8

5

10

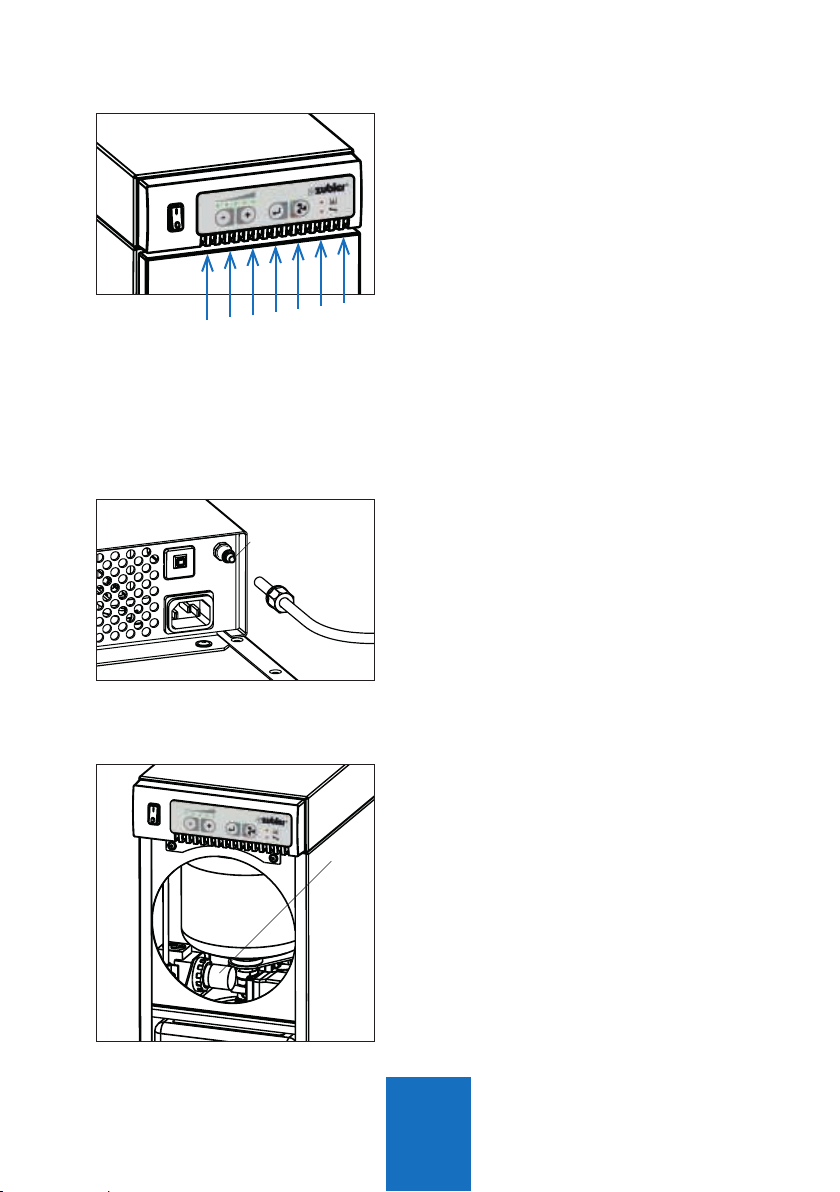

Fig. 3

Fig. 4

1.2.4 Compressed air

nThe suction unit Z1 PRO requires

compressed air for the filter cleaning.

The unit must not be used without

compressed air. Ensure there is a

compressed air supply available with

at min. 5 bar, free of oil and moisture.

nRemove the clamp screw of the

compressed air connector (5) and

insert the enclosed compressed air

hose (6mm). Plug the hose firmly

on the nozzle and tighten the clamp

screw. Connect the quick connector to

your compressed air supply.

nOpen the Frontdoor (Section 3.1, Fig.

14) and check if the pressure gauge

(10) on the pressure reducer shows

a pressure of 4-5 bar. The pressure

reducer is factory set and must not be

changed. Upon abnormal behaviour,

check your compressed air supply and

contact the Zubler Service.

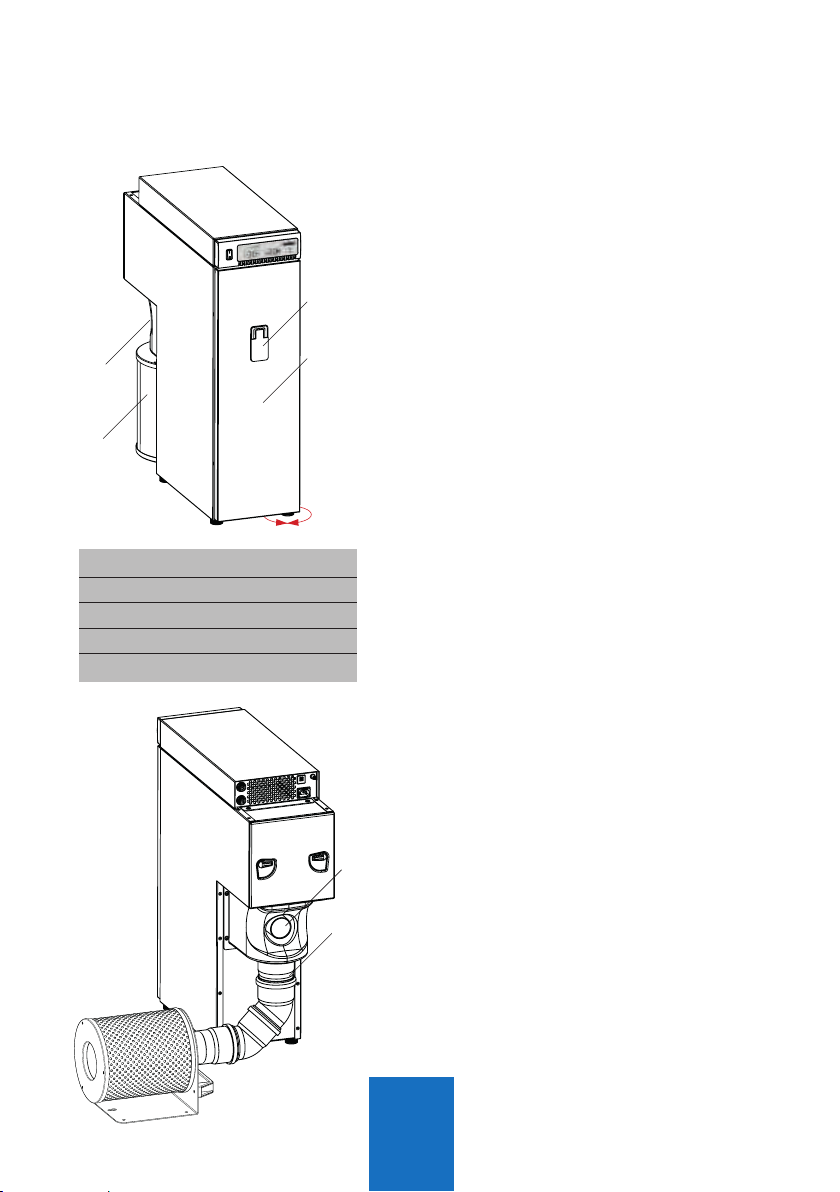

1.2.3 Furniture integration

If integrating the suction unit into cabinets

or niches the following requirements

must be taken into account:

nThe suction unit must be able to draw

cooling air from the front (Fig.4)

nThe hot exhausting air which is

released on the back of the suction

unit, must not reach the front.

Therefore it is necessary, that there is

a tight barrier surrounding the suction

unit, separating the front from the

back. Alternatively it is also possible

to guide the exhausting air away from

the suction unit, see chapter 1.2.2.

Cooling air

Fig. 5