Page 9 www.elector-water-treatment.com

elector – Electrochemical Water Treatment for Heating Systems

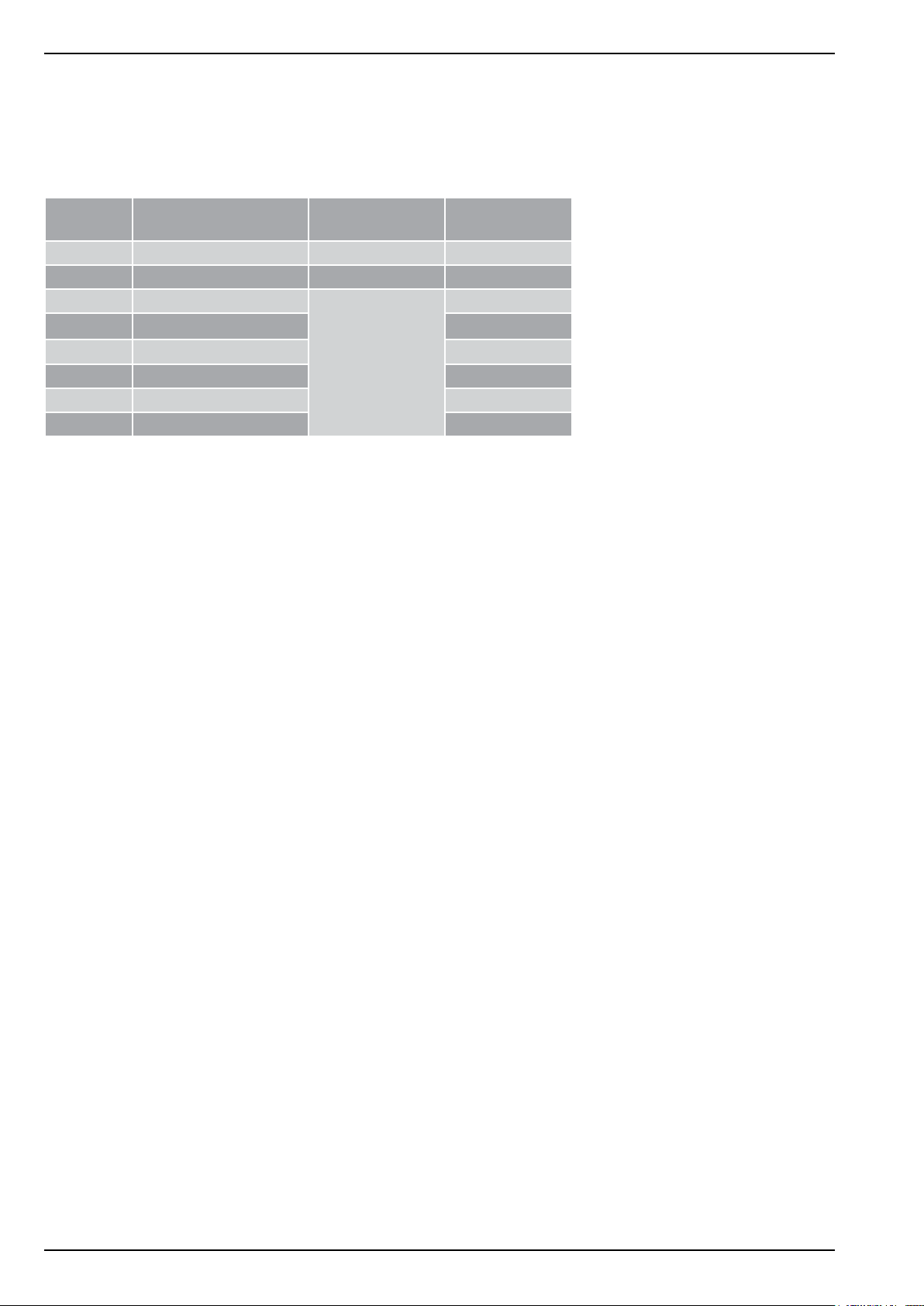

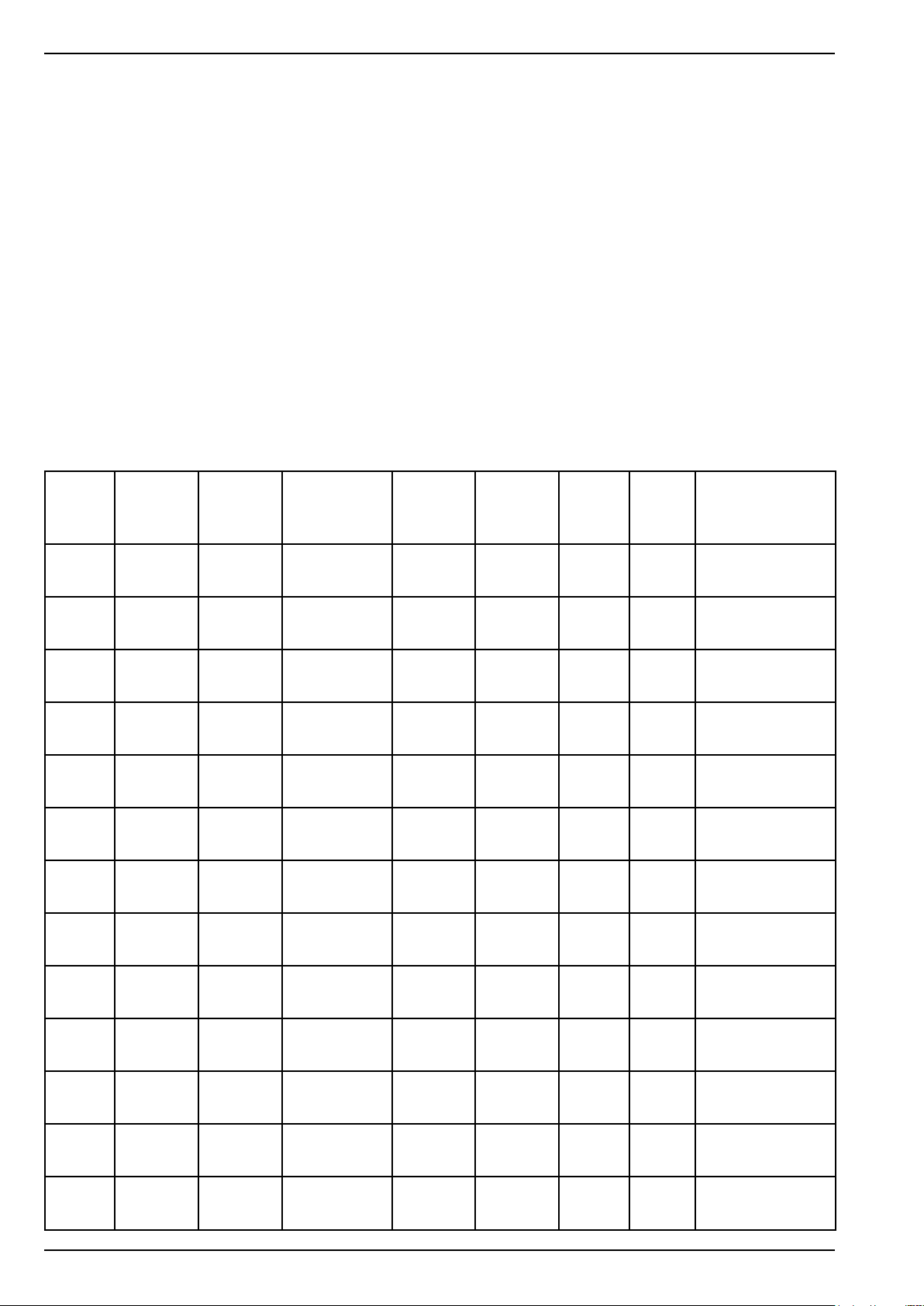

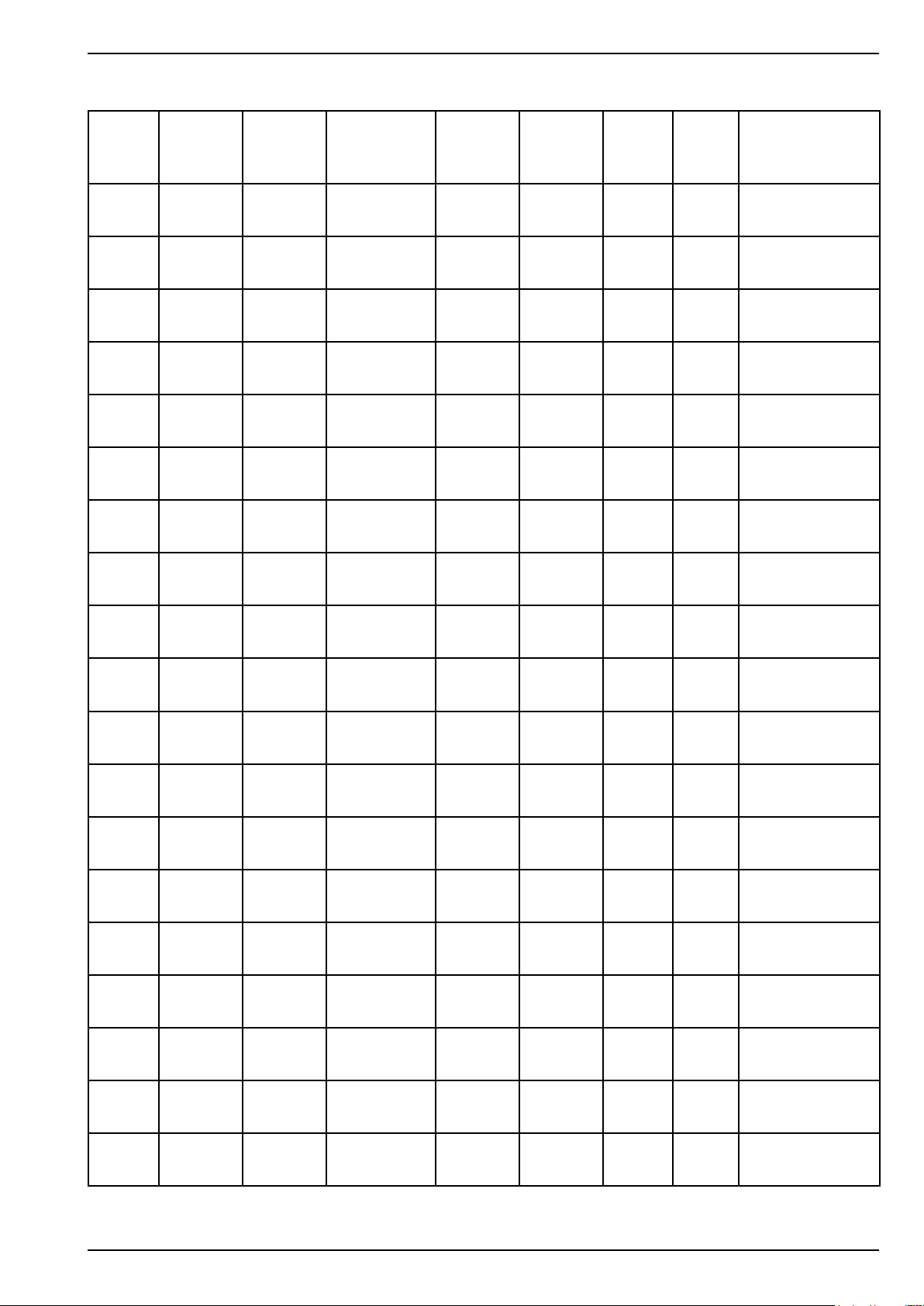

4.1 Water Quality by use of an elector

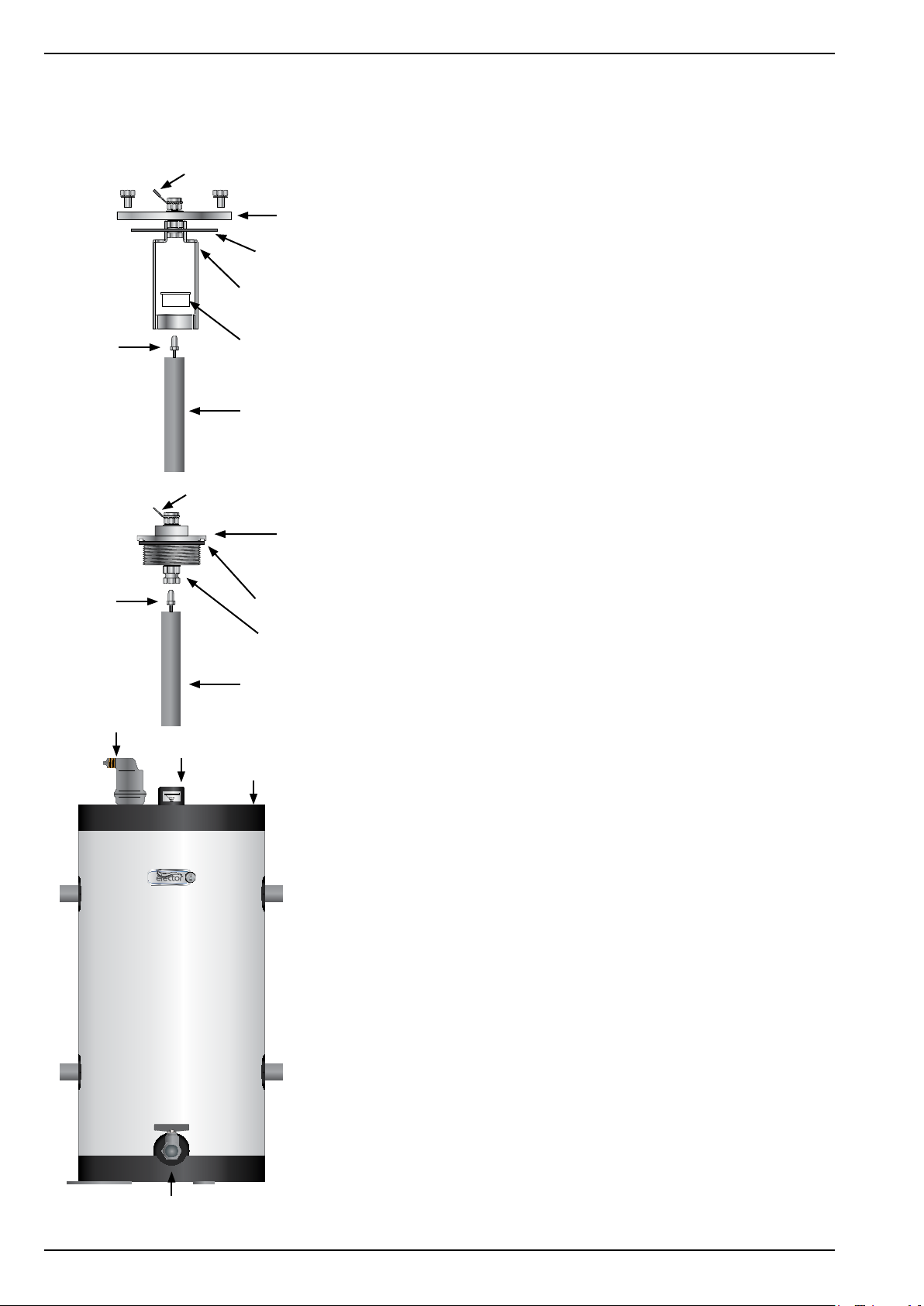

An elector reaction device is usually installed in heating systems, whenever a constant low pH is measured or

an constant oxygen ingress is to be expected.

In order to protect the heating system from corrosion and sludge, the consideration of the general water quality

is of utmost importance and should not be neglected even when installing an elector reaction device.

In connection with the installation of an elector, the water quality should comply with the following guideline

values, however, with regard to the fulfillment of any warranty conditions, the specifications of the respective

component manufacturers must be observed in the first place.

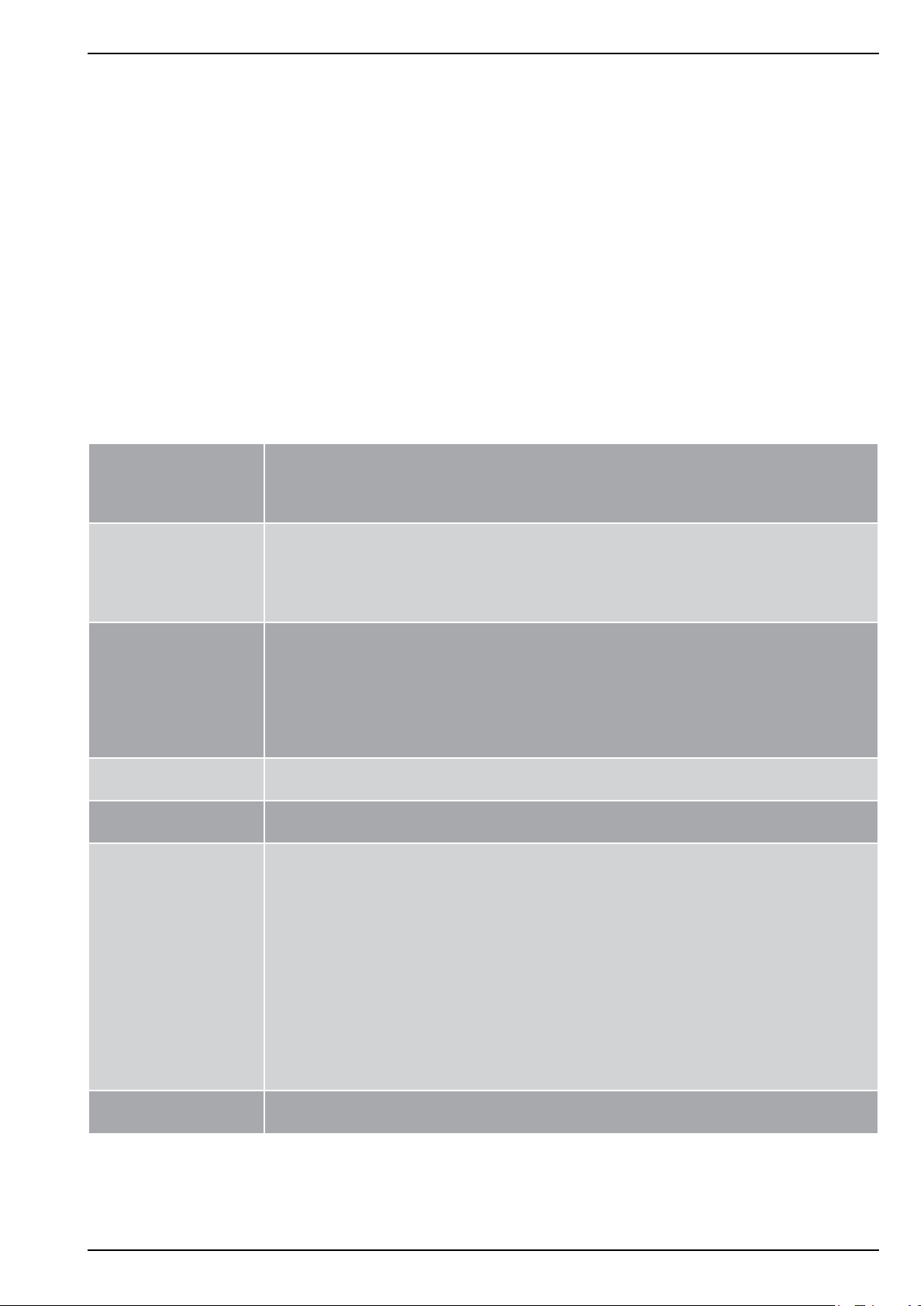

Heating water treatment -

Treatment of make-up and

feed water

The treatment of heating water or the treatment of make-up and feed water is ne-

cessary, if damage due to formation of limescale or corrosion can be expected as a

result of poor water quality. In conjunction with an elector device only untreated tap

water or demineralised (deionized) or partly demineralised water should be used.

Addition of chemicals Do not dose additional chemicals, such as inhibitors, into the system, when using

an elector.

Residues of chemicals If a system is pretreated or heavily contaminated with chemicals, it has to be

flushed completely before installing an elector device. This requires the use of our

cleaning and dispersing agent OXILIN-P20.

Sludge Basically the sludge in the system is removed by the function of the elector and

can easily be flushed out of the device. If heavy sludge problems have to be remo-

ved quickly, then the system has to be flushed by using our cleaning and disper-

sing agent OXILIN-P20 and an water-air-pulse flushing device.

pH The pH of the water gets automatically adjusted to 8.5 to 10 due to the function of

the electrochemical water treatment. This mechanism may be disturbed by chemi-

cals or due to atypical acid reactions which requires a case-by-case analysis.

Total hardness The amount of dissolved alkaline earth ions should not exceed 3 mol/m3

(~16,8°dH) at 1 m³ system volume and should decrease at higher system vo-

lumes.

Sodium Lowest possible value of sodium (<20 mg/l) is recommended. Sodium increases

the conductivity and can contribute in combination with hydroxide ions (OH-) to

severe corrosion problems.

Chlorides Chlorides increase the conductivity and can cause corrosion, even on stainless

steel. A value of <30 mg/l is recommended.

Sulphates / Nitrates Sulphates and nitrates increase the conductivity of the water and can contribute to

pitting corrosion on copper. A value of <50 mg/l should be maintained.

Dissolved metals Dissolved metals such as iron or manganese should not be dissolved in the make-

up and feed water.

Dissolved gases The content of dissolved gases such as oxygen and carbon dioxide is reduced by

the use of an elector device. In case of heavy oxygen input, e.g. by non diffusion

protected underfloor heating, a microbubble dearator should be installed additional-

ly.

TOC (organic carbon

dioxide)

The TOC-value expresses the amount of organic impurities in the water and as

such indicates the MIC (microbiologically inducted corrosion). A value of <30

mg/l is acceptable. In case of copper installations a value of 1,5 mg/l shall not be

exceeded.

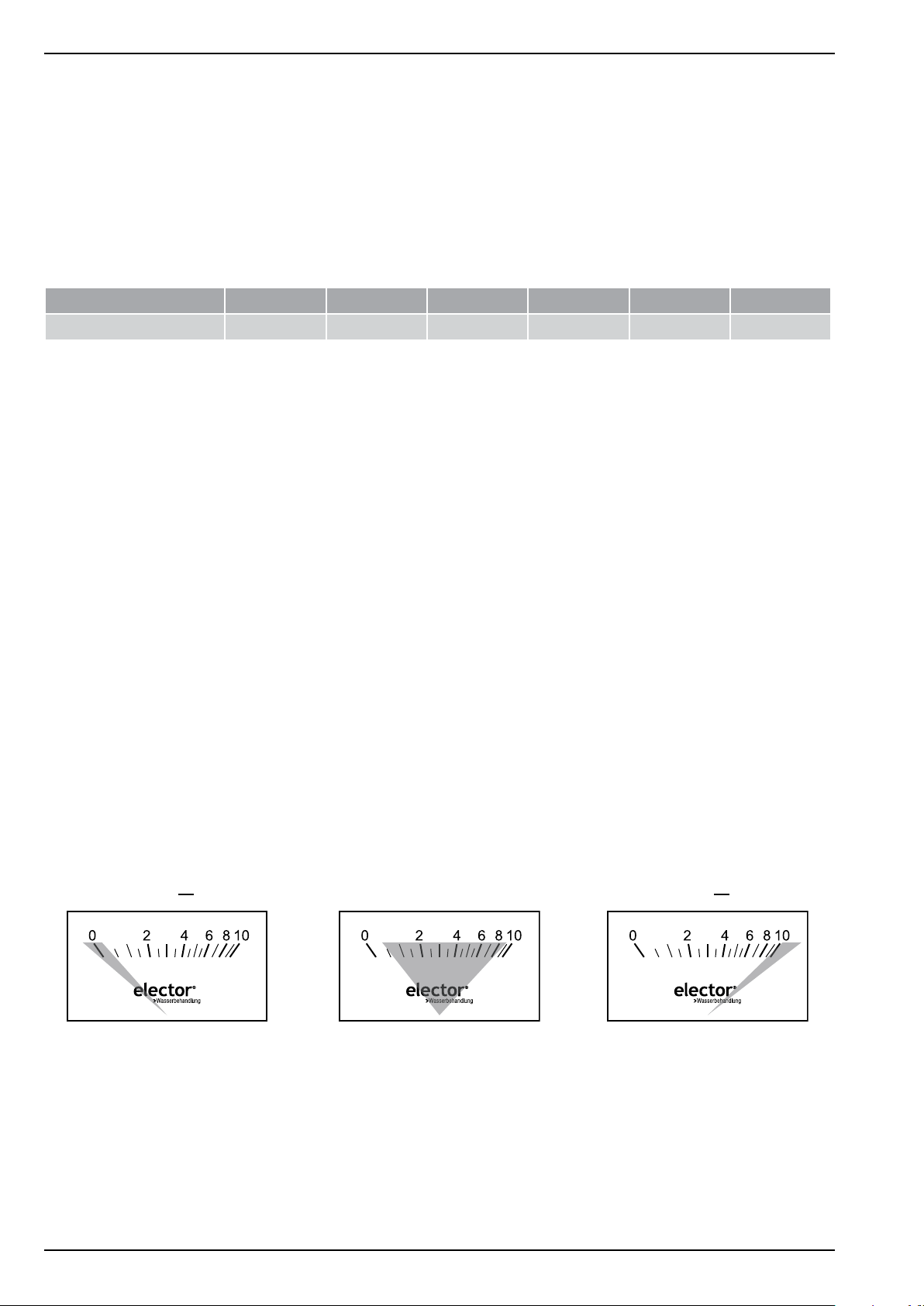

Electrical conductivity By use of an elector, the electrical conductivity of the system water should be 50 -

200 μS/cm.

Appearance The make-up water and the system water must be clear and clean.

Chapter 4 - Make-up Water Quality