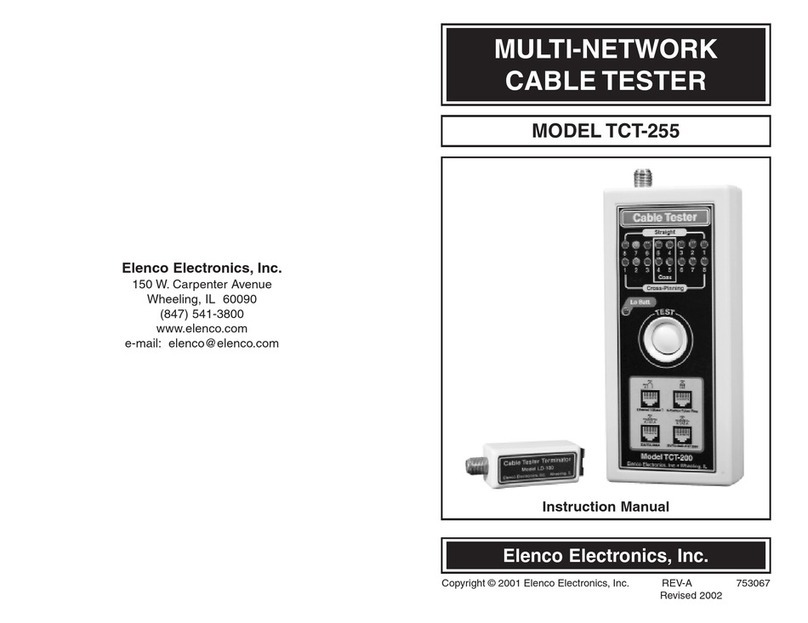

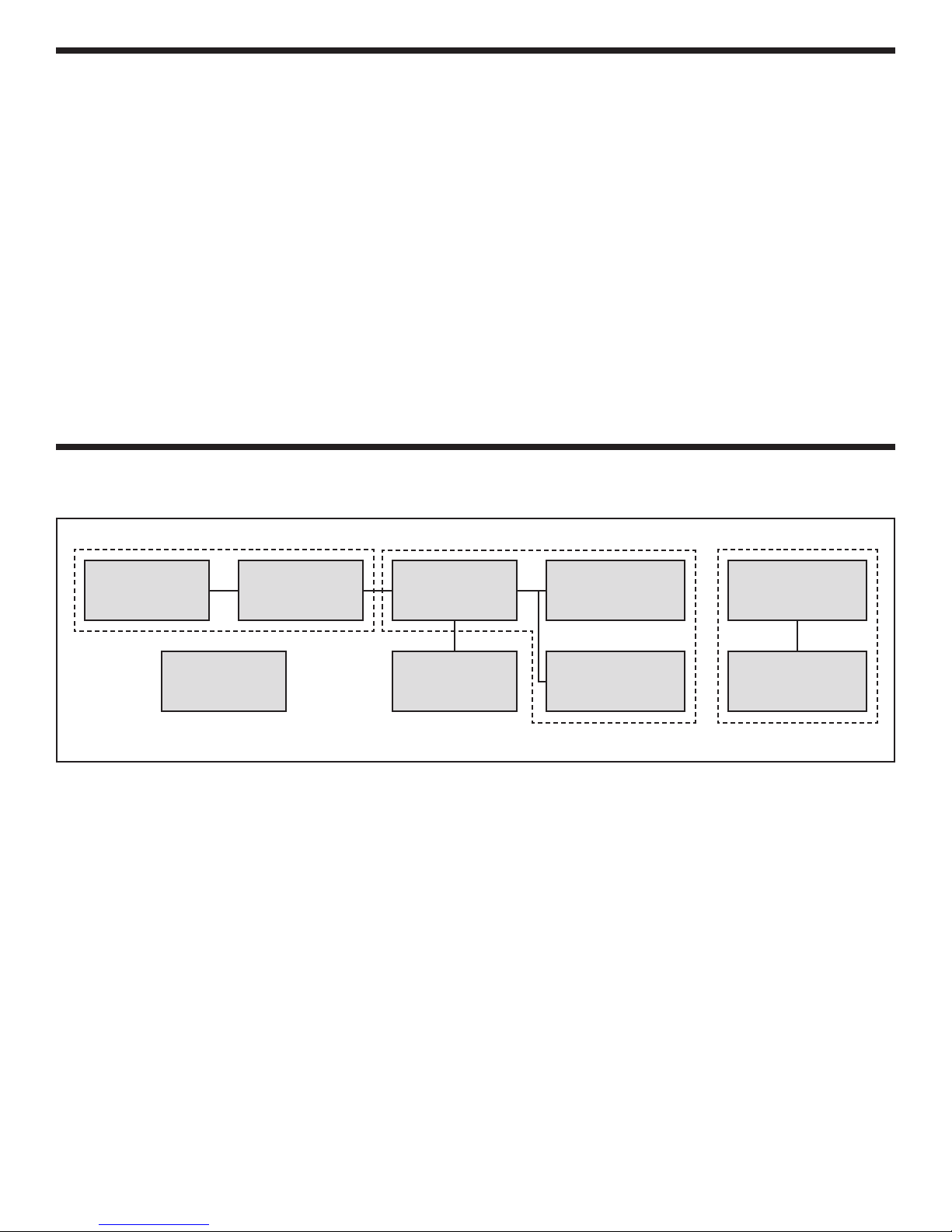

SECTION A - POWER SUPPLY

When the SW1 (test button) is pushed, capacitor C2

(see schematic diagram, Figure 1) is charged to the

battery voltage. Transistor Q1 turns on and all of the

circuits in the tester are powered. If you don’t push

SW1, capacitor C2 begins discharging. When the

voltage on C2 is less than 0.7V, transistor Q1 and

the power turn off after 30-50 seconds.

When the voltage of the battery is less than 7.5V,

transistors Q2 and Q3 turn on and LED D19 (Low

Battery) lights. The diode D17 protects the tester

from wrong polarity input voltage.

-7-

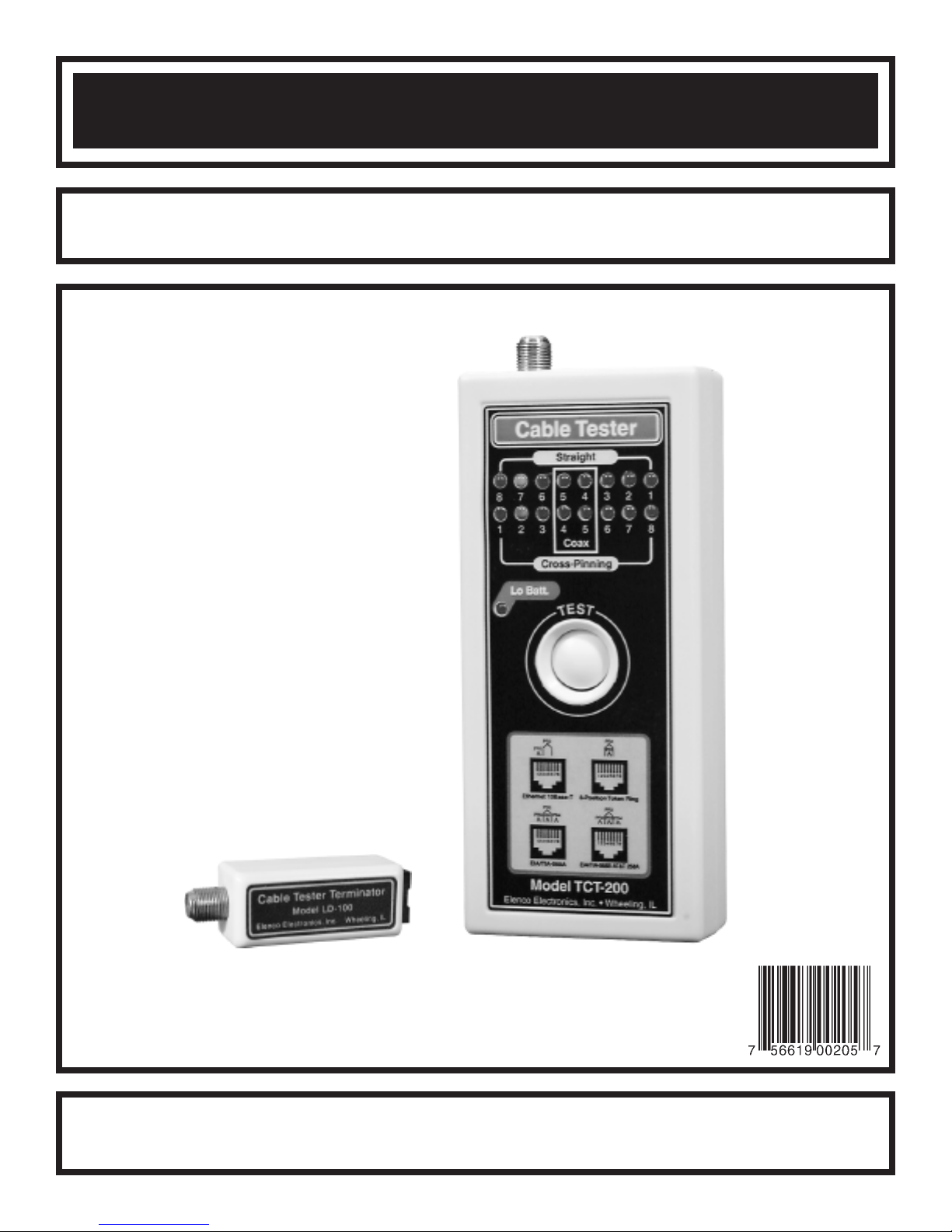

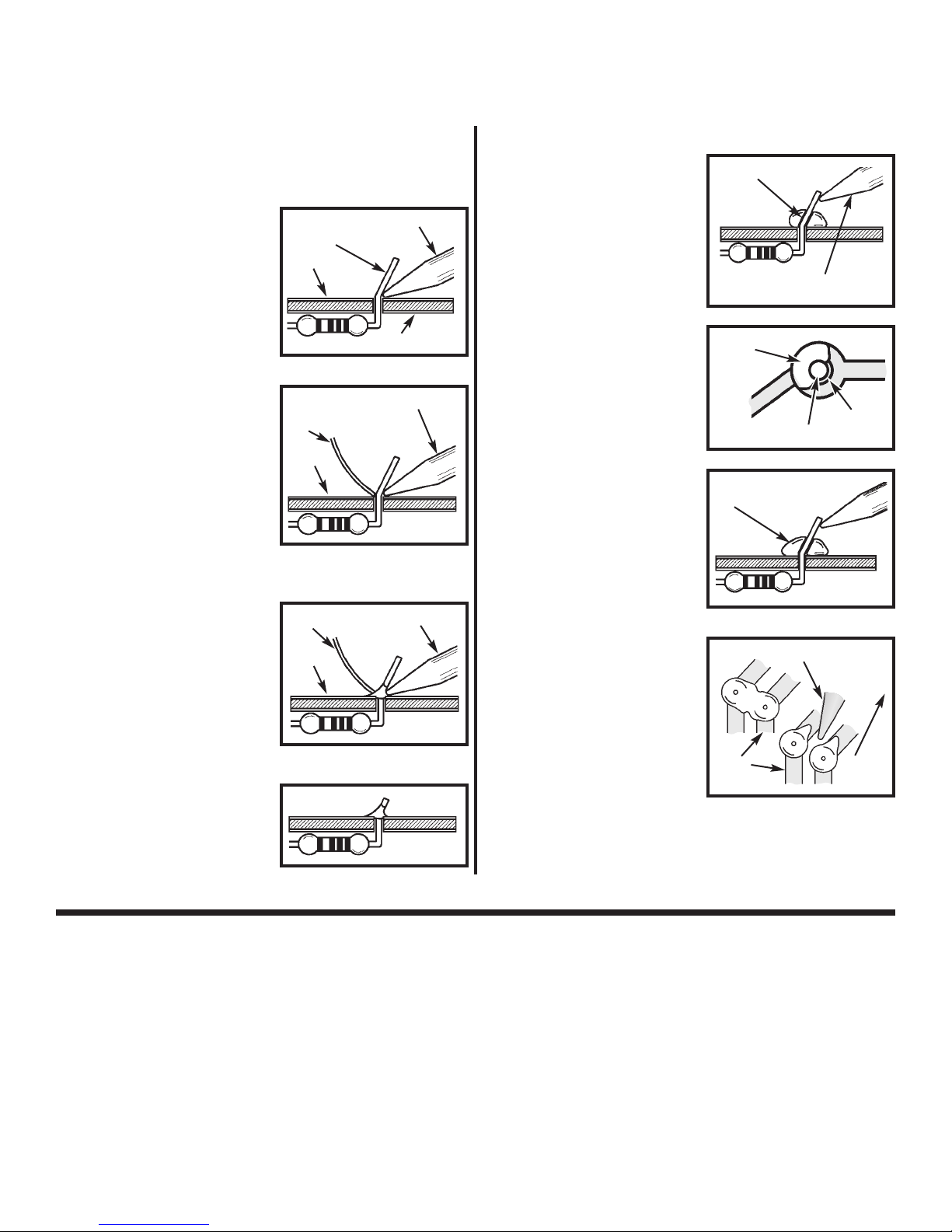

1. Connect the battery to the battery snap.

2. Set the voltmeter to read 20VDC and connect the

COM lead to the negative (--) side of the battery

and the V lead to the positive (+) side of the

battery as shown in Figure 2. The meter should

indicate 9-10VDC. Push switch SW1.

3.

Remove the V lead from the positive (+) side of the

battery and move to pad of pin 4 of IC U5. The

meter should indicate the same voltage, but after

30-50 seconds, the voltage should drop to 0V.

4. Push the switch SW1 again. The meter should

indicate the same voltage as in step 2. If not:

a) Check that the battery snap is connected

with the the right polarity as shown in the

assembly instructions.

b) Check that the transistor Q1 is 2N3906 and

mounted with the emitter, base and collector

leads as shown in the assembly instructions.

c) Check that R9, R12 and C2 are the correct

values.

d) Check that D17, D18, C2, U4 and SW1 are

installed as shown in the assembly

instructions.

5. Bend the zener diode 1N4736 (6.8V 1W, located

in a separate bag) as shown in Figure 3.

Push the switch SW1 again and short the battery

by the zener diode for 1-2 seconds (the side with

the band should be touching the “+” terminal of the

battery, see Figure 2). LED D19 (Lo Batt.) should

be lit. Remove the zener diode and the LED should

turn off. If not:

a) Check that the transistors Q2 and Q3 are

2N3904 and mounted as shown in the

assembly instructions.

b) Check zener diode D18 and LED D19. Be

sure that they are installed as shown in the

assembly instructions.

c) Check that resistors R15, R16 and R17 are

the correct values.

Remove the battery from the battery snap and

the leads from the tester.

TESTING

Figure 1

Figure 3

0.5” - 0.6”

VCOM

VDC +

9V

Figure 2

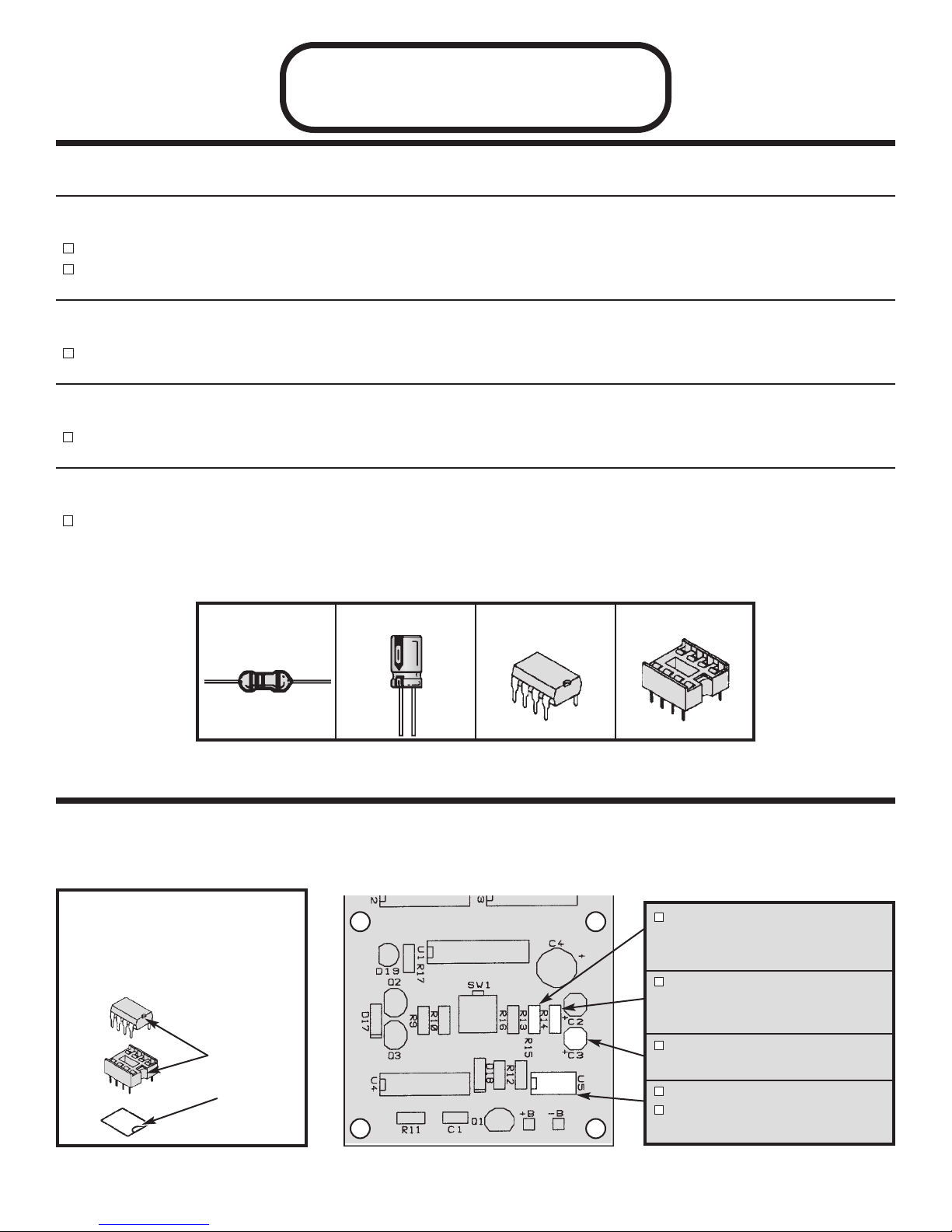

1

8