Maxair MEGA-MAX OPEN VERTICAL 6000 User manual

MEGA-MAX

OPEN

VERTICAL 6000

MEGA-MAX VERTICAL-6000

USE AND MAINTENANCE MANUAL

2807 PEDDLER LANE, KERRVILLE TEXAS USA 78028

WARNING!

DO NOT USE WITH ENRICHED AIR

SYSTEMS, ABOVE 21% OXYGEN,

(THE USE OF ENRICHED AIR WILL

VOID MANUFACTURES WARRANTY)

Revised 6-30-21

Page 2 Mega-MaxTM 6000 Use and Maintenance Manual

Model No. Mega-Max 6000 Date Mfg. ____________________

Serial No. ______________________________________________________

Final Pressure Switch Set At ____________________

Final Safety Relief Set At ____________________

oSingle Phase oThree Phase

o50hz o60hz

Horse Power ____________________

Voltage ____________________

acp0117

Use and Maintenance Manual Mega-MaxTM 6000 Page 3

MEGA-MAXTM 6000

2807 Peddler Lane West • Kerrville • Texas 78028 • USA

Tel. (830) 257-5006 • Fax (830) 257-3720 • e-mail: service@max-air.com

HIGH PRESSURE COMPRESSOR FOR BREATHING AIR

WARNING!

DO NOT USE WITH ENRICHED AIR

SYSTEMS, ABOVE 21% OXYGEN

(the use of enriched air, above 21% oxygen,

will void manufacturer’s warranty)

BEFORE USING THE COMPRESSOR READ THIS MANUAL

CAREFULLY

IMPORTANT:

Page 4 Mega-MaxTM 6000 Use and Maintenance Manual

Dear Customer,

Thank you for choosing Max-Air, where quality and commitment give you the best in technology and support

available today. This manual is provided together with the compressor to aid you in the use of the machine and

ensure that your compressor produces the best possible results.

Please read all the instructions and information provided on the following pages. Ensure that the manual is at

the disposal of the personnel who will be using/managing the compressor and carrying out any maintenance

on it.

Should you require any clarification, when using the compressor for the first time or at any other time it is used,

please remember that Max-Air is at your complete disposal.

Should you need to contact us our fax number is: (830) 257-3720 and our e-mail is: service@max-air.com

For routine or unscheduled maintenance note that Max-Air’s international technical service is able to provide

you with assistance and spare parts when required.

To ensure that your requests are dealt with quickly the following information is provided:

Manufacturer’s data: Max-Air

2807 Peddler Lane West

Kerrville, Texas 78028, USA

Tel: (830) 257-5006

Fax: (830) 257-3720

http://www.max-air.com

e-mail: service@max-air.com

Use and Maintenance Manual Mega-MaxTM 6000 Page 5

CHAPTER 1 - GENERAL 8

1.1 Preliminary information 8

1.2 Required operator training 9

1.3 Important information for the user 9

1.4 Foreword 10

1.5 Warranty 10

1.6 Assistance 11

1.7 Responsibility 11

1.8 Purpose of the machine 12

1.9 Where the machine may be used 14

1.10 Running in and testing the compressor 14

CHAPTER 2 - BASIC INFORMATION ON THE COMPRESSOR 15

2.1 Description of the compressor 15

2.2 Identifying the compressor 15

2.3 General instructions 16

CHAPTER 3 - SAFETY REGULATIONS 17

3.1 General safety rules 17

3.1.1 Know the machine 18

3.1.2 Wear protective clothing 17

3.1.3 Keep emergency equipment nearby 17

3.1.4 Warn others when doing checks/maintenance 17

3.2 General precautions 18

3.2.1 Important safety information 19

3.2.2 Accident prevent 19

3.2.3 Working safety 19

3.2.4 Safety info labels: location 20

3.2.5 Safety info labels: description 20

3.2.6 Residual risk zones 22

3.3 General safety regulations 23

3.3.1 Care and maintenance 23

3.3.2 Fire extinguishers and first aid 23

3.4 Maintenance precautions 24

3.4.1 Warning plates 24

3.4.2 Tools 24

3.4.3 Personnel 24

3.4.4 Keep the compressor clean 24

3.4.5 Periodic replacement of essential safety parts 24

CHAPTER 4 - TECHNICAL DATA 25

4.1 Technical characteristics 25

4.1.1 Monoblock, gooseneck, cylinders, pistons 25

4.1.2 Valves 25

4.1.3 Safety valves 25

4.1.4 Cooling pipes, lubrication 25

4.1.5 Frame, guards 25

4.1.6 Technical specifications table 26

4.1.7 Noise level 26

4.1.8 Dimensions and weight 27

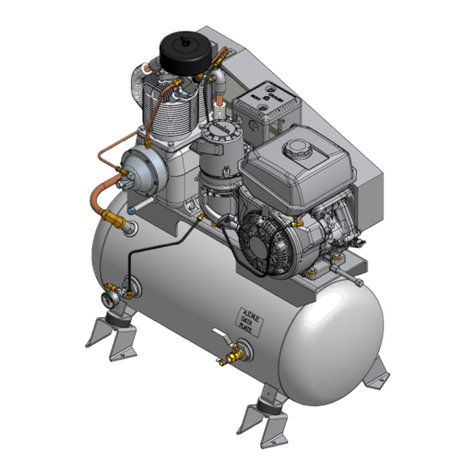

4.1.9 Machine parts 28

CONTENTS

Page 6 Mega-MaxTM 6000 Use and Maintenance Manual

CHAPTER 5 - HANDLING AND INSTALLATION 29

5.1 Unpacking 29

5.2 Handling 29

5.3 Installation 29

5.3.1 Positioning 29

5.3.2 Air intake extension connection 30

5.3.3 Reload hose connection 30

5.3.4 Electrical connection 31

CHAPTER 6 - USING THE COMPRESSOR 32

6.1 Preliminary checks before using for the first time 32

6.1.1 Filling with lubricant oil 32

6.1.2 Checking for proper electrical connection 32

6.2 Checks to be run at the start of each working day 33

6.2.1 Lubricating oil level check 33

6.2.2 Checking that the refill hoses are in good condition 33

6.2.3 Storing technical documentation 33

6.3 Control panel 34

6.3.1 Power indicator light 34

6.3.2 Stop-Emergency pushbutton 35

6.3.3 Hour counter 36

6.3.4 Lubrication oil circuit pressure gauge 36

6.3.5 1st stage pressure gauge 37

6.3.6 2nd stage pressure gauge 37

6.3.7 3rd stage pressure gauge 37

6.3.8 4th stage pressure gauge (final pressure) 37

6.3.9 Machine status fault light 38

6.3.10 Refill hose connection 38

6.4 Preliminary tasks 39

6.4.1 Safety valve checks 39

6.4.2 Automatic condensate discharge 40

6.5 Bottle refill 41

CONTENTS

Use and Maintenance Manual Mega-MaxTM 6000 Page 7

CHAPTER 7 - MAINTENANCE 42

7.1 Foreword 42

7.2 General 42

7.3 Unscheduled maintenance 42

7.4 Scheduled maintenance table 43

7.5 Troubleshooting 43

7.6 Checking and changing the lubricating oil and filter 44

7.6.1 Oil table 44

7.6.2 Checking the oil level 44

7.6.3 Changing the lubricating oil and filter 45

7.7 Changing the intake filter 46

7.8 Checking the safety valve 47

7.9 Transmission belts 47

7.10 Condensate discharge 48

7.10.1 Automatic condensate discharge 48

7.11 Active carbon filters / molecular sieve 49

7.11.1 Filter replacement frequency calculation table 49

7.11.2 Changing the active carbon filters 49, 50

7.12 Changing the flex hoses 51

CHAPTER 8 - STORAGE 52

8.1 Stopping the machine for a brief period 52

8.2 Stopping the machine for a long period 52

CHAPTER 9 - DISMANTLING AND PUTTING OUT IF SERVICE 53

9.1 Waste disposal 53

9.2 Dismantling the compressor 53

CHAPTER 10 - INSTRUCTIONS FOR EMERGENCY SITUATIONS 54

10.1 Fire 55

CHAPTER 11 - MAINTENANCE REGISTER 55, 56, 57

CHAPTER 12 - NOTES 58, 59, 60

CONTENTS

Page 8 Mega-MaxTM 6000 Use and Maintenance Manual

1.1 - PRELIMINARY INFORMATION

Do not destroy or modify the manual and update it with additional inserts only.

Manual P/N: MM-6000-UMM06

Revision no: 00 Edition: 09/2006

Machine type: High pressure compressor for breathing air

Model: MEGA-MAX 6000

Manufacturer’s data: Max-Air

2807 Peddler Lane West

Kerrville, Texas 78028, USA

Tel: (830) 257-5006

Fax: (830) 257-3720

http://www.max-air.com

e-mail: service@max-air.com

1 - GENERAL

Chap. 1 - General

Use and Maintenance Manual Mega-MaxTM 6000 Page 9

1.2 - REQUIRED OPERATOR TRAINING

This manual must be read carefully:

- all compressor operators / maintenance personnel must read this entire manual with due care and attention and

observe the instructions/information contained herein.

- employers must ensure that the operator has the required aptitude for operation of the compressor and that he/she

has read the manual.

1.3 - IMPORTANT INFORMATION FOR THE USER

The information/instructions for use contained in this manual concern the Max-Air

compressor Mod. Mega-Max 6000 only.

The instruction manual must be read and used as follows:

- read this manual carefully; treat it as an essential part of the compressor;

- the instruction manual must be kept where it can readily be consulted by compressor operators and maintenance

staff;

- keep the manual for the working life of the compressor;

- make sure updates are incorporated in the manual;

- make sure the manual is given to other users or subsequent owners in the event of resale;

- keep the manual in good condition and ensure its contents remain undamaged;

- do not remove, tear or re-write any part of the manual for any reason;

- keep the manual protected from moisture and heat;

- if the manual is lost or partially damaged and its contents cannot be read it is advisable to request a copy from the

manufacturer.

Important: you must understand the following symbols and their meaning. They highlight essential information:

Refers to additional information or suggestions for proper use of the compressor.

IMPORTANT:

Refers to dangerous situations that may occur during use of the compressor:

aims to ensure worker safety.

DANGER:

Refers to dangerous situations that may occur during use of the compressor:

aims to prevent damage to objects and the compressor itself.

WARNING:

Chap. 1 - General

Page 10 Mega-MaxTM 6000 Use and Maintenance Manual

1.4 - FOREWORD

The regulations/instructions for use contained in this manual constitute an essential component of the supplied

compressor.

These regulations/instructions are intended for an operator who has already been trained to use this type of

compressor. They contain all the information necessary and essential to safety and efficiency, proper use of the

compressor.

Hurried, incomplete preparation results in mistakes and this often leads to accidents.

Before beginning work, read the following suggestions carefully:

1) before using the compressor, gain familiarity with the tasks to be completed and the admissible working

position;

2) the operator must always have the instruction manual on hand;

3) program all work with due care and attention;

4) you must have a detailed understanding of where and how the compressor is to be used;

5) before starting work make sure that safety devices are working properly and that their use is understood; in

the event of any doubts do not use the compressor;

6) observe the warnings given in this manual with due care and attention;

7) constant and careful preventive maintenance will always ensure a high level of safety when using the

compressor. Never postpone repairs and have them carried out by specialized personnel only; use only

original spare parts.

1.5 - WARRANTY

Max-Air shall repair or replace those parts it acknowledges to be faulty during the warranty period.

In replacing the faulty part Max-Air shall not be liable for any other expenses sustained by the dealer or his

customer such as presumed damage (present or future), lost earnings or fines.

Routine and unscheduled maintenance must be carried out in compliance with the instructions contained

in this manual. Should the required work not be covered by the manual or assistance be required you are

advised to contact Max-Air directly by email, even where agreements have already been made on the phone.

Max-Air cannot be held liable for any delays or failure to execute work.

Max-Air cannot be held liable for any damage or malfunctions caused by work carried out on the compressor

by unauthorized personnel.

IMPORTANT:

Chap. 1 - General

The materials supplied by Max-Air are covered by a 12-month warranty, the validity of which begins on the

date of delivery as proven by the delivery document.

Max-Air guarantees that its compressors are free from defects vis-à-vis design, workmanship and the used materials

for a period of 12 months starting from the date of delivery of the compressor; should the customer note any flaws

and/or defects they must report them, in writing, to Max-Air within 14 (fourteen) days of delivery otherwise the

warranty could be rendered null and void. The warranty only covers flaws and faults that occur where the

compressor is used properly in compliance with the instructions contained in this manual and where periodic

maintenance is carried out. The warranty does not cover faults caused by improper use of the compressor,

exposure to atmospheric agents (rain etc.) or damage during transport; all materials subject to wear and those

subject to periodic maintenance are not covered by the warranty and are to be paid for by the customer in full; in

any event the warranty is rendered null and void if the compressor is tampered with or if work is carried out on it by

personnel who have not been authorized by Max-Air.

Use and Maintenance Manual Mega-MaxTM 6000 Page 11

1.6 - ASSISTANCE

Max-Air technicians are at your disposal for all routine/unscheduled maintenance work. Please forward your request

for assistance to Max-Air by calling, sending a fax or e-mail to:

Tel. (830) 830-5006

Fax. (830) 257-3720

service@max-air.com

1.7 - RESPONSIBILITY

Max-Air considers itself exonerated from any responsibility or obligation regarding injury or damage caused by:

- failure to observe the instructions contained in this manual that concern the running, use and maintenance of the

compressor;

- violent actions or incorrect maneuvers during use or maintenance of the compressor;

- modifications made to the compressor without prior written authorisation from Max-Air;

- incidents beyond the scope of routine, proper use of the compressor.

In any case, should the user impute the incident to a defect of the compressor, he/she must demonstrate that the

damage has been a major and direct consequence of this “defect”.

Maintenance and repairs must only be carried out using original spare parts.

Max-Air cannot be held liable for any damages caused by failure to observe this

rule. The compressor is guaranteed as per the contractual agreements made

at the time of sale. Failure to observe the regulations and instructions for use

contained in this manual shall render the warranty null and void.

WARNING:

Chap. 1 - General

A compressor that has been acknowledged as faulty on account of flaws in design, workmanship or materials shall

be repaired or replaced free of charge by Max-Air at its plant in Kerrville, Texas; costs regarding transport,

delivery of spare parts and any materials subject to wear shall be met by the customer. Should warranty-covered

work need to be carried out on the customer’s premises, travel and accommodation costs for personnel sent by

Max-Air shall be met by the customer. The act of taking delivery of machines and/or faulty components or the

sending of technicians to assess the presumed defects and/or flaws reported by the customer does not in itself

imply acknowledgement that the defect is covered by warranty. Repairs and/or replacements made by Max-Air

during the warranty period do not in any way prolong the latter itself. Acknowledgement that a defect is

covered by warranty does not in itself mean that Max-Air is in any way liable to award compensation. Max-Air

cannot be held liable for any other direct or indirect damages imputable to compressor defects and flaws (loss of

production or earnings etc.) except in cases where serious negligence is demonstrated.

Page 12 Mega-MaxTM 6000 Use and Maintenance Manual

1.8 - PURPOSE OF THE MACHINE

- Use only tested, certified bottles: do not exceed the working pressure indicated on

them.

- Aspirate unpolluted air that is not stale.

Use the compressor in areas free from dust, risk of explosion, corrosion and fire.

- It is forbidden to use the compressor with an internal combustion engine indoors.

Make sure that air intakes are a long way from fume exhausts.

- Improper use could have serious consequences for the user.

- Do not disconnect the hose from the fittings or the clamp when under pressure.

- Change the air purification filters regularly as described in section “7.11.2 Changing

the active carbon filters”.

- Drain the condensate regularly as illustrated in section “7.10 Condensate discharge”.

- The power breaker must be switched off:

- if there is a problem during use

- before carrying out any cleaning or maintenance tasks.

- Never pull the plug out, if so equipped, by tugging the lead, if so equipped.

Make sure the lead is not bent at a sharp angle and that it does not rub against

any sharp edges. Use of extensions is advised.

- Never run the compressor when:

- the power lead is damaged;

- there is evident damage;

- the side doors are open.

- All routine and unscheduled maintenance tasks must be carried out with the

compressor at standstill, the electrical power supply disconnected and the pumping

circuit depressurized, including purifier system.

DANGER:

Chap. 1 - General

The compressor mod. Mega-Max 6000 has been designed and built for the purpose of obtaining excellent quality

breathing air by drawing it from the surrounding environment. The air is free from any harmful fumes. The air is

passed through an intake filter and, after the filtration cycle, is stored in bottles constructed to contain air at high

pressure. Any other use is inappropriate: the manufacturer cannot be held liable for any personal injury or damage

to objects or the machine itself caused by improper use.

Use and Maintenance Manual Mega-MaxTM 6000 Page 13

- After switching off the compressor wait about 30 minutes before carrying out any

maintenance tasks so as to prevent burns.

- The high pressure flex hose that connects to the bottle (also called the refill hose)

must be in good condition, especially in the areas near the fittings.

The plastic sheath that covers the pipe must not show any signs of abrasion otherwise

moisture could get in, corrode the steel braid and weaken it.

The hose must be changed periodically (yearly) or when it shows signs of wear. Failure

to observe this rule could seriously endanger the users’ safety.

Make sue the minimum bending radius of the hose is no less than 250 mm (9¾”).

DANGER:

- Before carrying out any work on the compressor each operator must have a perfect

understanding of how the compressor works, know how to use the controls and have

read the technical information contained in this manual.

- It is forbidden to use the compressor under conditions / for purposes other than those

indicated in this manual and Max-Air cannot be held liable for breakdowns, problems

or accidents caused by failure to observe this rule.

- Check that the fittings provide a proper seal by wetting them with soapy water: eliminate

any leaks.

- Do not attempt to repair high pressure hoses by welding them.

- Do not empty the bottles completely, not even during winter storage as this practice

prevents damp air getting in.

- It is forbidden to tamper with, alter or modify, even partially, the systems and equipment

described in this instruction manual, especially as safety guards and safety symbols

are concerned.

- It is also forbidden to carry out work in any way other than that described or to neglect

the illustrated safety tasks.

- The safety information and the general information given in this manual are highly

important.

DANGER:

To ensure maximum working efficiency, Max-Air has constructed the compressor with carefully selected components

and materials. The compressor is tested prior to delivery. Continued compressor efficiency over time will also depend

on proper use and maintenance as per the instructions contained in this manual.

All the components, connections and controls used in its construction have been designed and built to a high degree

of safety so as to resist abnormal strain or in any case a strain greater than that indicated in the manual. Materials are

of the finest quality; their introduction and storage in the company and their utilization in the workshop are controlled

constantly so as to prevent any damage, deterioration or malfunction.

Chap. 1 - General

Page 14 Mega-MaxTM 6000 Use and Maintenance Manual

1.9 - WHERE THE MACHINE MAY BE USED

The compressor mod. Mega-Max 6000 has been designed and built for the purpose of obtaining excellent quality

breathing air by drawing it from the surrounding environment, free from any harmful fumes.

The air is passed through an intake filter and, after the filtration cycle, is stored in bottles constructed to contain air

at high pressure. The compressor must only be used in environments having the characteristics described in the

following table.

AREA OF MACHINE USE: ESSENTIAL DATA TABLE

Characteristic Unit of measure Data

Temperature °F (°C) min. -4°F - Max. +113°F (min. -20°C - Max. +45°C)

Air humidity (%) max. 80%

Max admissible wind when in use (m/s) max. 15

rain

Tolerated weather conditions hail None

snow

1.10 - RUNNING IN AND TESTING THE COMPRESSOR

- after starting let the compressor run on free flow for 5-6 minutes.

- change the compressor oil;

- change the oil filter;

- check and adjust nuts, bolts and belts.

When changing the oil filter, inspect the internal parts and check for any deposits;

if they are present track down the cause before restarting the compressor.

WARNING:

Chap. 1 - General

After the first 65 hours,carry out - in addition to the scheduled maintenance - the following tasks:

Each compressor is carefully adjusted and tested prior to delivery.

A new compressor must be used with caution during the first 50 working hours so as to complete proper break-in of

its components. If the compressor is subject to an excessive workload during initial use, its potential efficiency

will be prematurely compromised and functionality soon reduced.

During the break-in period proceed as follows:

Check that the area in which the compressor is to

be positioned is adequately ventilated: no dust and

no risk of explosion, corrosion or fire. If ambient

temperatures exceed 113°Fair conditioning will be

required. Position the compressor no closer

than 2 feet to surrounding walls; the gap between

compressor and ceiling should be at least 3 feet.

These distances ensure proper compressor operation

and proper cooling of the pumping unit. Make sure that

lighting in the area is sufficient to identify every detail

(such as the writing on the info plates/stickers);

use artificial lighting where daylight on its own is

insufficient.

3'

2'

2'

Use and Maintenance Manual Mega-MaxTM 6000 Page 15

2.1 - DESCRIPTION OF THE COMPRESSOR

2.2 - IDENTIFYING THE COMPRESSOR

2 - BASIC INFORMATION ON THE COMPRESSOR

High pressure compressor for breathing air.

Compatible process gases:

- Carbon dioxide

- Nitrogen (also dry)

- Benzene

- Butadiene

- Helium

- Sulphur hexafluoride

- Natural gas

- Synthesis gas

- Hydrogen

- Methane

- Carbon monoxide

- Propane

Note: Some gasses will require modifications - call Max-Air

for instructions

Each compressor has an identification serial # located on the block, manual (page 2) and identification sheet.

Chap. 2 - Basic information on the compressor

Page 16 Mega-MaxTM 6000 Use and Maintenance Manual

2.3 - GENERAL INSTRUCTIONS

- This manual must be read carefully before transporting, installing, using or carrying

out any maintenance on the compressor.

- It must be preserved carefully in a place known to compressor users, managers and all

transport/installation/maintenance/repair/final dismantling personnel.

- This manual indicates the purposes for which the compressor can be used and gives

instructions for its transport, installation, assembly, adjustment and use. It also

provides information on maintenance tasks, ordering spare parts, residual risks and

staff training.

- The use and maintenance manual can never replace proper experience; some

maintenance jobs are particularly difficult and in this regard the manual only offers

general guidelines on the most important tasks, which must be carried out by personnel

with proper training (e.g. acquired during training courses run by the manufacturer).

- This manual is an integral part of the compressor and must be stored in a suitable

container near the compressor until its final demolition. If the manual is lost or damaged

a copy can be requested from the manufacturer.

- Make sure all users have understood the regulations for use and the meaning of the

symbols on the compressor.

- Observance of these technical instructions can prevent accidents: instructions have

been drawn up in compliance with EEC Machinery Directive 89/392 and subsequent

amendments.

- In any case always observe national safety regulations.

- Do not remove or damage guards, labels or notices, especially those required by law.

- The adhesives attached to the compressor are there for safety purposes. They must be

replaced if they become illegible.

- This manual reflects the technical knowledge available at the time the compressor was

sold and cannot be considered inadequate simply because updated at a later time on

the basis of new experience.

- The manufacturer reserves the right to update products and manuals, without

any obligation to update preceding products or manuals except in exceptional

circumstances.

- To request or receive any updates or additions to this use and maintenance manual

(which shall be considered an integral part of the manual) apply via the contact

numbers given on page 11.

- Should you have any other queries or suggestions as to how to improve the manual

please contact the manufacturer.

- Should you sell the compressor Max-Air invites you to provide us with the details of the

new owner so that any new additions to the manual can be sent on.

WARNING:

Chap. 2 - Basic information on the compressor

Use and Maintenance Manual Mega-MaxTM 6000 Page 17

3.1 - GENERAL SAFETY RULES

3 - SAFETY REGULATIONS

3.1.1 - KNOW THE MACHINE

The compressor must only be used by qualified personnel. They must have an understanding of the arrangement

and function of all the controls, instruments, indicators, warning lights and the various info plates/labels.

3.1.2 - WEAR PROTECTIVE CLOTHING

All operators must use accident prevention items such as

gloves, hard hat, eye goggles, accident prevention shoes

and ear defenders against noise.

3.1.3 - KEEP EMERGENCY EQUIPMENT NEARBY

Make sure a first aid cabinet and a CO2fire extinguisher are

near the compressor.

Keep the extinguisher fully loaded. Use according to

standards in force.

3.1.4 - WARN OTHERS WHEN DOING CHECKS/MAINTENANCE

Apply a sign with the legend: “TESTING IN PROGRESS” on

all sides of the compressor.

Check the compressor carefully every day it is used as per

the task list given in this manual.

Chap. 3 - Safety regulations

Page 18 Mega-MaxTM 6000 Use and Maintenance Manual

3.2 - GENERAL PRECAUTIONS

The EEC Machinery Directive 89/392 provides the following definitions (appendix 1, 1.1.1):

«DANGEROUS ZONE»: any zone inside and/or near a machine in which the presence

of an exposed person constitutes a risk for his/her security and health.

«EXPOSED PERSON»: any person wholly or partially inside a dangerous zone.

«OPERATOR»: the person(s) charged with the task of installing, running, maintaining, cleaning, repairing and

transporting the machine.

- Before carrying out any task or operation with the compressor it is compulsory to read and follow the

instructions given in the use and maintenance manual. Doing so during work is too late: improper use or an

erroneous maneuver could cause serious damage or injury.

- The employer must provide workers with detailed information on the risk of accident, especially risks

deriving from noise, use of safety devices and the general accident prevention regulations provided for by

international laws or standards or national standards within the country of use. All operators must observe

both international accident prevention standards and the national ones relevant to the country of use.

- Before carrying out any work on the compressor each operator must have a perfect understanding of how

the compressor works, know how to use the controls and have read the technical information contained in

this manual.

IMPORTANT:

- Removing or tampering with any safety device is strictly forbidden.

- All installation, routine or unscheduled maintenance work must be carried out with the compressor at

standstill and disconnected from the electrical power supply.

- Once the compressor has been cleaned the operator must check for any worn, damaged or

loose parts; in this case seek assistance from the maintenance technician.

It is especially important to check that flex hoses or other parts subject to wear are in good condition. Check

also for any leaking of oil or other dangerous substances. If such situations arise it is forbidden to restart

the compressor before the situation is resolved. If these problems are observed at the end of the refilling

the operator must, before leaving the machine unattended, place a sign on the compressor indicating that

maintenance work is in progress and that it must not be restarted.

IMPORTANT:

It is forbidden to tamper with or replace compressor parts without obtaining prior

authorization from Max-Air.

The use of accessories, tools, materials subject to wear or spare parts other than those

recommended by the manufacturer and/or illustrated in this manual can constitute a

source of danger to operators and/or damage the machine.

Any modification to the compressor that has not been expressly authorized by Max-Air

shall exonerate the manufacturer from any civil or penal liability

WARNING:

Chap. 3 - Safety regulations

Use and Maintenance Manual Mega-MaxTM 6000 Page 19

- Never place hands or introduce screwdrivers, keys or other tools into moving parts.

- Never clean with flammable fluids.

- Periodically check the info plates/labels and restore/replace them where necessary.

- The workplace must be kept clean, tidy and free from objects that might hinder movement.

- Operators must avoid carrying out “awkward” tasks in uncomfortable positions that might cause

imbalance.

- Operators should be aware of the risk of entrapment caused by clothes or hair getting caught up in moving

parts; wear a cap to contain long hair.

- Necklaces, bracelets and rings can also be a source of danger.

- Workplace lighting must be adequate for the work in progress. Insufficient or excessive lighting can generate

risks.

- Always observe the instructions, accident prevention regulations and the warnings contained in this

manual.

IMPORTANT:

3.2.1 - IMPORTANT SAFETY INFORMATION

The compressor has been designed and built to state of the art construction and complies with technical regulations

in force concerning compressors for the production of high pressure breathing air. The laws, regulations, standards

and directives in force for such machines have been complied with.

Materials, parts, production procedures and quality controls all comply with the strictest safety and reliability

standards.

Using the compressor for the purposes described in this manual, handling it with due diligence and carrying

out maintenance and overhauls according to proper working practices will ensure long lasting performance and

functionality.

3.2.2 - ACCIDENT PREVENTION

The manufacturer cannot be held liable for accidents that occur during use of the compressor as a result of the

user’s non-observance of the laws, regulations, standards and directives in force for high pressure compressors. The

compressor has been designed for use in weather conditions as described on page 14.

3.2.3 - WORKING SAFETY

The manufacturer cannot be held liable for malfunction or damage to the compressor:

- is used for purposes other than that for which its is intended;

- is not handled or maintained according to the instructions specified in this manual;

- is not periodically and continually maintained as instructed or if non-original spare parts are used;

- machine parts are modified or replaced without written authorization from the manufacturer, especially where the

efficiency of safety devices has been reduced or eliminated;

- where it is used outside the admissible temperature range.

Chap. 3 - Safety regulations

Page 20 Mega-MaxTM 6000 Use and Maintenance Manual

3.2.5 - SAFETY INFO LABELS: DESCRIPTION

Warning label.

Unauthorized, unqualified personnel are forbidden from

opening the control panel.

The power supply must always be disconnected before

carrying out any work on the control panel

A

Chap. 3 - Safety regulations

Cooling fan direction of rotation info label (located on

top rear panel).

When using the machine for the first time check that the

fan rotates in the direction indicated by the arrow. If the

fan rotates against the direction of the arrow invert two

of the three phases on the main power lead.

B

Condensate collection tank info label.

This points out that the condensate separator must

be emptied regularly as per the instructions in this

manual.

C

Hot parts warning label.

Label warning that lubrication and maintenance must

never be carried out with the compressor running.

Label warning that safety devices and guards must not

be removed.

D

Table of contents

Popular Air Compressor manuals by other brands

Steca

Steca UGP 5.9 Technical troubleshhoting guide

Atlas Copco

Atlas Copco XAHS 146 Dd instruction manual

BAE Audio

BAE Audio 10DC instruction manual

California Air Tools

California Air Tools 10020C-22060 owner's manual

Metabo

Metabo Power 260 Operating instruction

Dover

Dover PSG Mouvex B600 Original instructions