Prodif SIL06J User manual

Page 8

MARKING - TRACKING.........P3

SPARE PARTLIST................P4/5

EXPLODED VIEW.................P 5

GUARANTEE.......................P 6

SAFETY VALVE Certificate....P7

Page 1

OILLESS COMPRESSOR / AUTOLUBRICATED:

MANUAL

USE

MAINTENANCE

SYNOPSIS :

INSTALLATION AND SITE....................P2

INSTRUCTIONS, USE OPERATING......P2

FOR YOUR SECURITY ......................P 2/3

MAINTENANCE..................................P 3

FAULTS / SOLUTIONS.........................P3

STAMPOFTHERETAILER

A-NoticeSIL06J-YW400.pmd 2015-03-03 THISDOCUMENTISNOTCONTRACTUAL. Technicalcharacteristicsforinformation only. Subject tomodifications withoutadvance notice.

SIL06JSIL06J

SIL06JSIL06J

SIL06J

SIL06J

3 - FOR YOUR SECURITY

ÜThe air delivered by your compressor allows you

to use many tools, follow conditions, advice and

in certain cases RESTRICTIONS OF USE for air

tools using compressed air.

2 - INSTRUCTIONS, USES ADVICE

To obtain the best efficiency, please respect the

following indications:

- HORIZONTAL SETTING: the compressor must be

installed on a horizontal plane, 15 ° angle is

allowable.

- PLACE: Use the compressor indoors or under

shelter, do not expose it to the rain or near water

jets. Do not use the compressor in an explosive

atmosphere.

- VENTILATION: The compressor must be in a place

which allows ventilation, do not cover the

ventilation openings.

- TEMPERATURE: Use the compressor between

(+ 5°C and +35°C) (Otherwise, there are risks for

the electrical motor.)

- TENSION: Check that the sector tension and

tension indicated on the label are the same :

(Single phase:230 Volts - 50 Hz)

INSTALLATIONANDSITE

INSTRUCTIONS,USEADVICE

SECURITY

You have just bought your air compressor, it will

give you appreciable services.

Inflation: Tyres - Balloons - Swimming pools -

inflatable boats etc ......

Blowing - Dusting - Painting - Stapling…

Before using it, it is imperative to read ENTIRELY

the present NOTE.

1 - INSTALLATIONAND SITE

- ADJUSTMENT OF PRESSURE:

- AFTER USING:

ÜNever stop by disconnecting the electrical cable.

ÜNever leave the compressor power connected under

pressure.

ØSwitch the interruptor in "Off" position (Ref: A, Pict.1)

ØEmpty the tank ØDrain the tank (Ref: P, Pict.1)

ØDisconnect the electrical cable.

ÜAdjust the pressure of use and the consumption of

air to the characteristics of the tools you wish to

use.

(See the documentation provided with your tools).

ÜThe quantity of air consumed depends on the type

of tool used: do not use a tool consuming more

than 60% of the possibilities of your compressor.

ÜThe pressure controller is adjusted in factory and

needs no re adjustment.

ÜPressure gauge (Ref: C, Pict.1) indicates the

pressure inside the tank.

ÜPressure gauge (Ref: U, Pict.1) indicates the

useful exit air pressure.

To adjust the output of air pressure , it is necessary to

turn the pressure reducer button (Ref: B, Pict.1)

In clockwise direction to increase pressure, and

opposite to decrease it.

You must use the tool only when the pressure in the

tank is higher than the pressure of use of the tool.

ÜTo use your compressor correctly, only use it

intermittently, i.e. 60% of use for 40% of

downtime.

Beyond this limit, the engine risks overheating

problems.

- PRECAUTIONS TO PAINT:

If the electric motor and the interior of the pump are

dirty, your compressor life expectancy will be

reduced:

ÜIn order to avoid this problem, only move away

the compressor by lengthening the tube of your

tool.

-OPERATINGTIME:

Page 2 Page 7

- USING APNEUMATIC EXTENSION:

ÜFor pressures higher than 7 bar, use pipes

reinforced with steel braid.

ÜCheck that the compressor has not been

damaged during the transport.

ÜThe switch (Ref: A, Pict.1) must be in position

«Off».

ÜConnect in a socket-outlet:

- Of 16 Amps under 230V.

- Connected to the ground.

- Connected to a differential protection.

- USING AN ELECTRIC EXTENSION:

- BEFORE USE:

ÜPlease only use an extension if absolutely

necessary.

We recommend the following dimensions: 5 meters

maximum length with section of wire of 2,5mm ².

ÜToo small diameter wire sections and big lengths

would cause serious damage to the engine.

ÜIt is better to extend air pipe, which also will give

you stock of air. F.MURET

ThePresident

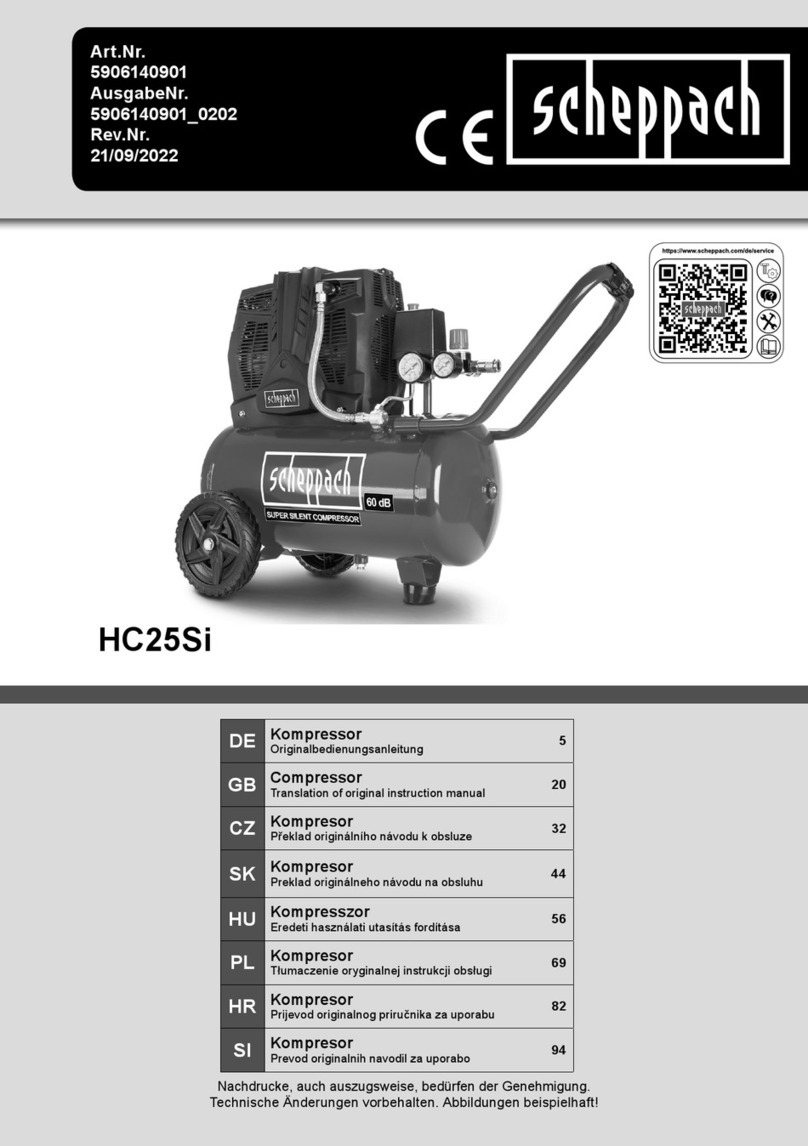

Buc the 2015-03-03

- Manufacturer's logo

- PT = Setting pressure 8 bar

- Q = Maximum opening flow 1895 l/min

- Input threading : 1/4" gaz

- Input pressure rated : 25 bar

- Opening diameter : 6 mm

- Opening area : 28,26 mm²

- Fluid type : Compressed air

- Working temperature : NBR -10°C +90°C

- The used materials fit to good functioning according to the working conditions and the

aforementioned fluids.

- The technical data that identify the safety valve are indicated on the plate.

- The mechanical locking of the setting is obtained by the application of a glue-sealing (Loctite

270).

-The setting of the safety valve is secured by a final punching on the body of the safety

valve.

- Satisfactory results were obtained after the final check and after the hydraulic test carried

out at 37,5 bar.

- The setting of this safety valve, carried out at T°=20°C, garantees an opening beginning

and a mawimum outflow according to the indicated values in the technical characteristics.

- These values are recalled on the identification sticker set on the security valve.

- Identification of the marking: PT= Setting pressure D= Opening diameter and Q= Flow

to full opening for the compressed air.

AUTOMATICSAFETYVALVECERTIFICATE

FOR SIMPLE PRESSURE TANKS CATEGORY1

REF:631408

TECHNICAL CHARACTERISTICS:

USEDMATERIAL:

a-Body valve :BRASS UNI EN 12164

b-Rubber gasket :NBR - VITON

c-Obturating :BRASS UNI EN 12164

d-Spring stop :BRASS UNI EN 12164

e-Spring :STEEL C98 UNI 3823

f-Conical tapped :BRASS UNI EN 12164

g-Plate :PLASTIC

h-Ring :STEEL C75

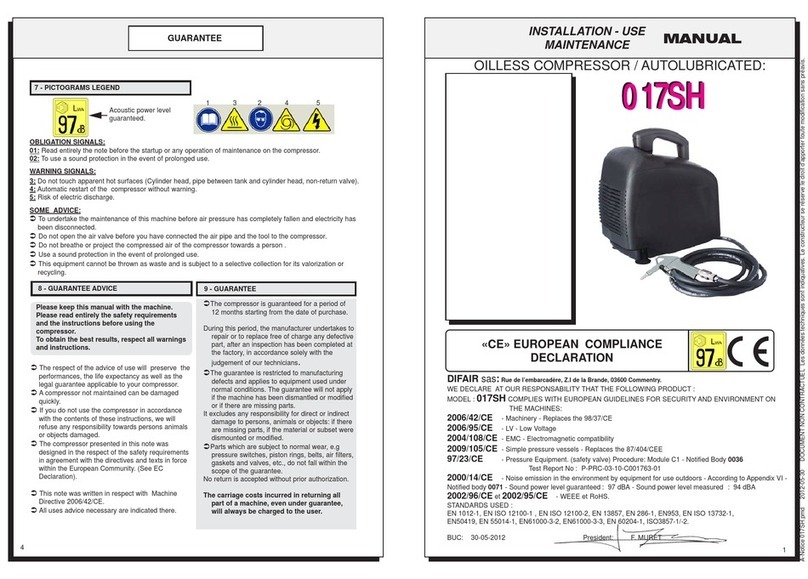

"CE"EUROPEAN COMPLIANCE DECLARATION

WEDECLAREUNDEROURRESPONSABILITYTHATTHISVALVECOMPLIESWITH

THESAFETYRULESREQUIREDINKEEPINGWITH:

European directive : 2006/42/CE - 97/23/CE (This soupape was classified

according to the annex II § 2 and therefore evaluated according to unit A)

This security valve is uniquely destined to equip simple pressure tanks

or equipments category 1.

Applied rule : ISO 4126-1

PRODIF : ZACdu PréClos -500 rueClément Ader- 78530BUC

Page 3

GUARANTEE

8- GUARANTEE

ÜThe compressor is guaranteed for a period of

12 months starting from the date of purchase.

During this period, the manufacturer undertakes

to repair or to replace free of charge any

defective part, after an inspection has been

completed at the factory, in accordance solely

with the judgement of our technicians.

ÜThe guarantee is restricted to manufacturing

defects and applies to equipment used under

normal conditions. The guarantee will not apply if

the machine has been dismantled or modified or

if there are missing parts.

It excludes any responsibility for direct or indirect

damage to persons, animals or objects: if there

are missing parts, if the material or subset were

dismounted or modified.

ÜParts which are subject to normal wear, e.g

pressure switches, piston rings, belts, air filters,

gaskets and valves, etc., do not fall within the

scope of the guarantee.

No return is accepted without prior authorization.

The carriage costs incurred in returning all

part of a machine, even under guarantee, will

always be charged to the user.

ÜThe respect of the advice of use will preserve

the performances, the life expectancy as well as the

legal guarantee applicable to your compressor.

ÜA compressor not maintained can be damaged

quickly.

ÜIf you do not use the compressor in accordance

with the contents of these instructions, we will refuse

any responsibility towards persons animals or objects

damaged.

ÜThe compressor presented in this note was

designed in the respect of the safety requirements in

agreement with the directives and texts in force within

the European Community. (See EC Declaration).

ÜThis note was written in respect with Machine

Directive 2006/42/CE.

ÜAll uses advice necessary are indicated there.

Please keep this manual with the machine.

Please read entirely the safety requirements

and the instructions before using the

compressor.

To obtain the best results, respect all warnings

and instructions.

7-GUARANTEEADVICE

-For any communication with the distributor, please

indicate the identification sticker data of the product

-The sticker is applied on the side of the compressor.

IDENTIFICATION STICKER OF THE PRODUCT

Model reference

6 - COMMUNICATION- TRACKING PRODUCT

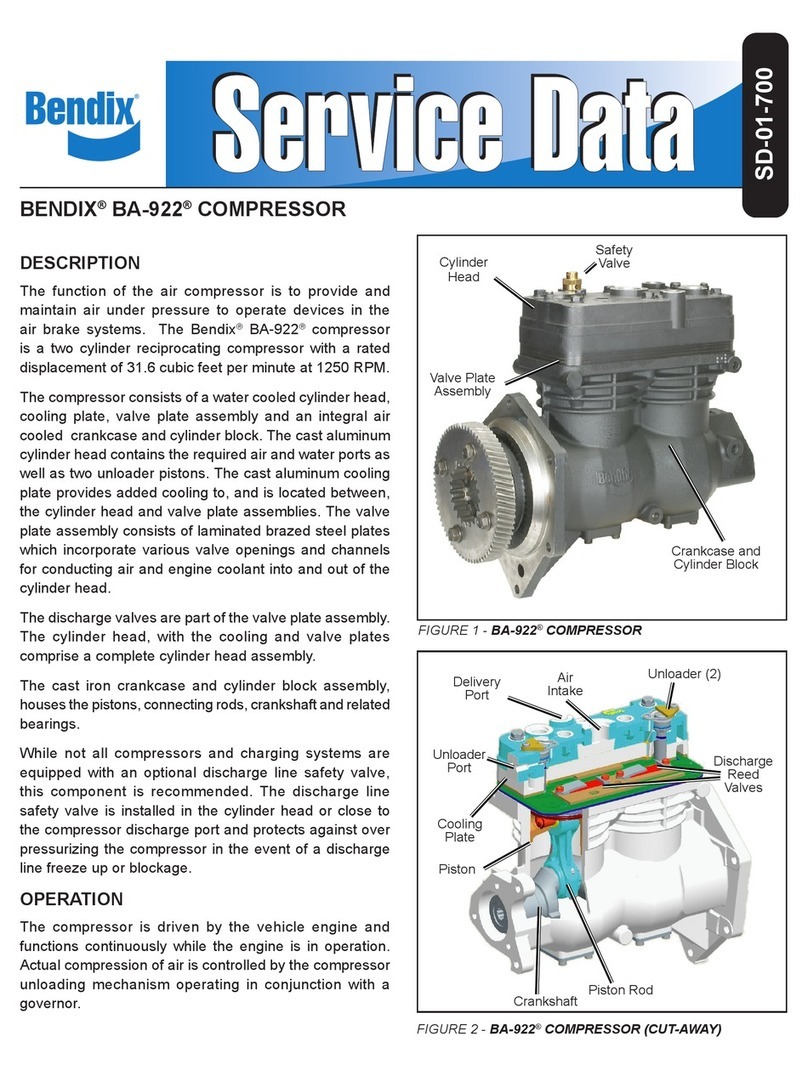

4-MAINTENANCE

Abnormal noises, vibrations:

-Loosened or worned parts.

-Worn group (mechanical noises).

-Bad chocking of the compressor.

Low flow rate, pressure does not increase:

-Air filter is dirty, you must clean it.

-Air pressured is leaking by the connections, check the

connections.

-Cylinder valves are broken or valve seat gasket torn,

you must check the pump.

-Excessive consumption by the segmentation, gasket

leakages, you must check the pump.

Impossible adjustment of the output air pressure:

- The internal diaphragm of the pressure reducer is torn

(Ref: 41, Pict.2) replace it.

5 - FAULTS / SOLUTIONS

ÜAvoid any degradation of the electric cable and

move away from heat sources higher than 70°C.

ÜAt the end of work, unplug the cable and roll up it

around the handle of the compressor.

ÜDo not use the compressor with bare or wet feet.

ÜDo not to touch the compressor with wet hands.

ÜDo not pull the cord to move the compressor or

to remove the plug.

ÜDo not allow children to use the compressor.

ÜDo not leave the compressor without monitoring

when it is connected; it can become source of

dangers.

ÜThe electric safety of this machine is assured

only when it is correctly connected with an

efficient grounding connection , as recommended

in the rules of electric safety requirements

ÜYour compressor is self lubricated (no oil).

ÜRoutine maintenance does not require

specializedpersonnel.

ÜThe maintenance of the pump and other more

complex organs, must be made by qualified

technician: Seek your dealer.

Specifications

The compressor don't stop or at another

pressure value:

- Defective valve of the pressure switch, change

it. (Contact a Reseller)

Pressure does not rise into the tank:

-No return valve blocked by an impurity or worn,

clean or change the no return valve or the internal

rubber valve with its spring. (Ref: 49, Pict.2)

The compressor does not start:

- No electrical supply.

-The compressor is already in pressure, empty the

tank.

The compressor starts with difficulty:

-The electric tension is insufficient. (210V Minimum).

-Electrical supply cord is too long, or wire section too

small. (electric cable coil)

-Engine overload by cold weather.

MAINTENANCE

FAULTS/ SOLUTIONS

MARKING

Page 6

Pictograms key:

1 -Read carefully this manual before startup or any

maintenanceoperation.

2 -Use a sound protection in the event of prolonged

use.

3 -Risk of electric discharge.

4 -Disconnect electricity before undertaking

compressor maintenance.

5 -Do not open the air valve before you have

connected the air pipe and the tool to the

compressor.

6 -Do not breathe or project towards a person the

compressed air of the compressor.

7 -This equipment cannot be thrown as waste and is

subject to a selective collection for its valorization or

recycling.

1 2 3 4 5 6 7

Acoustic power level

guaranteed.

“CE” EUROPEAN COMPLIANCE

DECLARATION

PRODIF : ZAC du pré clos - 500 rue Clément Ader - 78530 BUC

WE DECLARE AT OUR RESPONSABILITY THAT THE FOLLOWING PRODUCT :

MODEL : SIL06J

COMPLIES WITH EUROPEAN GUIDELINES FOR SECURITY AND ENVIRONMENT ON THE

MACHINES:

2006/42/CE - Machinery - Replaces the 98/37/CE

2006/95/CE- LV - Low Voltage

2004/108/CE - EMC - Electromagnetic compatibility

2009/105/CE - Simple pressure vessels - Replaces the 87/404/CEE

2000/14/CE - Noise emission by equipment used outdoors -Procedure: Annexe VI

Sound power level guaranteed:59 dBA - Sound power level measured: 48 dBA

2002/96/CE et 2002/95/CE - WEEE et RoHS.

STANDARDS USED : EN 1012-1, EN ISO 12100-1 , EN ISO 12100-2, EN 13857, EN 286-1, EN953, EN ISO

13732-1,EN50419, EN 55014-1, EN61000-3-2, EN61000-3-3, EN 60204-1, ISO3857-1/-2.

BUC: The 2015-03-03 Le président: F . MURET

Page 4 Page 5

PICTURES

SPARE PARTS PICTURES

SPARE PARTS

G-

P-

-U

-C

A- B-

Pict.1

Pict. 2 : SIL06J

FER EDOC NOITPIRCSED

04 **MC5103 M"4/1relpuockciuQ

14 *2611 relpuockciuQ+recudererusserP

24 *9901 "8/1-04Ø,eguagerusserP

34 *M5911 "4/1-05Ø,eguagerusserP

44 *1241 "4/1rotcennoC

54 *804136 rab8ottesevlavytefaS

64 *1480P *4183R htiw"4/1x3_"8/3x1rab8hctiwserusserP F"4/1_M"8/3noitcuder

74 74060LIS Fµ02-CAV054roticapaC

84 84060LIS revocroticapaC

94 94060LIS "8/3evlavnruteroN

05 05060LIS ebutgnidaolpU

15 15060LIS noitcennocelbixelF

25 25060LIS knaT

35 35060LIS eveelseldnaH

45 **M0491 "4/1evlavniarD

95 *6152 m2gL1x3gulpcirtcelE

06 J60LISPK .wercsgnitnuomhtiwteefrebbur4fokcaP

Pict. 3 : PUMP YW400

FER EDOC NOITPIRCSED

71 710004WY evlavnoisserpmoC

81 810004WY etalpevlaV

91 910004WY evlavnoitcuS

12 120004WY nafthgiR

22 220004WY tfahsknarC

32 320004WY Z2-6006gniraeB

62 620004WY esacknarcthgiR

72 720004WY etalP

13 130004WY rotatS

33 330004WY rotoR

43 430004WY Z2-3026gniraeB

53 530004WY colbtnelisnoitarbiV

83 830004WY retlifriA

93 930004WY woblE

FER EDOC NOITPIRCSED

1 100004WY draugevitcetorP

2 200004WY naftfeL

3 300004WY esacknarctfeL

4 400004WY dorgnitcennoC

5 500004WY pucnotsiP

6 600004WY etalpredniB

7 700004WY 001x6M09/cHFtloB

8 800004WY rednilyC

9 900004WY taesevlav,teksaG

01 010004WY daehrednilyc,teksaG

11 110004WY daehrednilyC

21 210004WY 52x5McHCtloB

31 310004WY 7,21ØgnirgnitarutbO

41 410004WY 7,21ØepipgnitcennoC

61 610004WY reniater evlaV

Other Prodif Air Compressor manuals

Popular Air Compressor manuals by other brands

Livoo

Livoo TEA306 user manual

Drum

Drum SC200 Installation operating & maintenance manual

Scheppach

Scheppach AIR FORCE 5 Translation of original instruction manual

Vmac

Vmac VR70 installation manual

Black & Decker

Black & Decker 9045854BND Instruction manual for owner's use

Sullair

Sullair LS12 Operators manual and parts lists

Brooks

Brooks 8200 Installation & operation manual

Craftsman

Craftsman 107.16575 owner's manual

Vmac

Vmac H400005 Installation and owner's manual

Scheppach

Scheppach HC25Si Translation of original instruction manual

Parkside

Parkside PKO 270 A3 Operation and safety notes

FScurtis

FScurtis CA series Installation and operation manual