleaning, switch the unit off and disconnect the power.

Use a soft cloth moistened with hand-warm mildly soapy water or household cleaning

detergent. Never use metal pads, chemicals, abrasive material or a stiff brush to clean

the unit.

NOTE: Do not use a steam-cleaner to clean the hood; electrical components could

be damaged or short-circuit as a result.

MONTHLY CLEANING FOR METALLIC ANTI-GREASE FILTER

ESSENTIAL NOTE: Clean the filter every month; an excessive build-up of grease

can become a fire hazard. The filter collects grease, smoke and dust, so the filter

directly affects the efficiency of the cooker hood. If it’s not cleaned, the grease

residue (potentially flammable) will saturate on the filter.

Clean it with a soft nylon brush in a mild solution of warm water and a small amount

of washing up liquid. Washing up liquid alone should not be used. After cleaning,

allow the filter to drain and then dry thoroughly.

The grease filter may also be dishwasher cleaned; using a 60°C program, with the

filter upright (short sides upright) in the lower basket. Please be aware some

dishwasher cleaning agents can permanently discolour the filter, though this will not

affect its performance.

Replacement grease filters are of the universal type available from many household

and DIY stores.

STAINLESS STEEL

The stainless steel must be cleaned regularly (e.g. Weekly) to ensure long

life expectancy.

Dry with a clean soft cloth. A specialized stainless-steel cleaning fluid may be used.

Ensure that wiping is done along with the grain of the stainless steel to prevent any

unsightly crisscross scratching patterns from appearing.

7

CONTROL PANEL SURFACE

The inlay control panel can be cleaned using warm soapy water. Ensure the cloth is

clean and well wrung before cleaning. Use a dry soft cloth to remove any excess

moisture left after cleaning.

Using neutral detergents and avoid using harsh cleaning chemicals, strong household

detergents or products containing abrasives, as this will affect the appliance

appearance and potentially remove any printing of artwork on the control panel and

will void manufactures warrantee.

GREASE MESH FILTERS

The mesh filters can be cleaned by hand. Soak them for about 3 minutes in water with

a mild detergent then brush it gently with a soft brush. Please do not apply too much

pressure, avoid to damage it . (Leave to dry naturally out of direct sun light)

Filters should be washed separately to crockery and kitchen utensils. it is advisable

not to use rinse aid.

INSTALLING GREASE MESH FILTERS

To install filters for the following four steps.

1. Angle the filter into slots at the back of the

hood.

2. Push the button on handle of the filter.

3. Release the handle once the filter fits into a

resting position.

4. Repeat to install all filters.

CARBON FILTER-not supplied

Activated carbon filter can be used to trap odours. Normally the activated carbon

filter should be changed at three or six months according to your cooking habit. The

installation procedure of activated carbon filter is as below.

1. Put the pin of the carbon filter into the

rectangular hole of the fan (as per the arrow

A shown below)

2. Push the other side of the carbon filter

toward the fan to make it flat (as per the

arrow B shown),and then press filter into fan.

3. If you want to remove the filter, press fastener of

filter and remove it by turning anticlockwise.

NOTE:

• Make sure the filter is securely locked. Otherwise,

it would loosen and cause dangerous.

• When activated carbon filter attached, the

suction power will be lowered.

Replacement carbon filters can be sourced from

the supplier using the code: eiqcf150

8

BULB REPLACEMENT

The bulb must be replaced by the manufacturer, its service agent or similarly

qualified persons.

Always switch off the electricity supply before carrying out any operations on the

appliance. When handling bulb, make sure it is completely cool down before any direct

contact to hands.

When handling globes hold with a cloth or gloves to ensure perspiration does not come

in contact with the globe as this can reduce the life of the globe.

Before changing the lights, make sure that the appliance is plugged off.

• Protect against danger when changing lights, such as wearing gloves.

CHANGING THE LIGHTS

1. Remove the grease filter.

2. Put one hand into the cavity to gently push out the LED light, and use the other

hand to grab the light and pull it out, and then pull out the light cable.

3. After changing the lamp, plug in the lamp cable, and put the lamp into the lamp hole.

ILCOS D code for this lamp is: DBR-2/65-H-64

• LED modules– round lamp

• Max wattage: 2×2 W

• Voltage range: AC 110-240V

9

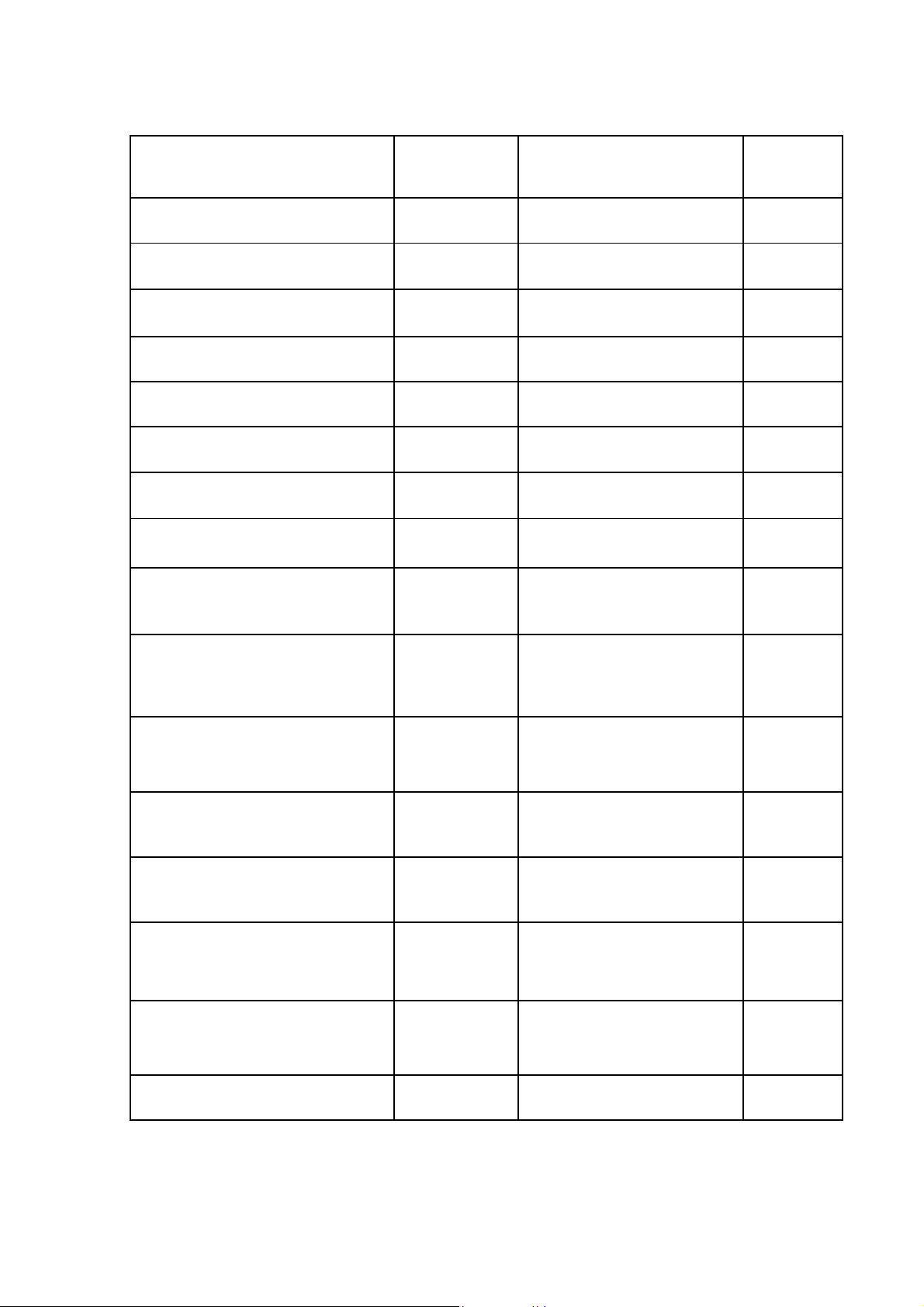

TROUBLESHOOTING

FAULT

CAUSE

SOLUTION

The fan blade is

Light on, but fan

jammed.

Switch off the unit. Repair to be carried

does not work

The motor is

out by qualified service personnel only.

damaged.

Both light and

Light bulb blown

Replace the bulb with correct rating.

fan do not work

Power cord loose

Plug in to the power supply again.

The fan blade is

Switch off the unit. Repair to be carried

Excessive

damaged.

out by qualified service personnel only.

Vibration

The fan motor is not

Switch off the unit. Repair to be carried

fixed tightly.

out by qualified service personnel only.

1 Grease filters

1 Clean or replace grease filters.

clogged

Suction

2. Readjust the distance to between

2 Distance between

performance

65cm and 75cm.

the unit and the

not good

cooking plane too

great.

INFORMATION FOR DISMANTLING

Do not dismantle the appliance in a way which is not shown in the user manual. The appliance

could not be dismantled by user. At the end of life, the appliance should not be disposed of with

household waste. Check with you Local Authority or retainer for recycling advice.

electriQ UK SUPPORT

www.electriQ.co.uk/support

www.electriQ.co.uk

Call: 0330 390 3061

Office hours: 9AM - 5PM Monday to Friday

Unit J6, Lowfields Business Park

Lowfields Way, Elland

West Yorkshire, HX5 9DA

Recycling facilities are now available for all customers at which you

can deposit your old electrical products. Customers will be able to

take any old electrical equipment to participating sites run by their

local councils. Please remember that this equipment will be further

handled during the recycling process, so please be considerate

when depositing your equipment. Please contact the local council

for details of your local household waste recycling centres.

10

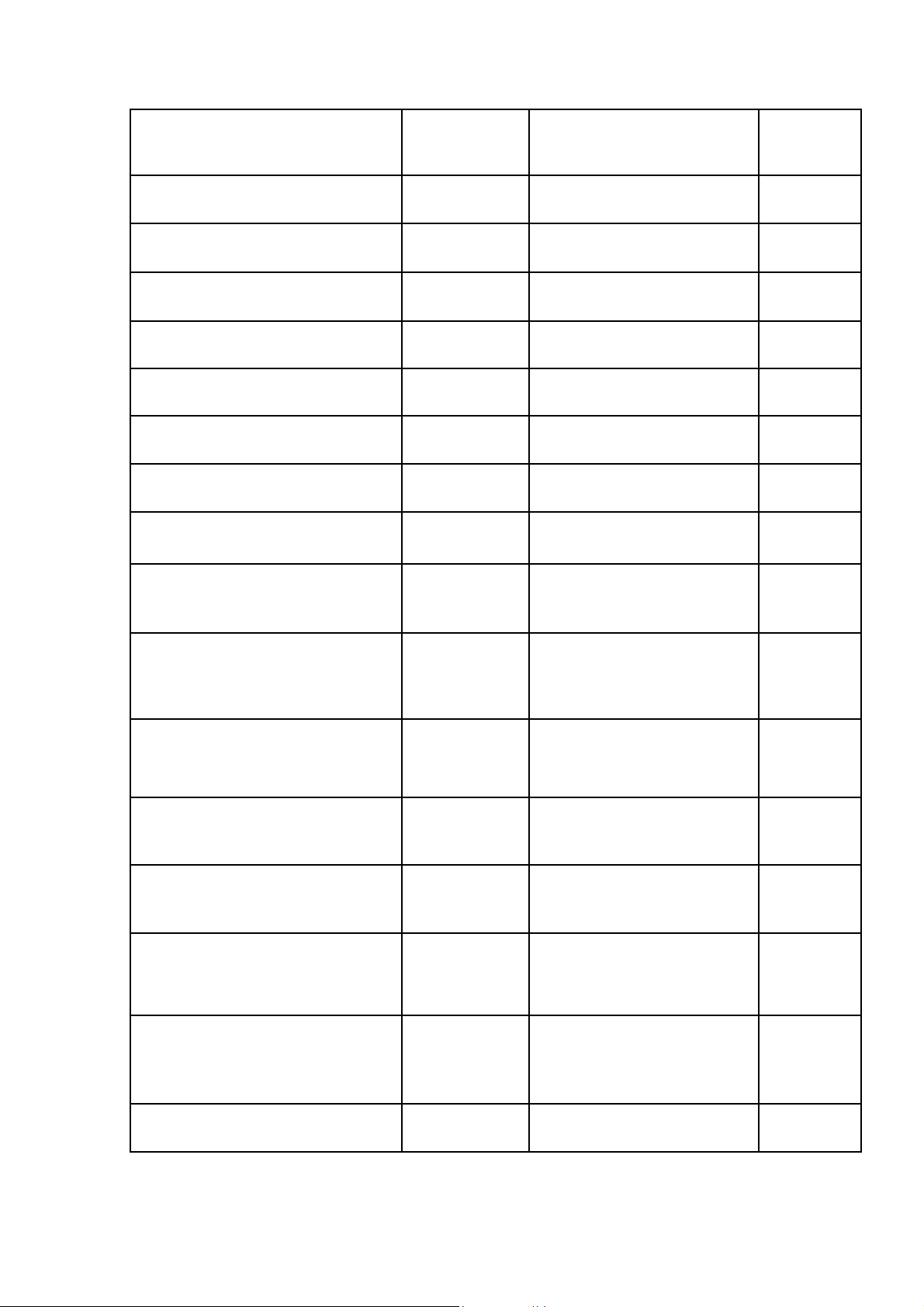

PRODUCT FICHE

Symbol

Value

Unit

Model identification

eiQ70CANOPY

Annual Energy Consumption

AEChood

49.0

kWh/a

Time increase factor

f

1.5

Fluid Dynamic Efficiency

FDE

hood

15.1

Fluid Dynamic Efficiency

Class D

class

Energy Efficiency Index

EEI

hood

76.8

Energy Efficiency class

Class C

Maximum airflow

Qmax

381.3

m

3

/h

Measured airflow rate at the

Q

BEP

227.7

m

3

/h

best efficiency

Measured air pressure at

PBEP

201

Pa

best efficiency point

Measured electric power

W

BEP

84.2

W

input at best efficiency point

Nominal power of the lighting

WL

4.0

W

system

Average illumination of the

lighting system on the

E

middle

165

lux

cooking surface

Measured power

PO

0.00

W

consumption on off mode

Measured power

consumption on standby

P

S

-

W

mode

Sound power level

LWA

Highest setting: 69

dB

Lowest setting: 58

Symbol

Value

Unit

Model identification

eiQ52CANOPY

Annual Energy Consumption

AEC

hood

52.7

kWh/a

Time increase factor

f

1.6

Fluid Dynamic Efficiency

FDEhood

11.2

Fluid Dynamic Efficiency class

Class E

Energy Efficiency Index

EEIhood

81.8

Energy Efficiency class

Class C

Maximum airflow

Q

max

364.7

m

3

/h

Measured airflow rate at the

QBEP

180.5

m

3

/h

best efficiency

Measured air pressure at best

P

BEP

190

Pa

efficiency point

Measured electric power input

WBEP

85.2

W

at best efficiency point

Nominal power of the lighting

WL

4.0

W

system

Average illumination of the

lighting system on the cooking

Emiddle

177

lux

surface

Measured power consumption

P

O

0.00

W

on off mode

Measured power consumption

PS

-

W

on standby mode

Sound power level

LWA

Highest setting: 68

dB

Lowest setting: 56

This manual suits for next models

1

Table of contents

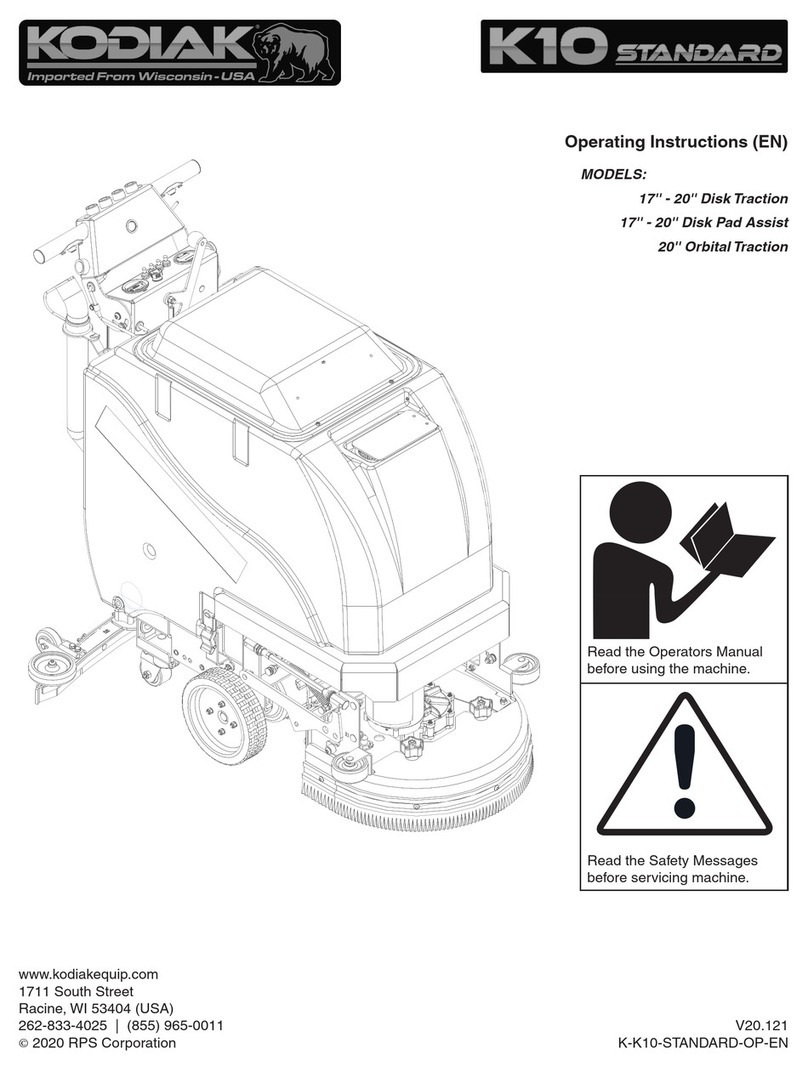

Popular Scrubber manuals by other brands

Renown

Renown REN08027-VP owner's manual

Alto

Alto 7760 Operator's manual & parts list

Numatic

Numatic TRG 720/200T Original instructions

Kärcher

Kärcher B 150 R manual

diversey

diversey TASKI swingo 455 B installation manual

R.P.S. Corporation

R.P.S. Corporation KODIAK K10 STANDARD Series operating instructions