Electricwingman Kinetic Aerial Air-Ro User manual

www.electricwingman.com

Builders guide –Kinetic Aerial Air-Ro

Safety First

Please build, fly and configure your drone safely. Moving propellers and mishandled

lithium batteries can cause serious damage to person and property. It is your

responsibility to operate safely when flying and handling your ‘drone’!

Some related external resources (by no means exhaustive!): -

•The Home of British FPV Racing

•Dronesafe

www.electricwingman.com

Why build this quad?

Somewhere late 2015 4 inch quads were becoming popular, then Rotor Riot

reviewed a 4 inch and were quite unimpressed. Generally, the point was that 4 inch

quads were basically 5 inch quads with half an inch cut off each arm and smaller

props. They had considerably less thrust and were barely any lighter. Since then a

number of things have come in to play; motors have improved considerably, smaller

and lighter components have become available and frame manufacturers have

started producing 4 inch quads that are designed as 4 inch quads, not sawn offs. On

top of that EASA and UK law are both lining up to make life difficult for anything

weighing more than 250 grams.

Building a quad like this produces something that flies like a 5 inch quad with under

250 grams weight. Although I say like, I should say I prefer it. The top speed is

pretty similar. However, agility is much better, I have alternated LiPos between one

of these and a 5 inch racer, in comparison the 5 inch is like driving a bus.

The Theory

Building 5 inch quads there is a temptation to put bigger, more powerful motors on

things, heavier props and generally look for the max. Building a superlight 4 inch is a

different mindset. Weight matters, this quad will be half the weight of a 5 inch racer,

its motors produce less thrust than the latest Carlos Fandango Super-Wide Motors

but only by about a third, so the thrust to weight ratio is actually better. With less

weight it carries less inertia, cornering is much quicker and crashes produce less

force and therefore less damage. There is a temptation to start looking at 1806

motors, if you do that you add the extra weight of the bigger motors, about 4 or 5

grams each, but you also increase the amp draw and need a bigger LiPo, suddenly

you have added 60-80grams to the quad, don’t do it.

Parts list

Frame: Kinetic Aerial Air-Ro 3mm

Flight Stack: HGLRC XJB F428 With TX20 VTX

Motors: T-Motor F20ii 3750Kv

Props: HQ 4x4.3x3V1S

Camera: RunCam Micro Swift

Receiver: FrSky XM+

LiPos: Tattu 650mAh 4s 75C

Ancillary Parts: 470uf 25V Low ESR Capacitor. XT30 connector, wires, heat shrink,

small zip ties

Optional Hop up parts: Demonrc Vee antenna, 4x M2x6 cap head bolts and

washers, Forevertube over the standoff antenna mounts.

www.electricwingman.com

Tools: Soldering iron and solder, side trimmers, craft knife, hot glue gun, hex drivers,

blue threadlock

Other useful stuff: files and wet-and-dry paper, hot air gun, tweezers.

Preparation and Dry Build

The first thing to decide is if you want to chamfer the edges of the carbon parts. If

so, in a bucket of water, because carbon dust is bad for your lungs, file off the edges

of the carbon parts and if you want it really neat then use wet and dry paper to

smooth it off. Even if you don’t intend to do this it is a good ideal to do it at the points

on the bottom pate where the battery strap will run to prevent the strap wearing on it.

Next take the battery pad, remove all the cur out sections before removing the

backing paper, then carefully take off the backing paper and stick the pad to the

bottom of the bottom plate, taking care to line up the mount holes on the plate with

the holes on the battery pad.

Next dry build the quad, this means assembling it without any solder. The purpose

of this is firstly to make sure you know where everything fits. Secondly once

everything is in place wires can be cut to the right length (see wiring diagram below).

Note wires should not be long, but equally should not be tight, it is always possible to

cut a little more off before you solder, sticking back on is a pain.

It is good practice to check the flight controller is working BEFORE soldering

anything to it. Once you have soldered a board it cannot be returned to retailers. To

check a flight controller, start the Betaflight configurator application from the Chrome

App Store and connect the flight controller to the PC with a USB cable. Click on

Connect and make sure the flight controller connects. On the Setup tab check the

model picture moves in concert with physical movements you make with the flight

controller.

One problem you will find with the build is the stack uses M2 bolts, the mount holes

on the frame are M3. To remedy this, I used metal M2x6mm cap head screws with

M2 washers to hold the stack to the frame, using metals screws allows them to be

tightened more without nylon ripping, an alternate approach would be to fill the holes

in the base plate with hot glue or using rubber to pad them out.

The next preparation step is to tin the ends of the wires and the pads that will be

used. For the newer audience, this means applying solder to the pads and ends of

wires in preparation for soldering the two together. Again, use the wiring diagram

below to identify which pads you need to Tin.

The LiPo pads on the HGLRC 4in1 ESCs are quite small, to make life easier find

some copper or multistrand wire that fits through it, push it through, fold it back on its

self and twist it together, then cut it off a couple of millimetres off the pad and solder

it in place this gives a much bigger area to solder the XT30 pigtail to

The Camera mount also can be prepped, the frame comes with three mounts, a full

sized, a mini and a micro. Although we are using a micro camera the micro mount is

quite big and bulky and has antenna holes that are a bit small, so we use the mini

www.electricwingman.com

mount and cut the strut that runs across the back off so it does not get in the way,

leaving two parts comprising the tube that fits over the standoff and the tab the

camera screws to.

The final piece of prep is the TX20 VTX has a large capacitor on it (a large black

cube with the number 220 on it), this type of surface mount component has a nasty

habit of falling off, so hot glue this to the board.

Wiring Diagram

The diagram below is the wiring diagram for the Quad:

ESCS:

www.electricwingman.com

Fight controller:

The Build

I find it easiest to do the wiring in the following order:

1. First solder the XT30 pigtail and Capacitor leads to the underside of the 4in1

ESC board.

2. Trim the arms on the capacitor and solder the leads to it (not forgetting first

to put heat shrink on the wires, once the capacitoris attached, push the heat

shrink over the solder joins and shrink it.

3. Without any of the aluminium spacers attached bolt the motors to the frame,

put the battery strap inplace and bolt the ESC board, use one nylon standoff

to hold the ESC board in place, making sure it is not on the corner you are

soldering on, then solder the motor wires in place.

4. Bolt the Flight controller on top of the ESC board (at this point the flight

controller and ESCs can be configured and tested if you want) again using

one standoff at a corner nowhere near where you are working with the

soldering iron to hold the FC in place

5. Solder the camera connections to the flight controller

6. Solder the receiver wires to the flight controller

www.electricwingman.com

7. Push the (Tinned) receiver wires through the holes in the receiver and

solder.

8. Heat shrink the receiver

9. Solder the VTX wires to the flight controller

10.Push the (Tinned) VTX wires through the holes in the VTX and solder in

place

11.Bolt the VTX in place

12.Bolt the Aluminium spacers to the bottom plate.

13.Attach the camera to the camera mounts

14.Slide the camera mounts over the standoffs. If you are using the over the

standoff antenna mounts putthem in place (I cut mine in half to save weight),

push the antenna through, measure how much protrudes and cut the tubes

to sufficient length to protect the antenna fully and go through the mounts,

slide the tubes over the antenna and push them into the mount holes.

15.Cable tie the capacitor in place (I put larger heat shrink over the cap to

protect it and help the cable tie hold it in place

16.Cable tie the XT30 in place

17.The receiver is simply on its side edge between the flight control stack and

the rear standoffs. It is not secured in any way, this has never been a

problem however if you want it can be secured to the top plate with strong

mounting tape or secured to the rear standoffs with cable ties.

18.Attach the VTX antenna to the VTX and side it through the top plate. If you

are concerned about the antenna hot glue can be used to supplement the

connector, although this makes it harder (but by no means impossible) to

replace the antenna, or the antenna can be cable tied to the top plate, again

I prefer not to do this, it encourages wear on the antenna sheath. I have not

found either measure necessary, but they are there as options if you want.

19.Screw the top plate down.

Once the Configuration steps are completed all the metal screws on the under side

of the quad should be secured with blue threadlock. The four metal screws on the

top plate could also be done however I prefer not to as these are most commonly

undone to work on the quad.

Configuration

There are two parts to the configuration, the flying components and the FPV

components. There are some good practice bits first:

1. Smoke stoppers –these are frequently used on the bench, essentially a light

bulb which is connected between the LiPo and the quad, the light bulb will act

as a fuse and blow if a short causes high amp draw, protecting components.

These are a good idea, there are plenty of guides on how to make them on the

internet

www.electricwingman.com

2. PROPS -never ever ever plug the LiPo in with props on when you are working

on your quad. Quite aside from any damage to your equipment, this is likely to

cause a very angry, sharp and fast moving set of blades to make contact with

your face or hands and result in very serious injury. Always remove the props

when working on the quad, it is a pain in the bum but you do not want to learn

the lesson the hard way. Make it a habit.

3. It is assumed the radio has been bound to the receiver, there are many guides

available on how to do this as well as instructions that come with the receiver

Configuring the Flying components

The first step is to flash the flight controller with the latest version of BetaFlight, At

the time of writing this is Version 3.2 RC 4. If you haven’t already, install the

Betaflight configurator from the chrome apps store.

Start the Betaflight configurator application and plug your USB cable in.

On the left had side select the third option –Flash firmware

On the Choose a board drop down select OMNIBUSF4

Switch on Show unstable releases

On the Choose a firmware version for OMNIBUSF4 drop down select the latest

version (currently 3.2.0 –RC4)

Click on Load Firmware Online in the bottom towards the right, the configurator will

load up the firmware.

Click on Flash Firmware and the firmware will install:

www.electricwingman.com

Note if the flight controller will not go into DFU mode, connect to it (top right button),

go to the CLI tab and type DFU and hit return, the flight controller will reboot into

DFU mode and you can continue as above.

Once the flight controller has been flashed it needs to be set up.

Click Connect,

Go to the setup tab and set uart1 to serial RX as shown blow, then click Save and

reboot

Once the flight controller has rebooted, click Connect, go to the Configuration tab,

set the esc protocol to Dshot600 and enable motor stop (note motor stop is not

absolutely necessary but it makes landing easy), on the left-hand side click Motor

Direction is reversed as shown below:

www.electricwingman.com

Scroll down, set the PID loop frequency to 4Khz, disable barometer if enabled and

give the craft a name (this will be displayed on the OSD, it is common to use the pilot

name) as shown below:

Scroll down, set the receiver to serial based receiver and the serial receiver provider

to SBUS as shown below:

www.electricwingman.com

Scroll down, disable all features except OSD and dynamic filter as shown below and

click on Save and reboot

Once the Board reboots, reconnect and go to the failsafe tab, make sure stage 2

failsafe is enabled and set to drop (it should be by default but it is worth double

checking) as shown below:

www.electricwingman.com

If you have rebooted, reconnect and go to the PID tuning tab.

The settings below are following a tuning, they will be quite close although may need

a little tweaking as every build is a little different. The Tune is set up for 4S LiPos, on

3S a couple of points can be added to P term on pitch and roll.

The rates (RC Rates and S Rates) have been increased from standard. These are

about what I would use for flying round a track, for freestyle I would increase the S

Rates to 0.87, however rates are a very personal thing, I would suggest a beginner

would probably want to start with stock rates to get used to flying.

Click Save.

www.electricwingman.com

Remaining on the PID tuning tab, click on Filter Settings

Set the D-Term Lowpass filter to PT1 and set both Gyro Notch filter frequencies to 0

as shown below and click Save

Go to the Receiver tab,

www.electricwingman.com

Set the Channel map to TAER1234, if you are wanting to use RSSI on the OSD set

the RSSI channel to 12. Because radios tend to vary a little I set 3 points on both

RC deadband and yaw deadband as shown below. Click Save.

Go to the modes tab. This assumes you have set up two three-position switches on

your radio, one on channel 5 which will be used for Dissarm / Arm / Arm and Air

Mode and the other on channel 6 for Angle / Horizon / Rate (also called Acro)

modes. If you are experienced you may just be flying Rate mode however this setup

is included for beginners. Set up the Arm, Angle, Horizon and Air mode settings as

shown in the two diagrams below, for each set the Aux channel and band to cover

the area in which the switch is set to achieve the desired setting. (Tip –without props

on, plug in the lipo and power up your radio, the orange dash below the bar will show

where the value is for that switch setting, you can move the switch and the orange

dash will move, this allows you to confirm the band you set is correct). When you

have finished click Save.

www.electricwingman.com

Go to the OSD tab and set up the items you want displayed (or disable the ones you

don’t want) – not for new people, a busy OSD may be impressive but it will be

distracting and lead to crashes. On the image of the screen drag and drop items to

where you want them displayed, when done clock Save.

www.electricwingman.com

Go to the motor tab. Make sure the props are removed. Plug in the LiPo, Click

the check box to confirm you have removed the props and enable motor control and

raise the master slider slightly, this will start the motors spinning. Compare the

direction they are spinning to the picture in the top left, if any of the motors are

spinning in the wrong direction take a note of the motor number. Slide the master

slider down, uncheck the box and disconnect from configurator:

www.electricwingman.com

With the props still off, the flight controller still connected to the PC and the LiPo still

plugged in start the BLHeli Chrome App:

Click Connect:

The following screen will appear. Click Read Setup

The following screen will appear:

www.electricwingman.com

If any of the motors were spinning in the wrong direction change the motor direction

for that esc to reversed and when they are all set, click on Write Setup

Flash all can be used to update BLHeli is necessary however currently the hardware

ships with the latest version.

Disconnect the BLHeli App, reconnect Betaflight configurator and retest the motor

direction as above.

Configuring the FPV components

The second part of the configuration doesn’t require a computer.

NOTE: Never power a video transmitter without an antenna attached, it will burn out

the transmitter.

Set up your goggles and receiver on the channel and band you want to use.

Following the instructions that came with the VTX, WITHOUT PROPS ON, plug the

LiPo in and use the button on the side of the VTX to set the band and channel on the

transmitter, the image will appear in the goggles when correct. (note that the image

may appear when you are on the wrong band and channel because the frequency is

close, this will be fine on the bench but will have dramatically less range. Use the

LED on the VTX and whatever mechanism is on your goggles to confirm they are on

the same band and channel with the image in the goggles as confirmation.

If you are using a Version of the camera that has a built in OSD, connect the OSD

cable, and switch off the OSD components (you don’t want two OSDs and the Flight

controller OSD is more useful)

www.electricwingman.com

Final things

Before flying for the first time (and regularly thereafter) test your failsafe (if you don’t

you will have what is termed a “Flyaway” at some point where your quad departs like

some homesick Mary Poppins and is never seen again.

To do this, WITH PROPS OFF, turn on your radio, power up the quad, arm it and

give it a little throttle so the motors start spinning, then turn the radio off. Within a

second or so the motors should stop dead.

Test Hover your quad somewhere safe. Do it Line of Sight, I usually do it in Angle

mode and from a safe distance before taking it to the field to fly for the first time.

Once you have tested failsafe and test hovered. Make sure everything is screwed

down tightly, use blue threadlock on the motor mount screws and the four screws

holding the standoffs to the bottom plate.

You are now good to fly, please do it safely and legally and ensure you have

appropriate insurance such as that provided by BMFA membership.

The pictures below show what the build hopefully looks like:

www.electricwingman.com

Popular Toy manuals by other brands

Horizon Hobby

Horizon Hobby Ultimate 2 instruction manual

Hasbro

Hasbro FurReal Friends Pom Pom My Baby Panda quick start guide

Smoby

Smoby 330309 manual

E-FLITE

E-FLITE Eratix 3D 25e Assembly manual

Laser Dollhouse Designs

Laser Dollhouse Designs Country Villa Assembly instructions

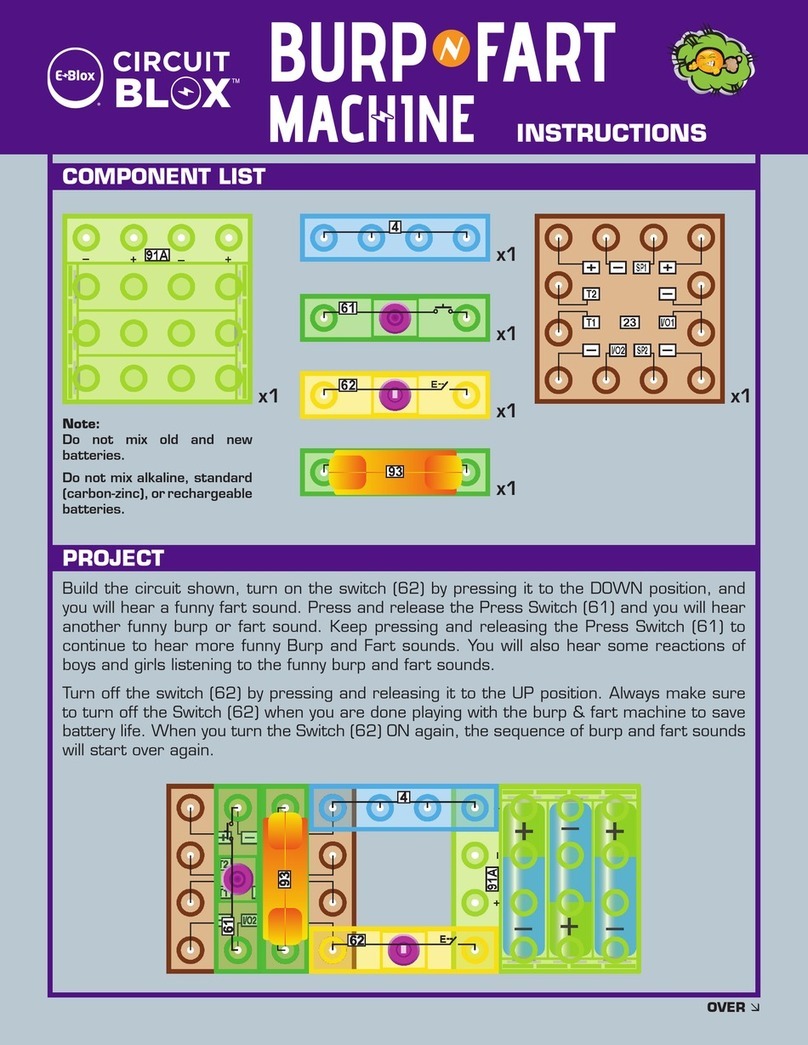

E-BLOX

E-BLOX CIRCUIT BLOX Burp 'n Fart Machine instructions