Electric Signal MMXV AD User manual

User manual

Delta Transconductance

band Compressor

Electric Signal

MMXV AD

Electric Signal 2016 - Revision Alpha

Delta Transconductance band Compressor

User manual

Electric Signal MMXV AD

Serial

number

a priori

Line voltage

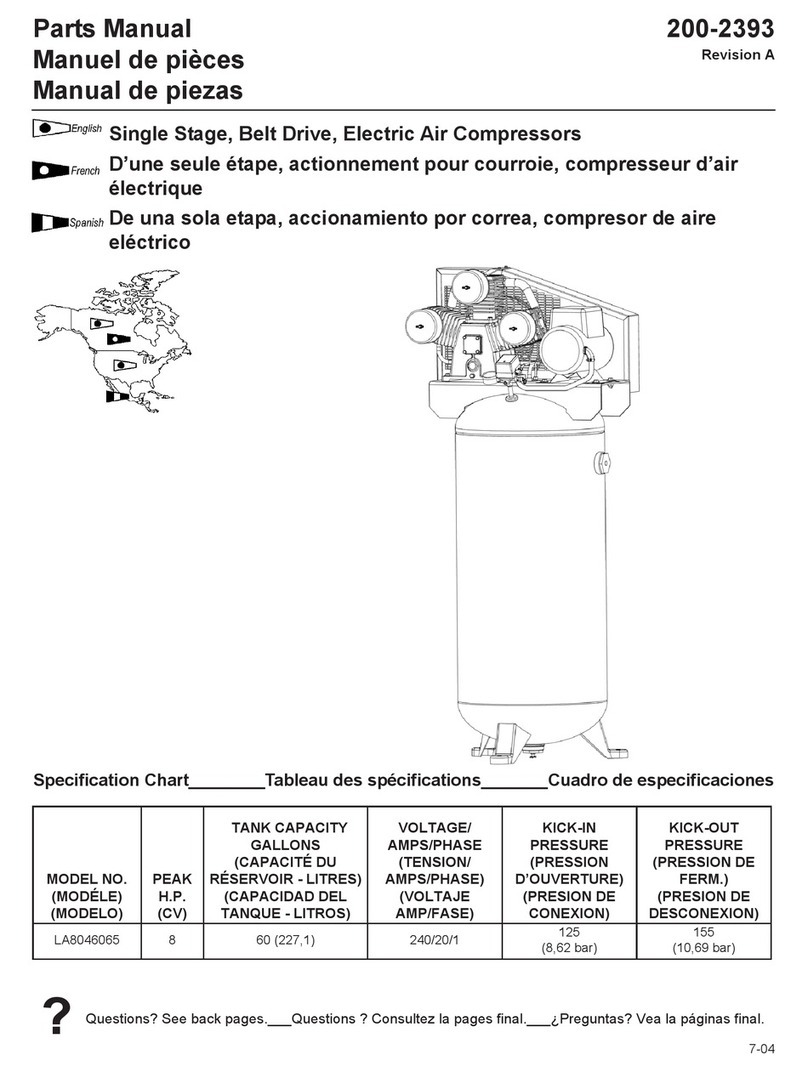

Table of Contents

I

1. Thank You 5

2. Introduction 5

3. Warning 6

II

1. Getting Started 7

2. Heat and ventilation 7

3. Operation voltage 8

III

Powering up the machine

1. Power 9

2. Balance measurement 9

3. Balance calibration 10

4. Meter zero/bias 10

5. Output stage balance/

measurement 11

IV

Using the system 12

1. Block chain of the Machine 13

2. Control Matrix 15

2.1 Input gain 16

2.2 Attack time

2.3 Release time

2.4 Threshold

2.5 Recovery gain

2.6 Stereo link 17

2.7 Mute

3. Gain reduction meters

4. Main output 18

4.1 Main mute

4.2 Main system bypass

4.3 Main input

V

1. Filter block chain 19

2. Bode plot’s of filter settings

2.1. high to mid 6dB/oct - mid to low 6dB/oct 21

2.2. high to mid 12dB/oct - mid to low 12dB/oct 23

2.3. high to mid 12dB/oct - mid to low 6dB/oct 25

2.4. high to mid 6dB/oct - mid to low 12dB/oct 27

V

3. Filter 29

3.1 Paralell compression

3.2 Crossover frequency

3.3 Lp bypass

3.4 Hp bypass 30

3.5 Order

VI

1. Tube complement 31

2. Replacing the tubes 32

VII

1. Disclaimer 33

2. Warrenty

VIII

Specifications

IX

Edison Effect 35

X

Declaration of Confirmity 36

XI

Contact details 36

XII

Recall sheet 37

Electric Signal MMXV AD Page 3

Delta Transconductace band Compressor

User Manual

Page 4

I.

1

Thank You

I.

3

Warning

For personal safety, please read this user

manual and warning thoroughly before using the

equipment. To reduce the risk of electric shock,

it is essential that the unit is disconnected from

the mains supply before removing the cover. The

Delta Transconductance band Compressor uses

thermionic vacuum electron tubes and works on

a lethal voltage up to 300 volts. Even after a

long period of disconnection, components can

still be charged.

Use and store the Delta Transconductance band

Compressor only in studio conditions. Do NOT

operate the Delta Transconductance band

Compressor in a hazardous area, near water

or moisture.

Due the amount of tubes, the Delta

Transconductance band Compressor

generates heat.

However the unit should never run this hot so that

it makes it untouchable. Ensure that adequate

ventilation is provided(see II.2).

In the event that this unit has been suffered an

impact, an electrical safety test must be carried

out before reconnection to the mains supply.

Refer servicing of the unit to qualified personnel

only.

For choosing the Electric Signal Delta

Transconductance band Compressor and trust

in us.

Eletric Signal has the mission to ensure the

professional audio engineer has reliable, high

quality equipment.

By knowing the status quo, annihilating the

dogma’s and standing on a many shoulders,

Electric Signal is always innovating. Pushing the

envelope further and tries to leave the real

decisions for the engineer. By knowing we are

only a switch in the chain we try to achieve to

give the engineer the maximum potential by

providing him the relevant choices.

It is tough to vocolise, however Arthur

Shoppenhauwer writes in ‘the world as will and

reprentation’

“The effect of music is so very much more

powerful and penetrating than is that of the

other arts, for these others speak only of the

shadow, but music of the essence.”

Electric Signal MMXV AD Page 5

Delta Transconductace band Compressor

User Manual

Page 6

The Delta Transconductance band compressor

is a vacuum tube based three band compressor

and is essentially three stereo compressors, a

three band passive crossover filter and a tube

based mixer

For the compression, the delta mu technology

is used. The 6386 tiode, used in many classic

compressors is ideal for this task, nowadays

difficult to obtain. Therefore the Delta

Transconductance band Compressor uses the

6ba6/5749 penthode in triode configuration and

has the same characteristics as the 6386 triode.

I.2Introduction

Like all delta mu compressors, balance needs to

be (re)calibrate to cancel out 2nd order

harmonics. Therefore these calibration settings

are on the front panel. To make proper settings

there are sockets on the front panel to measure

the (in)balance.

Furthermore, solid state components are used

in the power supply and the side chain. There are

no integrated circuit's, electrolytes or transistors

in the audio chain. The input and output are

transformer balanced.

The controls on the front panel are toggle

switches or rotary switches, so recall is possible.

These switches control relay based attenuators,

never touch the audio signal directly and

make a short as possible audio chain.

II.

3

Operation voltage

The Delta transconductance band compressor

can operate from 240 vac 50 Hz or 120 vac 60

Hz. The line voltage is set at the factory based

on the buyers request at time of the order.

To change the line voltage, padlock the machine

from mains. The line

voltage switches are located at the back of the

machin. Switch it in the correct

position. Do NOT operate the equipment with

the line voltage switch in the wrong position.

Electric Signal MMXV AD Page 7

Delta Transconductace band Compressor

User Manual

Page 8

II.

1

Getting Started

The package contains:

-this manual

-the Delta Transconductance band

Compressor

-a power inlet cable

If you’re not sure, control the operating voltage

is the correct one(II.3) While doing so check for

compromised vacuum and broken glass.

Use short XLR cables for input/output where:

pin 1: ground, shield

pin 2: positive phase, hot

pin 3: negative phase,cold

Use the power inlet cable to connect the

equipment with a earthed power source.

Make sure the unit is installed in a rack, with

sufficient ventilation(see II.2) or on a stable flat

surface.

II.

2

Heat and ventilation

Due to the amount of tubes the Delta

Transconductance band Compressor uses more

energy than a laptop and therefore generates

significantly amount of heat.

The machine is equipped with a very low noise

noctus fan and had a operation time of 100000

hour. Installed in a rack the unit should be inaudible.

It is recomended to have 1U of space between the

unit and other equipment. Make sure that the

ventilation slots are not obstructed. When rack

mounting this equipment, an external fan may be

required to provide sufficient airflow.

III Powering up

the Machine

Electric Signal MMXV AD Page 9

Delta Transconductace band Compressor

User Manual

Page 10

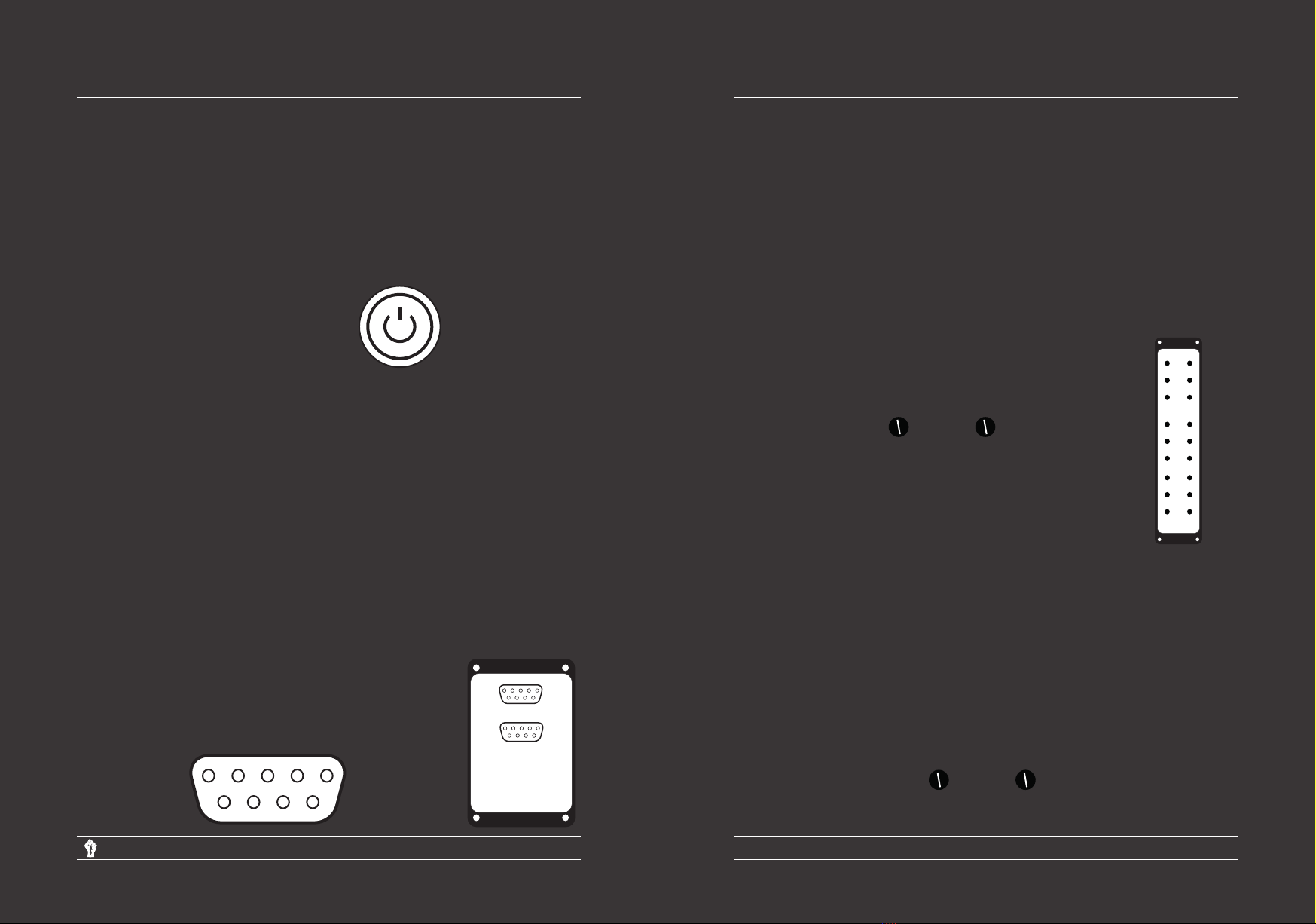

III.

1

Power

III.

2

Balance measurement

III.

3

Balance calibration

III.

4

Meter zero/bias

Power

Now that the Delta transconductance band

Compressor is installed and all connections are

made, it is ready to operate

Now the light in the power button will illuminate, and

the machine generate sa few clicks from the

relays. Now the tubes heat up, inside

them a physical process occures named ‘the

Edison effect’ and electrons will flow into the

micro universe of the tube. The gain reduction

meters measure the current trough the tubes

responsible for the compression and the leds of

the meters will lit up. After 30 to 60 seconds

the machine is ready for operation.

The machine is calibrated in our factory, however

the procedure is as follows. The tubes can drift

directly after the warm up so it is recommended to

leave the unit on for half an hour, before

calibration /measurement. For this procedure is

needed:

-a flat screwdriver

-a (digital) multimeter

Remove the the measurement panel.

Behind the measurement panel there

are two 9pins d-sub sockets, with the

numbering of pins:

While tubes age, their conductance decrease and

therefore the gain reduction meters will indicate

compression. Although this is not immediately a

problem, there is a way to recalibrate the idle

current of the tubes. Use a flat screwdriver to

adjust the zero pot-meter of the desired channel

(mid, high, low, and left or right) and set the

meter to 0 dB. If thie problem is not solved, a

tube replacement may be necessary. After

altering the bias, it is recommended to re balance

the stage.

zero

Set the multimeter to mV and connect the wires

of the meter to pin 1and pin 2 of the right D sub

socket, If the multimeter measures anthing other

than 0 volts the balance of this stage is not

calibrated properly. See next chapter for balance

calibration (III.3).

If an unbalance is measured, second

order harmonics occure. To rebalance

the stage, apply the multimeter to the

correct stage (see III.2) and use the flat

screw driver to adjust the balance

trim-pot until the multimeter indicates

0 volts.

Push the power button:

9 8 7 6

5 4 3 2

1

Pinout

1, 2: High

3, 4: Mid

5, 6: Low

7, 8: Main

9 : Gnd

Right

Left

9 8 7 6

5 4 3 2

1

9 8 7 6

5 4 3 2

1

level

zero

bal

level

zero

bal

level

zero

bal

l

e

f

t

r

i

g

h

t

bal

III.

5

Output stage balance/

measurement

Electric Signal MMXV AD Page 11

Delta Transconductace band Compressor

User Manual

Page 12

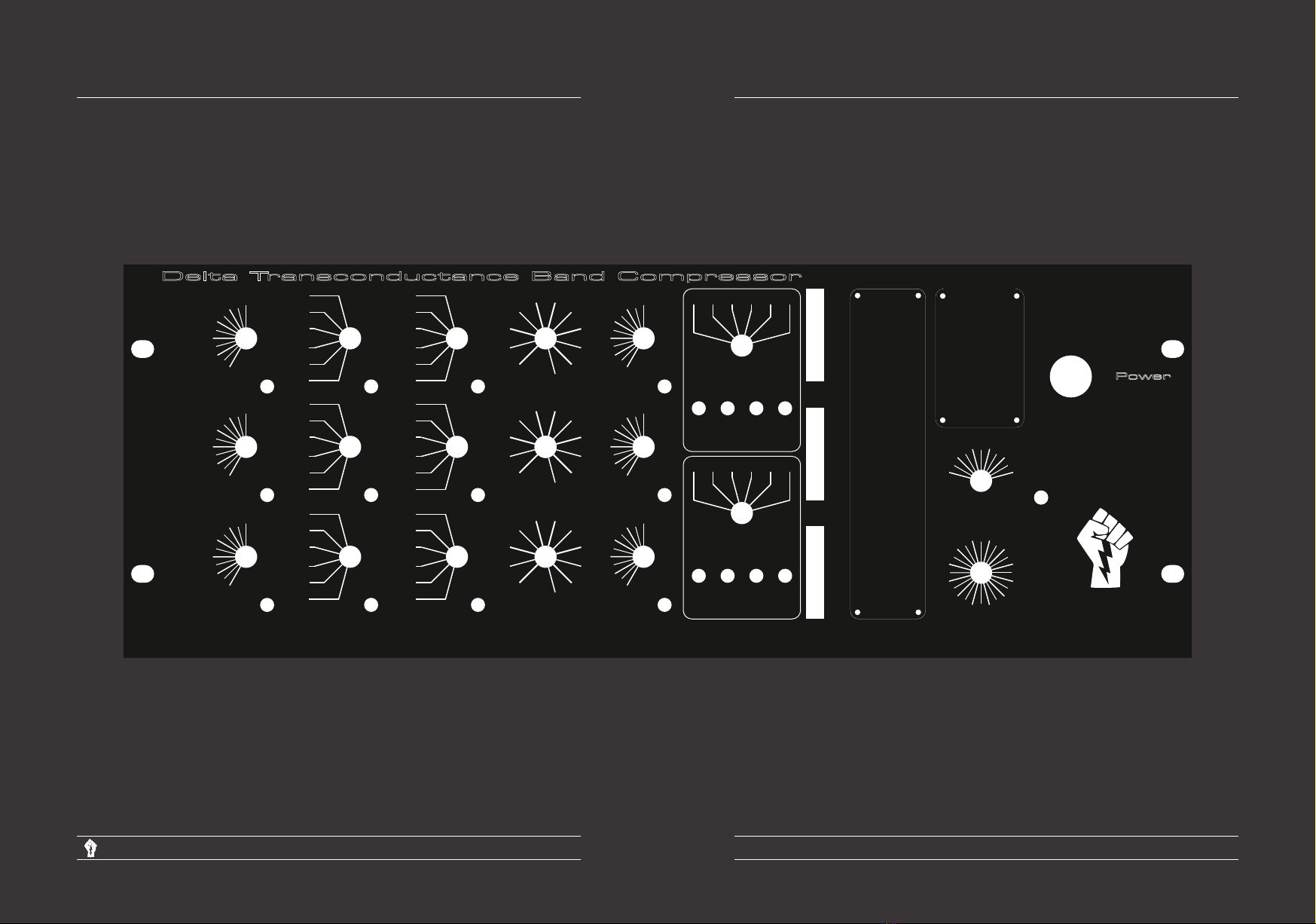

IV Using the system

The next chapters describe

how the machine can be used. Due to the high

amount of controls, compared to other

compressors, the front panel may be a bit

overwhelming, but is actually simple if familiar.

Remember there are three elements: Main, filter

and compressors. The controls for the

compressors are arranged in a matrix. This

matrix is present in the whole front panel design

exept for the filter and main section. The

controls for the filters are divided in two

sections, because there are two crossover

frequency’s. Furthermore all secondary functions

are engraved in red and all controls (besides the

calibration trim-pots) operates the left and the

right channel. As mentioned before, due to the

relative large number of operations and the

axiom; ‘a shorter signal pad is in most cases

better’ the Delta Transconductance band

Compressor uses more than 100 signal relays

and they may give a light ‘clicking’ sound if a

control is used.

On the next page there is a visual of the block

chain of the machine. In the manual and

on the front panel, the three compressors of the

machine will be defined by high, mid and low

channel. Once the filter is bypassed

this definition

(high, mid, low) it may partially loose it’s meaning, so

for example; bypassing the low pass filter of the

high to mid section resulting in the ‘high’

compressor working over the whole (20hz-

20kHz) frequency range.

This procedure is equal to the delta mu gain

stages; if an inbalance is measured at pin 7 and

8, the balance needs to be recalibrated. The

balance pots are next to the 6h30 tubes. (see

visual below)

There is a possibility that an imbalance may exist

between the levels low/mid/high and left/right.

These imperfections can be set properly

by adjusting the level trim-pots. They can

atttenuate 2.5dB.

III.

6

Level

level

left balance

right balance

Input

transformer

Main input

Filter

Side chain

voltage

controlled amp

Input gain

Gain reduction

leds

Balance

measurement Meter zero Balance Attack time Release time

0.1

0.6

0.3

0.8

1.0

1.5

4.0

34

20

50

100

130

0.01

0.04

0.05

0.08

0.10

0.13

0.2

1.2

0.5

1.5

0.8

1.8

XLR Input

level

Σ-∞

Main mute

Main output

-∞

High muteRecovery gain

Threshold Stereo link

link

mono

XLR Output

System bypass

On

output

transformer

Side chain

voltage

controlled amp

Input gain

Gain reduction

leds

Balance

measurement Meter zero Balance Attack time Release time

0.1

0.6

0.3

0.8

1.0

1.5

4.0

34

20

50

100

130

0.01

0.04

0.05

0.08

0.10

0.13

0.2

1.2

0.5

1.5

0.8

1.8

level

-∞

High muteRecovery gain

Threshold Stereo link

link

mono

Side chain

voltage

controlled amp

Input gain

Gain reduction

leds

Balance

measurement Meter zero Balance Attack time Release time

0.1

0.6

0.3

0.8

1.0

1.5

4.0

34

20

50

100

130

0.01

0.04

0.05

0.08

0.10

0.13

0.2

1.2

0.5

1.5

0.8

1.8

level

-∞

High muteRecovery gain

Threshold Stereo link

link

mono

I V. 1

Block chain

of system

Audio signal

Control signal

Electric Signal MMXV AD Page 13

Delta Transconductace band Compressor

User Manual

Page 14

I V.

2

Control Matrix

Electric Signal MMXV AD Page 15

Delta Transconductace band Compressor

User Manual

Page 16

This Control is an 11 position rotary switch, and

controls a relay based attenuater with a

resolution of 1.5dB per step. Together with the

Threshold control this defines the slope and the

threshold of the compression curve.

The attack control determines the speed with

which the compressor attacks a level above the

threshold point. It also determines the ratio of

action the compressor will have on short

duration spikes and transients.

The threshold control is used to adjust the

amount of compression in conjunction with the

input gain. With the control in the full clockwise

position (out), there will be no compression.

Turning the control anti-clockwise increases the

amount of compression.

It determines the time-rate of compression holding

action. Increasing the control clockwise lengthens

the holding time.

This Control is an 11 position rotary switch and

controls a relay based attenuater with a

resolution of 1.5dB per step. Besides amplefying

the signal after compression, this control can be

used to mix the low, mid and high band together.

IV.

2.1

Input Gain

IV.

2.2

Attack time

IV.

2.4

Threshold

IV.

2.3

Release time

IV.

2.5

Recovery gain

Behold the following visual: This is a manipulated

image from the front panel; the control, main and

the filter section are edited out. What is left is an

empty matrix.

The controls are arranged in that matrix:

High

Mid

Low

Input Gain (dB)/

stereo link

Attack time (ms)/

time adder

Recovery time (s)/

time adder

Threshold (dBu) Recovery gain

(dB)/mute

Gain

reduction

Calibration

High

Mid

Low

Input Gain (dB)/

stereo link

Attack time (ms)/

time adder

Recovery time (s)/

time adder

Threshold (dBu) Recovery gain

(dB)/mute

Gain

reduction

0.2

0

-0.5

-1

-2

-3

-6

-8

-10

-14

-20

r

i

g

h

t

9

-6

-3

3

0

12

-3

0

6

9

3

on

on

link on

mono off off mute

6

l

e

f

t

0.01

0.04

0.05

0.08

0.10

0.13

0.2

1.2

0.5

1.5

0.8

1.8

0.1

0.6

0.3

0.8

1.0

1.5

4.0

34

20

50

100

130

9

-6

-3

3

0

12

-3

0

6

9

3

on

on

link on

mono off off mute

6

0.01

0.04

0.05

0.08

0.10

0.13

0.2

1.2

0.5

1.5

0.8

1.8

0.1

0.6

0.3

0.8

1.0

1.5

4.0

34

20

50

100

130

9

-6

-3

3

0

12

-3

0

6

9

3

on

on

link on

mono off off mute

6

0.01

0.04

0.05

0.08

0.10

0.13

0.2

1.2

0.5

1.5

0.8

1.8

0.1

0.6

0.3

0.8

1.0

1.5

4.0

34

20

50

100

130

Calibration

r

i

g

h

t

l

e

f

t

0.2

0

-0.5

-1

-2

-3

-6

-8

-10

-14

-20

0.2

0

-0.5

-1

-2

-3

-6

-8

-10

-14

-20

level

zero

bal

level

zero

bal

level

zero

bal

l

e

f

t

r

i

g

h

t

out

9-6

-2

31

-8

7

14

0 5

out

9-6

-2

31

-8

7

14

0 5

out

9-6

-2

31

-8

7

14

0 5

Electric Signal MMXV AD Page 17

Delta Transconductace band Compressor

User Manual

Page 18

When switched to “mono”, the amount of

compression of the right channel is independent

of the left channel. When switched to “link” the

control voltage is combined, left and right

channel are reduced in gain by the same number

of dB.

Six meters, mid, high, low and left.right measure

the current trough the remote cutoff valves

responsible for the gain reduction/compression

and therefore measures the gain reduction. Over

time while the tubes age and the conductance of

them lowers, the meters may drop. However the

bias can be recalibrated if this occurs (see III.3)

IV.

2.6

Stereo link

Mutes the channel.

IV.

2.7

Mute

IV.

3

Gain reduction

meters

24 position rotary switch, controls the output

gain, with a resolution of 1 dB per step.

Removes all the electronics from the signal chain

and links the input to the output, see the block

chain IV.1.

IV.

4

Main output

If the main output rotary switch is turned

completelyanti clockwise to the - the output is

muted.

IV.

4.1

Main Mute

IV.

4.2

Main system

bypass

11 position rotary switch, controls the output

gain, with a resolution of 1dB per step, Notify that

this control can effect every compressor in the

unit. In combination with the input gain 121

gain combinations are possible

IV.

4.3

Main input

-3dB fc

6dB/oct

high pass filter

-6dB fc

12dB/oct

high pass filter

-3dB fc

1st order

low pass filter

-6dB fc

2nd order

low pass filter

On

Bypass

On

Bypass

Bypass

high

pass

bp

high

pass

bp

12 dB

/oct

6 dB

/oct

1.0k 1.2k 1.5k 1.8k 2.3k 3.0k

3.8k 4.8k 6.2k 8.0k 10k 14k

On

On

Bypass

V. 1

Filter

Block chain

high

pass

bp

mid to low

highpass filter

high

pass

bp

mid to low

lowpass filter

12 dB

/oct

6 dB

/oct

-3dB fc

6dB/oct

high pass filter

-6dB fc

12dB/oct

high pass filter

-3dB fc

1st order

low pass filter

-6dB fc

2nd order

low pass filter

1.0k 1.2k 1.5k 1.8k 2.3k 3.0k

3.8k 4.8k 6.2k 8.0k 10k 14k

Audio signal

Control signal

Filter I/O

2nd order

2nd order

1st order

1st order 1st order

1st order

2nd order

2nd order

Mid

output

High

output

Low

out

put

Filter

intput

mid to low

order

Crossover frequency

mid to low

Crossover frequency

high to mid

high to mid

highpass filter

high to mid

lowpass filter

high to mid

order

mid to low

highpass filter

mid to low

highpass filter

mid to low

highpass filter

order

mid to low

highpass filter

order

high to mid

highpass filter

high to mid

highpass filter

order

high to mid

highpass filter

order

high to mid

highpass filter

Phase

inverter

Phase

inverter

Electric Signal MMXV AD Page 19

Delta Transconductace band Compressor

User Manual

Page 20

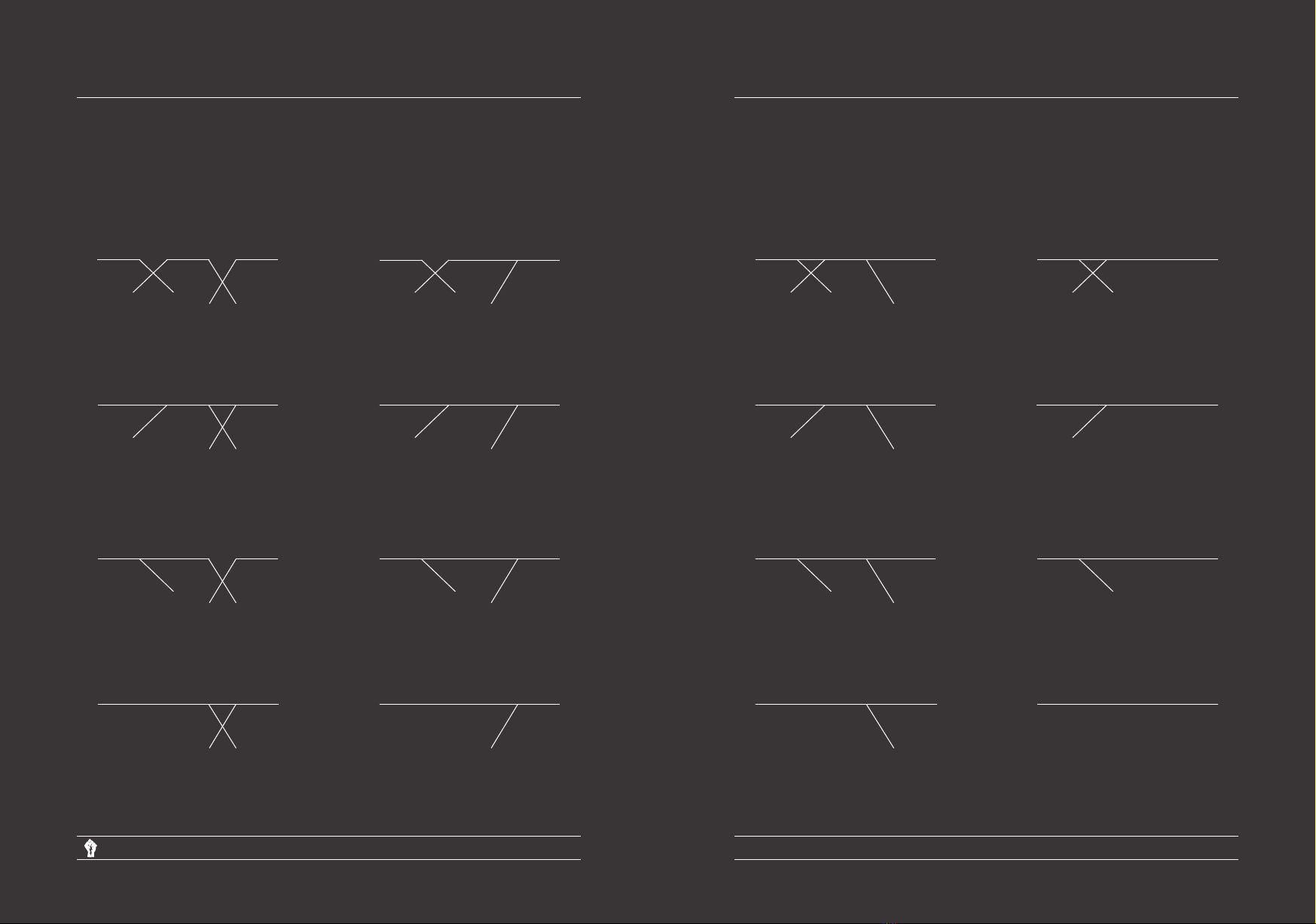

V.

2.1

Bode plot’s of

filter setting

-

high to mid 6dB/oct - mid to low 6dB/oct

high to mid hp:on lp:on

mid to low hp:on lp:on

mid to low

crossover

frequency

high to mid

crossover

frequency

Electric Signal MMXV AD Page 21

Delta Transconductace band Compressor

User Manual

Page 22

high to mid hp:on lp:on

mid to low hp:off lp:off

high to mid hp:on lp:on

mid to low hp:off lp:on

high to mid hp:on lp:on

mid to low hp:on lp:off

high to mid hp:on lp:off

mid to low hp:on lp:on

high to mid hp:on lp:off

mid to low hp:on lp:off

high to mid hp:on lp:off

mid to low hp:off lp:on

high to mid hp:on lp:off

mid to low hp:off lp:off

high to mid hp:off lp:on

mid to low hp:on lp:on

high to mid hp:off lp:on

mid to low hp:on lp:off

high to mid hp:off lp:on

mid to low hp:off lp:on

high to mid hp:off lp:on

mid to low hp:off lp:off

high to mid hp:off lp:off

mid to low hp:on lp:on

high to mid hp:off lp:off

mid to low hp:on lp:off

high to mid hp:off lp:off

mid to low hp:off lp:on

high to mid hp:off lp:off

mid to low hp:off lp:off

high to mid hp:on lp:on

mid to low hp:off lp:off

high to mid hp:on lp:on

mid to low hp:off lp:on

high to mid hp:on lp:on

mid to low hp:on lp:on

high to mid hp:on lp:on

mid to low hp:on lp:off

high to mid hp:on lp:off

mid to low hp:on lp:on

high to mid hp:on lp:off

mid to low hp:on lp:off

high to mid hp:on lp:off

mid to low hp:off lp:on

high to mid hp:on lp:off

mid to low hp:off lp:off

high to mid hp:off lp:on

mid to low hp:on lp:on

high to mid hp:off lp:on

mid to low hp:on lp:off

high to mid hp:off lp:on

mid to low hp:off lp:on

high to mid hp:off lp:on

mid to low hp:off lp:off

high to mid hp:off lp:off

mid to low hp:on lp:on

high to mid hp:off lp:off

mid to low hp:on lp:off

high to mid hp:off lp:off

mid to low hp:off lp:on

high to mid hp:off lp:off

mid to low hp:off lp:off

Electric Signal MMXV AD Page 23

Delta Transconductace band Compressor

User Manual

Page 24

V.

2.2

Bode plot’s of

filter setting

-

high to mid 12 dB/oct - mid to low 12 dB/oct

high to mid hp:on lp:on

mid to low hp:on lp:on

V.

2.3

Bode plot’s of

filter setting

-

high to mid 6 dB/oct - mid to low 12 dB/oct

high to mid hp:on lp:on

mid to low hp:off lp:off

high to mid hp:on lp:on

mid to low hp:off lp:on

high to mid hp:on lp:on

mid to low hp:on lp:off

high to mid hp:on lp:off

mid to low hp:on lp:on

high to mid hp:on lp:off

mid to low hp:on lp:off

high to mid hp:on lp:off

mid to low hp:off lp:on

high to mid hp:on lp:off

mid to low hp:off lp:off

high to mid hp:off lp:on

mid to low hp:on lp:on

high to mid hp:off lp:on

mid to low hp:on lp:off

high to mid hp:off lp:on

mid to low hp:off lp:on

high to mid hp:off lp:on

mid to low hp:off lp:off

high to mid hp:off lp:off

mid to low hp:on lp:on

high to mid hp:off lp:off

mid to low hp:on lp:off

high to mid hp:off lp:off

mid to low hp:off lp:on

high to mid hp:off lp:off

mid to low hp:off lp:off

Electric Signal MMXV AD Page 25

Delta Transconductace band Compressor

User Manual

Page 26

Electric Signal MMXV AD Page 27

V.

2.4

Bode plot’s of

filter setting

-

high to mid 12dB/oct - mid to low 6dB/oct

Delta Transconductace band Compressor

User Manual

Page 28

high to mid hp:on lp:on

mid to low hp:off lp:off

high to mid hp:on lp:on

mid to low hp:off lp:on

high to mid hp:on lp:on

mid to low hp:on lp:on

high to mid hp:on lp:on

mid to low hp:on lp:off

high to mid hp:on lp:off

mid to low hp:on lp:on

high to mid hp:on lp:off

mid to low hp:on lp:off

high to mid hp:on lp:off

mid to low hp:off lp:on

high to mid hp:on lp:off

mid to low hp:off lp:off

high to mid hp:off lp:on

mid to low hp:on lp:on

high to mid hp:off lp:on

mid to low hp:on lp:off

high to mid hp:off lp:on

mid to low hp:off lp:on

high to mid hp:off lp:on

mid to low hp:off lp:off

high to mid hp:off lp:off

mid to low hp:on lp:on

high to mid hp:off lp:off

mid to low hp:on lp:off

high to mid hp:off lp:off

mid to low hp:off lp:on

high to mid hp:off lp:off

mid to low hp:off lp:off

Electric Signal MMXV AD Page 29

Delta Transconductace band Compressor

User Manual

Page 30

V.

3.1

Crossover frequency

See V.2.1and V.1, Controls the crossover

frequency of the low passfilter and the highpass

filter. Notify the frequency multiplier switch(1x

white or 4x red) so Twelve cross over frequency

values can be set,

V.

3.3

Hp bypass

Activates or bypasses the highpass filter. see

V.2.1 to V.2.4

V.

3.4

Order

This cotrol defines the rollof slope, choose

beteween first order(6dB/oct) of second order

(12dB/oct). The first order filter crossoverpoint

is at -3dB. And the second order filter is -6dB.

V.

3.1

Paralell compression

New York compression, mowtown compression

or parralell compression is one or more

compressors working paralell on the same

material and later mixed together. Often, a

heavy compressed signal is combined with an

ligtly or uncompressed signal. The filter bypass

function makes it possible to change from a band

compressor to a set of three stereo

compressors configured in paralell, wich enables

paralell compression.

The bode plot’s in the prevous chapters indicates

that if the machine is set as three paralell

compressors, the order and filter crossover

frequency cotrol has no function, see for

example the right bottom bode plot (V.2.1-V.2.1)

V.

3

Filter

In general, the filter splits the signal in a low, mid

a high band. furthermore the filter settings

enables the user to enables/bypass filters and

sets the order or bypass all the filters to enable

paralell compression. The next subjects besides

cross over frequency discribes one of the two

filter sections but they work equally.

V.

3.2

Lp bypass

Activates or bypasses the lowpass filter, see

V.2.1 to V.2.4

VI.

1

Tube complement

Electric Signal MMXV AD Page 31

Delta Transconductace band Compressor

User Manual

Page 32

Tubes for replacement can be obtained from our

factory.

The Delta Transconductance band compressor

uses the following thermionic tubes:

12X 6ba6/5749/6k4p Compression

3X 6H30 Input/output

2X 6H2p(-ev/-er) Mixing

4X 12AT7/ECC83 PI/tonecontrol

Notify that the remote cutoff tubes, responsible

for the compression(6ba6/5749/6k4p) need to

be matched pairs. The 5749W (wich comes with

the compressor) is an joint Army Navy electron

tube from General Elecric.

The two 6h30 for the output need to be

matched triodes.

The Delta Transconductance band compressor

comes with two russian milspec 6h2p-er,

responsible for mixing, if desired to use an

european ecc81or an nowadays 12ax7 make

use of a ecc to 6h2p socket (contact electric

signal for more information)

Not every ECC83 is usable due to the maximum

rating specifications, contact electric signal for

more information.

See next subject for tube replacement.

VI.

2

Replacing the tubes

6ba6/5749/6k4p

ecc81/12at7

6h2p

6h30

To remove a tube, press the screening can down

and twist anti-clockwise, when it will spring out.

Then remove the tube by pulling upwards,

possibly using a cloth if it’s still hot. Take care

not to bend the pins when putting back in.

Electric Signal MMXV AD Page 33

Delta Transconductace band Compressor

User Manual

Page 34

VII.

1

Disclaimer

Electric Signal reserves the right to alter

specifications without prior notice. Electric Signal

cannot be held responsible for any damage

resulting in using the Delta Transconductace

band Compressor.

VII

Specifications

Input impedance

Output impedance

Signal to noise

Power consumption

Weight

Operating voltage

THD

Frequency responce

Attack time

Release time

VII.

2

Warrenty

The unit comes with a 24 month warranty

covering parts and labor, It is essential that it is

returned to our factory or to the dealer from

which it was purchased for repairs to be carried

out otherwise the warranty is invalidated.

Contact Electric Signal how to send it to us.

15k

600

>80dB

200Watt max

12kg

240vac/130vac

0,1%

-1dB 12Hz-30KHz

0,1-130ms

10ms-1s

Electric Signal MMXV AD Page 35

Delta Transconductace band Compressor

User Manual

Page 36

IX Edison Effect

Edison Effect or Thermionic emission:

Thermionic emission is the thermally induced

flow of charge carriers from a surface or over a

potential-energy barrier. This occurs because the

thermal energy given to the carrier overcomes

the work function of the material. The charge

carriers can be electrons or ions, and in older

literature are sometimes referred to as

"thermions". After emission, a charge that is

equal in magnitude and opposite in sign to the

total charge emitted is initially left behind in the

emitting region. But if the emitter is connected

to a battery, the charge left behind is neutralized

by charge supplied by the battery as the emitted

charge carriers move away from the emitter, and

finally the emitter will be in the same state as it

was before emission.

The classical example of thermionic emission is

the emission of electrons from a hot cathode

into a vacuum (also known as thermal electron

emission or the Edison effect) in a vacuum tube.

The hot cathode can be a metal filament, a

coated metal filament, or a separate structure

of metal or carbides or borides of transition

metals. Vacuum emission from metals tends to

become significant only for temperatures over

1,000 Kelvin The science dealing with this

phenomenon has been known as "thermionics",

but this name seems to be gradually falling into

disuse.

XDeclaration of

Confirmity

The Delta Transconductance band Compressor

complies with the requirements of Conformité

Européenne.

XI Contact details

Electric Signal

www Electricsignal.eu

Phone 0031640237096

Leiden, Netherlands

2332PZ

Electric Signal MMXV AD Page 37

Delta Transconductace band Compressor

User Manual

Page 38

XII Recall sheet

Electric Signal

High

Mid

Low

Input Gain (dB)/

stereo link

Attack time (ms)/

time adder

Recovery time (s)/

time adder

Threshold (dBu) Recovery gain

(dB)/mute

Crossover frequency

(Hz)/filter settings

Gain

reduction

Main

Power

Bal measurement

r

i

g

h

t

Output (dB)

Input (dB)/

system bypass

-∞

-22

-6

-2

0

-4

-8

-10-12

-14

-16

-18

-20

9

-6

-3

3

0

0

-2

-4-6

-8

-10

12

-3

0

6

9

3

on

on

link on

mono off off mute

MMXV AD

6

l

e

f

t

0.01

0.04

0.05

0.08

0.10

0.13

0.2

1.2

0.5

1.5

0.8

1.8

0.1

0.6

0.3

0.8

1.0

1.5

4.0

34

20

50

100

130

9

-6

-3

3

0

12

-3

0

6

9

3

on

on

link on

mono off off mute

6

0.01

0.04

0.05

0.08

0.10

0.13

0.2

1.2

0.5

1.5

0.8

1.8

0.1

0.6

0.3

0.8

1.0

1.5

4.0

34

20

50

100

130

9

-6

-3

3

0

12

-3

0

6

9

3

on

on

link on

mono off off mute

6

0.01

0.04

0.05

0.08

0.10

0.13

0.2

1.2

0.5

1.5

0.8

1.8

0.1

0.6

0.3

0.8

1.0

1.5

4.0

34

20

50

100

130

Mid to low

60 80 100 130 180 240

high

pass

bp

300 370 450 530 660 800

low

pass

bp

6 dB

/oct

12 dB

/oct

4x

1x

1.0k 1.2k 1.5k 1.8k 2.3k 3.0k

3.8k 4.8k 6.2k 8.0k 10k 14k

High to mid

high

pass

bp

low

pass

bp

6 dB

/oct

12 dB

/oct

4x

1x

Calibration

Delta Transconductance Band Compressor

r

i

g

h

t

l

e

f

t

on

bp

0.2

0

-2.5

-8

-12

-15

-20

0.2

0

-2.5

-8

-12

-15

-20

0.2

0

-2.5

-8

-12

-15

-20

out

9-6

-2

31

-8

7

14

0 5

out

9-6

-2

31

-8

7

14

0 5

out

9-6

-2

31

-8

7

14

0 5

Main Calibration

settings

behind this panel

Calibration settings

behind this panel

Table of contents

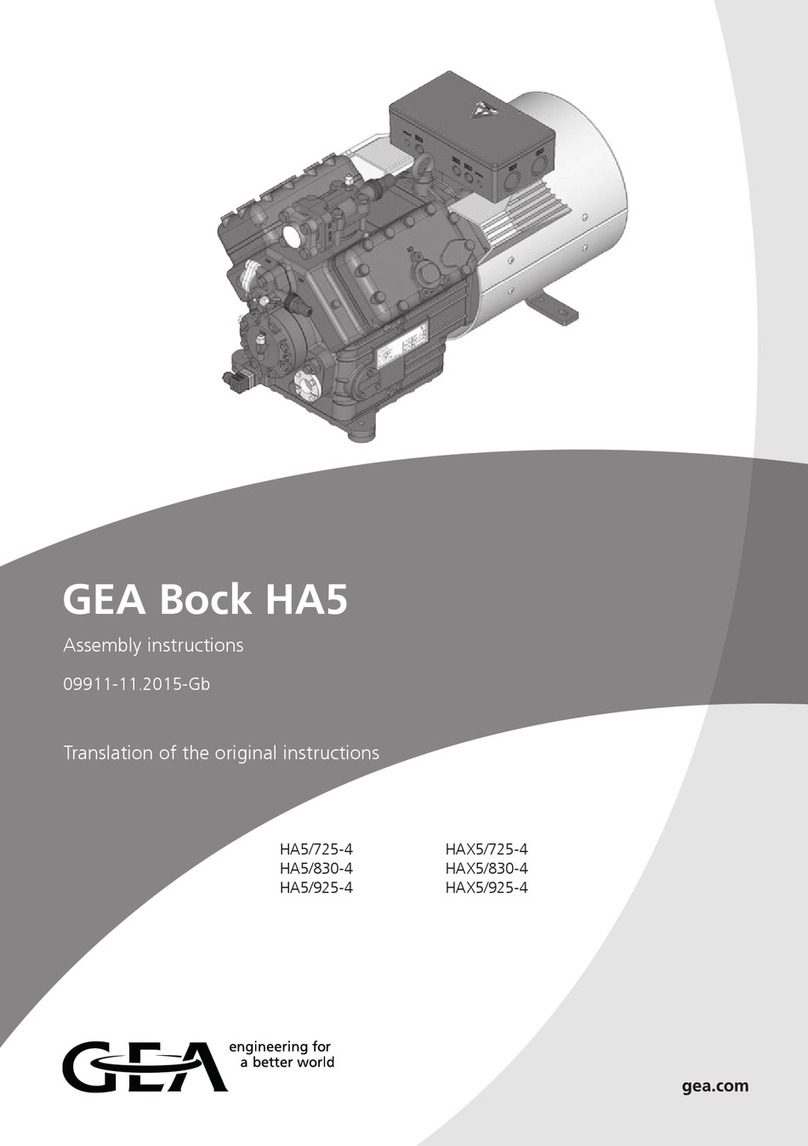

Popular Air Compressor manuals by other brands

Prodif

Prodif SIL06J Use and maintenance manual

GEA Bock

GEA Bock Bock HA5 Assembly instructions

Maxair

Maxair MEGA-MAX OPEN VERTICAL 6000 Use and maintenance manual

Emerson

Emerson Copeland Scroll K5 Series Application Bulletin

Craftsman

Craftsman 919.727350 owner's manual

Hitachi

Hitachi Highly WHP13100AEDPC9EQ installation manual