Electronic Systems Support EFC52 SERIES User manual

EFC52/EFC54 SERIES

BATTERY CABINET

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

MNL-000700

Rev B

January 2017

This manual provides instructions regarding safety, storage, installation, operation and

maintenance. Failure to observe the precautions as presented may result in injury or loss of

life.

This document is proprietary to Electronic Systems Support (ESS). This document cannot

be copied or reproduced in whole or in part, nor can its contents be revealed in any manner

or to any person except to meet the purpose for which it was delivered, without the express

written permission of Electronic Systems Support.

Please visit ess.to to check for updates to manual.

MNL-000700

Rev B 1 www.ess.to

January 2017

TABLE OF CONTENTS

1. INTRODUCTION..................................................................................................................................2

2. PRECAUTIONS....................................................................................................................................2

3. INSPECTION UPON RECEIPT OF GOODS.......................................................................................3

3.1 General..................................................................................................................................3

3.2 Visible damage......................................................................................................................3

3.3 Concealed damage ...............................................................................................................3

3.4 Return of damaged goods.....................................................................................................3

4. SYSTEM OVERVIEW ..........................................................................................................................3

5. GENERAL SYSTEM SPECIFICATIONS…………………….................................................................4

5.1 DC Output Characteristics.....................................................................................................4

5.2 Batteries.................................................................................................................................4

5.3 Grounding………………………………………………………………………… ........................4

5.4 Environmental Conditions......................................................................................................4

•Cabinet Dimensions..................................................................................................................4

•Cabinet Weights (Assembled) ..................................................................................................5

6. INSTALLATION PROCEDURES..........................................................................................................5

6.1 Preparation............................................................................................................................5

6.1.1 Necessary Equipment and Tools ..........................................................................5

6.1.2 Equipment Inspection............................................................................................5

6.1.3 Safety Precautions ................................................................................................6

7. INSTALLATION STEPS.......................................................................................................................6

7.1 Cabinet Location....................................................................................................................6

7.2 Cabinet Mounting ..................................................................................................................6

7.3 DC Connections ....................................................................................................................7

7.4 Grounding..............................................................................................................................7

7.5 System Operation..................................................................................................................7

8. SYSTEM MAINTENANCE....................................................................................................................8

8.1 Blown Fuse Replacement......................................................................................................8

8.2 Battery Replacement Steps...................................................................................................8

9. WARRANTY RELATED MAINTENANCE

10. DRAWINGS/SCHEMATICS...............................................................................................................10

•General Cabinet Drawing..........................................................................................................10

•Anchor Specifications ...............................................................................................................11

•Anchor Placement Dimensions.................................................................................................12-13

•480V, EFC52 Top Breaker – Mechanical/Electrical Drawing...................................................14

•384V, EFC52 Top Breaker – Mechanical/Electrical Drawing...................................................15

•360V, EFC52 Top Breaker – Mechanical/Electrical Drawing...................................................16

•384V, EFC42 Top Breaker – Mechanical/Electrical Drawing...................................................17

•288V, EFC42 Top Breaker – Mechanical/Electrical Drawing...................................................18

•480V, EFS52 Side Breaker – Mechanical/Electrical Drawing ..................................................19

•384V, EFS52 Side Breaker – Mechanical/Electrical Drawing ..................................................20

•480V, EFC54 Top Breaker – Mechanical/Electrical Drawing...................................................21

•384V, EFC54 Top Breaker – Mechanical/Electrical Drawing...................................................22

•360V, EFC54 Top Breaker – Mechanical/Electrical Drawing...................................................23

•384V, EFC44 Top Breaker – Mechanical/Electrical Drawing...................................................24

•288V, EFC44 Top Breaker – Mechanical/Electrical Drawing...................................................25

•480V, EFS54 Side Breaker – Mechanical/Electrical Drawing ..................................................26

•384V, EFS54 Side Breaker – Mechanical/Electrical Drawing ..................................................27

•360V, EFC51 Top Breaker – Mechanical/Electrical Drawing...................................................28

•Notes Page ...............................................................................................................................29

MNL-000700

Rev B www.ess.to

January 2017 2

1. INTRODUCTION

ESS EFC52 & EFC54 Series Front Terminal Battery Cabinets are shipped partially assembled, internally pre-

wired and come standard with an over current breaker. The removable hinged front doors and removable

rear cover also allow for easier battery access. Maintenance rear covers are not needed since all batteries

come with nylon straps for easier lifting and moving. Refer to the battery layout drawings and schematics at

the end of this manual. Consult the battery manufacturer’s battery operation and maintenance manual for

complete instructions.

These battery systems are Hi-Pot tested to UL 1778 standards at the factory prior to shipment. All system

settings are also adjusted at this time according to the specification sheet. Sales support for future equipment

or upgrades is provided by our sales staff and qualified representatives. All technical questions and service

issues should be directed to our office 972-272-2468.

2. PRECAUTIONS

It is very important to read, understand and follow the instructions in this manual. Also note all

SAFETY PRECAUTIONS before beginning the installation of this system.

Consult the Battery Manufacturer's Operation and Maintenance Manual for important battery

information.

Battery cabinet systems are very heavy. Total weight of a loaded cabinet can exceed 6100 lbs.

Use at least 3 people when unloading and setting equipment in place.

It is imperative that only qualified personnel work on this system and installation, maintenance or

upgrades be performed with insulated tools and equipment.

When installing this battery system, follow all applicable federal, state and local regulations and

industry guidelines to insure a proper installation.

DC power and battery supplies are dangerous and have extremely high short circuit currents.

Severe burns or death can result from a system short. They also can leak potentially explosive gas

(hydrogen). Never enclose batteries or battery cabinets in a sealed air tight room.

All jewelry and watches must be removed prior to installing or servicing this system.

Do not smoke or present flame near or around any battery cabinet system.

Never leave a panel off or door open and unattended.

3. INSPECTION UPON RECEIPT OF GOODS

3.1 General

Special precautions and care have been taken to ensure the cabinet system arrives safe and

undamaged. However, upon receipt, you should inspect the entire shipment, including the crate and any

boxes for evidence of damage that may have occurred during transit.

MNL-000700

Rev B 3 www.ess.to

January 2017

3.2 Visible Damage

It is the responsibility of the person receiving the shipment to inventory and fully inspect all materials

against the bill of lading or way bill IMMEDIATELY, while the carrier representative is still present. Ensure

that all items are accounted for, including number of skids and quantity of boxes. Also note any visible

external damage that may have occurred during transit. Make all applicable notations on the delivery

receipt before signing and file a damage report with the carrier.

3.3 Concealed Damage

Within 30 days of receipt, unpack the cabinet system and check for any concealed damage. Check the

materials received against the detailed packing list to verify the quantity and the condition as complete

and satisfactory.

Note any damage to the internal packaging, then request an inspection by the carrier and file a concealed

damage claim. If there is a material shortage, contact ESS at the number listed at the end of this manual.

Please contact your shipping company for all shipping damage. ESS is not responsible for any

shipping damage.

3.4 Return of Damaged Goods

A RMA number must be obtained before returning equipment to ESS. Please contact an ESS

representative or call the corporate number listed at the end of this manual.

4. SYSTEM OVERVIEW

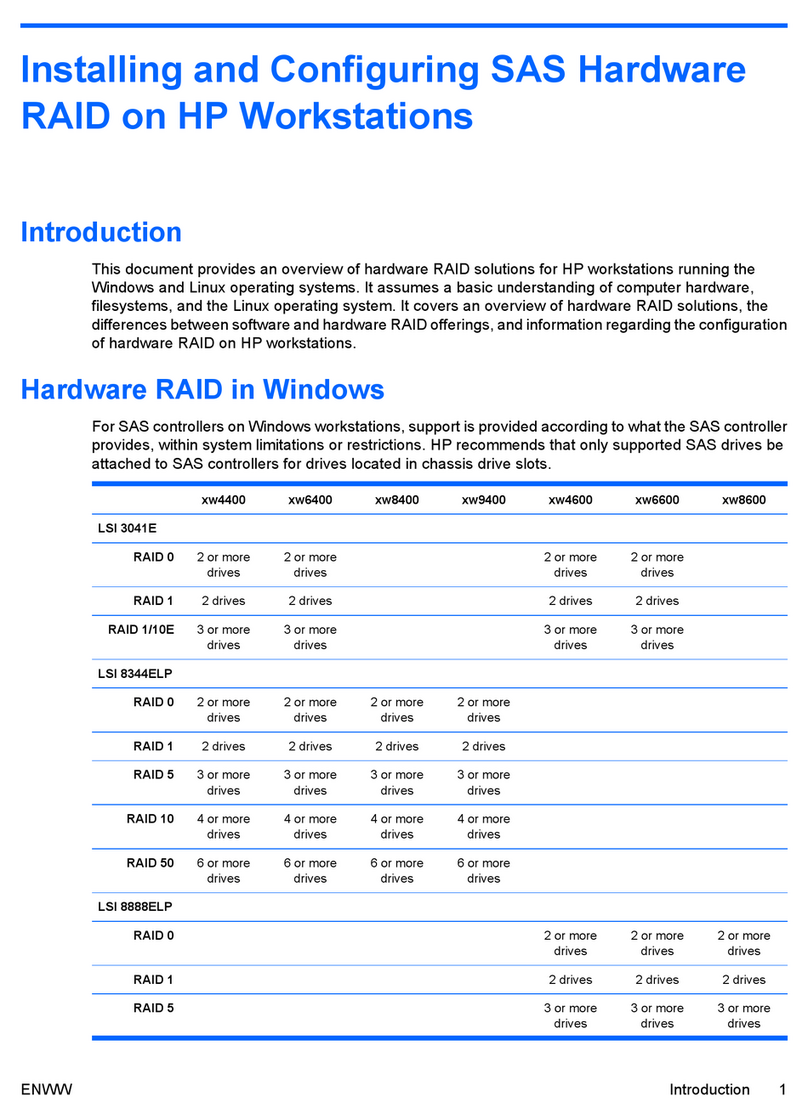

The enclosed cabinet systems provide the necessary DC backup power required in UPS applications. Over-

current breaker/fuse protection is supplied. DC connections are front accessible and made via terminal

blocks and/or mechanical lugs. Refer to the drawings and schematics at the end of this manual for these

connections. Cabinets are equipped with 3-pole breakers. There are 2 holes per polarity on 300 Amp to 600

Amp breakers. Breakers 30 Amps to 250 Amps have a single hole per polarity. See table below for

standard output lug sizes of breakers.

During normal conditions the UPS supplies the load power and the necessary power required to keep the

batteries at the proper float voltage. Verify that the charger is set to charge parameters within the approved

float voltage range of the batteries, refer to manufacturer’s battery operation and maintenance manual.

When AC fails, the batteries discharge in order to provide the necessary backup power. It is the responsibility

of the customer to make sure the batteries are not discharged below the battery manufacturer’s

recommendations. Always recharge batteries per manufacturer’s battery operation and maintenance manual.

Batteries will be damaged if not recharged right away. See the UPS or DC system manual for more

information.

BREAKERSIZING

BREAKERSIZEAMPS30A40A 50A 75A 100A125A

A.I.C.RATING,500DC20,000A.I.C20,000A.I.C 20,000A.I.C 20,000A.I.C 20,000A.I.C20,000A.I.C

OUTPUTLUGSIZE(1)#14‐3/0(1)#14‐3/0 (1)#14‐3/0 (1)#14‐3/0 (1)#14‐3/0(1)#4‐3/0

BREAKERSIZEAMPS150A175A 200A 225A 250A300A

A.I.C.RATING,500DC20,000A.I.C20,000A.I.C 20,000A.I.C 20,000A.I.C 20,000A.I.C20,000A.I.C

OUTPUTLUGSIZE(1)#4‐4/0(1)#4‐4/0 (1)3/0‐350 (1)3/0‐350 (1)3/0‐350(2)2/0‐500

BREAKERSIZEAMPS350A400A 450A 500A 600

A.I.C.RATING,500DC20,000A.I.C20,000A.I.C 20,000A.I.C 20,000A.I.C 20,000A.I.C

OUTPUTLUGSIZE(2)2/0‐500(2)2/0‐500 (2)2/0‐500 (2)2/0‐500 (2)2/0‐500

MNL-000700

Rev B www.ess.to

January 2017 4

5. GENERAL SYSTEM SPECIFICATIONS

5.1 DC Output Characteristics

•Voltage: (UPS Application) 48 to 480 VDC Nominal

•Breaker: Standard

•Fuse Type: Not standard, consult factory. If a fuse is provided, it is only to be replaced by a factory

service technician.

CAUTION! Fire Hazard Warning:

Replace only with same type and rating of fuses supplied with the system.

•Wire Size and Type: Per NEC and/or local building and electrical codes.

•Disconnect: If a fuse has been provided in lieu of a breaker inside the cabinet, a disconnecting

method must be provided per NEC code. This may be a fuse switch or circuit breaker. Size

accordingly.

5.2 Batteries

•Type: Valve Regulated Lead Acid (VRLA), sealed, non-spillable.

•Voltage: 12 Volt DC Nominal, Front Terminal Design.

UL approved battery models:

Enersys : 12XE1010F-FR, 12XE1110F-FR, 12XE1150F-FR

East Penn: HR3500ET, HR5500ET, HR7500ET

C&D: UPS12-355MRF, UPS12-615MRF, UPS12-700MRF, UPS12-410FRMX, UPS12-1000MRFX

Northstar: NSB12-450RT, NSB12-650RT, NSB12-730RT, NSB155FT, NSB170FT,NSB190FT,

NSB210FT

Fiamm - 12FLX700F

•Only cabinets with flame retardant batteries are suitable for computer room use!

5.3 Grounding

•All grounding should be derived from the main building ground source.

•Note: All cabinet systems require grounding.

5.4 Environmental Conditions

Breakers are located at the top of the cabinet for EFC configurations. For EFS configurations, the

breakers are located on the side of the cabinet. EFC5x and EFS5x cabinets have a maximum battery

configuration of 8 wide by 5 tiers high. EFC4x cabinets have a maximum battery configuration of 8 wide

by 4 tiers high.

MNL-000700

Rev B 5 www.ess.to

January 2017

Cabinet Dimensions:

EFC52, Top Breaker is 45.50” W x 29.5” D* x 84.0” H

EFC42, Top Breaker is 45.50” W x 29.5” D* x 72.0” H

EFS52, Side Breaker is 57.75” W x 29.5” D* x 74.8” H

EFC54, Top Breaker is 45.50” W x 31.5” D* x 84.0” H

EFC44, Top Breaker is 45.50” W x 31.5” D* x 72.0” H

EFS54, Side Breaker is 57.75” W x 31.5” D* x 74.8” H

For mounting hole dimensions, please refer to the cabinet layout drawing at the end of this manual. Also

included with each order is a floor template to mark anchor locations per cabinet.

Max Cabinet Weights: (Assembled)

Reference the drawings for each individual voltage available for cabinet weights depending on battery

manufacturer and model.

•Temperature: Normal operating temperatures are between 68ºF -77ºF. Note: Batteries typically

should be at 77ºF for optimum battery life and performance.

•Ventilation/Cooling: Provided through ventilation slots in the rear panel, bottom panel, front door and

top of cabinet, thus providing a chimney effect for natural convection cooling. If local codes require

forced air exhaust, unused covers serve as conduit entry or duct work entry points.

•Clearance: A minimum of four inches is required in both the front and the rear of the cabinet. This

refers to obstruction of ventilation only. Clearance around cabinet sides is suggested by NEC and

local codes.

CAUTION! Explosion/Fire Hazard Warning:

Batteries can generate potentially explosive gas (hydrogen).

Never enclose batteries or battery cabinets in a sealed, airtight room.

6. INSTALLATION PRODEDURES

BEFORE PROCEEDING WITH INSTALLATION READ THE FOLLOWING:

6.1 Preparation

6.1.1 Necessary Equipment and Tools

•Rigging tools for moving cabinets. Narrow pallet jack and forklift of 8,500 lbs. minimum capacity

when moving fully loaded cabinets.

•Heavily insulated assortment of hand tools.

•Digital Voltmeter

6.1.2 Equipment Inspection

Remove the packaging material from the cabinet and inspect for any concealed shipping damage

that may have been overlooked upon receipt of goods. Use the packing list to verify the system

has all components and cables for installation.

MNL-000700

Rev B www.ess.to

January 2017 6

6.1.3 Safety Precautions

DC VOLTAGE WARNING!

Hazardous DC Voltages are present in the battery cabinet. This hazard will always be present,

even when the battery system is off-line. Accidental short circuit of the positive and negative

terminals will cause tremendous currents to flow resulting in severe burns, fire and possible death.

Use extreme caution!

IMPORTANT SAFETY INSTRUCTIONS. SAVE THESE INSTRUCTIONS!!

All disconnecting means should be in the open/off position before servicing.

All installation drawings and schematics should be reviewed and clearly

understood before hooking up this system.

Only qualified DC power technicians or electricians should attempt to work on and install this

equipment.

All jewelry, rings and watches should be removed when working on this equipment.

All tool handles and shafts must be heavily insulated.

Do not rest any tools or loose cables on top of batteries.

Make sure all connections are properly torqued and secure. Torque values are provided on

battery label.

Do not smoke or present flames near or around any battery system.

Always wear safety glasses and gloves and use insulating mats to stand on when working on

this system.

Do not allow bare skin to come into contact with battery cabinet, as this could result in an

electrical shock.

Do not install any cable terminations until it has been verified that such a termination will not

create a short circuit.

7. INSTALLATION STEPS

7.1 Cabinet Location

Prior to installation, verify floor loading requirements and all applicable codes pertaining to the related

equipment. Environmental conditions should also be reviewed. Proper ventilation and cooling must be

adequate for optimum battery life and performance. A clearance of 4” is recommended at the front and

rear of the cabinet. This refers to obstruction of ventilation only. Clearance around the cabinet sides

should be as suggested by NEC and local codes. Ambient temperature should be between 68ºF -77ºF.

7.2 Cabinet Mounting

1. Remove any remaining packaging materials (cardboard, plastic).

2. Remove the kick plate from the base of the cabinet. Save this kick plate for re-installation later.

3. Unbolt the cabinet from the pallet. Remove the cabinets from the pallet using a forklift rated for at

least 8,500 lbs.

4. The battery cabinet is equipped with narrow pallet jack or forklift access openings in the front and rear

of the cabinet. Move the equipment into the desired location and set in place.

Note: When applicable, the cabinet labeled “Left” has the breaker and those cabinets should be

paired with any of the “Right” labeled cabinets.

MNL-000700

Rev B 7 www.ess.to

January 2017

5. In order to meet Zone 4 requirements, refer to the Zone 4 ANCHORING drawings included with this

manual. The following steps detail the necessary actions to be taken to meet Zone 4 mounting

requirements. Check applicable building codes for length and style of anchors to be used with the

flooring substrate. Install anchors per manufacturer’s instructions.

6. On the floor, mark the location of the 6 mounting holes found at the bottom of the cabinet legs.

7. Use the floor template or hole location drawing provided with each shipment to mark holes for

anchors. Use ½” or 13mm anchors. Install anchors per manufacturer’s instructions.

8. Move the cabinet into place, align holes, check levelness, and tighten hardware. Note: Should any

drilling be performed on this equipment, make sure all exposed batteries and connections are

completely covered using insulated type mats. Prevent dust from entering cabinets and clear any

debris that has collected.

9. Re-install the front kick plate on the cabinet.

10. Install the front doors on the cabinet.

11. If multiple battery cabinets are installed, repeat above steps. Check height and levelness with

adjoining cabinets.

7.3 DC Connections

CAUTION!

PLEASE READ ALL SAFETY INSTRUCTIONS BEFORE PROCEEDING.

1. Open the cabinet door and check for any noticeable problems or damage that may have occurred

during shipment. Remove the cardboard box from the cabinet (right cabinet in a dual cabinet

system). Use the packing list to verify all bus bars, cables, battery covers and hardware required for

assembly is available.

2. Review the installation drawing and schematic diagram included in this manual. Cables and bus bars

have been left off in the battery string for safety and will need to be installed later.

3. Connect main cables to the circuit breaker, when applicable, inside the cabinet from the UPS or

charger source. All cables should be sized per NEC and any other local codes pertaining to this

equipment. Refer to the UPS or charger manual for wiring external batteries. Note: Make sure

charging source is disconnected before making these connections; also verify the battery cabinet is

turned off.

4. Connect the battery interconnect bus bars that were left off during shipment and install as shown on

the installation drawing included in this manual. Torque connections properly. Torque values are

provided on battery label.

5. Install plastic covers onto batteries. Some covers may need to be notched for locations with bus bars

and/or cables in upward orientation.

7.4 Grounding

Ground the battery cabinet to the main building ground. A ground stud inside the cabinet is

provided for this.

7.5 System Operation

Refer to the UPS or charger manual for start up and operation of system.

MNL-000700

Rev B www.ess.to

January 2017 8

8. SYSTEM MAINTENANCE

CAUTION!

PLEASE READ ALL SAFETY PRECAUTIONS BEFORE PROCEEDING

8.1 Blown Fuse Replacement

If a fuse has blown in the system, contact an authorized factory technician to replace it.

CAUTION! Fire Hazard Warning:

Replace only with same type and rating of fuses supplied with the system.

8.2 Battery Replacement Steps

Servicing of batteries should be performed or supervised by personnel knowledgeable about batteries

and the required precautions. When replacing batteries, replace with the same type and number of

batteries.

CAUTION!

Do not dispose of batteries in a fire. The batteries may explode.

Do not open or mutilate batteries. Released electrolyte is harmful to the skin and eyes.

It may be toxic.

A battery can present a risk of electrical shock and high short-circuit current. The following precautions

should be observed when working on batteries:

•Remove jewelry, rings, watches or other metal objects.

•Use tools with insulated handles.

•Wear rubber gloves and boots. Wear safety glasses.

•Do not lay tools or metal parts on top of batteries.

•Disconnect charging source prior to connecting or disconnecting battery terminals.

•Determine if the battery is inadvertently grounded. Remove string from buss and check voltages to

ground. Contact with any part of a grounded battery can result in electrical shock. The likelihood of

such shock can be reduced if such grounds are removed during installation and maintenance

(applicable to equipment and remote battery supplies not having a grounded supply circuit).

1. Prepare the new battery for installation. Check to make sure the battery is the same type and amp-

hour rating. Use a non-metallic brush or scotch brite pad to clean the terminals. Apply a light coat of

No-ox grease to the terminal to avoid corrosion "per battery manufacturer's recommendation".

2. Disconnect the charger or UPS from the battery string by opening the breaker.

3. Remove the center jumper on the battery string to reduce the voltage. If replacing all batteries,

continue reducing the voltage in this manner.

4. Disconnect the interconnect bus bars and/or cables from the battery to be replaced.

5. Remove the old battery.

6. Install the new battery. Make sure the new battery is installed the same way regarding polarity

orientation and verify with drawing.

MNL-000700

Rev B 9 www.ess.to

January 2017

7. Reconnect bus bars and/or cables to the battery. Make sure connections are properly torqued.

Torque values are provided on the battery label.

8. Reconnect the center jumper. Make sure connections are properly torqued. Torque values are

provided on the battery label.

9. Check voltage at terminal block.

10. Close breaker when ready. If your model has a disconnect with an exterior handle to the door, close

and latch the door first before closing the breaker.

9. WARRANTY RELATED MAINTENANCE

1. The purchaser (user) shall give freshening charges to the battery a minimum of every six (6) months for

Lead-Calcium batteries after shipment from the factory and until final installation. Refer to the installation

and maintenance instructions for maximum storage intervals at different environmental situations.

Extreme heat could cause more frequent freshing charges.

2. At least once every twelve (12) months, purchaser (user) must take readings and record

information per battery manufacturer’s installation/maintenance instructions. These records must be

maintained for warranty claim purposes. If warranty records are not kept, the warranty shall be null and

void.

3. Parallel strings should be limited to five (5) strings

4. Movement of batteries from original point of installation shall immediately void the product

warranty, except with the expressed written consent from ESS.

5. Any storage shall be in a dry area having ambient temperature of 77º F (25° C), or less, and

in accordance with battery manufacturer published installation, operation and maintenance instructions.

Failure to follow the battery manufacturer’s published guidelines and/or instructions may invalidate the

product warranty, at the sole discretion of ESS.

6. During service or extended storage, a battery system monitor is recommended to be used to record

temperatures, voltages, AC ripple, Float currents, Discharge and more to provide more accurate battery

and environmental data for warranty with battery manufacturer's claims.

MNL-000700

Rev B www.ess.to

January 2017 10

10. DRAWINGS/SCHEMATICS

RETAINER

CABLE

TAKE-OFF

BATTERY

MAIN BREAKER

OUTPUT CABLE

SHUNT AND AUXILIARY

STRUCTURAL

HINGES

LOCKING

CABLE ENTRY

NEGATIVE CONTACT TERMINAL STRIP

MAIN BREAKER

GUSSETS

POSITIVE OUTPUT

CABLE

FRONT

LATCH

INTER-TIER

KNOCK-OUTS

COMPRESSION

KICK PLATE

PANELS

KNOCK-OUT

NEGATIVE OUTPUT

BUS BAR (ONLY)

3 ANCHOR POINTS

PER RAIL (3 RAILS)

BATTERY

INTER-CONNECTS

(BUS BARS)

MNL-000700

Rev B 11 www.ess.to

January 2017

MNL-000700

Rev B www.ess.to

January 2017 12

MNL-000700

Rev B 13 www.ess.to

January 2017

RED

BELL ALRAM OPT. RED

BELL ALRAM OPT.

YW

BL

NC

NO

COMM. BL / YW

+

-

TO 24/48 VDC SOURCE

AUXILLARY CONTACTS LISTED APPLICABLE WHEN

BREAKER IS IN THE CLOSED (ON) POSITION

BLK

BLK

TO UPS

FROM UPS

FROM BREAKER OPTIONS

TO UPS

BREAKER DETAIL

BRACKET

BREAKER

FROM BATTERY

OUTPUT TO UPS

GND

+

-

TYP 480V WIRING

-+-+-+-+-+-+-+-

+- -+-+-+-+-+-+-

-+-+-+-+-+-+

-

-+

-+-+-+-+-+-+--+

-+-+-+-+-+-+--+

+

+

+

+

TIER 1

TIER 2

TIER 5

TIER 3

TIER 4

+-

12345678

9101213141516

18192021222324

2526272829303132

3334353637383940

TO BREAKER OR

11

17

FUSE PANEL

+

R22.3 R22.9

SIDE VIEW

29.5

REAR VIEW

VENTILATION

LOUVERS

45.50

ISOMETRIC VIEW

3.

NEMA 1 DESIGN.1. EMPTY CABINET WEIGHT: 770 LBS. (350 KG)2. SEE TABLE FOR LOADED WEIGHTS.

CABINET NOTES:

ELECTRONIC SYSTEMS SUPPORT

B

EFC52 BATTERY CABINET

14 www.ess.to

FAX 972-276-9844

Garland, Texas 75041

PH. 972-272-2468www.ess.to

ESS

DOC-005000

8-26-14RNJ

8-26-14RNA 480V, 40 BLOCS

3233 W. Kingsley Rd.

MNL-000700

Rev B

January 2017

DO NOT SCALE DRAWING

PROHIBITED. SHEET 1 OF 1

UNLESS OTHERWISE SPECIFIED: REV

TITLE:

NAME DATE

APPR.

DRAWN

PROJECTION:

DIMENSIONS ARE IN INCHES

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

ELECTRONIC SYSTEMS SUPPORT. ANY

REPRODUCTION IN PART OR AS A WHOLE

WITHOUT THE WRITTEN PERMISSION OF

ELECTRONIC SYSTMES SUPPORT IS

DWG. NO.

FRONT VIEW

84.0

AA

BATTRYCABINETLOADEDWEIGHTS

BATTERYMODEL WEI GHT(LBS)

ENERSYS‐12XE1010F‐FR 5166

ENERSYS‐12XE1110F‐FR 5430

ENERSYS‐12XE1150F‐FR 6038

EASTPENN‐HR3500ET 4070

EASTPENN‐HR5500ET 5670

C&D‐UPS12‐355MRF 4070

C&D‐UPS12‐615MRF 5470

C&D‐UPS12‐700MRF 6110

C&D‐UPS12‐410MRF 4142

C&D‐UPS12‐1000MRF 8390

NORTHSTAR‐NSB12‐450RT 4350

NORTHSTAR‐NSB12‐650RT 5590

NORTHSTAR‐NSB12‐730RT 6350

NORTHSTAR‐NSB155FT 5710

NORTHSTAR‐NSB170FT 6150

NORTHSTAR‐NSB190FT 6350

NORTHSTAR‐NSB210FT 6950

GNB‐ S12V645FT 5790

GNB‐ S12V735FT 6430

RED

BELL ALRAM OPT. RED

BELL ALRAM OPT.

YW

BL

NC

NO

COMM. BL / YW

+

-

TO 24/48 VDC SOURCE

AUXILLARY CONTACTS LISTED APPLICABLE WHEN

BREAKER IS IN THE CLOSED (ON) POSITION

BLK

BLK

TO UPS

FROM UPS

FROM BREAKER OPTIONS

TO UPS

BREAKER DETAIL

BRACKET

BREAKER

FROM BATTERY

OUTPUT TO UPS

GND

+

-

-

15

TYP 384V WIRING

FUSE PANEL

17

11

TO BREAKER OR

32 31 30 29 28 27 26 25

24 23 22 21 20 19 18

16 14 13 12 10 9

87654321

-+

TIER 4

TIER 3

TIER 2

TIER 1

+

+

+

+- -+-+-+-+-+-+-

+- -+-+-+-+-+-+-

-+-+-+-+-+-+--+

-+-+-+-+-+-+-++

R22.3 R22.9

3.

NEMA 1 DESIGN.1. EMPTY CABINET WEIGHT: 770 LBS. (350 KG)2. SEE TABLE FOR LOADED WEIGHTS.

CABINET NOTES:

8-26-14

FAX 972-276-9844

ELECTRONIC SYSTEMS SUPPORT

384V, 32 BLOCS

8-26-14RNA

www.ess.to

15

PH. 972-272-2468www.ess.to

ESS

DOC-005100 B

RNJ EFC52 BATTERY CABINET

Garland, Texas 75041

3233 W. Kingsley Rd.

MNL-000700

Rev B

January 2017

PROPRIETARY AND CONFIDENTIAL

DIMENSIONS ARE IN INCHES

DO NOT SCALE DRAWING

PROHIBITED. SHEET 1 OF 1

UNLESS OTHERWISE SPECIFIED: REV

TITLE:

NAME DATE

APPR.

DRAWN

PROJECTION:

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

ELECTRONIC SYSTEMS SUPPORT. ANY

REPRODUCTION IN PART OR AS A WHOLE

WITHOUT THE WRITTEN PERMISSION OF

ELECTRONIC SYSTMES SUPPORT IS

DWG. NO.

FRONT VIEW

84.0

AA

REAR VIEW

VENTILATION

LOUVERS

45.50

SIDE VIEW

29.5

ISOMETRIC VIEW

WEIGHT(LBS)

4294

4518

4998

3430

4710

3430

4550

5062

3462

6886

3464

4646

5254

4742

5094

5254

5734

4806

5318

C&D‐UPS12‐1000MRF

BATTRYCABINETLOADEDWEIGHTS

BATTERYMODEL

ENERSYS‐12XE1010F‐FR

ENERSYS‐12XE1110F‐FR

ENERSYS‐12XE1150F‐FR

EASTPENN‐HR3500ET

EASTPENN‐HR5500ET

C&D‐UPS12‐355MRF

C&D‐UPS12‐615MRF

C&D‐UPS12‐700MRF

C&D‐UPS12‐410MRF

NORTHSTAR‐NSB210FT

GNB‐ S12V645FT

GNB‐ S12V735FT

NORTHSTAR‐NSB12‐450RT

NORTHSTAR‐NSB12‐650RT

NORTHSTAR‐NSB12‐730RT

NORTHSTAR‐NSB170FT

NORTHSTAR‐NSB155FT

NORTHSTAR‐NSB190FT

RED

BELL ALRAM OPT. RED

BELL ALRAM OPT.

YW

BL

NC

NO

COMM. BL / YW

+

-

TO 24/48 VDC SOURCE

AUXILLARY CONTACTS LISTED APPLICABLE WHEN

BREAKER IS IN THE CLOSED (ON) POSITION

BLK

BLK

TO UPS

FROM UPS

FROM BREAKER OPTIONS

TO UPS

BREAKER DETAIL

BRACKET

BREAKER

FROM BATTERY

OUTPUT TO UPS

GND

+

-

++

-

FUSE PANEL

TO BREAKER OR

+

30

+-

TYP 360V WIRING

17

11

29 28 27 26 25

24 23 22 21 20 19 18

16 15 14 13 12 10 9

87654321

TIER 4

TIER 3

TIER 5

TIER 2

TIER 1

+

+

-+ -+ -+ -+ -+

+- -+-+-+-+-+-+-

-+-+-+-+-+-+--+

-+-+-+-+-+-+--

R22.3 R22.9

REAR VIEW

VENTILATION

LOUVERS

45.50

SIDE VIEW

29.5

3.

NEMA 1 DESIGN.1. EMPTY CABINET WEIGHT: 770 LBS. (350 KG)2. SEE TABLE FOR LOADED WEIGHTS.

CABINET NOTES:

ELECTRONIC SYSTEMS SUPPORT

B

EFC52 BATTERY CABINET

16 www.ess.to

FAX 972-276-9844

Garland, Texas 75041

PH. 972-272-2468www.ess.to

ESS

DOC-005200

8-26-14RNJ

8-26-14RNA 360V, 30 BLOCS

3233 W. Kingsley Rd.

MNL-000700

Rev B

January 2017

DO NOT SCALE DRAWING

PROHIBITED. SHEET 1 OF 1

UNLESS OTHERWISE SPECIFIED: REV

TITLE:

NAME DATE

APPR.

DRAWN

PROJECTION:

DIMENSIONS ARE IN INCHES

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

ELECTRONIC SYSTEMS SUPPORT. ANY

REPRODUCTION IN PART OR AS A WHOLE

WITHOUT THE WRITTEN PERMISSION OF

ELECTRONIC SYSTMES SUPPORT IS

DWG. NO.

FRONT VIEW

84.0

AA

ISOMETRIC VIEW

WEIGHT(LBS)

4080

4290

4740

3270

4470

3720

4320

4800

3300

6510

3290

3228

4980

4500

4830

3228

5430

4560

5040

ENERSYS‐12XE1110F‐FR

ENERSYS‐12XE1150F‐FR

EASTPENN‐HR3500ET

EASTPENN‐HR5500ET

C&D‐UPS12‐355MRF

GNB‐S12V735FT

BATTERYMODEL

BATTRYCABINETLOADEDWEIGHTS

NORTHSTAR‐NSB12‐730RT

NORTHSTAR‐NSB155FT

NORTHSTAR‐NSB170FT

NORTHSTAR‐NSB190FT

NORTHSTAR‐NSB210FT

GNB‐S12V645FT

C&D‐UPS12‐615MRF

C&D‐UPS12‐700MRF

C&D‐UPS12‐410MRF

C&D‐UPS12‐1000MRF

NORTHSTAR‐NSB12‐450RT

NORTHSTAR‐NSB12‐650RT

ENERSYS‐12XE1010F‐FR

BREAKER DETAIL

BELL ALRAM OPT.

-

+

GND

OUTPUT TO UPS

FROM BATTERY

BREAKER

BRACKET

TO UPS

FROM BREAKER OPTIONS

FROM UPS

TO UPS BLK

BLK

BREAKER IS IN THE CLOSED (ON) POSITION

AUXILLARY CONTACTS LISTED APPLICABLE WHEN

TO 24/48 VDC SOURCE

-

+

BL / YW

COMM.

NO

NC BL

YW

BELL ALRAM OPT. RED

RED

-

+

TYP 384V WIRING

FUSE PANEL

17

11

TO BREAKER OR

32 31 30 29 28 27 26 25

24 23 22 21 20 19 18

16 15 14 13 12 10 9

87654321

-+

TIER 4

TIER 3

TIER 2

TIER 1

+

+

+

+- -+-+-+-+-+-+-

+- -+-+-+-+-+-+-

-+-+-+-+-+-+--

-+-+-+-+-+-+-++

R22.3 R22.9

FRONT VIEW

72.00

AA

ELECTRONIC SYSTEMS SUPPORT

B

EFC42 BATTERY CABINET

17 www.ess.to

FAX 972-276-9844

Garland, Texas 75041

PH. 972-272-2468www.ess.to

ESS

DOC-005300

8-26-14RNJ

8-26-14RNA 384V, 32 BLOCS

3233 W. Kingsley Rd.

MNL-000700

Rev B

January 2017

DO NOT SCALE DRAWING

PROHIBITED. SHEET 1 OF 1

UNLESS OTHERWISE SPECIFIED: REV

TITLE:

NAME DATE

APPR.

DRAWN

PROJECTION:

DIMENSIONS ARE IN INCHES

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

ELECTRONIC SYSTEMS SUPPORT. ANY

REPRODUCTION IN PART OR AS A WHOLE

WITHOUT THE WRITTEN PERMISSION OF

ELECTRONIC SYSTMES SUPPORT IS

DWG. NO.

3.

NEMA 1 DESIGN.1. EMPTY CABINET WEIGHT: 680 LBS (309 KG)2. SEE TABLE FOR LOADED WEIGHTS.

CABINET NOTES:

SIDE VIEW

29.50

REAR VIEW

VENTILATION

LOUVERS

45.50

ISOMETRIC VIEW

WEIGHT(LBS)

4204

4428

4908

3340

4620

3340

4460

4972

3397

6796

3564

4556

5164

4652

5004

5164

5644

4716

6188GNB‐S12V735FT

BATTERYMODEL

BATTRYCABINETLOADEDWEIGHTS

NORTHSTAR‐NSB12‐730RT

NORTHSTAR‐NSB155FT

NORTHSTAR‐NSB170FT

NORTHSTAR‐NSB190FT

NORTHSTAR‐NSB210FT

GNB‐S12V645FT

C&D‐UPS12‐615MRF

C&D‐UPS12‐700MRF

C&D‐UPS12‐410MRF

C&D‐ UPS12‐1000MRF

NORTHSTAR‐NSB12‐450RT

NORTHSTAR‐NSB12‐650RT

ENERSYS‐12XE1010F‐FR

ENERSYS‐12XE1110F‐FR

ENERSYS‐12XE1150F‐FR

EASTPENN‐HR3500ET

EASTPENN‐HR5500ET

C&D‐UPS12‐355MRF

RED

BELL ALRAM OPT. RED

BELL ALRAM OPT.

YW

BL

NC

NO

COMM. BL / YW

+

-

TO 24/48 VDC SOURCE

AUXILLARY CONTACTS LISTED APPLICABLE WHEN

BREAKER IS IN THE CLOSED (ON) POSITION

BLK

BLK

TO UPS

FROM UPS

FROM BREAKER OPTIONS

TO UPS

BREAKER DETAIL

BRACKET

BREAKER

FROM BATTERY

OUTPUT TO UPS

GND

+

-

-+

TYP 288V WIRING

FUSE PANEL

17

11

TO BREAKER OR

24 23 22 21 20 19 18

16 15 14 13 12 10 9

87654321

-+

TIER 4

TIER 3

TIER 2

TIER 1

+

+

+- -+-+-+-+-+-+-

-+-+-+-+-+-+--+

-+-+-+-+-+-+-+

R22.3 R22.9

SIDE VIEW

29.50

REAR VIEW

VENTILATION

LOUVERS

45.50

ISOMETRIC VIEW

ELECTRONIC SYSTEMS SUPPORT

B

EFC42 BATTERY CABINET

18 www.ess.to

FAX 972-276-9844

Garland, Texas 75041

PH. 972-272-2468www.ess.to

ESS

DOC-005500

8-26-14RNJ

8-26-14RNA 288V, 24 BLOCS

3233 W. Kingsley Rd.

MNL-000700

Rev B

January 2017

DO NOT SCALE DRAWING

PROHIBITED. SHEET 1 OF 1

UNLESS OTHERWISE SPECIFIED: REV

TITLE:

NAME DATE

APPR.

DRAWN

PROJECTION:

DIMENSIONS ARE IN INCHES

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

ELECTRONIC SYSTEMS SUPPORT. ANY

REPRODUCTION IN PART OR AS A WHOLE

WITHOUT THE WRITTEN PERMISSION OF

ELECTRONIC SYSTMES SUPPORT IS

DWG. NO.

FRONT VIEW

72.00

AA

3.

NEMA 1 DESIGN.1. EMPTY CABINET WEIGHT: 680 LBS (309 KG)2. SEE TABLE FOR LOADED WEIGHTS.

CABINET NOTES:

WEIGHT(LBS)

3348

3516

3876

2700

3660

2700

3540

3924

2743

5292

2868

3612

4068

3684

3948

4068

4428

3732

4116GNB‐ S12V735FT

BATTERYMODEL

BATTRYCABINETLOADEDWEIGHTS

NORTHSTAR‐NSB12‐730RT

NORTHSTAR‐NSB155FT

NORTHSTAR‐NSB170FT

NORTHSTAR‐NSB190FT

NORTHSTAR‐NSB210FT

GNB‐ S12V645FT

C&D‐UPS12‐615MRF

C&D‐UPS12‐700MRF

C&D‐UPS12‐410MRF

C&D‐UPS12‐1000MRF

NORTHSTAR‐NSB12‐450RT

NORTHSTAR‐NSB12‐650RT

ENERSYS‐12XE1010F‐FR

ENERSYS‐12XE1110F‐FR

ENERSYS‐12XE1150F‐FR

EASTPENN‐HR3500ET

EASTPENN‐HR5500ET

C&D‐UPS12‐355MRF

This manual suits for next models

1

Table of contents

Popular Storage manuals by other brands

Sony

Sony VAIO PCGA-HD740 Service manual

DANE-ELEC

DANE-ELEC SO READY quick start guide

AVC Technology

AVC Technology UHP900 user manual

Quantum

Quantum Scalar i40 user guide

Sun Microsystems

Sun Microsystems StorageTek StreamLine SL8500 Best practices guide

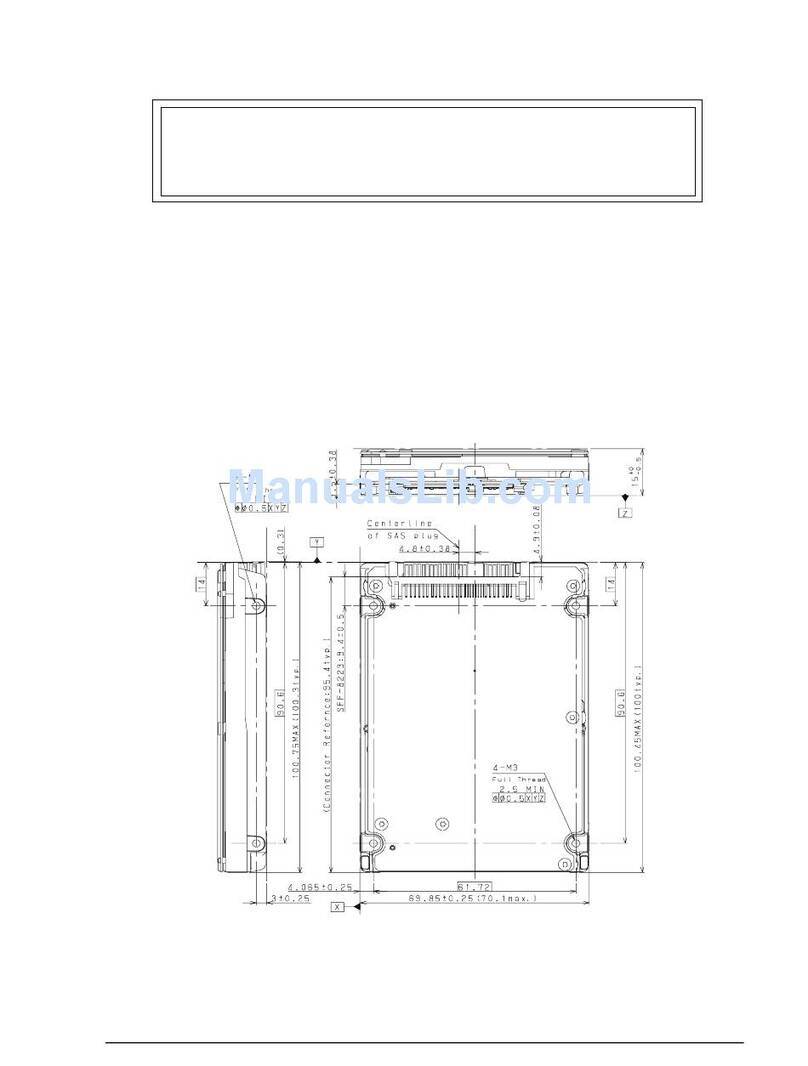

Fujitsu

Fujitsu MAV2036RC - 36.7 GB Hard Drive Installation requirements