To access a staple jammed

in the tip, actuate the lever

on the side of the service

shutter (item 8) to open it,

thenremovejammedstaple.

Turn exhaust deflector (item

5)to desired position.Setthe

working pressure to the

lowest recommended pres-

sure(4.0bar).Connectionto

the pressurised air source is

made by 6 mm flexible air

hose fitted with a quick

coupler.

Set the tacker, checked for

proper functioning, to the

point the fastener is to be

driven and pull the trigger

(item 3). Increase or de-

crease the working pressure

in 0.5 bar increments, until

the desired result is achie-

ved. The tacker should be

operated at the lowest

possiblepressure.Take care

to avoid working pressures

over 7 bar and shots without

fasteners in the magazine.

A faulty or not properly wor-

king tool must be discon-

nected from the pressurised

air source immediately and

presented to a competent

person for inspection.

Disconnect tool from air

supply and empty the

magazine during extended

work breaks or when work is

completed.

3.2 Tool Safety

Air-powered tackers shall

only be operated and ser-

viced by persons having

been instructed in the oper-

ation of such tools.

Keep out of the reach of

children.

Before every use check to

see that all safety and trig-

gering devices are func-

tioning properly. Also check

the tightness of all screws

and nuts. The tool must not

be modified, nor shall any

emergency repairs or con-

version be made. Avoid

damage or weakening of the

tool. Never dismount or

disable parts such as the

tool’s trigger.

Always wear safety glasses

andhearingprotectionwhen

working with a tacker.

4. Initial Operation

The tool must be discon-

nectedfromthe air supplyfor

loading its magazine!

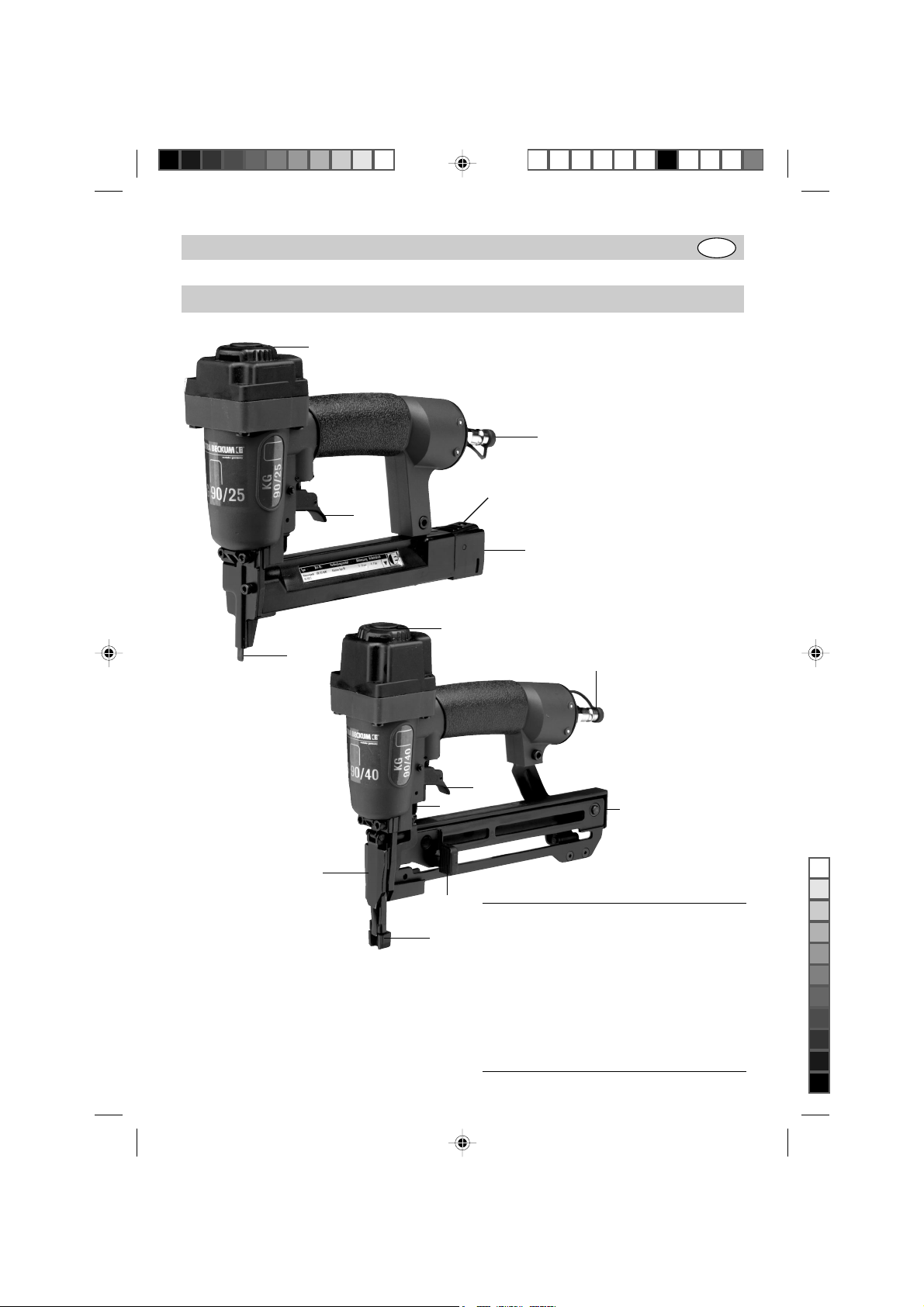

KG 90/25: by pressing the

catch lever (item 4) the

magazine is unlocked and

the magazine slide (item 6)

can be pulled back. Put

fastenersinto magazine from

below and push magazine

slide (item 6) forward until it

engages at the catch lever.

KG 90/40: pull magazine

slide back against the

magazine lock. The staples

can then be loaded from the

top. When loaded, press

magazine lock and push

magazine slide forward. The

KG 90/40 features a depth

adjustment (item 9), which

allowsfor adjusting thedepth

thestaplesaredriven in.The

KG 90/40 is also fitted with a

protectingcapon the contact

trip,to prevent damagewhen

working planed or otherwise

finished surfaces. When

fastening grooved and ton-

gued boards the protecting

cap should be removed.

3.3 Work Safety

Never aim an operable

tacker against yourself or

other persons. When wor-

king, hold the tacker in such

waythatyourhead and body

willnot beinjuredinthe event

of possible recoil. Never pull

the trigger with the nozzle in

the air.

Whenthetackerisoperable,

carryit at thehandleonly and

never with the trigger pulled.

Whenworking, take carethat

fasteners are not shot

through thin material and do

not slide off at corners or

edges.